efacec EFAPOWER EV-QC45 User manual

E F A P O W E R EV- Q C 4 5 - I N S T A L L A T I O N A N D U S E R M A N U A L

7 | 32

5INSTALLATION

All matters for installing the EFAPOWER EV-QC45 are described in this chapter.

5.1 ENVIRONMENTAL REQUIREMENTS

EFAPOWER EV-QC45 reliability is dependent upon compliance of environmental specifications. The design of the

environmental control system for your EFAPOWER EV-QC45, in case of extreme environmental conditions, must

ensure that the Unit can operate reliably while remaining within the range of its operating specifications.

5.1.1 LOCAL CONDITIONS

The installation of EFAPOWER EV-QC45 shall not be made in a commercial garage (repair facility) or

closer than 6,1m (20 feet) of an outdoor motor fuel dispensing device.

EFAPOWER EV-QC45 is in an IP54, IK10 (NEMA 3R) enclosure. This Unit is intended to work below 50ᵒC (122ᵒF)

ambient temperature.

Clearance around the cabinet

The air must circulate freely throughout the ventilation grids in order for the charger’s cooling system to be

effective. The ventilation areas on the sides and back must not be blocked, assuring that the Quick Charger

cooling system can be effective. Efacec recommends clearance of at least 1meter (40’’) in the front (HMI

interface) and on right side (output cables) and 500mm (20’’) of clearance in the remaining sides of the cabinet.

Input Power Cables

AC input cables must be copper with appropriate power rating.

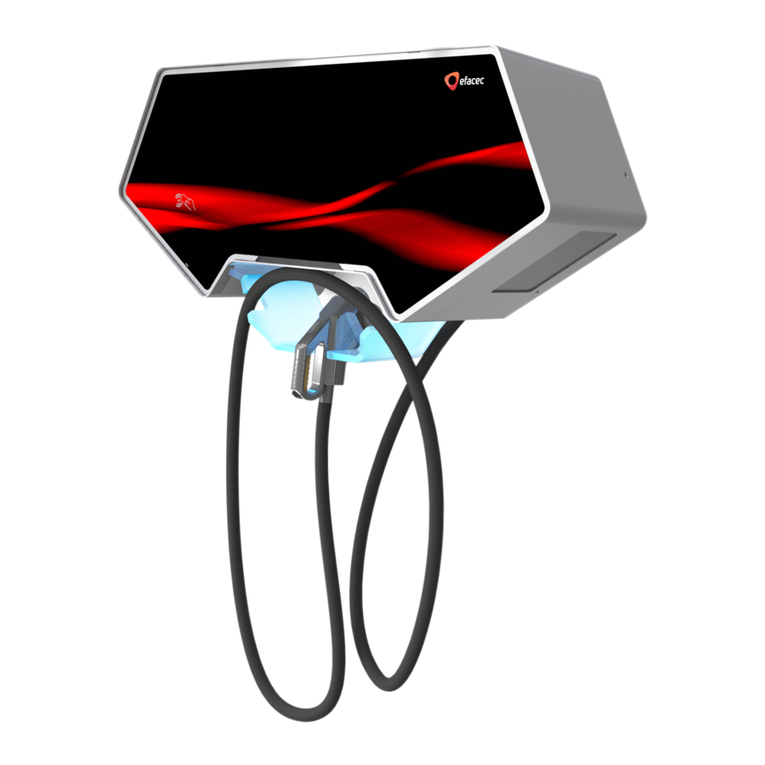

EFAPOWER EV-QC45 can be placed in 3 alternative positions as showed in Figure 5.

Figure 5 - EFAPOWER EV-QC45 alternative orientations

E F A P O W E R EV- Q C 4 5 - I N S T A L L A T I O N A N D U S E R M A N U A L

8 | 32

Even though, non-conductive dust does not influence the system’s operation, it may however, with excessive

accumulation, not allow proper cooling, therefore limiting the equipment’s thermal capabilities. Consequently,

dust accumulation must be avoided in order to guarantee a better thermal performance.

Conductive dust and acid vapors must be kept away from the Quick Charger.

On locations with harsh weather conditions (high temperatures, heavy dust, snow and/or very low temperatures)

it’s recommended to provide additional protection, either inside a building or a shelter, or providing a protection

roof for the Unit. See example in Figure 6.

Figure 6 - EFAPOWER EV-QC45 with shelter

5.1.2 SITE VERIFICATION AND INSPECTION

✓Check if the installation of the Quick Charger is not planned to be made in a commercial garage (repair

facility) or closer than 6,1m (20 feet) of an outdoor motor fuel dispensing device;

✓Check if the access passages to the Quick Charger Station layout site are not blocked in order to allow its

transportation;

✓Check if Quick Charger Station layout site is compliant with the specified clearance around the cabinet.

E F A P O W E R EV- Q C 4 5 - I N S T A L L A T I O N A N D U S E R M A N U A L

9 | 32

5.2 SITE PREPARATION

Once the local conditions are verified, it is time to set up the site to be ready for the installation of the EFAPOWER

EV-QC45.

5.2.1 UPSTREAM WIRING INFORMATION

Depending on the configuration of the EFAPOWER EV-QC45 we can have different circuit breakers in the service

panel:

▪DC and AC outputs connections (not available for USA market):

Requires a dedicated 160A circuit breaker 3P C curve

Figure 7 - EFAPOWER EV-QC45 Wiring Information

NOTES

In areas with frequent thunder storms, Efacec recommends adding transient voltage surge

suppression (TVSS) at the service panel for all circuits.

Unless required by local codes it is not necessary to install a residual-current device (RCD) for the circuit

breaker. The EFAPOWER EV-QC45 already has this protection.

EFAPOWER EV-QC45

Service Panel

Neutral

GR

Ground protection

connection

Main Breaker

Quick Charger

Power Cabinet

L1

L2

L3

L1

L2

L3

N

E F A P O W E R EV- Q C 4 5 - I N S T A L L A T I O N A N D U S E R M A N U A L

10 | 32

5.2.2 SURFACE PREPARATION

Efacec recommends a concrete pad of at least 800mm (31.5”) square, by 254mm (10”) deep. Check local codes

to ensure compliance.

Flatness

To avoid warping of the doors, the Quick Charger Station power cabinet must be mounted on a surface with a

maximum slope of 2mm/m (¼ inch rise per 10 feet of run).

5.2.3 RESOURCES FOR INSTALLATION

The following resources will be needed for installation of the EFAPOWER EV-QC45:

Fasteners:

▪4 (four) chemical anchors, M8 (5/16’’), 10mm thread diameter –length must comply with local codes, but

must have at least 120mm (5”)

▪4 (four) galvanized bolts M8 (5/16’’), with matching nuts and washers (must extend at least 30.5mm (1.2”)

above the concrete and 89.5mm (3.52”) into the concrete)

▪4 (four) sealing screws: Socket head button cap screws M12x25 (metric), with matching flat rubber washers

(supplied with the Quick Charging Station)

End terminals for input wiring:

▪Depending on the EFAPOWER EV-QC45 configuration:

▪Only DC outputs: 5 (five) end terminals up to 35mm2(3phases + neutral + protective ground), or

▪DC and AC outputs (not available for US market): 5 (five) end terminals up to 35mm2+ 5 (five) end

terminals up to 16mm2 (3phases + neutral+ protective ground)

Tools:

▪13mm (1/2") wrench - for anchoring the Unit on the pad

▪10mm Hex key/bit - for Sealing Screws

▪Crimping tool - for power and earth cables

▪Torque screwdriver with flat blade - for input terminal blocks

5.2.4 SITE VERIFICATION AND INSPECTION

✓Check if Quick Charger has the appropriate upstream protection depending on the configuration of it

✓Check if the surface where the Quick Charging Station will be placed is leveled as specified

E F A P O W E R EV- Q C 4 5 - I N S T A L L A T I O N A N D U S E R M A N U A L

11 | 32

5.3 HANDLING AND PLACING

Before installing stations

The instructions provided in this manual assume that the appropriate wiring, circuit protection, and

metering are in place at the installation location.

To assist in the process of preparing the installation site, it is recommended that before you begin

installing the Quick Charging Station, you thoroughly review the contents of this document to

familiarize yourself with the required installation steps.

In case of any doubt regarding items described in this guide, please contact us at:

5.3.1 PACKAGING

EFAPOWER EV-QC45 is shipped in a package with the following dimensions (WxDxH):

▪1150x850x2150mm (45.3x33.5x84.6 inches)

5.3.2 VISUAL INSPECTION

✓Check if the exterior packaging has been damaged by mechanical impacts or any accidents during

transportation

✓If applicable, check if the exterior panels of the EFAPOWER EV-QC45 are in perfect condition

✓Check if the interior of the Quick Charger Station is clean

✓Check if the door of the Quick Charger Station is working properly

✓Check for proper Quick Charger Station protective ground connection point, which should be

interconnected with the low voltage switchboard ground connection during the installation

Rua Eng.º Frederico Ulrich - Apartado 3078

4471-907 MOREIRA MAIA - PORTUGAL

Tel: (+351) 229403241 - Fax: (+351) 229403209

service[email protected]

www.electricmobility.efacec.com

2725 Northwoods Parkway, Ste. B

Norcross, Georgia 30071 USA

Tel: (1) 470 395-3648 -

Fax: (1) 770 446 8920

support.e[email protected]om

www.electricmobility.efacec.com

Power

cabinet

Other manuals for EFAPOWER EV-QC45

1

Table of contents

Other efacec Batteries Charger manuals