efacec EFAPOWER EV-QC45 User manual

ii

Copyright and trademarks

©2014 EFACEC. All rights reserved. This material is protected by the copyright laws of Portugal and other

countries. It may not be modified, reproduced or distributed without the prior, express written consent of

EFACEC. All other products or services mentioned are the trademarks, service marks, registered trademarks or

registered service marks of their respective owners.

iii

TABLE OF CONTENTS

1GENERAL PRODUCT DESCRIPTION ...............................................................................2

2GENERAL CHARACTERISTICS ........................................................................................3

2.1 TECHNICAL CHARACTERISTICS ...........................................................................................................3

2.2 STANDARDS...................................................................................................................................4

3PRODUCT PARTS PRESENTATION.................................................................................5

4IMPORTANT SAFETY INSTRUCTIONS ............................................................................6

5INSTALLATION.............................................................................................................7

5.1 ENVIRONMENTAL REQUIREMENTS .....................................................................................................7

5.1.1 Local Conditions ....................................................................................................................................................7

5.1.2 Site Verification and Inspection.............................................................................................................................8

5.2 SITE PREPARATION..........................................................................................................................9

5.2.1 Upstream Wiring Information...............................................................................................................................9

5.2.2 Surface Preparation ............................................................................................................................................10

5.2.3 Resources for Installation....................................................................................................................................10

5.2.4 Site Verification and Inspection...........................................................................................................................10

5.3 HANDLING AND PLACING .............................................................................................................. 11

5.3.1 Packaging............................................................................................................................................................11

5.3.2 Visual Inspection .................................................................................................................................................11

5.3.3 Handling..............................................................................................................................................................12

5.3.4 Placing.................................................................................................................................................................12

6START-UP..................................................................................................................16

6.1 VERIFICATION AND INSPECTION...................................................................................................... 16

6.2 SWITCH ON................................................................................................................................ 16

7USER MANUAL ..........................................................................................................20

7.1 OUTPUT CONNECTORS AND OUTLETS ............................................................................................. 20

7.1.1 CHAdeMO connector...........................................................................................................................................20

7.1.2 CCS connector......................................................................................................................................................20

7.1.3 AC connector .......................................................................................................................................................21

7.1.4 AC outlet..............................................................................................................................................................21

7.2 OPERATION ................................................................................................................................ 22

7.2.1 Options Interfaces ...............................................................................................................................................23

7.2.2 CHAdeMO Charging System Interfaces ...............................................................................................................24

7.2.3 Combined Charging System (CCS) Interfaces.......................................................................................................25

7.2.4 AC43 Charging System Interfaces .......................................................................................................................26

7.2.5 AC22 Charging System Interfaces .......................................................................................................................27

8MAINTENANCE MANUAL...........................................................................................28

8.1 POWER UP ERRORS ...................................................................................................................... 28

8.2 PREVENTIVE MAINTENANCE.......................................................................................................... 29

8.3 CHARGER /VEHICLE PROBLEMS..................................................................................................... 29

1/32

The information presented in this guide is subject to change without previous notice.

The technical specifications indicated here do not constitute a contractual obligation.

No part of this document may be photocopied, reproduced or translated to other language without the written

consent from EFACEC.

In case of any doubt regarding a subject described in this manual, please contact us at:

Electronic Power Systems Unit

Rua Eng.º Frederico Ulrich - Apartado 3078

4471-907 MOREIRA MAIA - PORTUGAL

Tel: (+351) 229432248 - Fax: (+351) 229403209

www.efacec.com

Electronic Power Systems Unit

Electronic Power Systems Unit

2725 Northwoods Parkway, Ste. B

Norcross, Georgia 30071 USA

Tel: (1) 470 395-3648 - Fax: (1) 770 446 8920

support.eem.usa@efacec.com

www.efacecusa.com

2/32

1GENERAL PRODUCT DESCRIPTION

EFAPOWER EV-QC45 charging station is able to charge all electric vehicles compliant with CHAdeMO charging

system and Combined Charging System (CCS) standards.

Depending on the battery capacity, EFAPOWER EV-QC45 can charge properly equipped electric vehicles from

0% to 80% in roughly 30 minutes.

The battery charging state is displayed on the HMI and the

charging cycle finishes by itself or can be interrupted by user

command.

Optional AC outputs are available:

43kVA, 22kVA, 7kVA and 3kVA (Not in USA market).

EFAPOWER EV-QC45 is user friendly and safe. After user

identification, it only requires coupling the charger’s output plug

in the EV for automatic starting if all safety features are

accomplished.

Different configurations are available such as:

Power Cabinet Standalone - which is represented in this

installation and user manual - or

Kiosk with Power Cabinet –for a more personalized and

attractive user experience (for more information please contact

our commercial department).

EFAPOWER EV-QC45 has a means of measuring the output

energy that can be used for information and monitoring

purposes. It uses remote IP communication via GPRS, ADSL,

WIFI or any other to communicate business management

data and technical data.

The Quick Charger power electronics unique design results in top tier specifications for conductive DC fast

charging, such as high power output with an industry best power factor, THD and efficiency.

The Quick Charger is highly recommended for EV fleet bases, service stations, EV service workshops and public

EV infrastructure for fast charging.

EFAPOWER EV-QC45 codification and configurations are presented in chapter 3.

Figure 2 - EFAPOWER Kiosk

Figure 1 - EFAPOWER EV-QC45 STANDALONE

3/32

2GENERAL CHARACTERISTICS

2.1 TECHNICAL CHARACTERISTICS

EFAPOWER EV-QC45 technical characteristics are indicated in the Table 1.

This unit is intended to have at least one DC output connection (CHAdeMO and/or CCS) and in addition can

have one of the two AC output

1

connections (AC43 or AC22).

Table 1 –EFAPOWER EV-QC45 Technical Characteristics

Specifications are subject to change, without prior notice.

In case of an AC output connection one of the following scenarios can be supplied:

AC and DC output connections can only charge one at a time:

In this case only the nominal current input referred above in Table 1 is needed.

AC and one DC output connections can charge simultaneous:

-For AC43: the total nominal current input needed is 136 A.

-For AC22: the total nominal current input needed is 105 A.

1

AC output not available for US market

Technical Data

CE

ETL

Nominal Input

Phases/Lines

3 phases + neutral + PE

Voltage

(400 ± 10%) V a.c.

(480 ± 10%) V a.c.

Current

73 A

64 A

Power

53kVA (@50kW peak power); 48kVA (@45kW)

Frequency

(50 ± 10%) Hz

(60 ± 10%) Hz

Efficiency

> 93%

Power Factor

0,98

THD Input Current

12,3

DC Output:

CHAdeMO

Voltage

(50 to 500) V d.c.

Current

120 A d.c.

Nominal Power

50kW at peak; 45kW at continuous

Communications with EV

JEVS G104 - CHAdeMO

Plug

JEVS G105 - CHAdeMO

DC Output:

CCS

Voltage

(50 to 500) V d.c.

Current

120 A d.c.

Nominal Power

50kW at peak; 45kW at continuous

Communications with EV

PLC

Plug

CCS –Type 2

SAE –Type 1

AC Output:

AC43 (or AC22)

Voltage

(400 ± 10%) V a.c.

Current

63 A a.c. (or 32 A a.c.)

Nominal Power

43kVA (or 22kVA)

Not Available

Plug (or Socket)

IEC62196 Type 2

Insulation

Input / Output / Ground

1500 V a.c.

1500 V a.c.

Control Circuit / Ground

500 Vac

Cabinet

Dimensions(WxDxH)

600 x 600 x 1800 mm

24” x 24” x 74.5” high

Weight

600 kg

1,323 lbs.

Protection Degree

IP54, IK10

IP54, IK10, NEMA 3R

HMI and Command

Unit

Contactless card specification

Mifare Classic 1K&4K | Mifare DesFire EV1

(Others under request)

Local interface

TFT Color display 6.4”

Buttons

Communication

Protocol (others under request)

Web Services over IP; Router 3G (GSM or CDMA)

OCPP; Efacec; others

Emergency STOP

Yes

Environment

Conditions

Temperature

Cold option (under request)

-25ᵒ to +50ᵒC

-35ᵒ to +50ᵒC

-13ᵒ to +122ᵒF

-31ᵒ to +122ᵒF

Humidity

5% to 95%

Place of installation

Indoor / Outdoor

Altitude

Up to 1000m

Up to 3280 feet

Sound Noise

<55 dB in all directions

4/32

2.2 STANDARDS

The EFAPOWER EV-QC45 Quick Charging Station complies with the following standards:

Table 2 –EFAPOWER EV-QC45 Applicable Standards

Efacec is an official member of the CHAdeMO Association

2

2006/95/CE: Low Voltage Directive

3

2004/108/CE: EMC directive

4

EN/IEC 61851-1: Electric vehicle conductive charging system. Part 1: General Requirements

5

IEC 62196: Plugs, socket-outlets, vehicle connectors and vehicle inlets - Conductive charging of electric vehicles

6

UL 2231-1: Personnel Protection Systems for Electric Vehicle (EV) Supply Circuits: General Requirements

7

UL 2231-2: Personnel Protection Systems for Electric Vehicle (EV) Supply Circuits: Particular Requirements for

Protection devices for Use in Charging Systems

8

UL 2202: Electric Vehicle (EV) Charging System Equipment

9

SAEJ1772: SAE Surface Vehicle Recommended Practice J1772, SAE Electric Vehicle Conductive Charge Coupler

10

ADA: American with Disabilities Act

11

EN/IEC 61851-23: Electric vehicle conductive charging system - Part 23: DC electric vehicle charging station

12

EN/IEC 61851-24: Electric vehicle conductive charging system - Part 24: Digital communication between a d.c.

EV charging station and an electric vehicle for control of d.c. charging

13

EN/IEC 61000-6-2: Electromagnetic compatibility (EMC). Part 6-2: Generic standards –Immunity for industrial

environments

14

EN/IEC 61000-6-4: Electromagnetic compatibility (EMC). Part 6-4: Generic standards –Emission standard for

industrial environments

15

EN/IEC 61851-22: Electric vehicle conductive charging system. Part 22: AC Electric Vehicle Charging Station

16

EN/IEC 61000-6-1: Electromagnetic compatibility (EMC). Part 6-1: Generic standards - Immunity for

residential, commercial and light-industrial environments

17

EN/IEC 61000-6-3: Electromagnetic compatibility (EMC). Part 6-3: Generic standards - Emission standard for

residential, commercial and light-industrial environments

Technical Data

CE

ETL

Applicable

Standards

Universal:

2006/95/CE2

2004/108/CE3

EN/IEC 61851-14

IEC 621965

UL 2231-16

UL 2231-27

UL 22028

SAE J17729

ADA10

DC Charging System:

EN/IEC 61851-2311

EN/IEC 61851-2412

EN/IEC 61000-6-213

EN/IEC 61000-6-414

---

AC Charging System:

EN/IEC 61851-2215

EN/IEC 61000-6-116

EN/IEC 61000-6-317

EV-READY

----

(not available)

5/32

3PRODUCT PARTS PRESENTATION

The mechanical structure is composed by a standalone Power Cabinet. Its codification is presented below.

Figure 4 - EFAPOWER EV-QC45 Parts

Figure 3 - EV-QC45 Standalone Codes

EV-QC45 YY GCCB ZZZZ ZZZZ ZZZZ Y

- –without extras

C–Cold option

L–CHAdeMO Lock

DCA –CHAdeMO

DCC –CCS

AC43

AC22P

AC22S

AC11P

AC11S

AC7P

AC7S

AC3P

AC3S

At least one

One at most

CE –European markets

UL –USA & Canada markets

EFAPOWER EV-QC45 has 9 possible output combinations as

showed in the next figure:

1

1

1

6/32

4IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that must be followed during installation of the EFAPOWER EV

QC45 Quick Charging Station.

Grounding instructions

The EFAPOWER EV QC45 Quick Charging Station must be connected to a grounded, metal, permanent wiring

system; or an equipment-grounding conductor is to be run with circuit conductors and connected to the

equipment grounding terminal or lead on the Electric Vehicle Supply Equipment (EVSE). Connections to the

EVSE shall comply with all local codes and ordinances.

Safety and compliance

This document provides instructions to install the EFAPOWER EV QC45 Quick Charging Station and should not

be used for any other product. Before installing the EFAPOWER EV QC45 Charging Station, you should review

this manual carefully and consult with a licensed contractor, licensed electrician and trained installation expert

to ensure compliance with local building practices, climate conditions, safety standards, and state and local

codes. The EFAPOWER EV QC45 Quick Charging Station should be installed only by a licensed contractor and a

licensed electrician and in accordance with all local and national codes and standards. The EFAPOWER EV QC45

Quick Charging Station should be inspected by a qualified installer prior to the initial use. Under no

circumstances will compliance with the information in this manual relieve the user of his/her responsibility to

comply with all applicable codes or safety standards. This document describes the most commonly-used

installation and mounting scenarios. If situations arise in which it is not possible to perform an installation

following the procedures provided in this document, contact EFACEC. EFACEC is not responsible for any

damages that may occur resulting from custom installations that are not described in this document.

No accuracy guarantee

Reasonable effort was made to ensure that the specifications and other information in this manual are accurate

and complete at the time of its publication. However, the specifications and other information in this manual

are subject to change at any time without prior notice.

Warranty information and disclaimer

Your use of, or modification to, the EFAPOWER EV QC45 Quick Charging Station in a manner in which the

EFAPOWER EV QC45 Quick Charging Station is not intended to be used or modified will void the limited

warranty. Other than any such limited warranty, the EFACEC products are provided “AS IS,” and EFACEC and its

distributors expressly disclaim all implied warranties, including any warranty of design, merchantability, fitness

for a particular purposes and non-infringement, to the maximum extent permitted by law.

Limitation of liability

IN NO EVENT SHALL EFACEC OR ITS AUTHORIZED DISTRIBUTORS BE LIABLE FOR ANY INDIRECT, INCIDENTAL,

SPECIAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMITATION, LOST PROFITS, LOST

DATA, LOSS OF USE, COST OF COVER, OR LOSS OR DAMAGE TO THE EFAPOWER EV QC45 CHARGING STATION,

ARISING OUT OF OR RELATING TO THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF EFACEC OR ITS

AUTHORIZED DISTRIBUTORS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

7/32

5INSTALLATION

All matters for installing the EFAPOWER EV-QC45 are described in this chapter.

5.1 ENVIRONMENTAL REQUIREMENTS

EFAPOWER EV-QC45 reliability is dependent upon compliance of environmental specifications. The design of

the environmental control system for your EFAPOWER EV-QC45, in case of extreme environmental conditions,

must ensure that the Unit can operate reliably while remaining within the range of its operating specifications.

5.1.1 LOCAL CONDITIONS

The installation of EFAPOWER EV-QC45 shall not be made in a commercial garage (repair facility)

or closer than 508mm (20 feet) of an outdoor motor fuel dispensing device.

EFAPOWER EV-QC45 is in an IP54, IK10 (NEMA 3R) enclosure. This Unit is intended to work below 50ᵒC (122ᵒF)

ambient temperature.

Clearance around the cabinet

The air must circulate freely throughout the ventilation grids in order for the charger’s cooling system to be

effective. The ventilation areas on the sides and back must not be blocked, assuring that the Quick Charger

cooling system can be effective. Efacec recommends clearance of at least 1meter (40’’) in the front (HMI

interface) and on right side (output cables) and 500mm (20’’) of clearance in the remaining sides of the cabinet.

Input Power Cables

AC input cables must be copper with appropriate power rating.

EFAPOWER EV-QC45 can be placed in 3 alternative positions as showed in Figure 5.

Figure 5 - EFAPOWER EV-QC45 alternative orientations

8/32

Even though, non-conductive dust does not influence the system’s operation, it may however, with excessive

accumulation, not allow proper cooling, therefore limiting the equipment’s thermal capabilities. Consequently,

dust accumulation must be avoided in order to guarantee a better thermal performance.

Conductive dust and acid vapors must be kept away from the Quick Charger.

On locations with harsh weather conditions (high temperatures, heavy dust, snow and/or very low

temperatures) it’s recommended to provide additional protection, either inside a building or a shelter, or

providing a protection roof for the Unit. See example in Figure 6.

Figure 6 - EFAPOWER EV-QC45 with shelter

5.1.2 SITE VERIFICATION AND INSPECTION

Check if the installation of the Quick Charger is not planned to be made in a commercial garage (repair

facility) or closer than 508mm (20 feet) of an outdoor motor fuel dispensing device;

Check if the access passages to the Quick Charger Station layout site are not blocked in order to allow its

transportation;

Check if Quick Charger Station layout site is compliant with the specified clearance around the cabinet.

9/32

5.2 SITE PREPARATION

Once the local conditions are verified, it is time to set up the site in order to be ready for the installation of

the EFAPOWER EV-QC45.

5.2.1 UPSTREAM WIRING INFORMATION

Depending on the configuration of the EFAPOWER EV-QC45 we can have two wiring schemes as represented

in Figure 7:

Only DC output connections:

Requires dedicated 80A circuit breaker 3P C curve for DC output(s)

or

AC and one DC output connections (not available for USA market):

Requires dedicated 80A circuit breaker 3P C curve for DC output(s)

+ Depending on the AC output connection:

Requires dedicated 80A circuit breaker 3P C curve for AC output and its wiring

or

Requires dedicated 40A circuit breaker 3P C curve for AC output and its wiring

Figure 7 - EFAPOWER EV-QC45 Wiring Information

NOTES:

In areas with frequent thunder storms, Efacec recommends adding transient voltage surge suppression (TVSS)

at the service panel for all circuits.

Unless required by local codes it is not necessary to install a residual-current device (RCD) for the circuit breaker. The

EFAPOWER EV-QC45 already has this protection.

EFAPOWER EV-QC45

Service Panel

Neutral

GR

Ground

protection

connection

Main Breaker

Quick Charger Power

Cabinet terminal

X1

L1

L2

L3

L1

L2

L3

N

AC output wiring

Neutral

Additional

Breaker

Quick Charger Power

Cabinet terminals

X11

L1

L2

L3

L1

L2

L3

N

10/32

5.2.2 SURFACE PREPARATION

Efacec recommends a concrete pad of at least 800mm (31.5”) square, by 254mm (10”) deep. Check local codes

to ensure compliance.

Flatness

To avoid warping of the doors, the Quick Charger Station power cabinet must be mounted on a surface with a

maximum slope of 2mm/m (¼ inch rise per 10 feet of run).

5.2.3 RESOURCES FOR INSTALLATION

The following resources will be needed for installation of the EFAPOWER EV-QC45:

Fasteners:

4 (four) chemical anchors, M8 (5/16’’), 10mm thread diameter –length must comply with local codes, but

must have at least 120mm (5”)

4 (four) galvanized bolts M8 (5/16’’), with matching nuts and washers (must extend at least 30.5mm (1.2”)

above the concrete and 89.5mm (3.52”) into the concrete)

4 (four) sealing screws: Socket head button cap screws M12x25 (metric), with matching flat rubber washers

(supplied with the Quick Charging Station)

End terminals for input wiring:

Depending on the EFAPOWER EV-QC45 configuration:

Only DC outputs: 5 (five) end terminals up to 35mm2(3phases + neutral + protective ground), or

DC and AC outputs (not available for US market): 5 (five) end terminals up to 35mm2+ 5 (five) end

terminals up to 16mm2 (3phases + neutral+ protective ground)

Tools:

13mm (1/2") wrench - for anchoring the Unit on the pad

10mm Hex key/bit - for Sealing Screws

Crimping tool - for power and earth cables

Torque screwdriver with flat blade - for input terminal blocks

5.2.4 SITE VERIFICATION AND INSPECTION

Check if Quick Charger has the appropriate upstream protection depending on the configuration of it

Check if the surface where the Quick Charging Station will be placed is leveled as specified

11/32

5.3 HANDLING AND PLACING

IMPORTANT: Before installing stations

The instructions provided in this manual assume that the appropriate wiring, circuit protection, and metering

are in place at the installation location.

To assist in the process of preparing the installation site, it is recommended that before you begin installing

Quick Charging Station, you thoroughly review the contents of this document to familiarize yourself with the

required installation steps.

In case of any doubt regarding items described in this guide, please contact us at:

5.3.1 PACKAGING

EFAPOWER EV-QC45 is shipped in a package with the following dimensions (WxDxH):

1150x850x2150mm (45.3x33.5x84.6 inches)

5.3.2 VISUAL INSPECTION

Check if the exterior packaging has been damaged by mechanical impacts or any accidents during

transportation

If applicable, check if the exterior panels of the EFAPOWER EV-QC45 are in perfect condition

Check if the interior of the Quick Charger Station is clean

Check if the door of the Quick Charger Station is working properly

Check for proper Quick Charger Station protective ground connection point, which should be

interconnected with the low voltage switchboard ground connection during the installation

Power

cabinet

Electronic Power Systems Unit

Rua Eng.º Frederico Ulrich - Apartado 3078

4471-907 MOREIRA MAIA - PORTUGAL

Tel: (+351) 229432248 - Fax: (+351) 229403209

www.efacec.com

Electronic Power Systems Unit

2725 Northwoods Parkway, Ste. B

Norcross, Georgia 30071 USA

Tel: (1) 470 395-3648 -

Fax: (1) 770 446 8920

support.eem.usa@efacec.com

www.efacecusa.com

12/32

5.3.3 HANDLING

Due to its heavy weight, 4 (four) lifting hooks are provided on the top of the Power Cabinet as indicated on

Figure 8.

I IMPORTANT:

Never try to move the power cabinets by using tools under panels; this will create a risk of deformation.

Figure 8 - EFAPOWER EV-QC45 lifting hooks

After the power cabinet is placed, the lifting hooks must be removed, and the M12 sealing screws must be

inserted in their holes in order to guarantee the IP54, IK10 (NEMA 3R) protection degree.

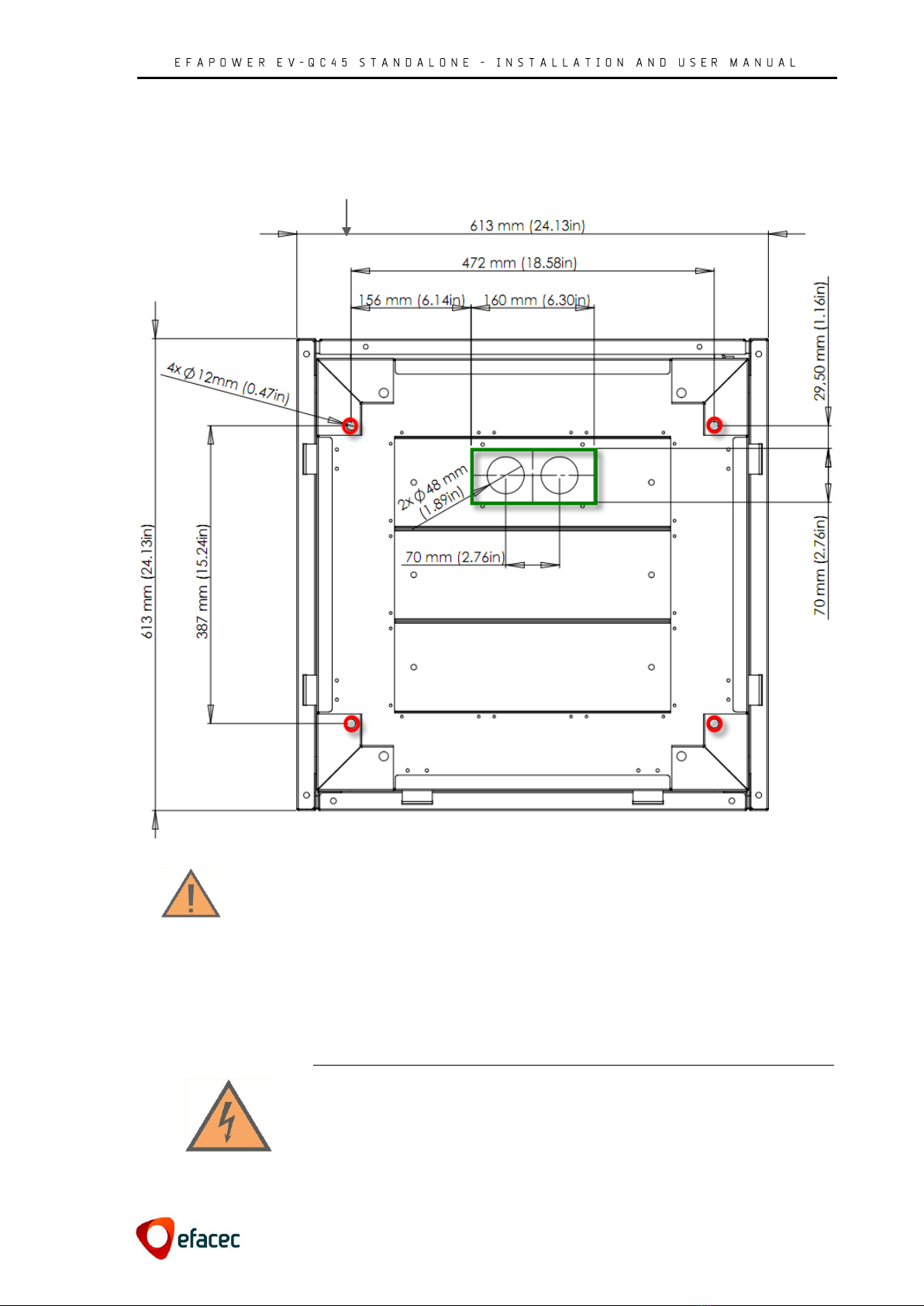

5.3.4 PLACING

5.3.4.1 ANCHORING TO THE CONCRETE PAD

The Quick Charging Station must be anchored on the surface compliant with the specifications mentioned in

chapter 5.2.2.

The power cabinet must be installed on a concrete pad using 4 (four) chemical anchors, M8 (5/16’’), 10mm

thread diameter –length must comply with local codes, but must have at least 120mm (5”).

In the following figure some details are shown regarding the drilling layout for the Power Cabinet.

Only 4(four) points are needed to anchor the Unit on the concrete pad (marked with a red circle).

13/32

For the power cabinet, the conduits must extend 160mm (6.3”) above the concrete, or according to local

codes. The cable entrance shall only be located as shown in the image below (marked in green).

The access to all the controls and commands including the buttons and the card reader, must comply with local

codes and ADA requirements. That includes being under 1200mm (48”) off the ground.

Figure 9 - EFAPOWER EV-QC45 Drilling and conduits layout

(bottom view)

IMPORTANT:

The use of chemical anchors must be in compliance with the manufacturer’s instructions

For the Power Cabinet it’s advised to have a concrete block of at least 800mm (31.5”) square, by 254mm

(10”) deep. Check local codes to ensure compliance

The bolts must extend at least 30.5mm (1.2”) above the concrete and 89.5mm (3.52”) into the concrete

ALL SERVICING MUST BE PERFORMED ONLY BY QUALIFIED PERSONNEL. DO NOT

ATTEMPT TO SERVICE THE EFAPOWER EV QC45 QUICK CHARGING STATION

YOURSELF.

BY OPENING THE DOOR OR REMOVING THE EFAPOWER EV QC45 QUICK

CHARGING STATION SIDE PANELS YOU RUN THE RISK OF EXPOSURE TO

DANGEROUS VOLTAGES!

Front Side

14/32

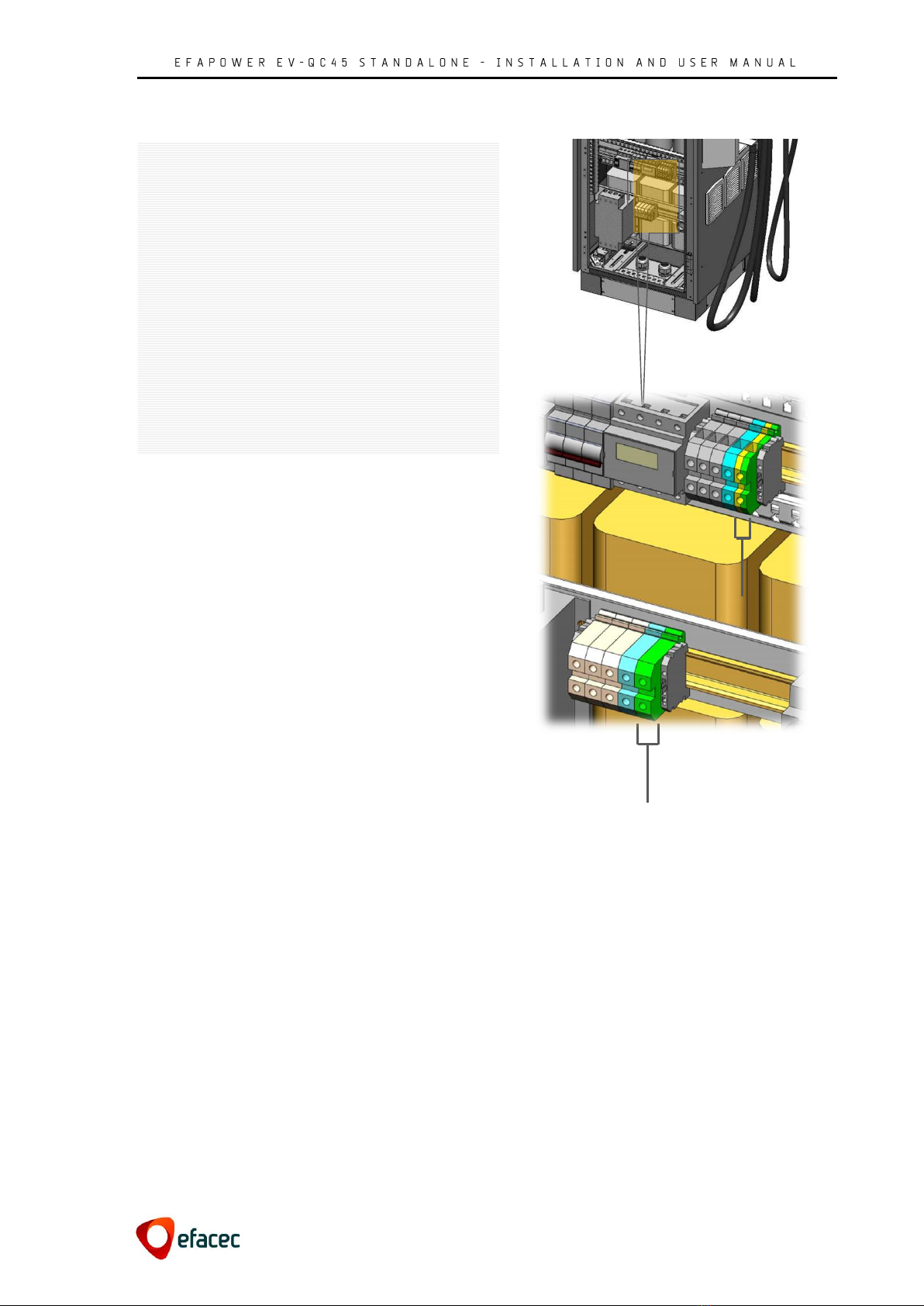

5.3.4.2 POWER CABLES CONNECTION

Figure 10 - EFAPOWER EV-QC45 Input Terminals

The connection to the AC input terminals of each Quick

Charger Station is accessed through the bottom of the

cabinet:

X1 –MUST BE CONNECTED regardless of the

EFAPOWER EV-QC45 configuration

(35mm2terminal blocks)

X11 –Must be connected if AC OUTPUT is available

(16mm2 terminal blocks)

Strip wires 24 mm (0.94”), crimp the end terminal and

insert into the terminal block as shown, and tighten

screws between 3.2 N.m (28.3 inch-lbs) and 3.7 N.m

(32.7 inch-lbs).

IMPORTANT:

Always requires dedicated 80A circuit . .

. breaker 3P C curve

If AC output available, additional circuit breaker is

needed:

80A circuit breaker 3P C curve, or

40A circuit breaker 3P C curve

Use copper conductors only

Before starting to work on the Quick Charger

Station, connect the ground wire to the ground

terminals of the Quick Charger Station

In areas with frequent thunder storms, we advise to

add transient voltage surge suppression (TVSS) at

the service panel for all circuits

All bolts/nuts must be sealed

Strip length 0.94”

24mm

X11

X1

15/32

5.3.4.3 PROTECTIVE GROUND

The metallic structure of the rectifier system is

connected to the protective ground connection,

which should be interconnected with the low

voltage switchboard ground connection.

The protective earth cable must have a section,

at least of 16 mm2 (#6AWG) or according to

local codes.

Figure 11 - EFAPOWER EV-QC45 Earth Terminal

Earth

Terminal

Earth

Terminal

16/32

6START-UP

6.1 VERIFICATION AND INSPECTION

Check if the bolts of the AC and protective ground cables of the Quick Charging Station are correctly

tightened to the specified torque

Check the resistance between the Quick Charger protective ground and the low voltage switchboard

ground connection; the value must be according to local codes

Before switching ON all the fuses and circuit breakers, check the supply voltage between lines: it must be

400V ± 10% 50Hz, for CE marked Units (and 480V ± 10% 60Hz for ETL marked Units)

At this stage, whenever the Unit shall be integrated with a Network Management System, Efacec shall

already have the following information:

For Unit configuration: Station(s) ID and Central Management Endpoint

For Router configuration: APN and PIN, Username and Password (if applicable)

6.2 SWITCH ON

BEFORE ATTEMPTING TO INSTALL OR START UP THE EFAPOWER EV QC45 QUICK

CHARGING STATION THE USER MUST ENSURE THAT THE SAFETY INSTRUCTIONS

IN THIS MANUAL ARE CAREFULLY READ AND OBSERVED BY TECHNICALLY

COMPETENT PERSONNEL.

KEEP THIS MANUAL WITH THE EFAPOWER EV QC45 QUICK CHARGING STATION

FOR FUTURE REFERENCE.

THIS EFAPOWER EV QC45 QUICK CHARGING STATION MUST NOT BE STARTED OR

PUT INTO USE WITHOUT HAVING BEEN COMMISSIONED BY A FULLY TRAINED

AND AUTHORIZED PERSON.

ALL SERVICING MUST BE PERFORMED ONLY BY QUALIFIED PERSONNEL. DO NOT

ATTEMPT TO SERVICE THE EFAPOWER EV QC45 QUICK CHARGING STATION

YOURSELF.

BY OPENING THE DOOR OR REMOVING THE EFAPOWER EV QC45 QUICK

CHARGING STATION SIDE PANELS YOU RUN THE RISK OF EXPOSURE TO

DANGEROUS VOLTAGES!

IN CASE OF ANY KIND OF DOUBT REGARDING THIS, PLEASE CONTACT:

EFACEC WILL ASSUME NEITHER RESPONSIBILITY NOR LIABILITY DUE TO

INCORRECT OPERATION OR MANIPULATION OF THE EFAPOWER EV QC45 QUICK

CHARGING STATION.

EFACEC HAS TAKEN EVERY PRECAUTION TO PRODUCE AN ACCURATE, COMPLETE

AND EASY TO UNDERSTAND MANUAL AND WILL THEREFORE ASSUME NO

RESPONSIBILITY NOR LIABILITY FOR DIRECT, INDIRECT OR ACCIDENTAL

PERSONAL OR MATERIAL DAMAGE DUE TO ANY MISINTERPRETATION OR

UNDESIRED MISTAKES IN THIS MANUAL.

THIS MANUAL MAY NOT BE COPIED NOR REPRODUCED WITHOUT PRIOR

WRITTEN PERMISSION OF EFACEC

Electronic Power Systems Unit

Rua Eng.º Frederico Ulrich - Apartado 3078

4471-907 MOREIRA MAIA - PORTUGAL

Tel: (+351) 229432248 - Fax: (+351) 229403209

www.efacec.com

Electronic Power Systems Unit

2725 Northwoods Parkway, Ste. B

Norcross, Georgia 30071 USA

Tel: (1) 470 395-3648 -

Fax: (1) 770 446 8920

support.eem.usa@efacec.com

www.efacecusa.com

17/32

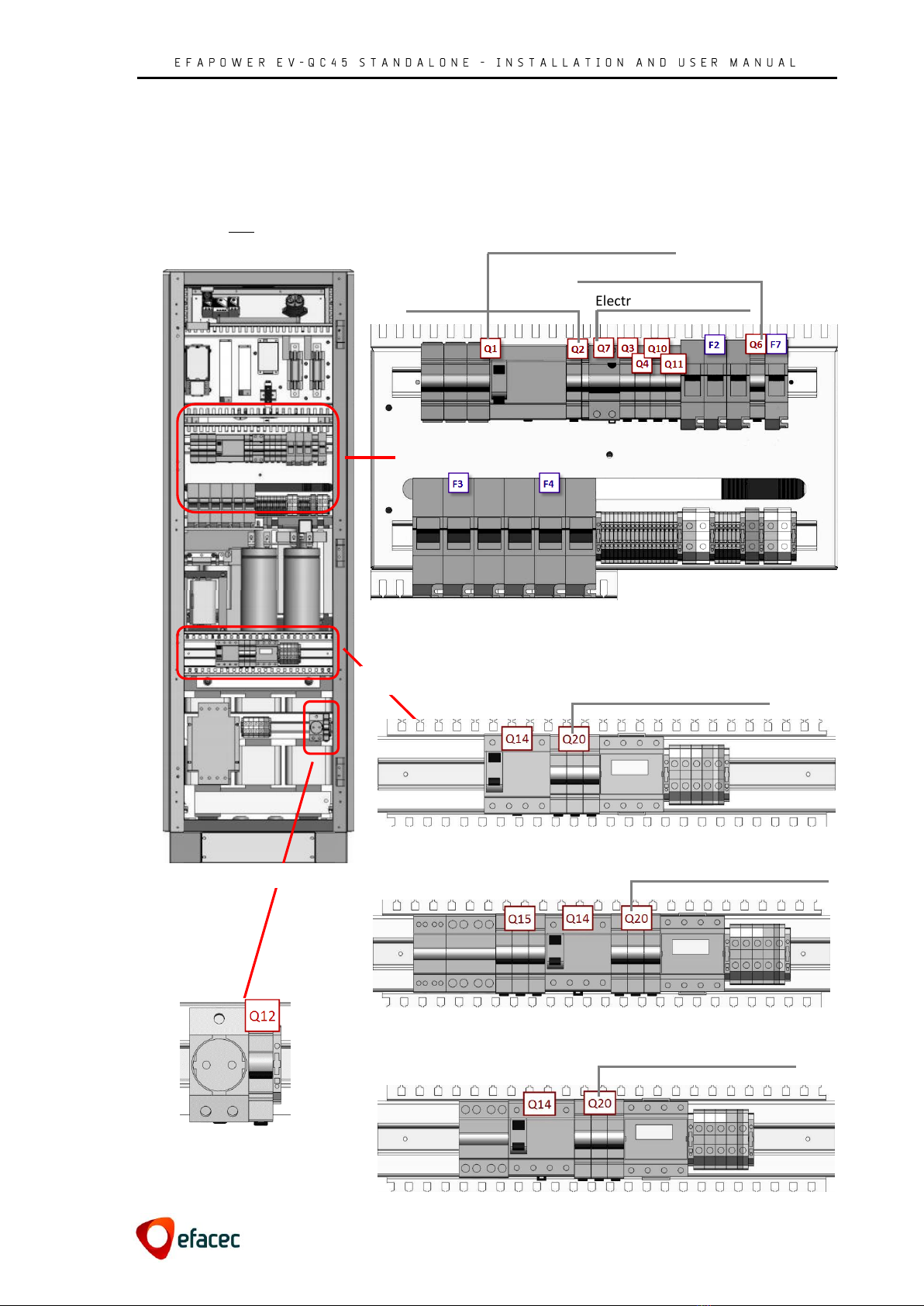

Switch on all the fuses and circuit breakers in the Quick Charging Station power cabinet:

Fuses: F2, F7, F3, F4

Circuit Breakers: Q1, Q2, Q7, Q3, Q4, Q10, Q11 (only if cold option), Q6, Q12 (auxiliary supply for

maintenance), Q14 (only if AC43 or AC22 outputs), Q20 (only if AC43 output), Q15 (only if AC22S output)

EV-QC45 CE components layout

DC output –power main input

or

If AC output connections:

Figure 16 –Auxiliary supply

for maintenance

Figure 12 –CE Input Plate

Figure 13 –AC43 Plate

Figure 15 - AC22S Plate

Output contactors command

Electronics power supply

AC output –power main input

AC output –power main input

or

AC output –power main input

Figure 17 - AC22P Plate

230V auxiliary power supply

Figure 14 - EV-QC45 interior front view

Other manuals for EFAPOWER EV-QC45

1

Table of contents

Other efacec Batteries Charger manuals

Popular Batteries Charger manuals by other brands

ANSMANN

ANSMANN PHOTOCAM IV operating instructions

Horizon Hobby

Horizon Hobby dynamite PROPHET SPORT instruction manual

Samlexpower

Samlexpower SeC-1215UL owner's manual

Philips

Philips SCB1280NB/12 user manual

Porter-Cable

Porter-Cable PCCB122 instruction manual

Gude

Gude V 621 C Translation of original operating instructions