CONTENT

Introductions .............................................................................. 1

Features ..................................................................................... 1

Applications................................................................................ 1

1. Basic User Interface ................................................................ 2

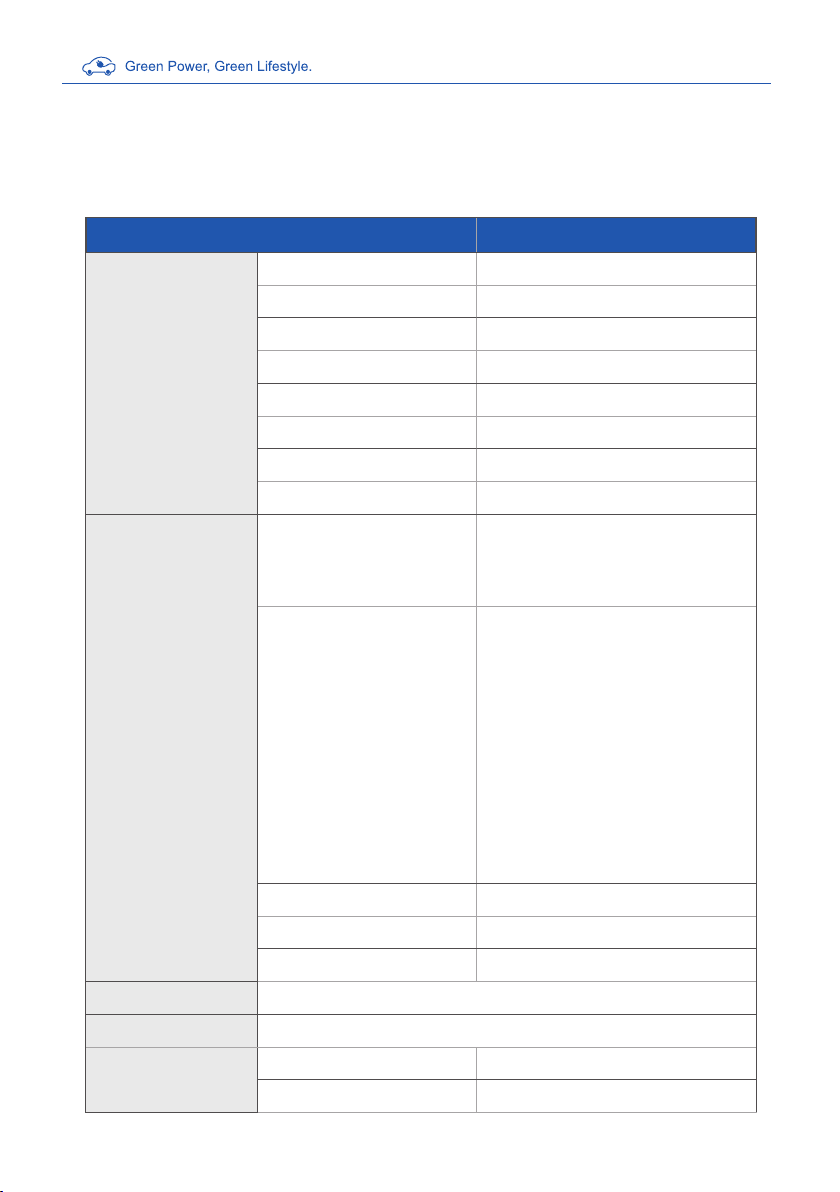

2. Specication ........................................................................... 3

2.1 Product Specication ....................................................... 3

2.2 DSYx601 Version Description ........................................... 5

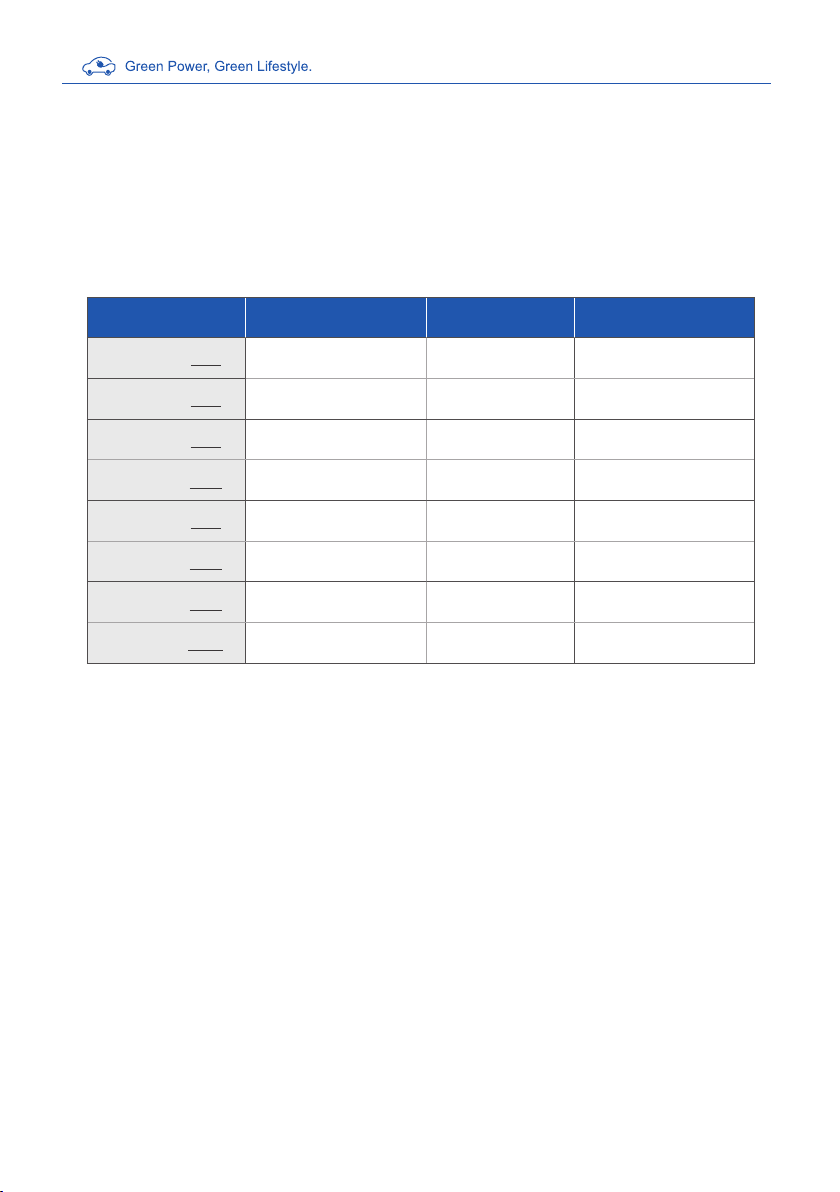

2.3 LED Indication and Operation Status................................. 6

2.4 Dimensions ...................................................................... 6

2.5 Direction of cooling Airflow............................................... 7

3. Installation Instruction ............................................................ 8

3.1 Before Installation ............................................................ 8

3.2 Grounding and Safety Requirement ................................... 9

3.3 Unpack the charger ........................................................ 11

3.4 Recommended Tools for Installation and Inspection........ 13

3.5 Installation Procedure .................................................... 14

3.6 Installation Inspection & Commissioning ........................ 18

4. Network Setting .................................................................... 21

4.1 Wi-Fi Network Setting .................................................... 21

4.2 3G/4G Setting................................................................. 23

5. Operation Process................................................................. 25

5.1 Operating Sequence ....................................................... 25

5.2 Operating Procedure....................................................... 25

5.3 Troubleshooting ............................................................. 30

5.4 Status Codes.................................................................. 30

6. Maintenance ......................................................................... 46

6.1 General Maintenance...................................................... 46

6.2 Replacement Kits and Accessories.................................. 49

Limited Product Warranty.......................................................... 50

Appendix - Package list............................................................. 51