EFFEKTIV TRIUMPHATOR 1700X User manual

DOMESTIC OVERLOCK MACHINE

EN USER MANUAL RU РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

ES MANUAL DE USUARIO FR MANUEL DE L’UTILISATEUR

DE BENUTZERHANDBUCH IT MANUALE D’USO

TRIUMPHATOR 1700X / 1800X

32

TRIUMPHATOR 1700X / 1800X

RU FR

CONTENTS

1. Principal parts (names) .......................................6

2. Accessories that come with the overlock ........8

3. Needle .....................................................................9

4. How to remove the frontal lid .............................9

5. Beginning to sew ................................................10

6. Foot pedal ............................................................10

7. Using the free arm. .............................................11

8. Stitch length regulator.........................................11

9. Stitch width regulator .........................................11

10. Differential feed .................................................13

11. Assembling the thread stand…………...............15

12. Thread spool conservers ................................15

13. Spool of thread net......................................... 15

14. Thread tension release button..................... 16

15. Threading the upper looper.......................... 16

16. Threading the lower looper........................... 17

17. Using the automatic lower looper threading

mechanism...................................................... 17

18. Threading the left needle .............................. 18

19. Threading the right needle............................ 19

20. Chart with combinations of fabrics, threads

and needles ..................................................... 20

21. Thread tension adjustment.......................... 21

22. Tension adjustment chart (two-needle

overlocks)......................................................... 22

23. Beginning to sew ........................................... 23

24. Chain stitching ................................................ 24

25. Thread breakage during sewing.................. 24

26. Adjusting the pressure of the presser foot on

the fabric .......................................................... 25

27. Malfunctions and troubleshooting.............. 26

28. Rolled and narrow hem................................. 27

29. Rolled and narrow hem sample chart........ 29

30. Using different presser feet.......................... 30

31. Removing the upper knife............................. 32

32. Switching the kinfe......................................... 32

32. Convert upper looper to 2 thread serging...33

33. Cleaning and lubrication ............................... 34

34. Changing the backlight lamp ....................... 35

35. Machinespecications ................................. 36

ОГЛАВЛЕНИЕ

1. Наименованиеосновныхчастей ............ 40

2. Аксессуары,поставляемыевкомплектес

оверлоком ...................................................... 42

3. Игла .................................................................. 43

4. Какснятьпереднююкрышку.................. 43

5. Началошитья................................................ 44

6. Ножнаяпедаль.............................................. 44

7. Использованиерукавнойплатформы...45

8. Регулировкадлиныстежка....................... 45

9. Регулировкадлиныстрочки..................... 45

10. Дифференциальнаяподачаткани ........ 46

11. Установкастойкинитенаправителя.......49

12. Ограничителидлякатушкиниток .......... 49

13. Сеткадлякатушкиниток .......................... 49

14. Кнопкаослаблениянатяжениянити...... 50

15. Заправкаверхнегопетлителя.................. 50

16. Заправканижнегопетлителя................... 51

17. Использованиемеханизмаавтоматиче-

скойзаправкинитинижнегопетлителя.....

.............................................................................51

18. Заправкалевойиглы.................................. 52

19. Заправкаправойиглы................................ 53

20. Таблицакомбинацийтканей,нитейиигл...

.............................................................................54

21. Регулировканапряжениянити ................ 55

22. Таблицарегулировкинатяжения(двухи-

гольныеоверлоки)....................................... 55

23. Пробноешитье.............................................. 57

24. Выполнениецепногостежка .................... 58

25. Обрывнитивпроцессешитья................. 58

26. Регулировкадавленияприжимнойлапки

наткань........................................................... 59

27. Неисправностииметодыихустранения...

.............................................................................60

28. Ролевыйиузкийподрубочныйшов....... 61

29. Использованиеразличныхприжимных

лапок ................................................................ 64

30. Снятиеверхнегоножа ................................ 66

31. Заменаножа.................................................. 66

32.Конвертерверхнегопетлителядляпрове-

дения2-ниточнойобметкиткани............67

33. Чисткаисмазка ........................................... 68

34. Заменалампыподсветки ......................... 69

35. Спецификациямашины............................ 70

EN ES

2 3

TABLA DE CONTENIDO

1. Nombre de las partes principales ............... 74

2. Accesorios suministrados en el set............ 76

3. Aguja ................................................................. 77

4. Cómo quitar la cubierta frontal ................... 77

5. Empezar a coser............................................. 78

6. Pedal ................................................................. 78

7. Usando la plataforma de mangas... ........... 79

8. Ajuste de la longitud de la puntada............. 79

9. Ajuste de la longitud de la puntada............. 79

10. Alimentación diferencial de tejidos............. 80

11. Instalación del bastidor de guía de hilo.......83

12. Guías de hilo.................................................... 83

13. Red de hilo ....................................................... 83

14. Botón de liberación de tensión del hilo ...... 84

15. Enhebrado del áncora superior.................... 84

16. Enhebrado del áncora inferior...................... 85

17. Utilizar el mecanismo automático

Enhebrado de bucle inferior...........................85

18. Enhebrado de la aguja izquierda................. 86

19. Enhebrar la aguja derecha............................ 87

20. Tabla de combinaciones de tejidos, hilos y

agujas ... ............................................................88

21. Ajuste de la tensión del hilo.......................... 89

22. Tabla de ajuste de tensión (overlock de doble

cabezal) ............................................................ 89

23. Costura de prueba.......................................... 91

24. Costura de cadena......................................... 92

25. Rotura del hilo durante el proceso de.........92

26. Regulacion de presion del prensatelas sobre

tela..................................................................... 93

27. Fallas y solución de problemas....................94

28. Costuras de dobladillo enrolladas y

estrechas.......................................................... 95

29. Utilizar diferentes tipos de prensatelas...... 98

30. Extracción de la cuchilla superior .............100

31. Reemplazo de la cuchilla............................100

32. Para convertir el corchete superior de 2

hilos..........101

33. Limpieza y lubricación.................................102

34. Sustitución de la bombilla ..........................103

35. Información técnica ....................................104

TABLA DE CONTENIDO

1. Nom des parties principales ......................108

2. Accessoires fournis avec la surjeteuse....110

3. Aiguille ............................................................111

4. Comment retirer le capot avant ................111

5. Début de la couture......................................112

6. Pédale rheostat.............................................112

7. Utilisation de la plateforme pour manche.......

...........................................................................113

8. Réglage de la longueur de point................113

9. Réglage de la largeur de point ...................113

10. Alimentation différentielle...........................114

11. Installationdel’antenneduguide-l....... .117

12. Bloque-bobines.............................................117

13. Filetdeprotectionpourbobinedel ........117

14. Molettederelachementdelatensiondul....

...........................................................................118

15. Enlageduboucleursupérieur....................118

16. Enlageduboucleurinférieur ....................119

17. Utilisation du mécanisme automatique

d’enlageduboucleurinférieur...................119

18. Enlagedel’aiguillegauche .......................120

19. Enlagedel’aiguilledroite ..........................121

20. Tableaudecomparaisondestissus,lset

aiguilles............................................................122

21. Réglagedelatensiondul.........................123

22. Tableauderéglagedelatensiondul

(surjeteuse a deux aiguilles).......................123

23. Test de couture.............................................125

24. Réalisation d’un point de chainette ..........126

25. Aucasoulelsecasseraitpendantla....126

26. Réglage de la pression du pied presseur sur

le tissu.............................................................127

27. Dysfonctionnements et moyens de.................

....................128

28. Point d’ourlet roulé / de surjet étroit.........129

29. Utilisation de différents pieds presseurs.132

30. Retrait du couteau supérieur......................134

31. Changement du couteau ............................134

32. Convertir l’enrouleur supérieur pour surjet 2

ls..........135

33. Nettoyage et graissage ...............................136

34. Changement de la lampe d’éclairage.......137

35. Caractéristiques techniques .....................138

54

TRIUMPHATOR 1700X / 1800X

IT

DE TABLA DE CONTENIDO

1. Nom des parties principales ......................142

2. Mitgeliefertes zubehör für die overlock....144

3. Nadel...............................................................145

4. Wie sie die frontabdeckung entfernen .....145

5. Beginn des nähens.......................................146

6. Fußedal...........................................................146

7. Verwendung des freiarmes... .....................147

8. Stichlänge einstellen:...................................147

9. Nahtlänge einstellen ....................................147

10. Differenzialer stofftransport.......................148

11. Einstellen der fadenführungtragstange....151

12. Stopper für die fadenrolle ...........................151

13. Gitter für fadenrolle......................................151

14. Fadenspannungs-löseknopfl......................152

15. Bestücken des oberen schleifengänge

rs.......................................................................152

16. Bestücken des unteren schleifengänge

rs.......................................................................153

17. Benutzung des automatischen

bestückungssystems des unteren

schleifenfängers ...........................................153

18. Einfädeln der linken nadel...........................154

19. Einfädeln der rechten nadel........................155

20. Tabelle der stoff-, faden- und

nadelkombinationen ....................................156

21. Einstellen der fadenspannung ...................157

22. Spannungseinstelltabelle (doppelnadel-

overlock-maschinen)...................................157

23. Versuchsnähen.............................................159

24. Nähen eines kettenstichs ...........................160

25. Fadenbruch beim nähen.............................160

26. Einstellen des andrucks der stoffstange .161

27. Störungen und fehlersuche........................162

28. Roll- und schmale saumnaht... .................163

29. Verwendung unterschiedlicher Stoffstangen

...........................................................................166

30. Entfernen des obermessers.......................168

31. Messerersatz.................................................168

32. Oberer schleifengängerkonverter für 2-faden

säumen des stoffes......................................169

33. Reinigung und schmierung ........................170

34. Auswechseln der beleuchtungslampe.....171

35. Maschinenspezikation .............................172

TABLA DE CONTENIDO

1. I nomi delle parti principale ........................176

2. Accessori in dotazione con overlock........178

3. Ago ..................................................................179

4. Come togliere il coperchio anteriore ........179

5. L’inizio di cucitura.........................................180

6. Interruttore a pedale ....................................180

7. L’uso della piattaforma.................................181

8. Regolazione della lunghezza del punto ...181

9. Regolazione della lunghezza del................181

10. Differenziale di avanzamento del tessu

to......................................................................182

11. L’installazionedibanchialguidalocon...........

...........................................................................185

12. Limitatoriperbobinedilo.........................185

13. Magliaperbobinedilo..............................185

14. Pulsante di allentamento della tension.....186

15. Ricarica superiore looper.............................186

16. Ericarica bobina inferiore ............................187

17. L’uso di un meccanismo automatico di

rifornimentolobobinainferiore................187

18. Ericarica dell’ago sinistro.............................188

19. Ricarica dell’ ago destro...............................189

20. Tabellacombinazioniditessuti,lieaghi........

...........................................................................190

21. Regolazionedellatensionedello.............191

22. Tabella di regolazione della tensione (due

aghi zig zag) ..................................................191

23. Prova cucito...................................................193

24. Rl’esecuzione di catenella...........................194

25. Rotturadellodurantelacucitura ...........194

26. Regolazione della pressione del piedino

premistoffa ....................................................195

27. Malfunzionamenti e tecniche per la loro

risoluzione......................................................196

28. Cucitura di ruolo e a taglio..........................197

29. L’utilizzo di diversi tipi di pressione Del

piedino ............................................................200

30. Rimozione del coltello superiore ...............202

31. Sostituzione del coltello ..............................202

32. Il convertitore del crochet superiore per

eseguireilsopraggittoa2li......................203

33. Puliziaelubricazione.................................204

34. Sostituzione della lampadina.....................205

35. Informazioni tecniche .................................206

USER MANUAL

7EN

EN

TRIUMPHATOR 1700X / 1800X

6

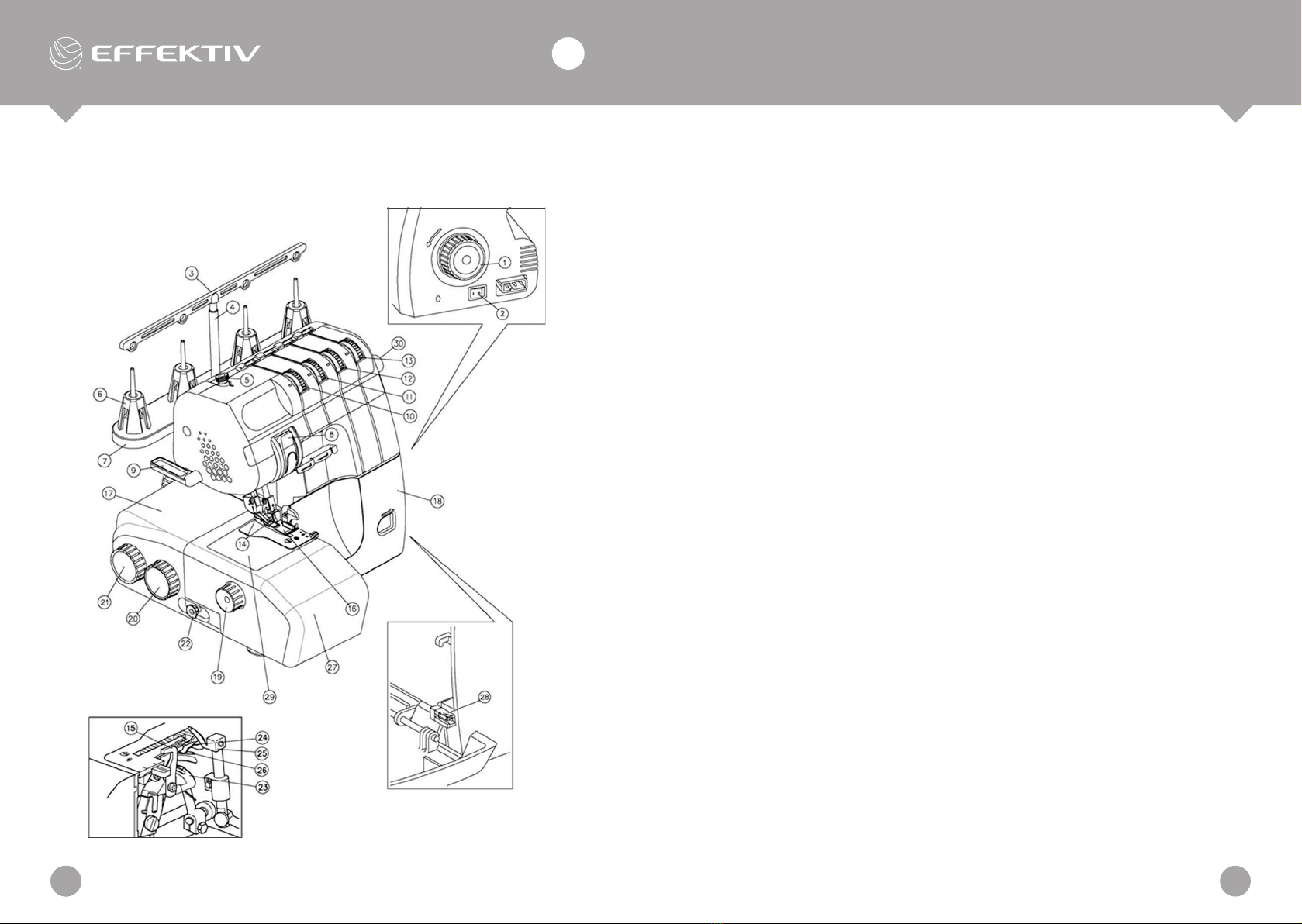

PRINCIPAL PARTS (NAMES) 1. Handwheel

2. Power/backlight switch

3. Thread quide

4. Thread guide support rod

5. Presser foot adjusting screw

6. Spool retainer

7. Spool holder

8. Thread guide lid

9. Pressure foot lifter

10. Left needle thread tension regulator

11. Right needle thread tension regulator

12. Upper looper thread tension regulator

13. Lower looper thread tension regulator

14. Needles

15. Upper knife

16. Presser foot

17. Fabric placement platform

18. Front lid

19. Stitch width regulator

20. Stitch length regulator

21. Differential feed regulator

22. Upper knife regulating knob

23. Lower looper thread guide

24. Feed dog rack gear

25. Upper looper

26. Lower looper

27. Sleeve platform

28. Microfuse

29. Sleeve platform lid

30. Instant thread tension release button

USER MANUAL

9EN

EN

TRIUMPHATOR 1700X / 1800X

8

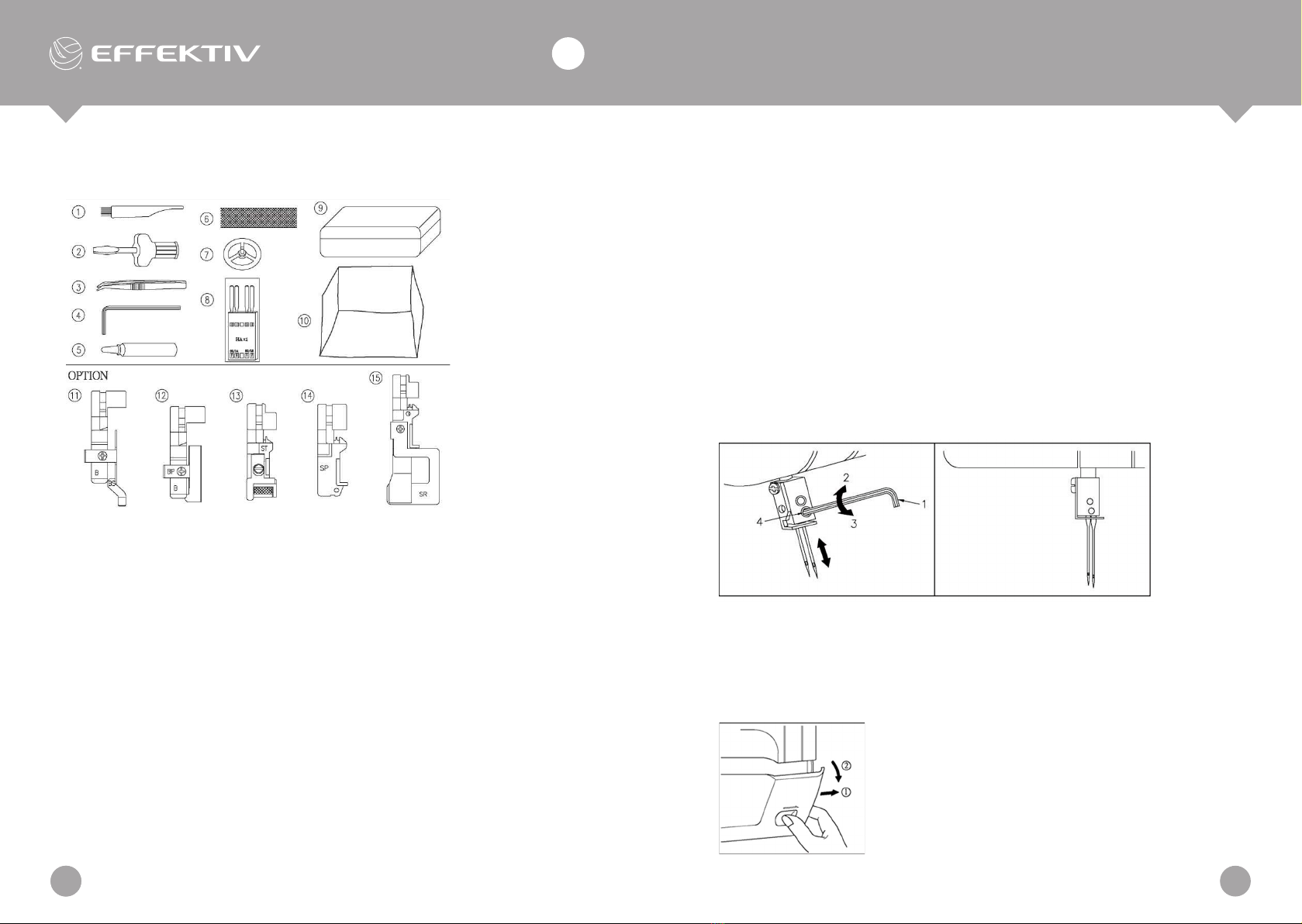

NEEDLE

This overlock is designed to work with standard needles. Use needles type:

НАх1 (130/70SH)

SWITCHING THE NEEDLE

1. Turn the handwheel towards you to bring the needle to its highest po-

sition.

2. Loosen the needle clamp screw with the supplied hex-key.

3. Insert a new needle into the needle holder (flat side facing away from

you) as far as it will go.

4. Tighten the needle clamp screw.

HOW TO REMOVE THE FRONT LID

To remove the front lid, slide it as far to the right

as possible, as shown in g.1.

Pull the lid towards you, as shown in g. 2

ACCESSORIES THAT COME WITH THE OVERLOCK

The numbers in the illustrations correspond to the numbers of the sewing

accessories:

1. Brush

2. Screwdriver

3. Tweezers

4. Hex-key

5. Oiler

6. Nets (4)

7. Spool of thread saver (4)

8. Set of needles: Hax1.80 / 12: 2

pcs. 90/14: 2 pcs..

9. Sewing box

10. Overlock case:

Optional (is not included, sold

separately)

11. Blindstitch foot

12. Bead/sequin sewing foot

13. Stretch stitch foot

14. Bias binding foot

15. Gathering foot

This manual suits for next models

1

Table of contents

Languages:

Other EFFEKTIV Kitchen Appliance manuals