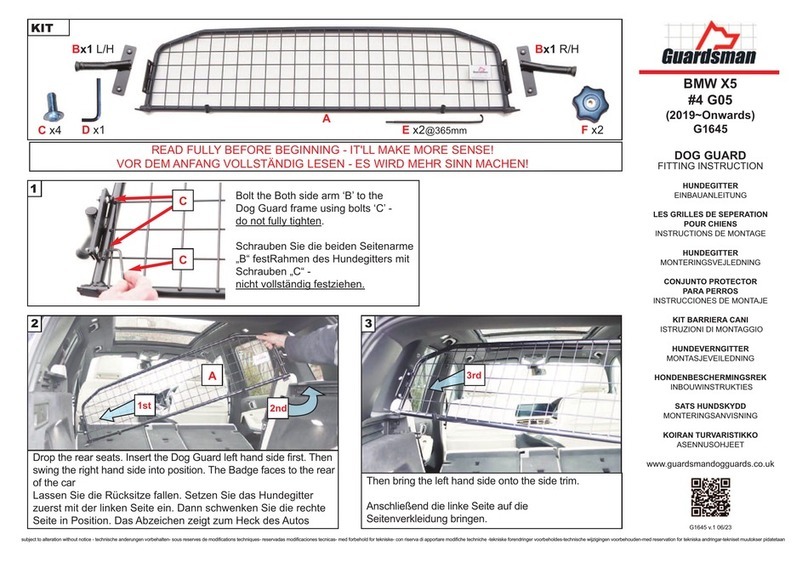

EGR RollTrac User manual

RT0063

Page 1 of 33

ISSUE 4: 26/04/23

Installation time: 180 minutes (without tubliner)

INSTALLATION INSTRUCTIONS

ELECTRIC

• Check that all work practices comply with safety standards.

• Please wear appropriate clothing and use safety equipment.

Caution

Safety Notes

• Do not attach EGR RollTrac in a location or by a method not specified.

• Do not use this product for any vehicle make or model, other than those specified in this document.

• Do not remove the plaque or label from this product.

• Do not modify the structure of the EGR RollTrac in any way.

• Read through the fitting instructions before installation of EGR RollTrac.

• Always install the accessory following the fitting instructions. Failure to do so may cause damage to the vehicle or the accessory.

• Ensure all recyclable discarded vehicle accessory components and packaging are recycled following local recycling regulations.

• It is always recommended that this accessory is fitted by a qualified Technician.

• Safely store and protect any removed vehicle components.

• Ensure all bare metal surfaces are protected using Automotive Bare Metal Primer and touch-up paint.

• Remove all metal swarf and dust from all vehicle surfaces if surface is used for accessory installation.

General Notes

Vehicle Model: FORD RANGER

Year of manufacture: MY22 onwards

*RT0063*

IMPORTANT:

IF THE EGR ROLLTRAC IS FITTED TO THE VEHICLE WITH ANY ACCESSORY

LOADED WITH MORE THAN 45KG, A TUB REINFORCEMENT KIT MUST BE

FITTED. THE TUB REINFORCEMENT KIT CAN BE PURCHASED FROM YOUR

LOCAL FORD DEALER OR DIRECTLY FROM EGR (PART No. KIT040256).

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

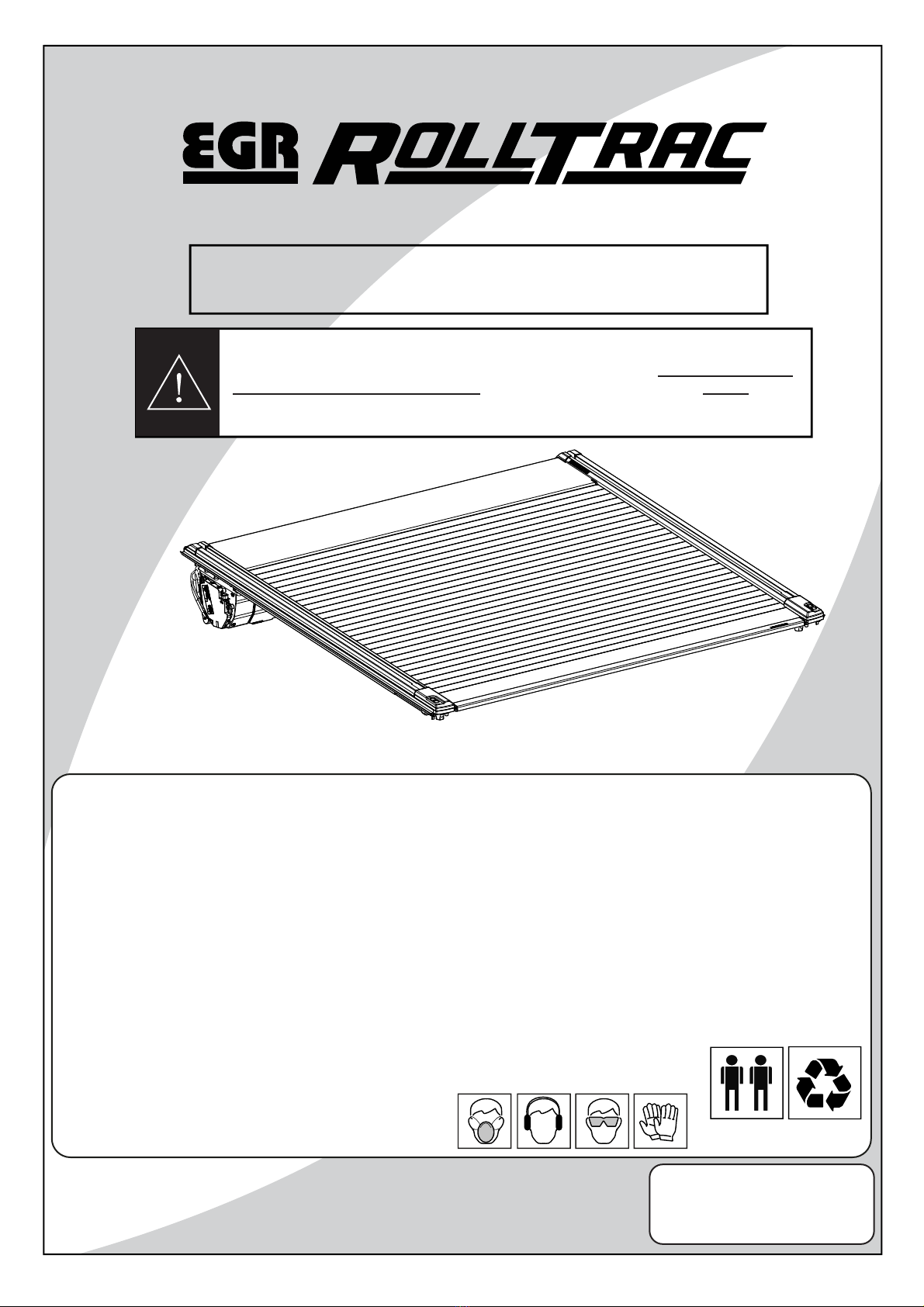

RT0063

TUB PREP

SECTION B

STEP 1-14

ELECTRICAL

SECTION A

STEP 1-8

EGR ROLLTRAC

ASSEMBLY

SECTION C

STEP 1-11

CALIBRATION

SECTION E

OPERATIONS

FINAL NOTES

FINISH

EGR ROLLTRAC

INSTALLATION

SECTION D

STEP 1-8

Page 2 of 33ISSUE 4: 26/04/23

FINISH

START

INSTALLATION PROCESS

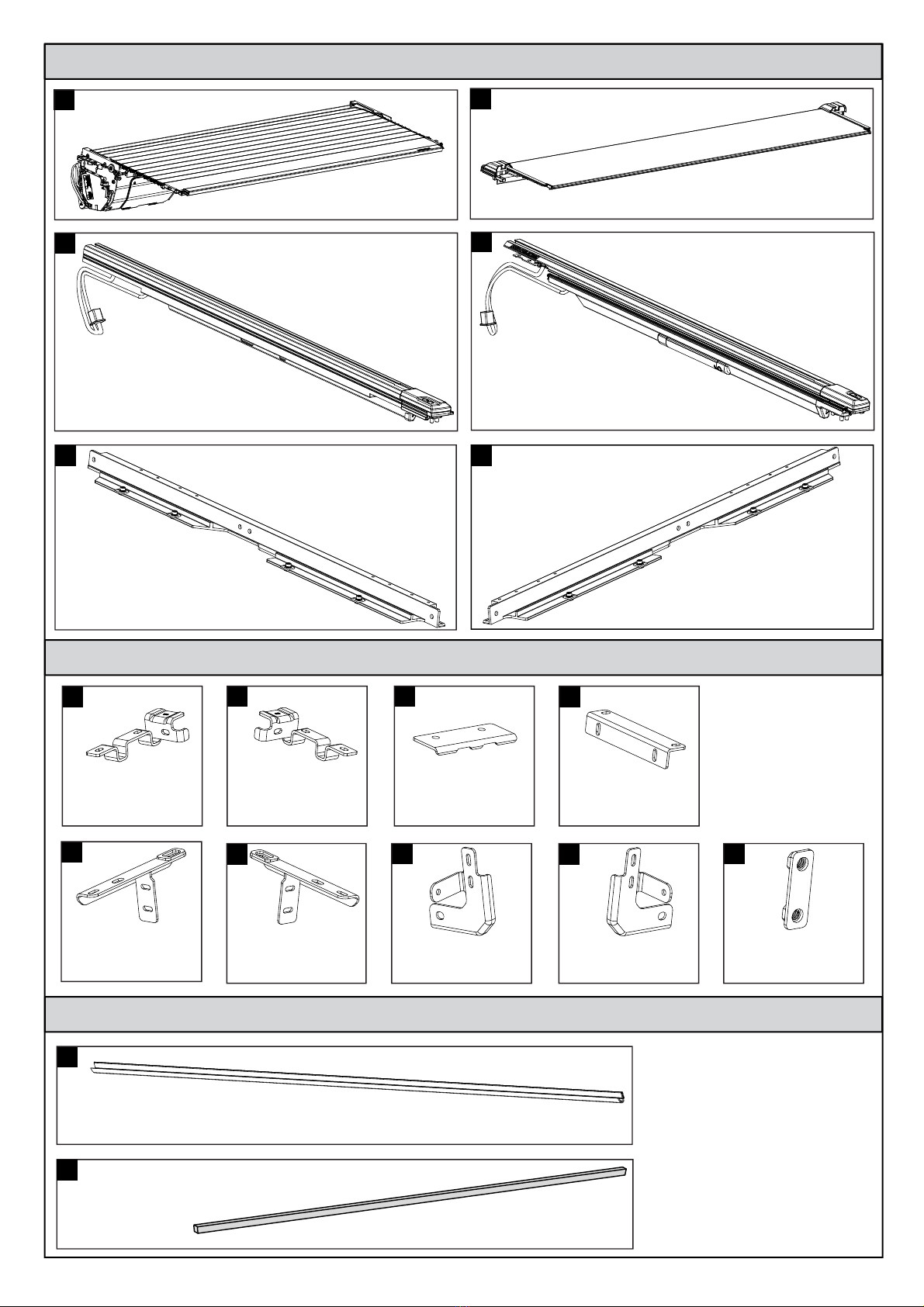

UNPACKING

FITTING KIT

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

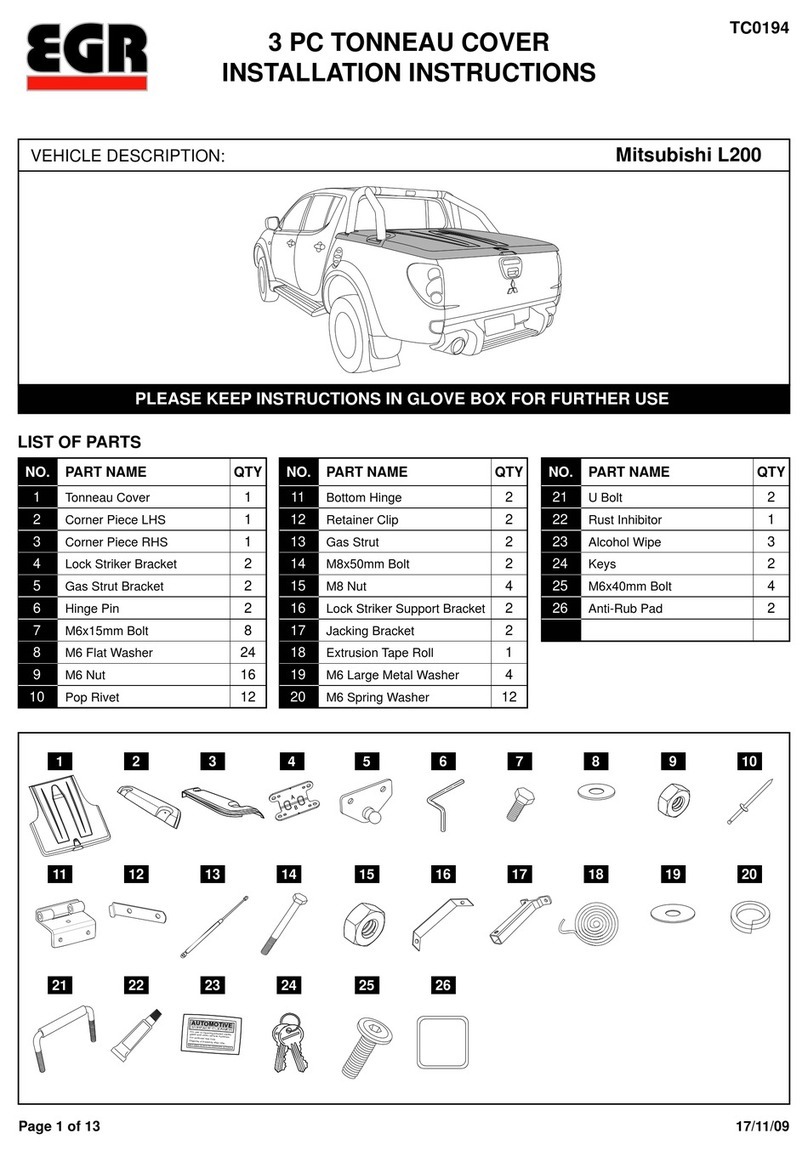

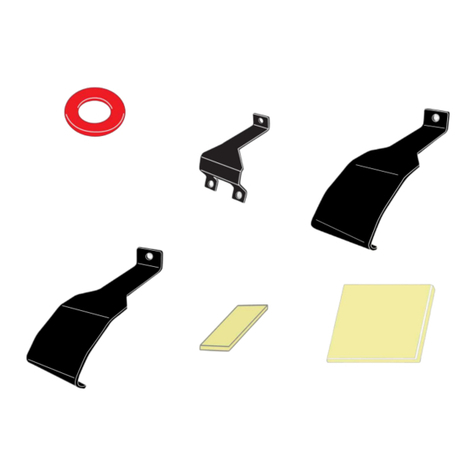

KIT CONTENTS - COMPONENT NUMBER AND QUANTITY

LHS RAIL QTY: 1

FR MNT BRK

CLIP3932PC-LH

QTY: 1

MNT BAR

TGAT0032-LH

QTY: 1

MNT BAR

TGAT0032-RH

QTY: 1

FR MNT BRK

CLIP3932PC-RH

QTY: 1

H-BAR CRN BRK

CLIP4106

QTY: 2

MNT BRK

CLIP4108

QTY: 4

REAR SUPP BRK

CLIP4110-LH

QTY: 1

REAR SUPP BRK

CLIP4110-RH

QTY: 1

REAR MNT BRK

CLIP4109-LH

QTY: 1

REAR MNT BRK

CLIP4109-RH

QTY: 1

M6 NUT PLATE

MISC5793

QTY: 2

RHS RAIL QTY: 1

FRONT COVER QTY: 1

CANISTER ASM. QTY: 1

12

34

56

789

11 12 13 14 15

16

10

EGR EGR ROLLTRAC CLAMP KIT IN BAG

EGR EGR ROLLTRAC BULB KIT IN BAG

RT0063

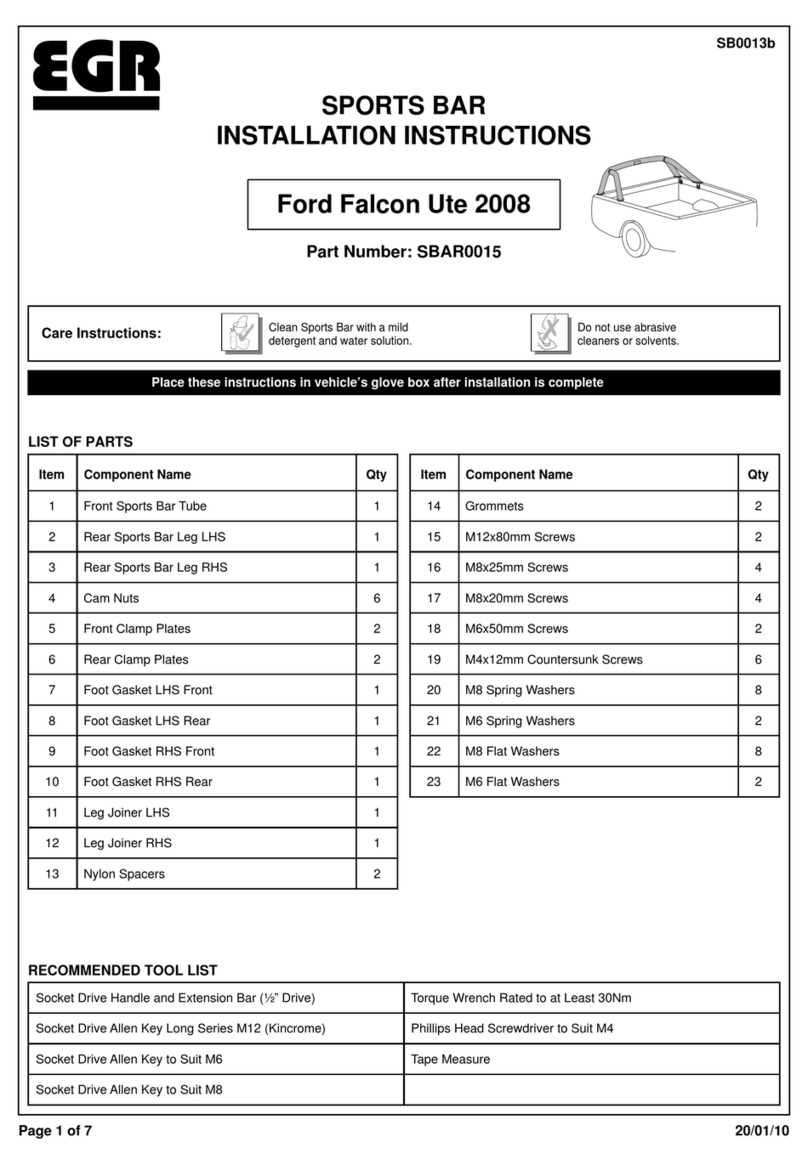

Page 3 of 33ISSUE 4: 26/04/23

17

SIDE RAIL SEAL

EXTR0112-32

QTY: 2

FRONT RAIL SEAL

TAPE0752

QTY: 1

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

SCREW END PAD

MISC5812

QTY: 8

M6x50 HEX HEAD

SCRW0967

QTY: 8

M6x20 HEX HEAD

SCRW0997

QTY: 10

M6x15 HEX DRIVE

SCRW0973

QTY: 14

M6x15 HEX DRIVE

SCRW0973

QTY: 6

M8x25 BUTTON HEAD

HEX DRIVE

SCRW0974

QTY: 6

EGR EGR ROLLTRAC MBAR HARDWARE KIT IN BAG

EGR EGR ROLLTRAC FITTING KIT IN BOX

INSTALLATION

INSTRUCTIONS

&

OWNERS MANUAL

RT0063

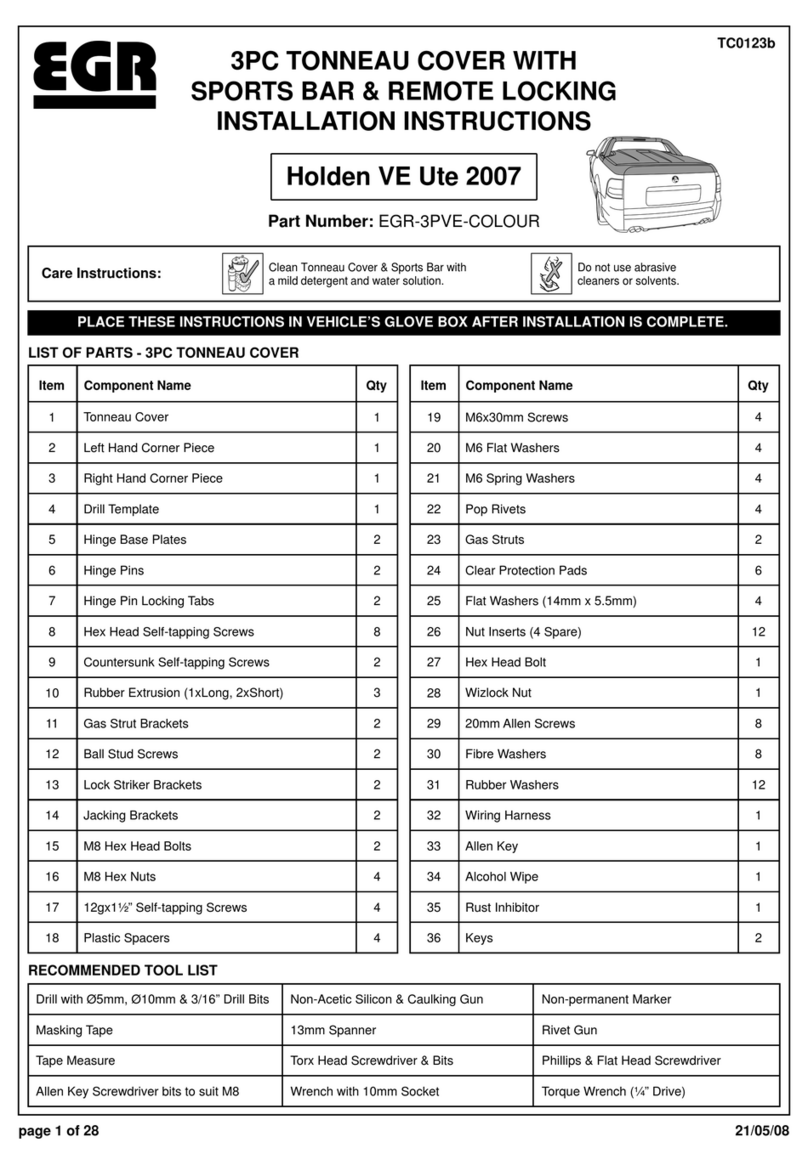

Page 4 of 33

ISSUE 4: 26/04/23

18 19 20 21

M6x15 HEX HEAD

SCRW01001

QTY: 16

SPACER

MISC5457

QTY: 6

WATER DUCT

INJM0274-RH

QTY: 1

REAR DRAIN TUBE

(VEHICLES WITHOUT DDK ONLY)

QTY: 2

M6 HEX NUT

NUTS0285

QTY: 8

M6 HEX NUT

NUTS0284

QTY: 2

FIT JIG

MISC5822

QTY: 1

22

23 24 25

26 27

FR DRAIN TUBE

MISC5222

QTY: 2

28 30

31

REAR DRAIN TUBE

(DDK ONLY)

MISC5223-32

QTY: 2

32

CABLE TIE BASE

MISC5128

QTY: 2

33

WATER DUCT

INJM0274-LH

QTY: 1

29

CONS70097

CABLE TIE

QTY: 8

34

35

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

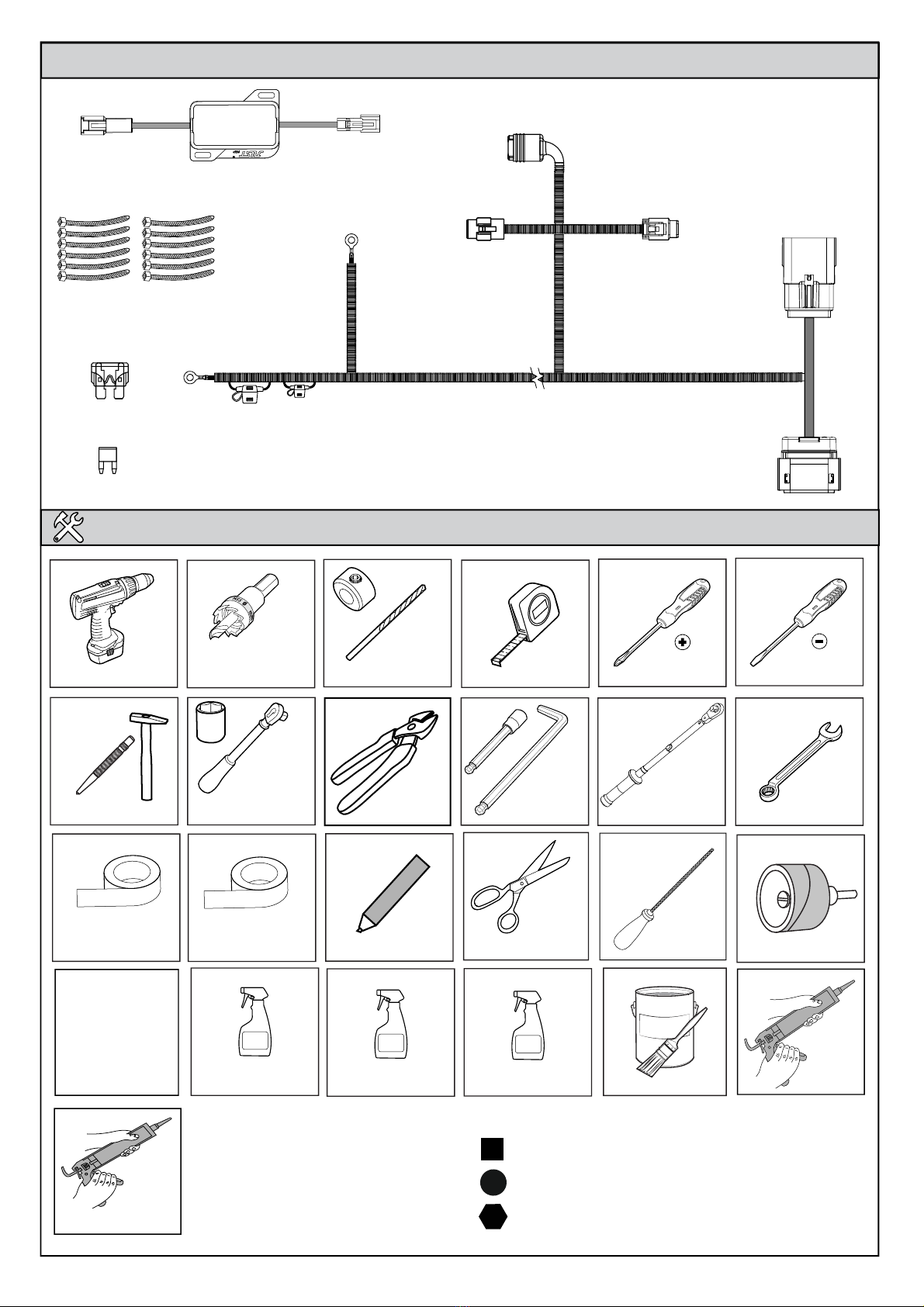

PARTS IN VEHICLE HARNESS

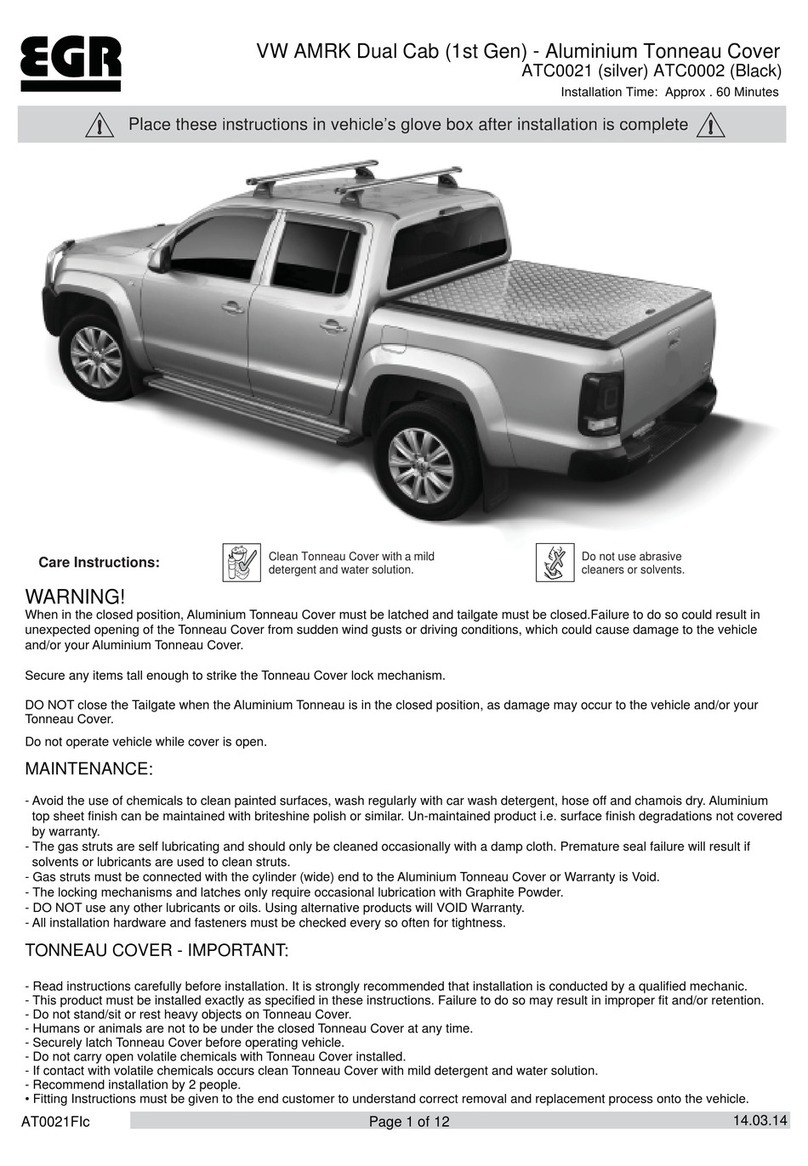

TOOLS REQUIRED - NOT SUPPLIED IN KIT

Page 5 of 33ISSUE 4: 26/04/23 RT0063

ANTI RUST

Torque Wrench

50/50

Isopropyl Alcohol/Water Soapy Water

Silicone Spray

Silicone

Silicone

(non-acidic)

Rust Inhibitor

Flat Screwdriver

Spanners 8,10,13mm

Allen Key 2.5 & 4mm

Ratchet & Sockets

7,10,13mm

Phillips Screwdriver

Drill Tape Measure

Scissors

Masking Tape

Fiberglass Tape

Black Cloth Tape

Anti-abresion tape to seal

holes & slots Non-permanent pen

Drill Bits

Bobbin Sander Ø60mm

Ø60mm

Ø38mm

Ø29mm

Drill Stop

Centre Punch & Hummer

Holesaw

Side Cutters

Cutting device

needed to trim

bed cap

6mm File

1

1

1

GLOSSARY:

Number inside a square indicate part number

Number inside circle indicate the sequence within a step

Number inside the hexagon indicate torque instruction

SPP UNIT

VEHICLE HARNESS

CABLE TIE

QTY: 12

MINI FUSE

25A FUSE

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

RT0063

SECTION - A ELECTRICAL SECTION

Page 6 of 33ISSUE 4: 26/04/23

A

C

DEF

G

H

I

B

AB

CD

FG

E

STEP 1

STEP 2

STEP 5,6

STEP 7

STEP 4

STEP 3

IMPORTANT: DISCONNECT CAR BATTERY NEGATIVE TERMINAL.

FIT THE SUPPLIED FUSES AT THE END OF INSTALLATION.

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

RT0063

Page 7 of 33ISSUE 4: 26/04/23

IMPORTANT: Make sure the fuses are not fitted before making connection.

Connect the vehicle harness branch (B) to vehicle body negative ground as shown and secure with M6 hex nut (35).

Connect the vehicle harness branch (A) to the positive terminal of the battery and secure with M6 hex nut (35).

Once it is positioned, secure in place using two cable ties as shown.

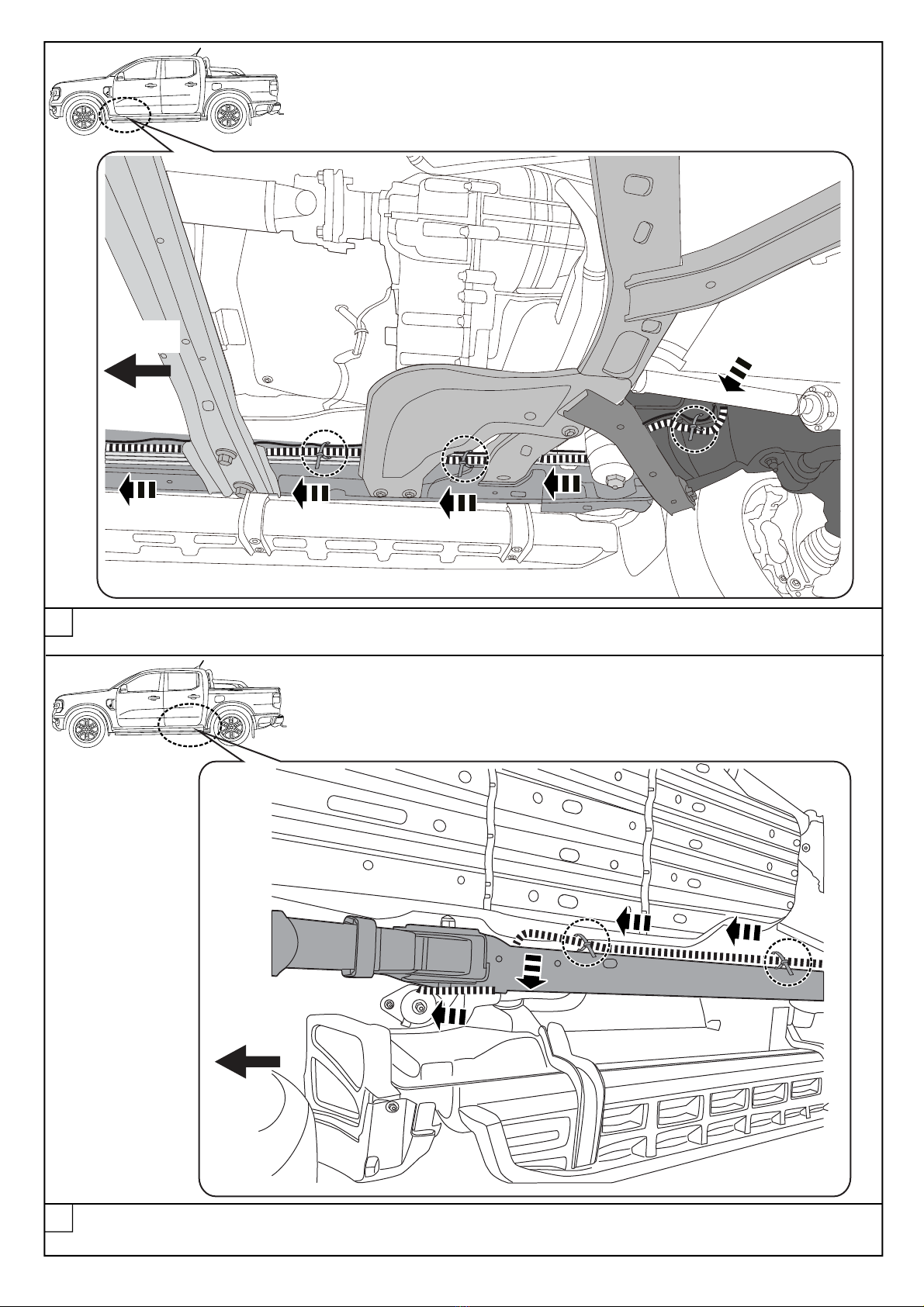

Pull the vehicle harness from engine bay down to the floor behind the front left wheel. Direct it towards the rear of

the vehicle. Secure the vehicle harness to the vehicle loom in the two areas shown using cable ties.

A

A

B

B

BATTERY

POSITIVE TERMINAL

NEGATIVE TERMINAL

A

B

REAR

1

2

35

35

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

RT0063

Page 8 of 33ISSUE 4: 26/04/23

Continue running the vehicle harness along the chassis rail inner side. Feed the harness to the outside of the

chassis rail (over the top of the rail) at the rear wheel arch as shown. Secure with two cable ties as shown.

Continue to the rear along the chassis rail inner side (above the crossmembers). Secure the vehicle harness to

the existing vehicle harness as shown using cable ties.

REAR

REAR

4

3

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

RT0063

Page 9 of 33

ISSUE 4: 26/04/23

CD

E

CD

E

H

I

Push a draw wire down through the opening in the front LHS of the tub. Under the tub, wrap the vehicle harness

connectors: C, D & E to the draw wire as shown. Pull them up into the tub until approximately 300mm protrudes.

Remove tape and draw wire from the harness.

DRAW

WIRE

TAPE

VEHICLE

HARNESS

DRAW WIRE

VIEW INSIDE TUB

VIEW INSIDE TUB

REAR

C

D

E

5

6

Connect the SPP unit to the vehicle harness as shown. Secure SPP unit and connectors to underside of tub

flange using cable ties and cable tie base x2.

SPP UNIT

TUB

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

RT0063

Page 10 of 33ISSUE 4: 26/04/23

F G

Run the vehicle harness along the inner chassis rail aide and along the tail end of the vehicle till reaching the

loom connectors on as shown. Using cable ties, secure the vehicle harness to the vehicle tub in 4 locations as

shown . Disconnect the 16 pin vehicle loom connectors and patch it using the vehicle harness connectors F& G.

VEHICLE HARNESS

VEHICLE LOOM VEHICLE LOOM

RHS

REAR

REAR

Push the remaining harness over to the chassis rail inner and continue running it towards the rear of the vehicle.

Secure with 3 Cable Ties as shown.

REAR

7

8

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

RT0063

SECTION - B TUB PREPARATION

Page 11 of 33ISSUE 4: 26/04/23

1

2

If CMS rail is present, remove and retain CMS rail, hex head screws (A) and torx screw (B). If CMS rail is not pres-

ent, remove torx screw (B) located at the rear of the tub. Retain the CMS bar and hardware for refit.

If Sportsbar is present, remove it and store in safe place. Keep brackets attached to the tub. Clean the top and inside

of the tub. Remove the tail lights.

T40

13mm

RHS SHOWN

AA

A

A

A

B

PERFORM THIS STEP ONLY IF CMS IS FITTED

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

Page 12 of 33ISSUE 4: 26/04/23 RT0063

3

FRONT DRAIN TUBES - TUB DRILLING WITH TUBLINER

127mm

185mm

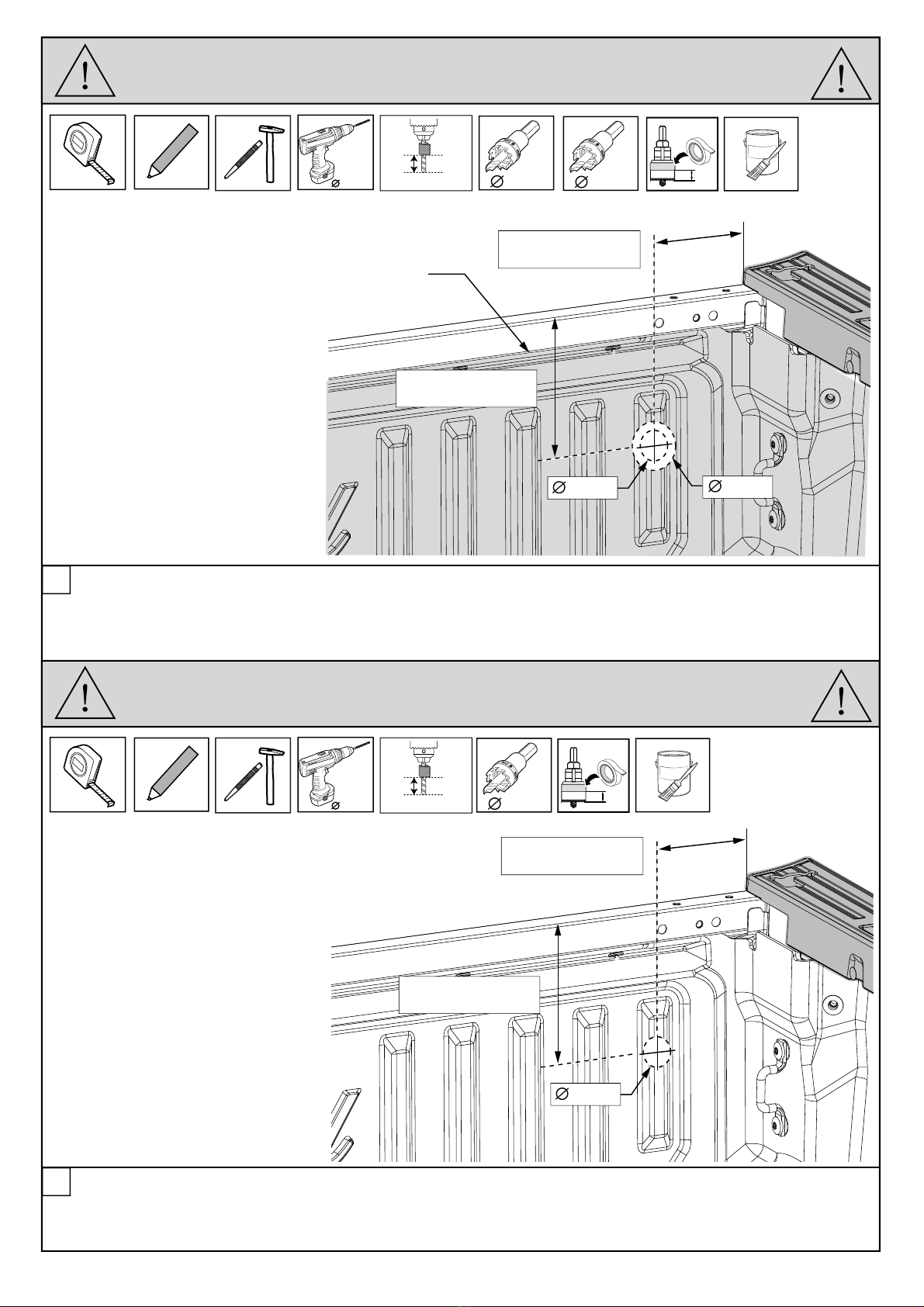

On the tub front panel, measure and markup the positions for the front drain tubes.

Centre punch the locations and drill 5.5mm pilot hole through the tub and tubliner.

Using hole saw drill 60mm hole in the tubliner only, use 10mm stop. With a 38mm hole saw, drill hole in the tub

following the pilot hole. Deburr both holes and apply rust inhibitor to the metal. Repeat for LHS.

4

On the tub front panel, measure and markup the positions for the front drain tubes.

Centre punch the locations and drill 5.5mm pilot hole through the tub.

Using hole saw drill 60mm hole in the tubliner only, With a 38mm hole saw, drill hole in the tub following the pilot

hole use 10mm stop. Deburr both holes and apply rust inhibitor to the metal. Repeat for LHS.

FRONT OF TUB - RHS

FRONT OF TUB - RHS

DRILL STOP 10mm

DRILL STOP 10mm

TUBLINER

5.5mm 38mm

60mm

60mm

38mm

ANTI RUST

10mm

FRONT DRAIN TUBES - TUB DRILLING (NO TUBLINER)

5.5mm 38mm

ANTI RUST

10mm

127mm

185mm

38mm

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

Page 13 of 33ISSUE 4: 26/04/23 RT0063

105mm

40mm

5

On the tub rear panel, measure and markup the positions for the rear drain tubes.

Centre punch the locations and drill 5.5mm pilot hole through the tubliner ONLY!

Using hole saw drill 29mm hole in the tubliner. Use 10mm stop. Repeat for LHS.

REAR OF TUB - RHS

DRILL STOP 10mm

TUBLINER

TUBLINER

300mm

5.5mm 29mm

EGR ROLLTRAC SPECIFIC DDK’S ARE AVAILABLE FROM YOUR DEALER.

IF A DDK IS TO BE INSTALLED, IT SHOULD BE FITTED AFTER INSTALLING EGR ROLLTRAC.

NOTE THAT IF DDK IS TO BE INSTALLED, DRILLING AT REAR OF TUB IS NOT REQUIRED.

10mm

29mm

REAR DRAIN TUBES - TUBLINER FITTED (NO DDK)

STEP 5 & 6

6

RHS & LHS

Trim the drain tube conduit as shown and fit from the outside of the tubliner in through the drilled hole. Spray tubes

with soapy water to help with fitment. Repeat for LHS.

2

1

31

SECTION VIEW

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

Page 14 of 33ISSUE 4: 26/04/23 RT0063

105mm

40mm

On the tub rear panel, measure and markup the positions for the rear drain tubes.

Centre punch the locations and drill 5.5mm pilot hole through the tub.

Using hole saw drill 29mm hole in the tub. Use 10mm stop. Repeat for LHS.

REAR OF TUB - RHS

5.5mm

DRILL STOP 10mm

29mm

ANTI RUST

7

8

10mm

REAR DRAIN TUBES - TUB DRILLING (NO TUBLINER & NO DDK)

STEP 7 & 8

RHS & LHS

Fit the rear drain tubes from the inside of the tail lamp cavity up through the drilled hole. Spray tubes with soapy water

to help with fitment. Repeat for LHS.

2

1

31

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

Cutting device

needed to trim

bed cap

Page 15 of 33ISSUE 4: 26/04/23 RT0063

21

9

13mm

A

Inside the tub locate the RHS bed cap and cover the inside face with masking tape to allow marking with pen and

avoid scratching during trimming. Mark the bed cap as shown above and trim the area using suitable tool.

If CMS rail fitted, remove the 4 M6 screws as shown. Repeat for LHS.

Fit the two h-bar corner brackets (9) to the top of the front of the tub and secure with two screws (21). Repeat for the

LHS. Apply the front rail seal (17) along the top of the h-bar as shown and ensure ends touch the endcap. Apply

Silicone in the gap between the rail seal, bracket and tub rail as shown. NOTE: Seal all holes in the tub as required.

BED CAP - RHS

9

10

34mm

947mm

AAA

17

9

x2

21

x2

22Nm

1

1

1

5mm 5mm

17

9

FRONT TUB

SECTION VIEW

SEAL TOUCH

SEAL TOUCH

NOT SUPPLIED

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

Page 16 of 33ISSUE 4: 26/04/23 RT0063

19 18

13mm

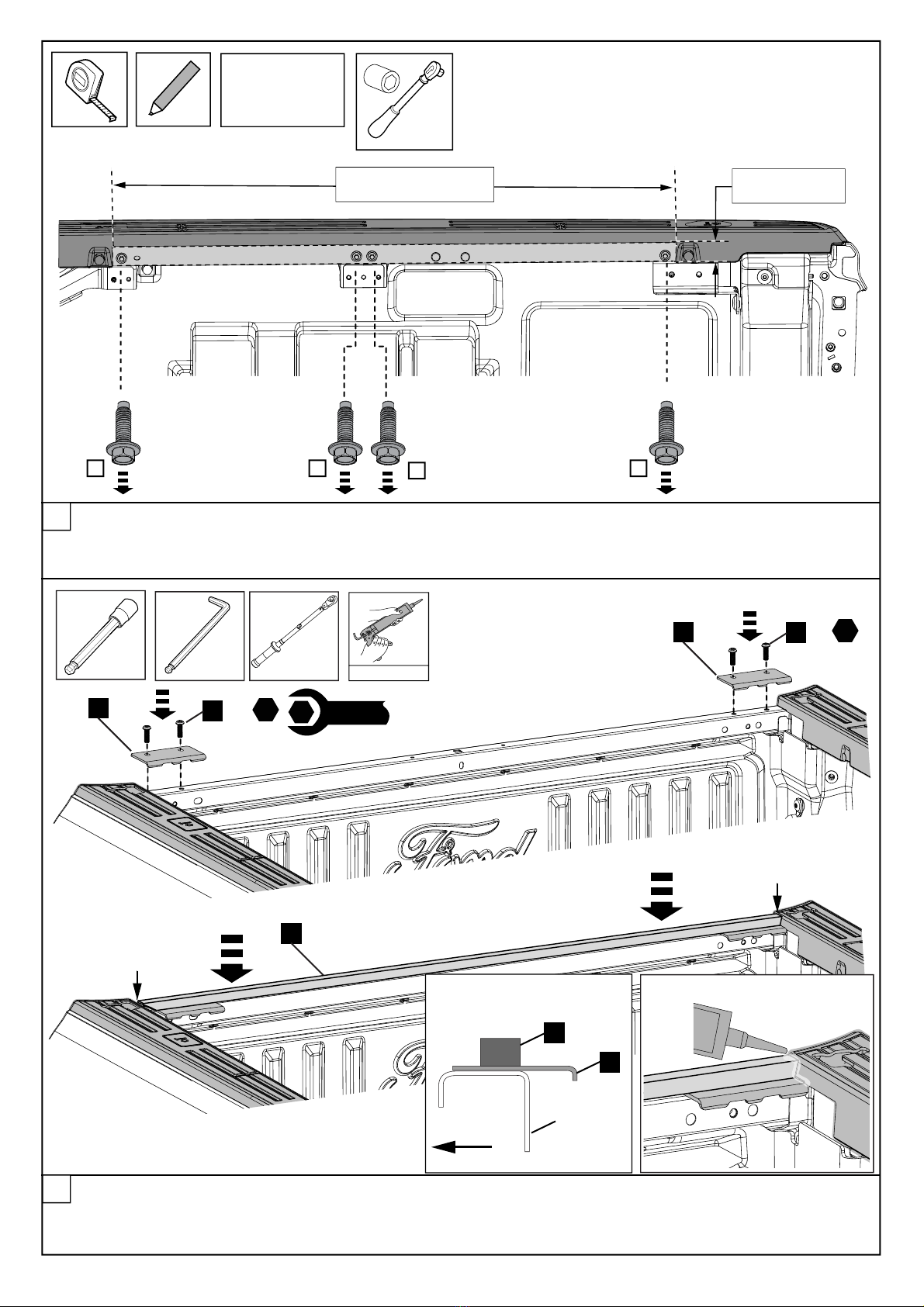

Fit the 4 screws (19) into the RHS mounting rail (6) and fit the end pads as shown. Set the screws height as shown

in detail. Repeat for the LHS mounting rail.

NOTE: Screws will be adjusted in later stage once fitted to the tub.

MNT BAR - RHS

MNT BAR - LHS

11

x4

19

x4

x4

18

x4

5

6

SET SCREW HEIGHT

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

Page 17 of 33ISSUE 4: 26/04/23 RT0063

19

18

Fit the RHS mounting bar to the tub as shown. Secure with 4 screws (20) and nuts (25). Torque to 5.5Nm.

NOTE: Level the bar by pushing it up till it contacts the tub (see section view).

Turn the screw (19) up until the cap (18) contacts the inner tub sheet metal (see section view). Do not overtighten.

12

1

5.5Nm

1

4mm 4mm

MNT BAR - RHS

NOT REQUIRED IF CMS BAR BRACKETS FITTED

6

6

20

25

x4

x4

SECTION VIEW

TUB

BED CAP

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

Page 18 of 33ISSUE 4: 26/04/23 RT0063

21

22

24

24

Fit the RHS rear mounting bracket to the tub and secure with 2 screws (21) and (22) as shown.

Use 2x spacers (24) behind the bracket (screw (21) location) and 1x spacer (screw (22) location).

Torque to 13.5Nm & 5.5Nm. Repeat for LHS.

NOTE: Clearance hole may have to be drilled in the tubliner for the spacer (24).

13

29mm 10mm

1

2

13.5Nm

1

5.5Nm

2

4mm 4mm

14

x2

14

Connect the front drain tubes (8) to the tub. Make sure that both tubes engage over the wall of the tub. Leakage will

occur if they are not properly installed.

INSTALL FRONT DRAIN TUBES TO TUB

21

28

28

29mm

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

RT0063

Page 19 of 33

ISSUE 4: 26/04/23

EGR RollTrac ASSEMBLY

SECTION C

RHS

FIT FIRST

LHS

4

3

1

1

4mm

DURING ASSEMBLY PROCEDURE SUPPORT AT CENTRE OF CANISTER ONLY,

PLACE ON TOP AND BASE CARTON (OR SIMILAR), COVER WITH FOAM BLANKET.

TO AVOID SCRATCHING POWDERCOATED SURFACES.

DO NOT LOAD ELECTRICAL CONNECTORS OR MOTOR COVER.

Place the canister (1) on two protected boxes as shown, ensure hand rail and slat ends are aligned. Tape up the seal

on the Side Rail (3) as shown.

IMPORTANT: Carefully align and slide the rail over the handrail and canister endplate taking particular care to ensure

that the siderails are slid straight and no undue force is applied to the rail. Details in following steps.

APPROX

300mm

HOLD SEAL FLAT

USE CLOTH TAPE

RHS SHOWN

1ATTENTION: SEAL MUST FACE IN THE

DIRECTION AS SHOWN. WARRANTY VOID IF

ASSEMBLED INCORRECTLY.

ENSURE ENDS ARE

ALIGNED & CENTRED

2ATTENTION: EXPOSE 3 SLATS PRIOR TO

FITTING SIDE RAILS.

C/L

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

RT0063

ISSUE 4: 26/04/23 Page 20 of 33

ALIGN CAREFULLY

CAUTION

REMOVE THE TAPE FROM TOP OF THE RAIL

AND PULL OUT HORIZONTALLY

CHECK SEAL IS IN POSITION AND NOT DAMAGED

Carefully lay the assembly over onto a protected surface. Remove the tape holding the rubber seal and check the seal

position as shown.

3

DURING ASSEMBLY PROCEDURE SUPPORT AT CENTRE OF CANISTER ONLY,

PLACE ON TOP AND BASE CARTON (OR SIMILAR), COVER WITH FOAM BLANKET.

TO AVOID SCRATCHING POWDERCOATED SURFACES.

DO NOT LOAD ELECTRICAL CONNECTORS OR MOTOR COVER.

45

TUCK LOOM TO THE SIDE

FIT

20

SLIDE INTO POSITION ALIGN HOLES

GENTLY WIGGLING THE PART INTO THE FINAL

POSITION MAY HELP

INSERT SCREWS AND TIGHTEN LOOSELY

ALIGN

HOLES

90°

Pull hand rail to expose 3 slats. Slide the side rail over slat ends and onto endcap location pins. Align the holes and

secure loosely with a M6x15mm screw (20). Do not tighten. Repeat for LHS Rail.

2

3

ATTENTION: SEAL MUST FACE IN THE

DIRECTION AS SHOWN. WARRANTY VOID IF

ASSEMBLED INCORRECTLY.

2

1

-- EGR Document ID#121541 v5 2023-05-09 23:59:32 awilmott --

Other manuals for RollTrac

2

Table of contents

Other EGR Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Whispbar

Whispbar K666 manual

Torklift

Torklift C4201 Important owner-operator installation instructions

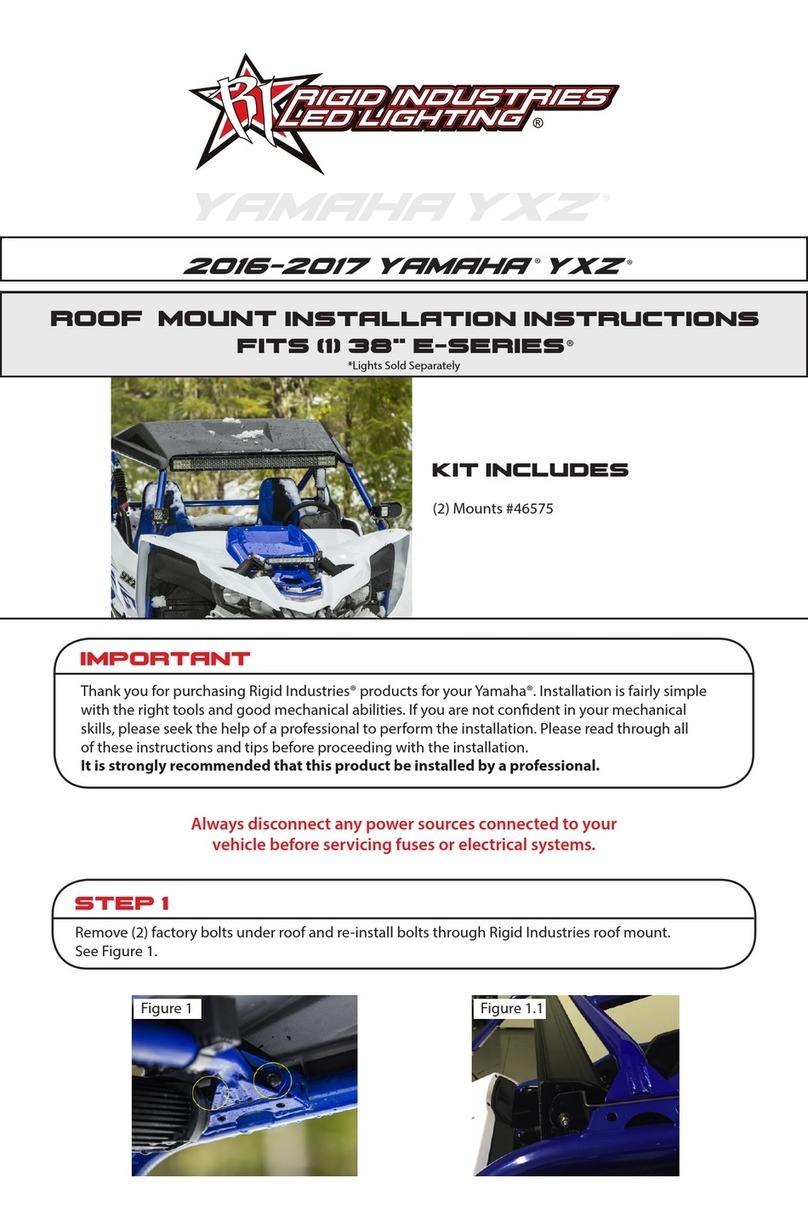

Rigid Industries

Rigid Industries E Series installation instructions

Metra Electronics

Metra Electronics 95-7298B installation instructions

Parrot

Parrot Easydrive user guide

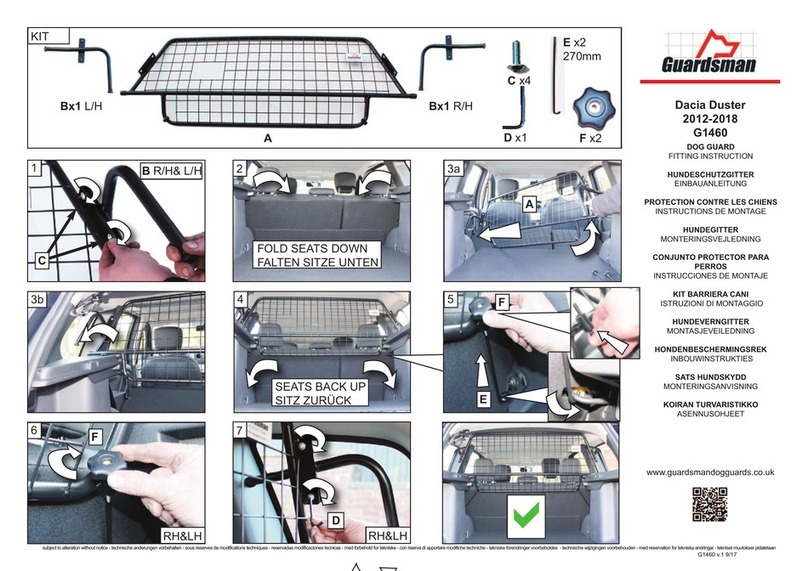

Guardsman

Guardsman G1460 FITTING INSTRUCTION

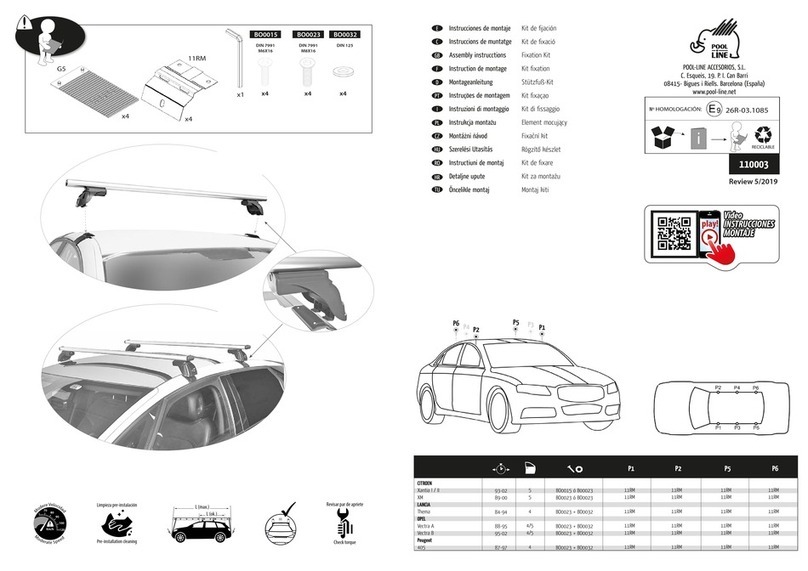

POOL-LINE

POOL-LINE 110003 Assembly instructions

Eaton

Eaton VORAD AlwaysAlert installation guide

Discount Car Stereo

Discount Car Stereo PXDX-CTS Quick start installation guide

Road Angel

Road Angel RA8100 User's installation guide

Lippert

Lippert SolidStep Gen 2 Installation and owner's manual

tams elektronik

tams elektronik FCS-2 manual