-2-

Contents

SERVICE MANUAL ................................................... 1

Contents ........................................................................ 2

Safety Instructions......................................................... 3

Safety Precautions ..........................................................3

Product Safety Notice .....................................................3

Service Personnel Warning.............................................3

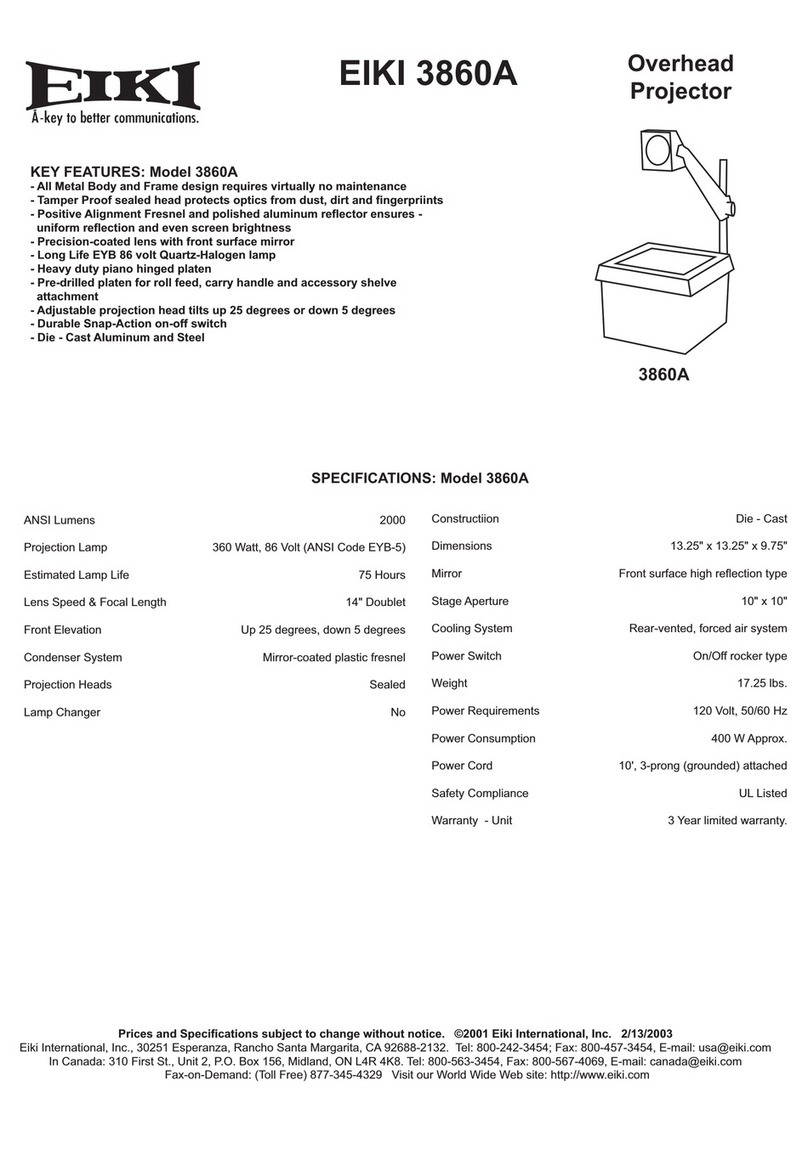

Specifications ................................................................ 4

Circuit Protections ......................................................... 5

Fuses (F601, F602, F603)...............................................5

Thermostats (SW903, SW904, SW905, SW906) ...........6

Temperature sensors, wind sensors ...............................7

Power failure, fan lock and filter error detection ..............8

Maintenance.................................................................. 9

Maintaining the AMC unit ................................................9

Replacing the Filters .....................................................10

Resetting the Filter counter ........................................... 11

Lamp management ....................................................... 12

Lamp replacement ........................................................ 13

Checking the projector used time and lamp used time. 14

Quick maintenance ....................................................... 15

Cleaning the optical parts.............................................. 16

Cleaning the Projection lens ......................................... 16

Cleaning the Projector cabinet ...................................... 16

Security Function Notice ............................................. 17

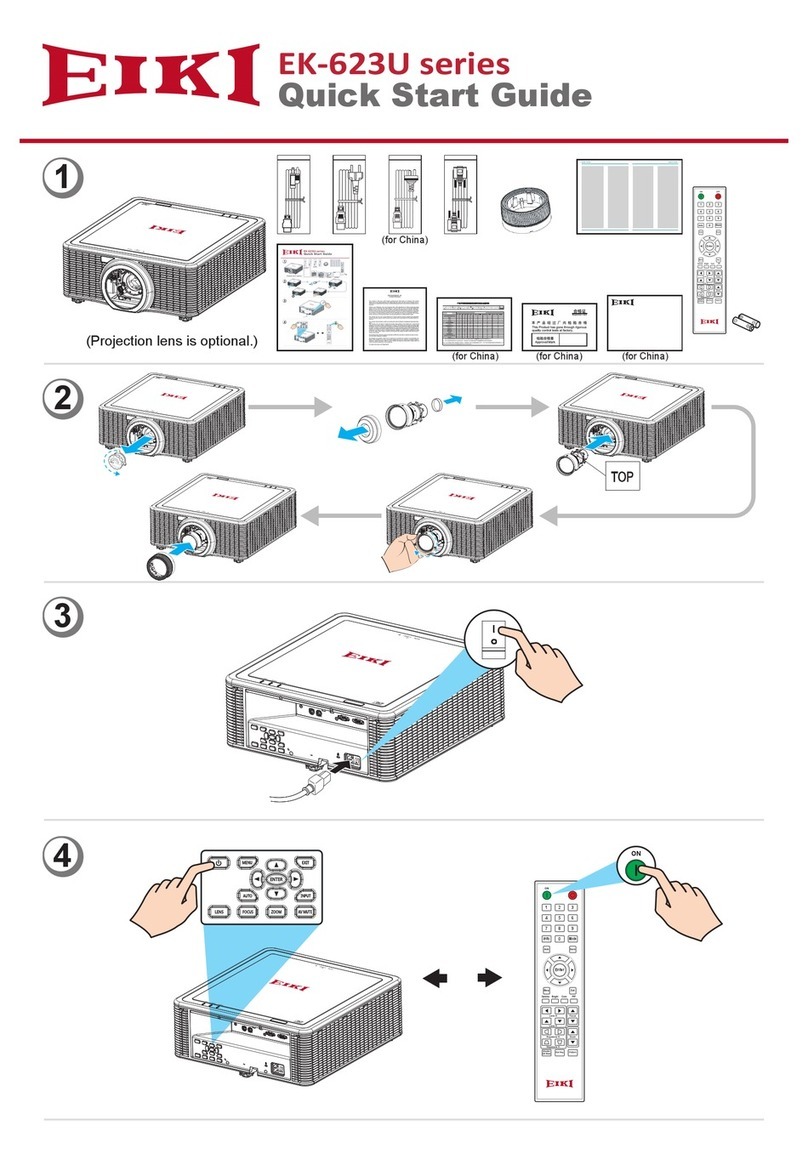

Lens Mounting............................................................. 18

Mechanical Disassembly............................................. 22

Mechanical disassembly flow chart...............................22

Mechanical disassembly ...............................................23

Optical Parts Disassembly .......................................... 44

Adjustments................................................................. 58

Adjustments after Parts Replacement...........................58

Note on Main board replacement..................................58

Optical Adjustments .................................................... 59

Optical adjustment location...........................................59

Before adjustment .........................................................60

1. Optical center adjustment..........................................62

2. PBS adjustment.........................................................66

3. Contrast adjustment ..................................................67

4. Back focus adjustment ..............................................68

5. Convergence adjustment ..........................................69

Adjustment ....................................................................72

Electrical Adjustments................................................. 73

Service adjustment menu operation .............................73

Circuit adjustments........................................................ 74

Test points and locations...............................................78

Service adjustment data................................................79

Chassis Description .................................................. 157

Chassis over view........................................................ 157

Boards connection ...................................................... 158

Troubleshooting......................................................... 159

No Picture.................................................................... 159

No Power..................................................................... 163

Power supplies to boards ............................................ 164

AC-DC power board ....................................................165

DC power borad .......................................................... 166

PFC-1 & PFC-2 board .................................................167

Power supply and power failure detection...................168

Power drive and power failure signals......................... 171

Fan control system ...................................................... 172

Motor control system ................................................... 173

Temperature abnormality ............................................ 174

Lamp abnormality........................................................ 175

Lamp control system ................................................... 176

Power failure detection system ...................................177

Error information table................................................. 177

Error history log ........................................................... 178

Diagnosis of power failure with RS-232C port ............ 179

Diagnosis procedure ................................................... 179

Indicators and projector condition ............................... 180

Serial Control............................................................. 183

Serial control interface ................................................183

Control Port Functions............................................... 185

IC Block Diagrams..................................................... 188

Parts Location Diagrams........................................... 194

Mechanical Parts List ................................................ 212

Electrical Parts List.................................................... 214

Diagrams & Drawings.................................................. A1

Parts description and reading in schematic diagram ..A2

Schematic Diagrams ...................................................A3

Printed Wiring Board Diagrams................................. A19

Pin description of diode, transistor and IC ................A33

Note on Soldering......................................................A34