-2-

Contents

SERVICE MANUAL ................................................... 1

Contents ........................................................................ 2

Safety Instructions ......................................................... 3

SAFETY PRECAUTIONS ........................................... 3

PRODUCT SAFETY NOTICE .................................... 3

SERVICE PERSONNEL WARNING ........................... 3

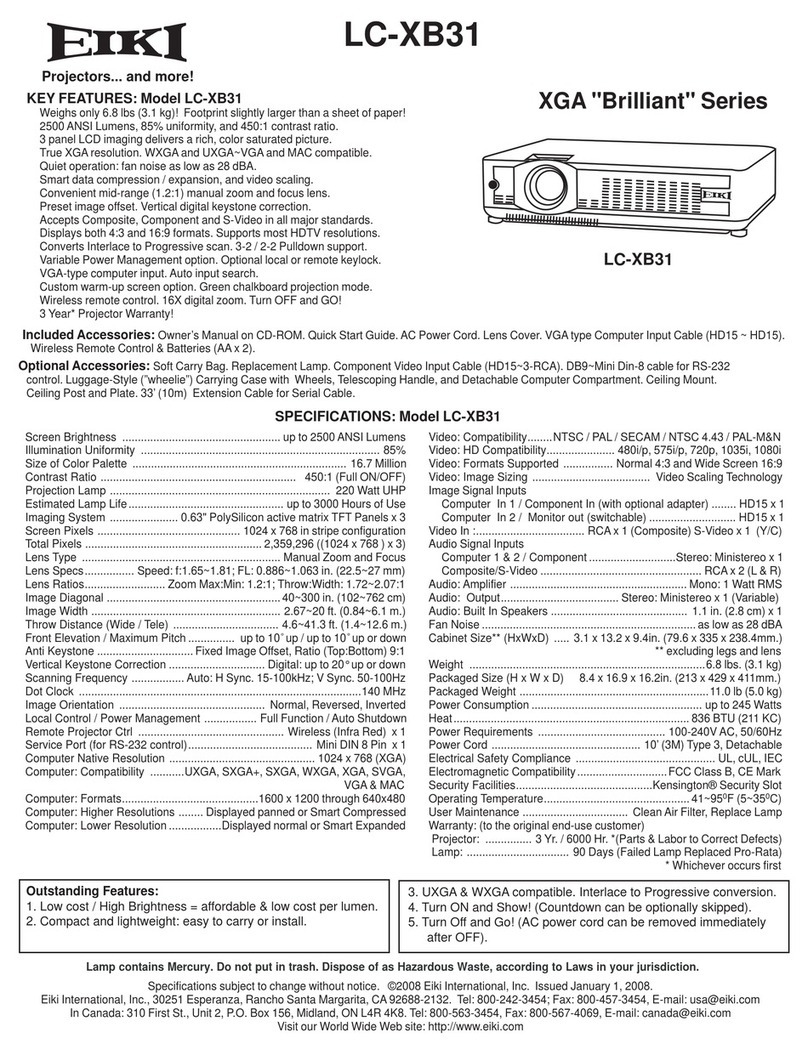

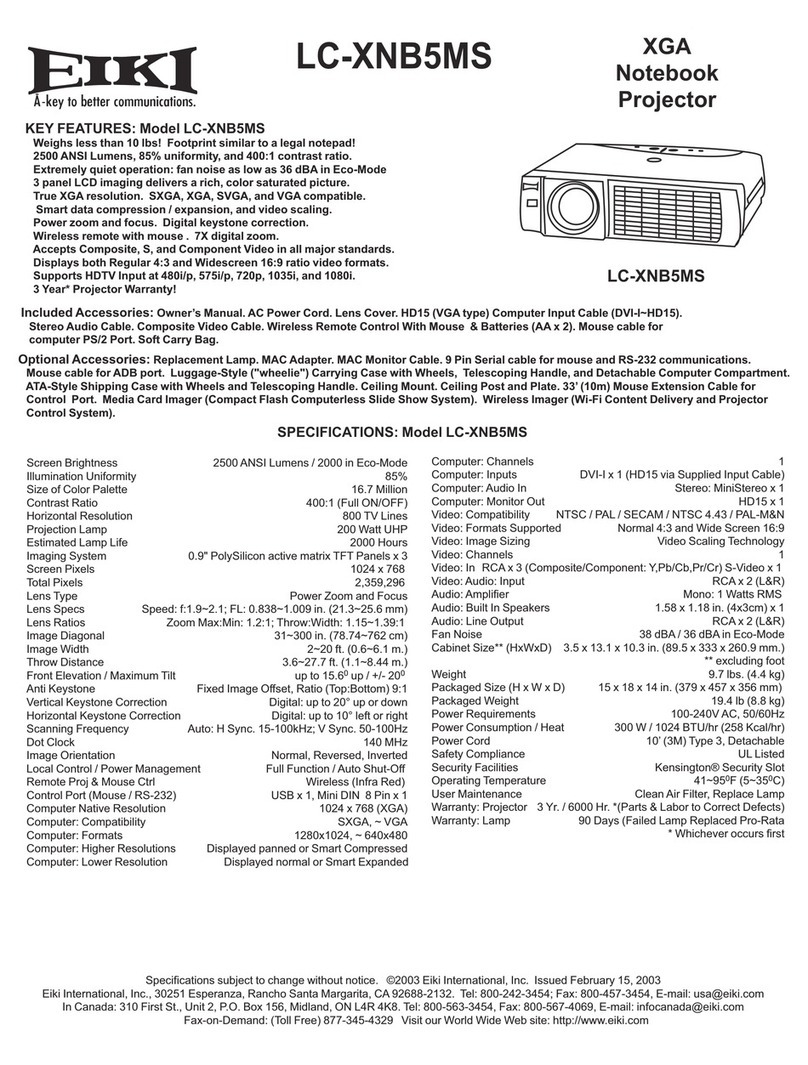

Specifications ................................................................ 4

Circuit Protections ......................................................... 5

Fuse ............................................................................ 5

Thermal switch ........................................................... 5

Interlock switch ........................................................... 5

Warning temperature and power failure protection ..... 6

Air filter care and cleaning .......................................... 6

Lamp Replacement ....................................................... 7

How to reset Lamp Replace Counter ......................... 7

How to check Lamp use time ...................................... 7

Mechanical Disassemblies ............................................ 8

Optical Parts Disassemblies ........................................ 13

LCD Panel/Prism Ass’y Replacement ......................... 18

Adjustments ................................................................. 19

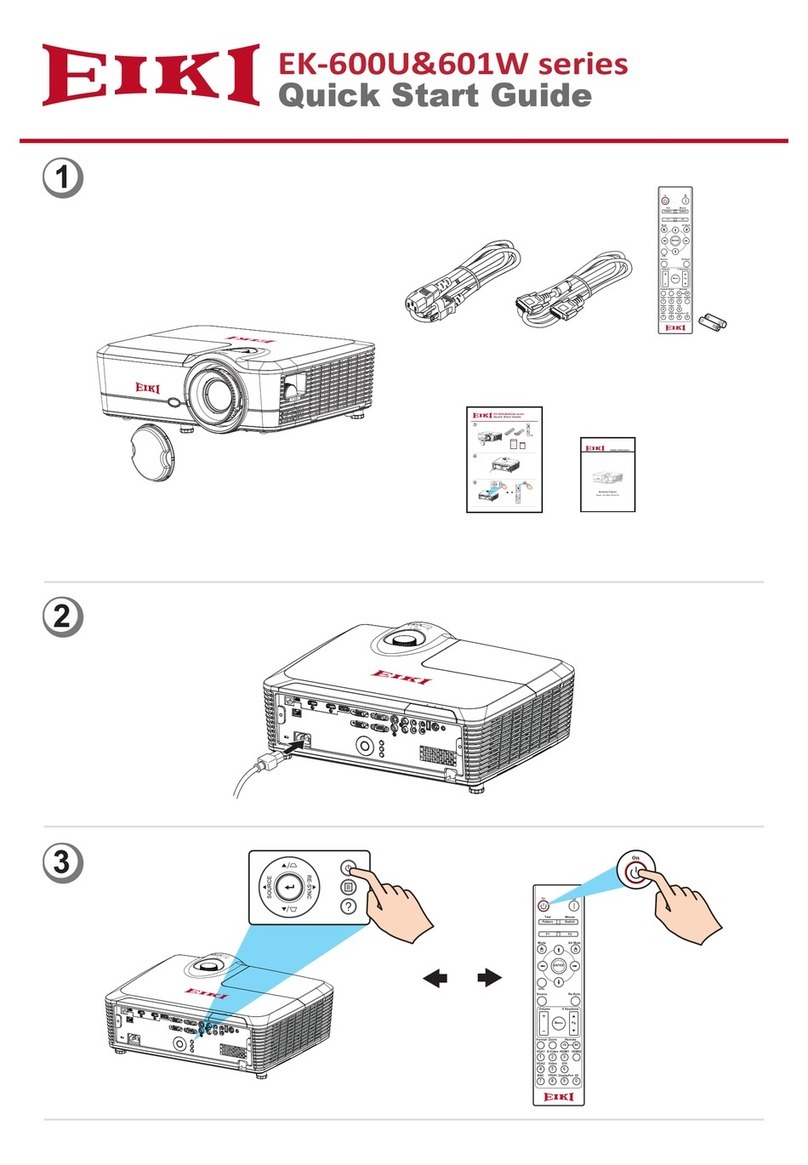

Turning On the Projector ........................................... 19

Adjustments after Parts Replacement ...................... 19

Optical Adjustments ..................................................... 20

Electrical Adjustments ................................................. 23

Service Adjustment Menu Operation ........................ 23

Memory IC Replacement (IC802) ............................. 23

Circuit Adjustments ................................................... 24

Test Points and Locations ......................................... 27

Service Adjustment Data Table ................................. 28

Chassis Description ..................................................... 45

Block Diagrams ......................................................... 45

Chassis over view ..................................................... 45

Input & video precessing stage ................................ 46

LCD panel driving stage ........................................... 47

Audio signal precessing stage .................................. 48

Lamp control stage ................................................... 49

Fan control stage ..................................................... 50

Motor control stage .................................................. 51

Serial bus control stage ........................................... 52

Power supply control & power failure detection ........ 53

LED indicators and projector condition ..................... 54

Power failure detection system ................................ 55

Power failure detection tree ...................................... 56

Error History Log ...................................................... 57

Diagnosis of Power Failure with RS-232C port ......... 58

Diagnosis procedure ................................................. 58

Error information table .............................................. 59

Control Port Functions ................................................. 60

System Control & I/O Port Table ............................... 60

Cleaning ...................................................................... 67

IC Block Diagrams ....................................................... 68

Electrical Parts List ...................................................... 77

Mechanical Parts List ................................................ 108

Cabinet Parts Location ........................................... 108

Optical Parts Location ............................................ 109

Mecanical Parts List ............................................... 113

Diagrams & Drawings ..................................................A1

Parts description and reading in schematic diagram ...A2

Schematic Diagrams ...................................................A3

Printed Wiring Board Diagrams .................................A11

Pin description of diode, transistor and IC .................A17