-2-

Contents

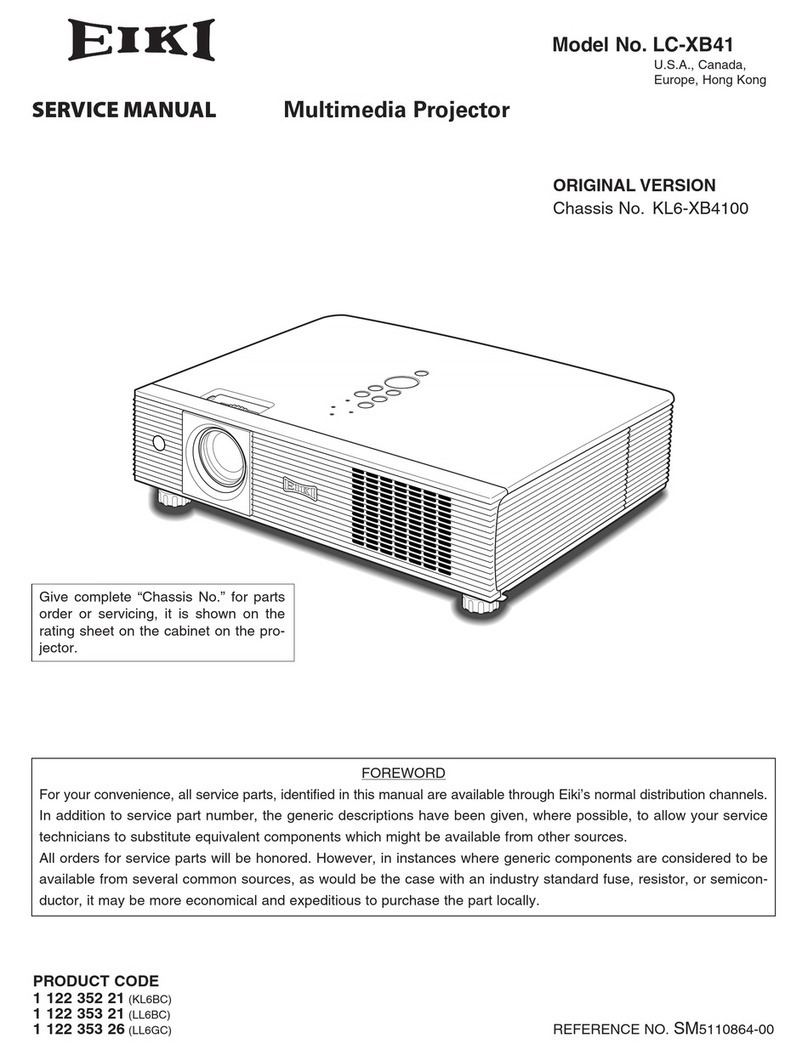

SERVICE MANUAL....................................................... 1

Contents ........................................................................ 2

Safety Instructions ......................................................... 3

Safety Precautions ..................................................... 3

Product Safety Notice................................................. 3

Service Personnel Warning ........................................ 3

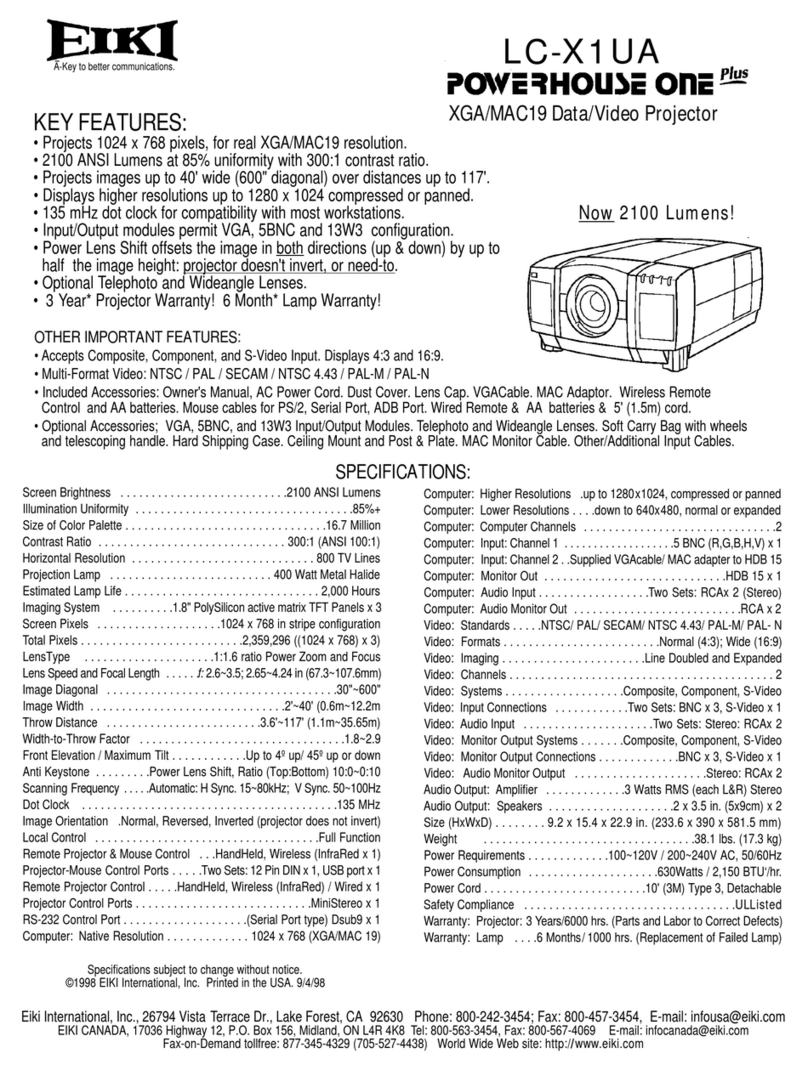

Specifications ................................................................ 4

Circuit Protections ......................................................... 5

Thermal switch ........................................................... 5

Lamp cover switch...................................................... 5

Fuse............................................................................ 5

Warning temperature and power failure protection..... 6

Maintenance.................................................................. 7

Cleaning the Filter ...................................................... 7

Resetting the Filter Counter........................................ 7

Lamp Replacement .................................................... 8

Resetting the Lamp Counter....................................... 9

How to check Lamp Used Time.................................. 9

Cleaning ................................................................... 10

Security Function Notice.............................................. 11

Security Function Disable......................................... 11

Mechanical Disassembly ............................................. 12

Optical Parts Disassembly........................................... 16

Adjustments................................................................. 22

Adjustments after Parts Replacement ...................... 22

Optical Adjustments..................................................... 23

Contrast adjustment ................................................. 23

Integrator lens adjustment ........................................ 24

Relay lens-Out adjustment ....................................... 25

Electrical Adjustments ................................................. 26

Service Adjustment Menu Operation ........................ 26

Memory IC (IC1391) Replacement........................... 26

Circuit Adjustments................................................... 27

Test Points and Locations......................................... 31

Service Adjustment Data Table................................. 32

Chassis Block Diagrams.............................................. 48

Chassis over view..................................................... 48

System control.......................................................... 49

Lamp control............................................................. 50

Audio circuit .............................................................. 51

Power supply & protection circuit ............................. 52

Fan control circuit ..................................................... 53

IIC bus control circuit ................................................ 54

Troubleshooting........................................................... 55

Indicators and Projector Condition ........................... 55

No Power.................................................................. 56

No Picture................................................................. 57

No Sound.................................................................. 58

Control Port Functions................................................. 59

Scaler I/O Port Functions (PW190) .......................... 59

Waveform .................................................................... 60

IC Block Diagrams....................................................... 61

Electrical Parts List...................................................... 68

Electrical Parts Location ........................................... 69

Electrical Parts List ................................................... 70

Mechanical Parts List .................................................. 89

Cabinet Parts Location ............................................. 89

Optical Parts Location .............................................. 90

Mechanical Parts List ............................................... 94

Diagrams & Drawings..................................................A1

Parts description and reading in schematic diagram...A2

Schematic Diagrams ...................................................A3

Printed Wiring Board Diagrams...................................A8

Pin description of diode, transistor and IC.................A12

Note on Soldering......................................................A13