5

CONTENTS

Introduction ...................................................................................................3

The Statement................................................................................................4

1.General Introduction ...............................................................................7

2、Proper use ................................................................................................8

3.Introduce of the product.........................................................................9

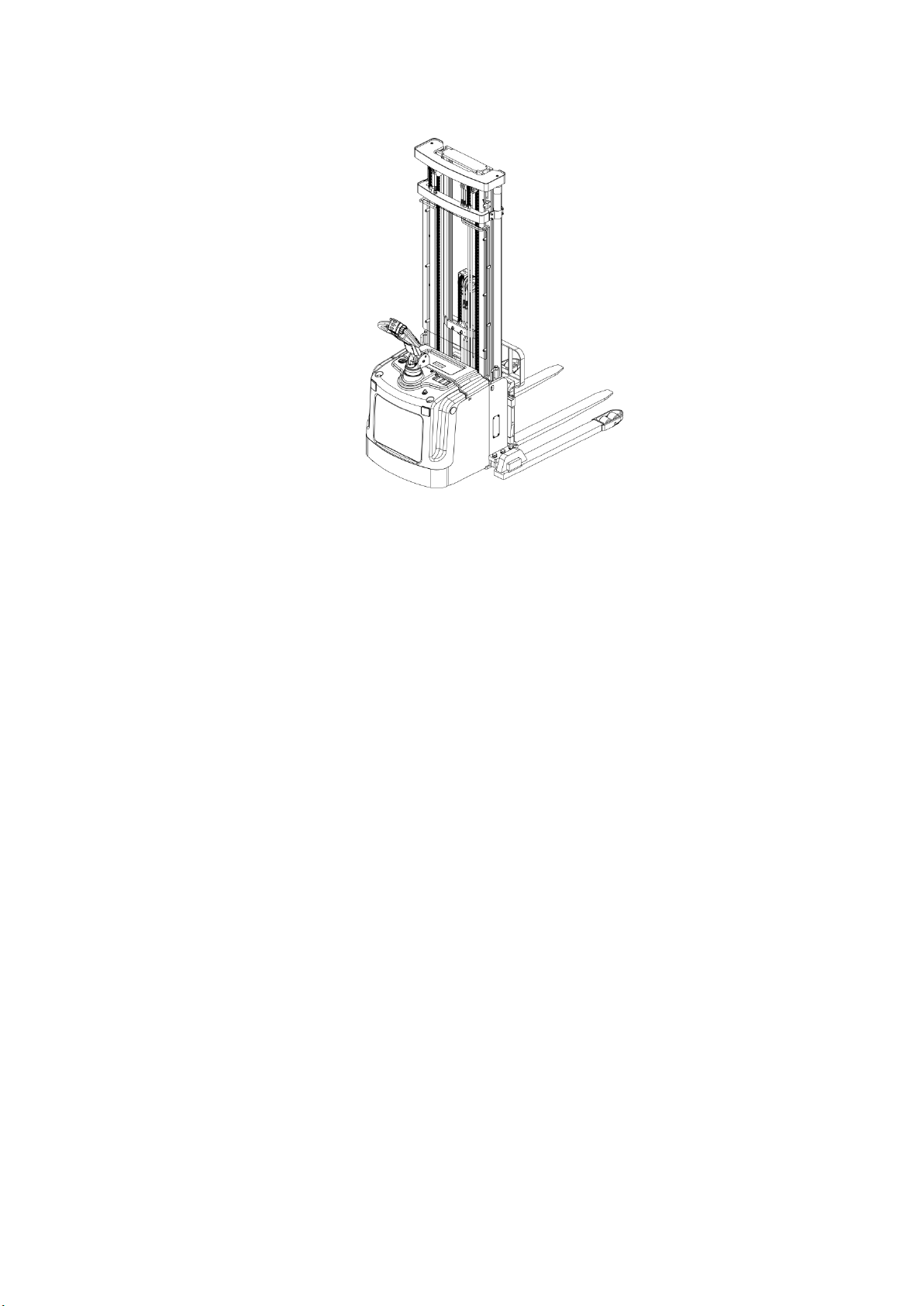

3.1Product overview ............................................................................................................................................9

3.2Model Parameter...........................................................................................................................................10

3.3Safety Operation and warning label description.............................................................................12

3.4Nameplate ......................................................................................................................................................12

4.Safety Caution.......................................................................................... 13

5.Test run,Transportation,Outage ....................................................... 14

5.1Test run .............................................................................................................................................................14

5.2Lifting & Transportation............................................................................................................................14

5.3Outage................................................................................................................................................................14

6.Routine Inspection................................................................................. 15

7. The Schematic diagram of Operating Mechanism...................... 16

8.Operating specification........................................................................ 16

8.1Parking ..............................................................................................................................................................16

8.2Loading capacity Graph..............................................................................................................................17

8.3Lifting up/Lowering down .......................................................................................................................17

8.4Traveling...........................................................................................................................................................18

8.5Steering .............................................................................................................................................................19

8.6Braking..............................................................................................................................................................19

8.7Brake structure &Brake Schematic.......................................................................................................20

8.8Trouble........................................................................................................................................................... 200