MONZUN M2, M3

07/2016 - 9 - NP-M2-M3-5_07-2016

OPERATION

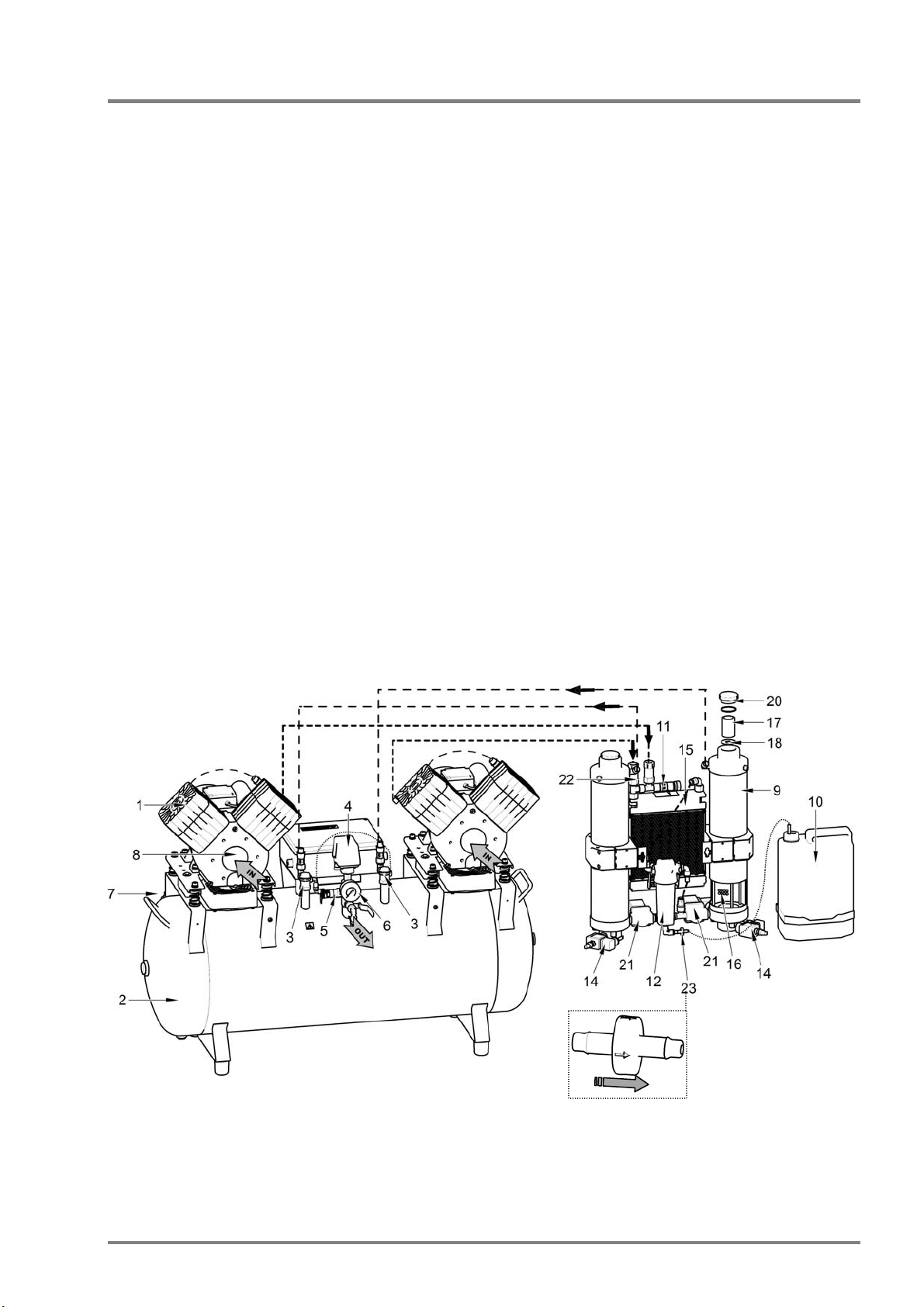

6. PRODUCT OPERATION

Proper dryer operation depends on the compressor activity and does not require any operation. The

pressure vessel does not need to be drained as the compressed air into the air tank is already dried.

The working pressure settings for the pressure switch set by the manufacturer cannot be changed.

Compressor operation at lower working pressures than the switching pressure is evidence that the

compressor is overloaded (high air consumption) caused by an appliance, a failed seal in the air line,

compressor problem or dryer.

Before connecting the dryer to the air tank used on a compressor without a dryer, the internal surface of

the air tank must be properly cleaned and all condensed liquids must be completely removed. The

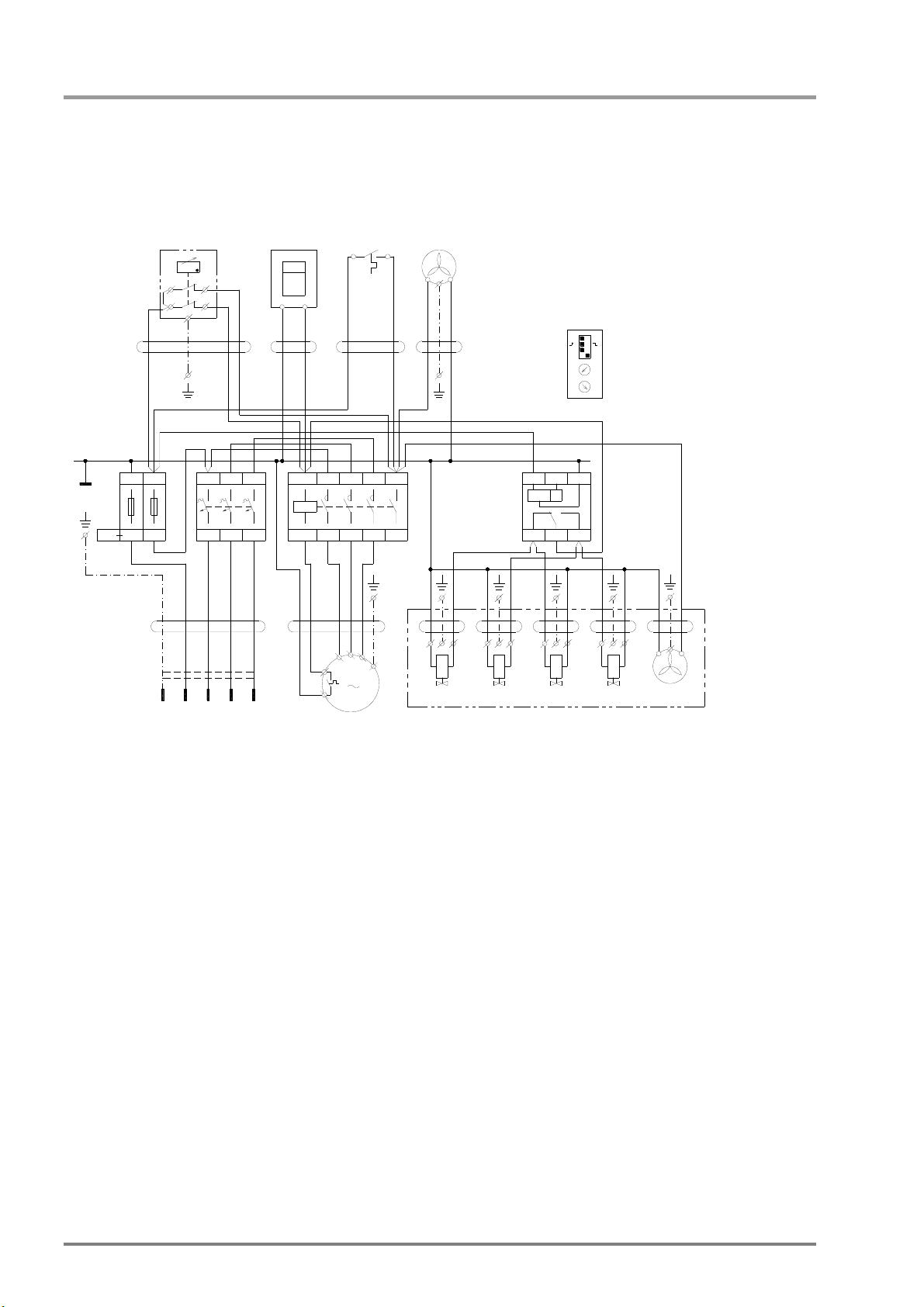

electrical portion of the dryer is then to be connected to the compressor following the electrical schematic

pursuant to valid regulations.

Dimensions of the regeneration jets for a dryer

Compressor Jet size switch on

- off pressure

Quantity of dry air

at atmospheric

pressure:

Quantity of regeneration

air:

DK50 2V/110/M2 Ø 0,4 mm 5 – 7 bar 140 l/min. 10 l/min. / 5 bar

DK50 2x2V/110/M2 Ø 0,85 mm 5 – 7 bar 280 l/min. 45 l/min. / 5 bar

DK50 2V/110/M2 Ø 0,4 mm 6 – 8 bar 140 l/min. 11 l/min. / 6 bar

DK50 2x2V/110/M2 Ø 0,85 mm 6 – 8 bar 280 l/min. 50 l/min. / 6 bar

DK50 2V/110/M2 Ø 0,4 mm 8 – 10 bar 140 l/min. 15 l/min. / 8 bar

DK50 2x2V/110/M2 Ø 0,6 mm 8 – 10 bar 280 l/min. 35 l/min. / 8 bar

DK50 2V/50/M3 Ø 0,6 mm 5 - 8 bar 140 l/min. 25 l/min./ 5bar

DK50 2V/50/M3 Ø 0,6 mm 5 - 7 bar 140 l/min. 25 l/min./ 5bar

DK50 2V/50/M3 Ø 0,6 mm 6 - 8 bar 140 l/min. 30 l/min./ 6bar

DK50 2V/50/M3 Ø 0,4 mm 8 - 10 bar 140 l/min. 14 l/min. / 8 bar

DK50 2V/M3 Ø 0,6 mm 5 - 7 bar 140 l/min. 25 l/min./ 5bar

DK50 2V/M3 Ø 0,6 mm 6 - 8 bar 140 l/min. 30 l/min./ 6bar

DK50 4VR/50/M2 Ø 0,85 mm 5 - 8 bar 280 l/min. 50 l/min./ 5bar

MAINTENANCE

7. MAINTENANCE SCHEDULE

Maintenance that must be performed Chapter Time interval Performed by

• Replacement of filter in dryer 8.1 1 x year qualified technician

• Replacement of refill in dryer NI 1 x every 4 years qualified technician

• Replacement of the buoy in the

water separator 8.2 1 x year qualified technician

8. MAINTENANCE

Before proceeding, depressurize the air tank to zero and disconnect the appliance from

the electrical mains!

The equipment has been constructed and produced to keep maintenance to a minimum.

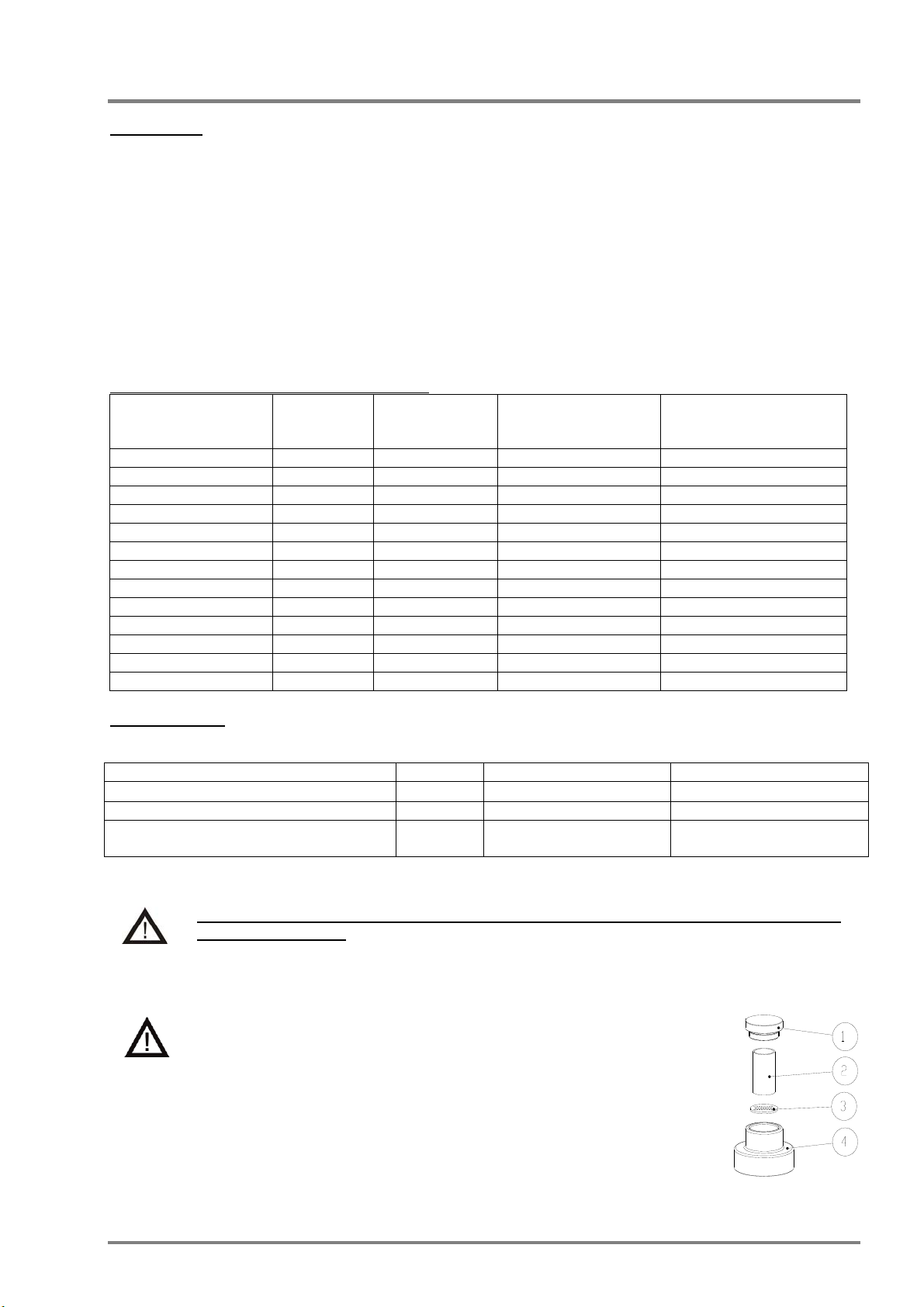

8.1. Replacement of filter in drier

Before proceeding, depressurize the air tank to zero and

disconnect the appliance from the electrical mains.

The dryer filter in the upper section must be replaced during regular dryer

operation or when eliminating a fault caused by contamination.

Remove the dryer plug (1) by unscrewing to the left from the dryer head (4).

Replace the filter (2) and the clean the screen (3).

After removing the screen, check and replace the desiccant in the dryer.

Annex 1 / Technical Instruction – Replacing dryer desiccant/

Refit the dryer plug to the dryer head (4) and tighten it to the right.