EKSMA OPTICS DPB-10-4.2 User manual

HIGH VOLTAGE

DRIVERS

DPB-10-4.2

DPB-10-4.2-Al

DPB-5-5.5

DPB-5-5.5-Al

Technical Description

Rev. 2201

2022

Lithuania

i

www.eksmaoptics.com

CONTENTS

CHAPTER 1 WARRANTY ..................................................................................................................... 1

1.1. WARRANTY STATEMENT ....................................................................................................................... 1

1.2. SERVICE CONTACT INFORMATION ............................................................................................................ 1

CHAPTER 2 SPECIFICATIONS............................................................................................................... 2

2.1. GENERAL INFORMATION ....................................................................................................................... 2

2.1.1. Models .................................................................................................................................... 2

2.1.2. Main Components ................................................................................................................... 2

2.2. TECHNICAL SPECIFICATIONS ................................................................................................................... 3

CHAPTER 3 DEVICE LAYOUT ............................................................................................................... 4

CHAPTER 4 SAFETY ............................................................................................................................ 7

CHAPTER 5 IMPORTANT NOTES ......................................................................................................... 8

CHAPTER 6 QUICK START GUIDE ...................................................................................................... 10

6.1. SET JUMPER #5 TO REQUIRED OPERATION MODE ....................................................................................... 10

6.2. CONNECT WIRES TO THE POCKELS CELL ................................................................................................... 10

6.3. GROUND THE POCKELS CELL DRIVER TOGETHER WITH THE GENERATOR AND HV SUPPLY ...................................... 10

6.4. SUPPLY VOLTAGE TO THE DRIVER FROM THE DC POWER SUPPLY .................................................................... 11

6.5. SUPPLY VOLTAGE FROM THE HV SUPPLY.................................................................................................. 11

6.6. PROVIDE SYNCHRONIZATION PULSES FROM THE GENERATOR......................................................................... 11

ii

www.eksmaoptics.com

LIST OF FIGURES

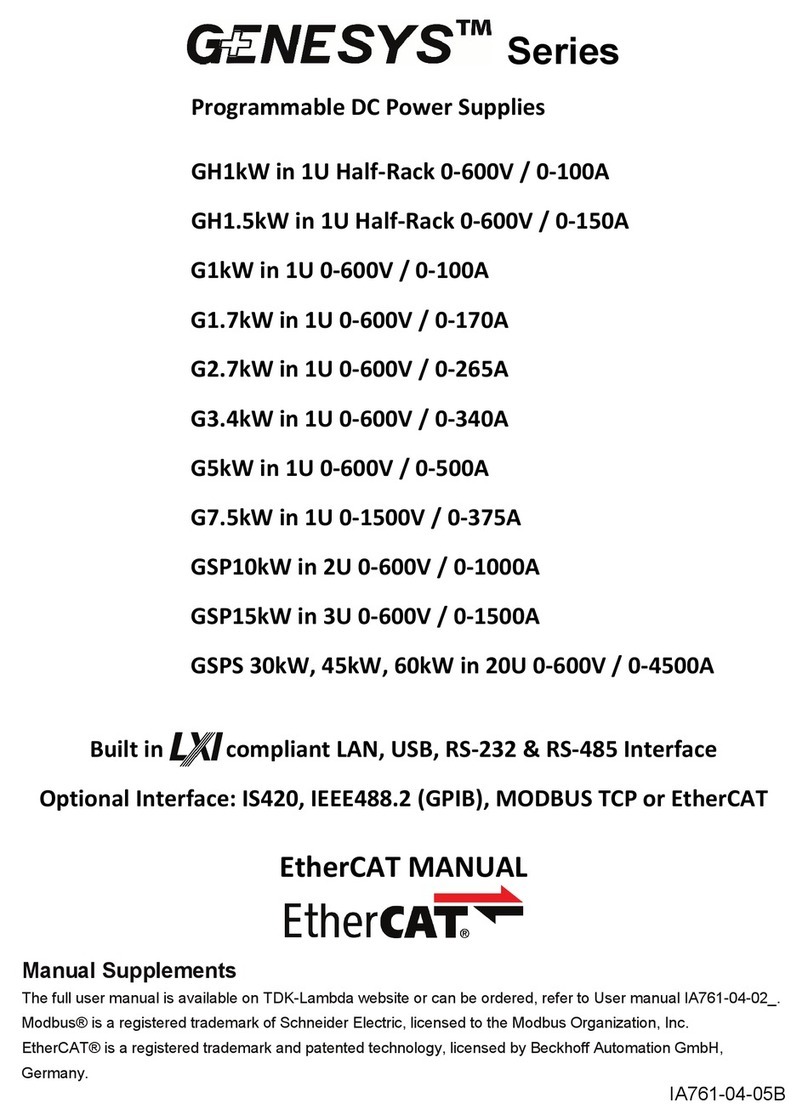

FIGURE 1. OUTLINE DRAWING AND DIMENSIONS OF THE DRIVER WITHOUT HV SUPPLY .................................................... 4

FIGURE 2. OUTLINE DRAWING AND DIMENSIONS OF THE DRIVER WITH HV SUPPLY WITHOUT CASE ..................................... 4

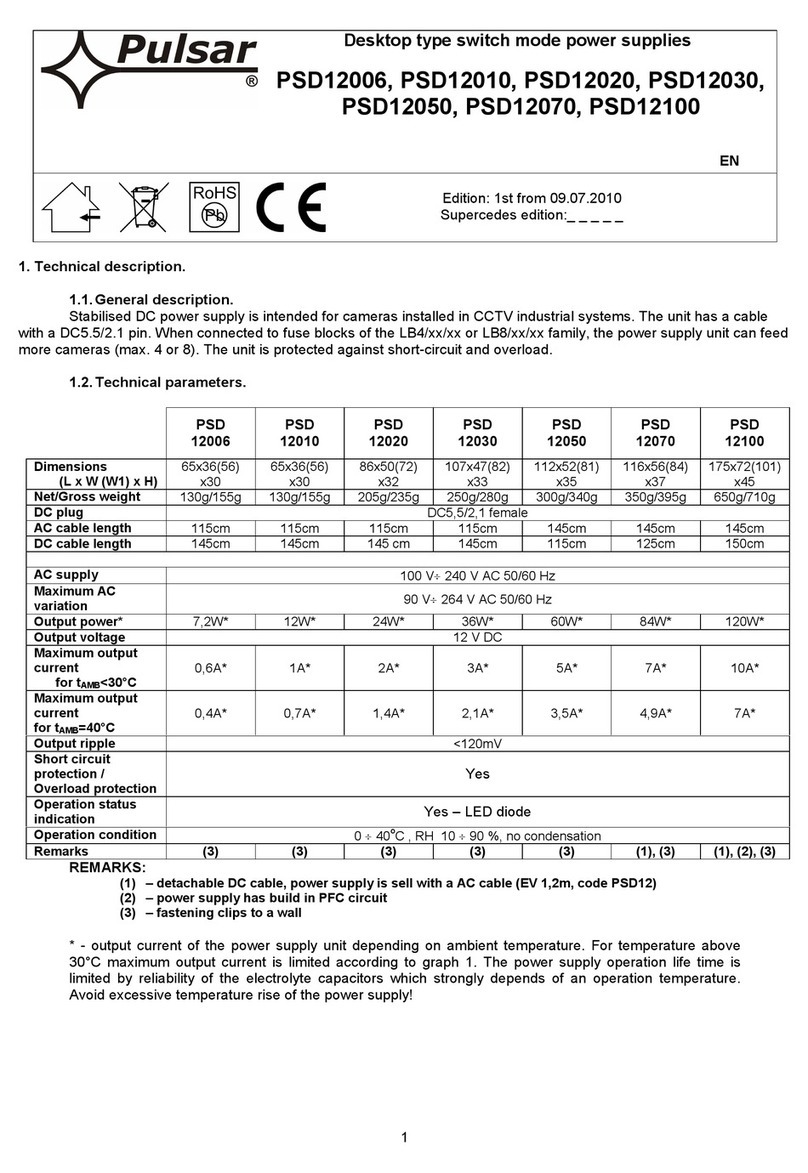

FIGURE 3. OUTLINE DRAWING AND DIMENSIONS OF THE DRIVER WITH CASE AND HV SUPPLY (-AL) .................................... 5

FIGURE 4. VIEW OF THE ENCASED DRIVER WITH HV SUPPLY (-AI) .............................................................................. 5

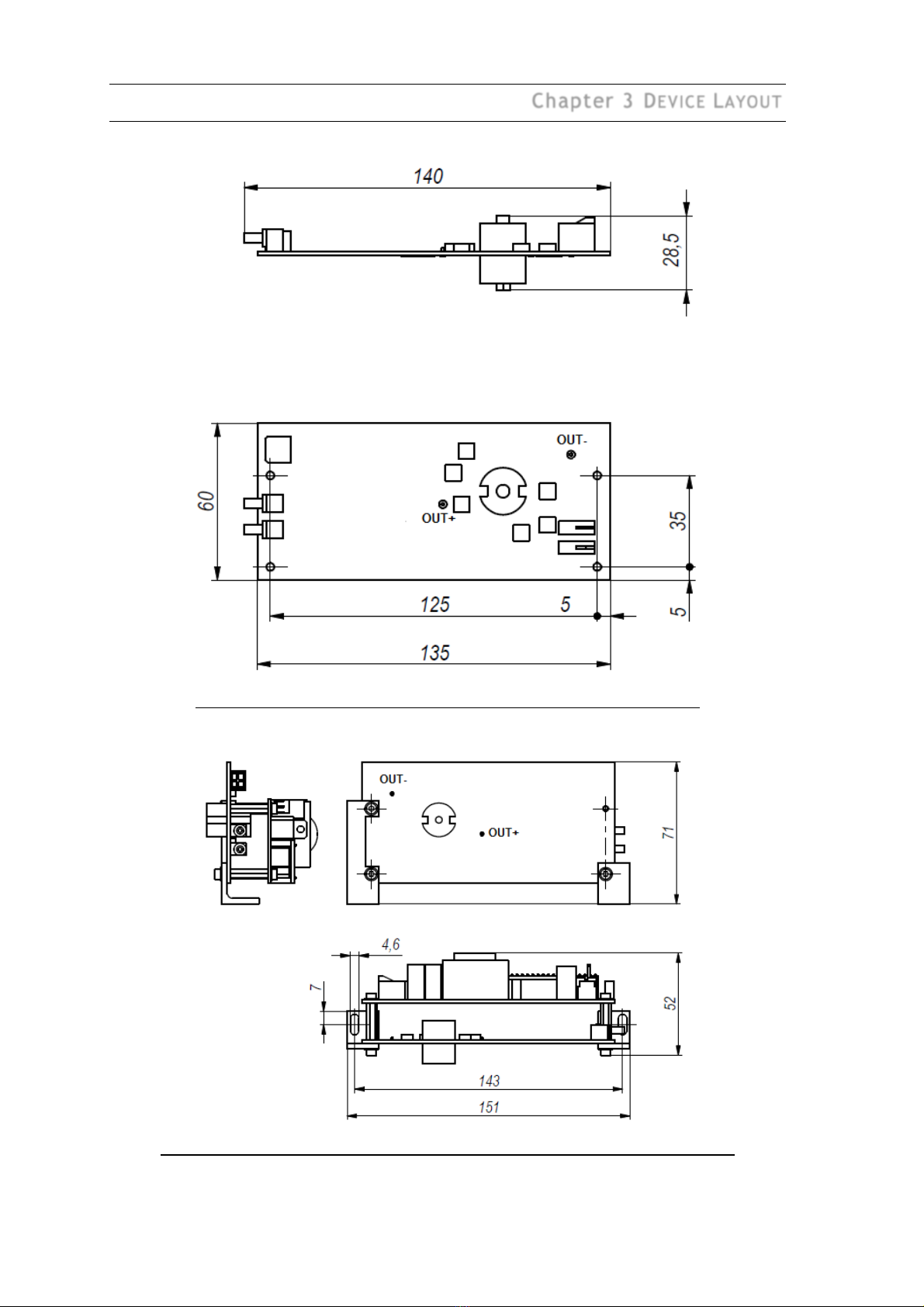

FIGURE 5. VIEW OF THE DRIVER WITHOUT CASE..................................................................................................... 6

FIGURE 6. DRIVER OPERATION CHART ................................................................................................................. 8

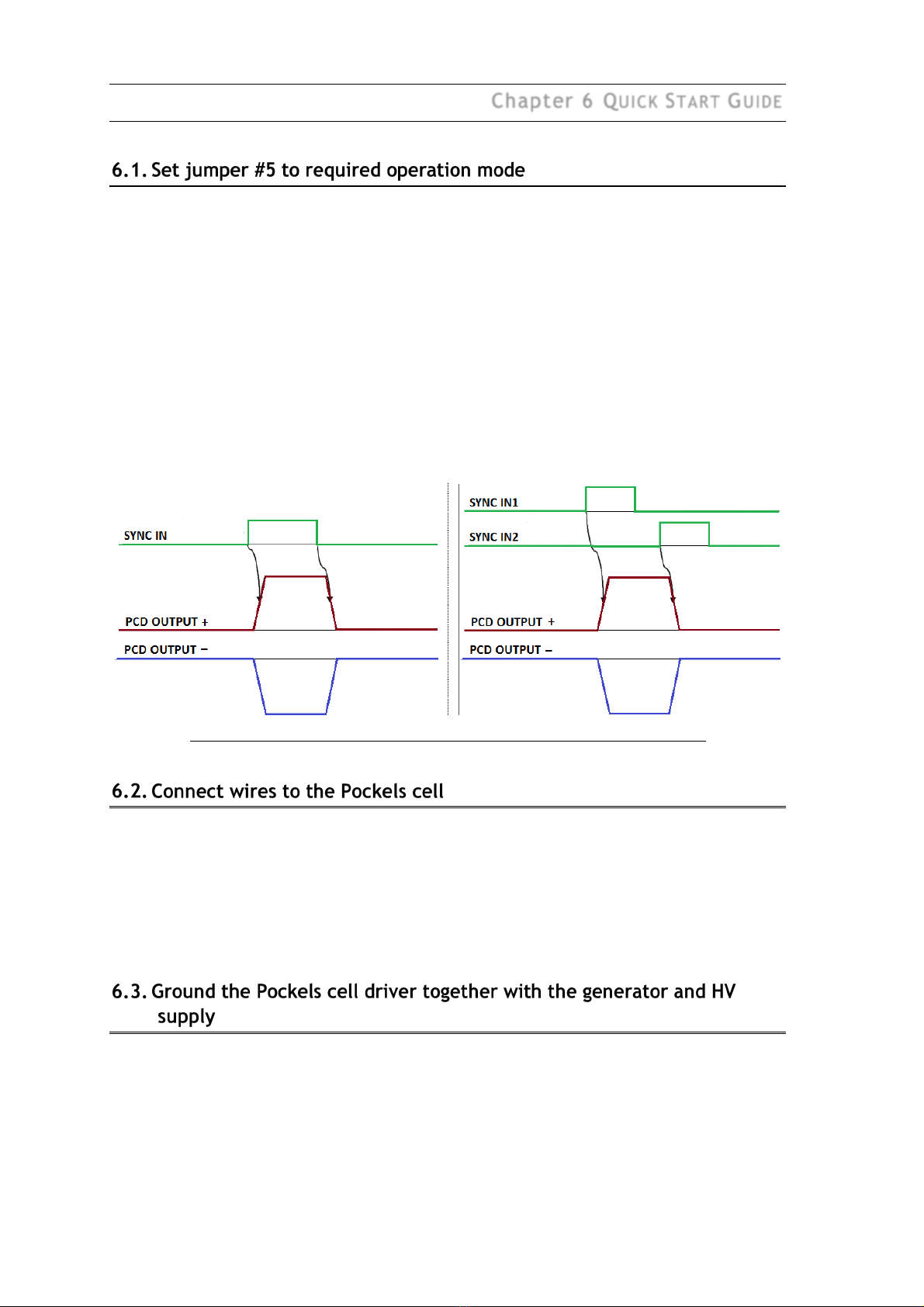

FIGURE 7. CONTROL TIMING FOR 1-INPUT (LEFT) AND 2-INPUT (RIGHT) CONTROLLED DRIVER ......................................... 10

FIGURE 8. INPUT CIRCUIT OF DRIVER................................................................................................................. 12

LIST OF TABLES

TABLE 1. MODELS ......................................................................................................................................... 2

TABLE 2. MAIN COMPONENTS .......................................................................................................................... 2

TABLE 3. TECHNICAL SPECIFICATIONS.................................................................................................................. 3

TABLE 4. PORTS SEEN IN TOP VIEW OF THE DRIVER ................................................................................................. 6

1

www.eksmaoptics.com

Chapter 1

WARRANTY

The Pockels cell drivers are protected by a one-year warranty covering labor and parts. The

warranty enters into validity since the shipment date. Any evidence of improper use or

unauthorized repair attempts voids the warranty.

For service/warranty requests, please contact:

EKSMA OPTICS, UAB

c/o EKSMA Optics, UAB

Dvarcioniu st. 2B

LT-10233 Vilnius, Lithuania

Phone:

Fax.:

E-mail:

Website:

+370 5 272 99 00

+370 5 272 92 99

info@eksmaoptics.com

www.eksmaoptics.com

2

www.eksmaoptics.com

Chapter 2

SPECIFICATIONS

Table 1. Models

Model

Description

DPB-10-4.2

10kHz repetition rate, 4.2kV output, open PCB

DPB-10-4.2-Al

10kHz repetition rate, 4.2kV output, with case and HV supply

DPB-5-5.5

5kHz repetition rate, 5.5kV output, open PCB

DPB-5-5.5-Al

5kHz repetition rate, 5.5kV output, with case and HV supply

Table 2. Main components

Component

Quantity

Notes

High voltage (HV) driver DPB-*-*-*

1

-

DC power cable (l=1.5m)

1

-

BNC-SMB cables (l=1.5m)

2

-

HV power supply cable (l=1m)

1

Not supplied if DPB-*-*-* driver and HV

power supply are ordered and screwed

together.

Pair of cables for HV output to the

Pockels cell (<10 cm)

1

-

Technical description

1

-

3

www.eksmaoptics.com

Table 3. Technical specifications

Parameter

Value(s)

DPB-10-4.2(-Al)

DPB-5-5.5(-Al)

Maximum output pulse amplitude (HV), kV

4.2

at 2.2 kV HV supply

5.5

at 2.8 kV HV supply

Minimum output pulse amplitude (HV), kV1

±1.4

Maximum HV consumption (DPB load = 6 pF),

W

5

Polarity output

Bipolar

External triggering input

1 or 2 pulses

Maximum capacity load at maximal repetition

rate and HV supply voltage, pF2

12

6 for – AI models

HV pulse rise/fall time, ns (HV load=6pF)

<6/6

<7/7

HV pulse duration, ns

30…3000

Maximum HV repetition rate, kHz

10

5

HV pulse delay, ns

~30

External triggering pulse amplitude @50W load,

V

2…6

External triggering pulse rise time, ns

<10

External triggering pulse duration for 2-input

control mode, ns

>20

External triggering pulse delay between IN1

and IN2 for 2 input control mode or IN1 pulse

duration in 1- input control mode , ns

30…3000

Low voltage DC requirements

15…25 V, 150 mA

or

12 V, 200 mA

DC Connectors

Molex Micro-Fit 3.0

Dimensions, mm

See figure(s) in CHAPTER 3 DEVICE LAYOUT

140×60×29 (without HV supply)

151×71×52 (with HV supply)

192×81×75 (-Al)

Weight, g

70 (without HV supply)

200 (with HV supply)

480 (-Al)

1

Minimal voltage limit can be switched off, see CHAPTER 5 Specifications .

2

Voltage or repetition rate derating is necessary if capacitance of your Pockels cell is higher. Contact

Eksma Optics for suggestions.

4

www.eksmaoptics.com

Chapter 3

DEVICE LAYOUT

Figure 1. Outline drawing and dimensions of the driver without HV supply

Figure 2. Outline drawing and dimensions of the driver with HV supply without case

5

www.eksmaoptics.com

Figure 3. Outline drawing and dimensions of the driver with case and HV supply (-Al)

Figure 4. View of the encased driver with HV supply (-AI)

6

www.eksmaoptics.com

Figure 5. View of the driver without case

Table 4. Ports seen in top view of the driver

#

Port

1

Connector Molex 4 (Microfit series) - interface for +DC (24 VDC) supply (“A” is +DC; “B” is

GND)

2.1

X1(SYNC IN1) for HV opening, or SYNC IN in 1-input control mode

2.2

X2 (SYNC IN2) for HV closing

3.1

Connector for GND input from HV supply

3.2

Connector for +HV input from HV supply

4.1

HV pulse output pin +OUT

4.2

HV pulse output pin -OUT

5

Jumper to toggle SYNC IN mode between one-and-two pulses control

6

Jumper for commutation of DC voltage mode (with jumper- +12V; without jumper- +15…25V)

7

Protection jumper

8

HV power supply tuning port (only for –Al drivers)

9

Grounding screw (only for –Al drivers)

7

www.eksmaoptics.com

Chapter 4

SAFETY

Equipment is designed to be safe under normal environmental conditions according to 1.4.1.

61010-1@IEC:2010 (Safety requirements for electrical equipment, control and laboratory use):

1. indoor use;

2. altitude up to 2000 m;

3. temperature 5ºC to 35˚C;

4. maximum relative humidity 80% for temperatures up to 31ºC decreasing linearly to 50%

relative humidity at 35ºC;

5. POLLUTION degree 1: no POLLUTION or only dry, non-conductive POLLUTTION occurs.

Warning:

The safety of the system incorporating driver and HV power supply is the

responsibility of the assembler of the system.

Operating the driver is allowed to persons acquainted with the operation manual and having

permission to deal with voltages over 1000 V.

Do not remove unit covers while power cable is connected to the mains (if applicable).

Do not touch any parts of the system when high voltage is applied, as it may cause injury or

death.

Do not operate the unit until it is grounded and the load is connected.

Do not use the unit if any defects have been detected.

8

www.eksmaoptics.com

Chapter 5

IMPORTANT NOTES

Please read these important notes before using the product!

1. Different voltages may be supplied to the driver depending on the jumper #6 in Figure 5:

• Without jumper: +15…25V

• With jumper: +12V±0.5V

2. External triggering pulses to inputs X1 (SYNC IN1) and X2 (SYNC IN2) may be applied only

if high voltage and DC power are provided and turned on. When turning off the driver, first

turn off synchronization pulses, then turn off the power. Otherwise the driver may be

damaged.

Incorrect driver operation.

SYNC IN pulses appears before HV and

24V; SYNC IN pulses continues after 24V is

switched off; HV supply gives an overshot.

Correct driver operation

Figure 6. Driver operation chart

The DPB driver has protection against damage due above wrong SYNC IN timing. However,

this protection blocks output if HV supply is set below 0.5Umax. If you still need to operate

below this limit, the protection can be switched off by shortening pins of jumper #7 Figure

5). This case HV supply voltage and following amplitude of output pulses can be reduced

down to 0 V. You should be absolutely sure that correct operation conditions as per Figure

6 are fulfilled.

3. The output pulse is provided between OUT+ and OUT- connectors. Do not connect an

oscilloscope or any other device to the OUT connector. The wire contact with the Pockels

cell must be proper in order to avoid a discharge, which may damage the driver. Do not

connect the driver without a capacitive load (4…10 pF) as this may damage the driver.

4. The pulse shape (including fronts) can be measured indirectly. On your oscilloscope, select

1 V sensitivity and the 1 MW input. Use isolated 1:10 oscilloscope probe for measurement.

Move the probe slowly and carefully toward the hot output wire. When the probe is ~10 mm

away from the hot output wire, the pulse shape should appear in the oscilloscope

(amplitude should be several volts). Do not place the probe too close to the hot output wire

– a discharge may start and damage the driver. This measurement method is not suitable for

measuring >500 ns pulses.

9

www.eksmaoptics.com

5. Do not attempt to measure the parameters of any parts of the driver’s electronics using

an oscilloscope, especially when the driver is running in pulsed mode. Attempts to measure

parameters of certain parts of the driver’s circuitry may lead to damage.

10

www.eksmaoptics.com

Chapter 6

QUICK START GUIDE

This step describes the commutation jumper marked “#5”in Figure 5 / Table 4

The DPB series driver may be controlled by one or two SYNC IN signals (see Figure 7), depending

on the jumper position:

• Jumper position 1: 1-input control mode

SYNC IN1 rising edge turns HV to Pockels cell on, falling edge turns the voltage off.

• Jumper position 2: 2-input control mode

SYNC IN1 rising edge turns voltage on, SYNC IN2 rising edge turns the voltage off.

Either of the two jumper positions must be selected when operating the driver. Do not leave the

driver with no position set on the jumper.

Cables from generator must be of equal length for control by two synchronization pulses.

Figure 7. Control timing for 1-input (left) and 2-input (right) controlled driver

The wires leading from outputs OUT1 and OUT2 to the Pockels cell must be about 0.24 mm2 CSA.

Both the wires must be as short as possible and equal length. The length of each wire must be

not exceeding 100 mm. They should be located at least 5 mm away from any conductive

material (including the operator’s fingers and instruments) – this is done to avoid any additional

capacitive load. Otherwise, driver characteristics may degrade and/or the driver may get

damaged.

The driver output of several kilovolts (kV) with very fast edges is a powerful source of

electromagnetic interference (EMI). Please ensure proper wiring and grounding to avoid

problems caused by interference.

The best solution to minimize EMI is to mount the driver and the HV power supply on the metal

body of the laser. The driver base plate must have very good contact with the ground wire of the

HV power supply, such as the four mounting holes on the edges of the board. This is enough in

11

www.eksmaoptics.com

most cases, provided the driver is firmly attached to the metal laser body and the HV power

supply is attached to the same body via all available mounting holes.

If the EMI level is still very high, attempt mounting ferrites on all power and control wires

leading to the driver and power supply (except wires to the Pockels cell).

Please note that the aluminum case of the driver is not designed to provide effective EMI

shielding. Essentially, correct wiring provides best results.

For a safe start of the driver, the DC power supply must provide at least 0.6 A peak current when

turning on. Although most DC power supplies are capable of providing this, it is recommended

to double-check your supply as an insufficient peak current may damage the driver.

Set output voltage from HV supply.

If the HV power supply is manufactured by a third party, before supplying voltage, ensure there

is no overvoltage while turning it on.

If driver is fixed together with HV power supply, connect CAN cable to HV tuning port #8 in

Figure 4 or set HV voltage by potentiometer.

It is necessary to measure the generator output voltage with a 50W load before applying

synchronization signals to the DPB driver. The signal voltage must be at 2…6 V level. Make sure

that the duration of SYNC IN1 pulse is longer than 30 ns in single-pulse driving, or delay between

SYNC IN1 and SYNC IN2 is greater than 30 ns in two-pulse driving. A shorter duration or delay of

the synchronization pulses may damage the driver.

After the generator output voltage is measured, remove the 50W load and provide

synchronization pulses to the driver.

Note that the output pulse duration and delay depend of the control pulse signal level and HV

pulse rise/fall time (edges of HV pulse); the duration may vary in the order of several

nanoseconds (in positive and negative directions). It is not recommended to use control signals

with edges longer than 10 ns. Figure 8 presents the input circuit. Below 30 ns, driver output

voltage starts decreasing. Output pulses shorter than 30 ns can damage the driver.

Note:

After +DC voltage is applied, the first synchronization pulse is skipped.

12

www.eksmaoptics.com

Figure 8. Input circuit of driver

This manual suits for next models

3

Table of contents

Other EKSMA OPTICS Power Supply manuals

EKSMA OPTICS

EKSMA OPTICS HV-200 User manual

EKSMA OPTICS

EKSMA OPTICS HV-170-1.8 User manual

EKSMA OPTICS

EKSMA OPTICS HVS-100 Parts list manual

EKSMA OPTICS

EKSMA OPTICS PS-170 User manual

EKSMA OPTICS

EKSMA OPTICS PS-80 User manual

EKSMA OPTICS

EKSMA OPTICS PS-40 Parts list manual

EKSMA OPTICS

EKSMA OPTICS PS-120 User manual