Elastocon Cell Ageing Oven EB 36 User manual

Manual

Cell Ageing Oven EB 36

© 2021, Elastocon AB, SWEDEN

Contents

1. Setting up the Cell Ageing Oven p. 2

2. Running the Cell Ageing Oven p. 2

3. Programming of cycling temperatures p. 9

4. Temperature calibration p. 17

5. Service and maintenance p. 17

6. Troubleshooting p. 17

7. Safety p. 17

8. Technicalspecication p. 18

Technical documentation supplied

on USB flash drive

ma-eb36_01_2110

Elastocon AB •Tvinnargatan 25 •SE-507 30 Brämhult •Sweden

2

Elastocon Manual – Cell Ageing Oven EB 36

1. Setting up the Cell Ageing Oven

Place the ageing oven on a stable and horizontal bench.

Connect the oven to a grounded mains outlet, according to the type label on

the oven. We recommend the use of an Earth Leakage Detector.

The oven should be connected to a compressed air supply of 5 to 7 bar for the

air exchange. The connector on the oven is found on the back of the oven.

Connect it with a 6 mm hose for compressed air with a push in connector.

Astandardparticlelterandwatertrapshouldbeinstalledbeforetheoven

connection.Thisltershouldbeinspectedregularlyanddrainedforwater.

Therearetwoparticleltersonthebackoftheoven,onenelterwitha

pressurecontrollersetat1bar,andonesub-microlterwithwatertraps.

Theseltersshouldbeinspectedannually.

2. Running the Cell Ageing Oven

2.1 Starting

Switch on the power (red switch).

Reset the power failure and alarm, see 2.2.3 and 2.2.5.

Set the temperature and test time on the PLC, see 2.2.1.

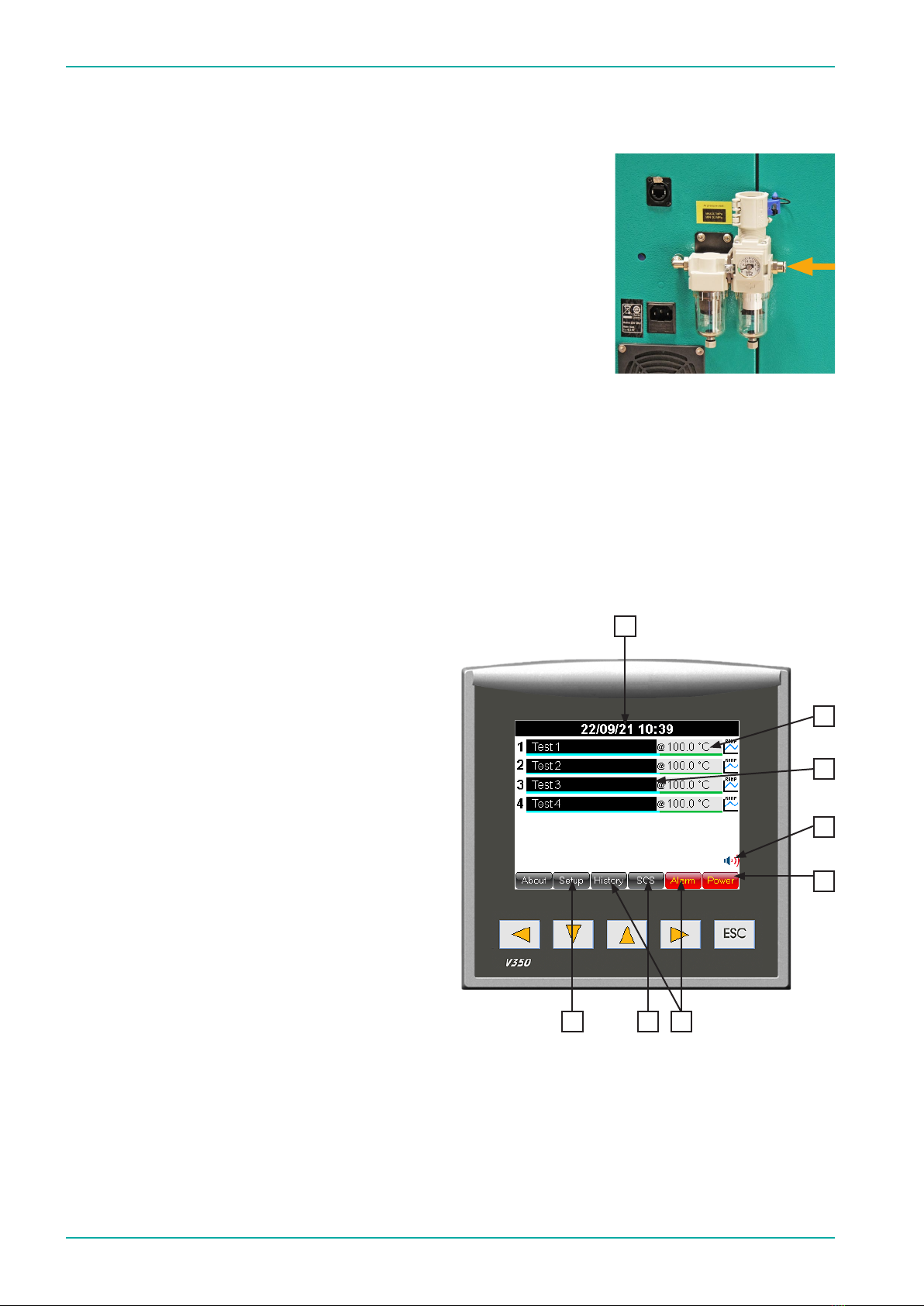

2.2 Settings

Explanation

1. Date & time

2. Temperature set for this cell

3. Test name

4. Alarm Buzzer on or off

5. Power Failure

6. Alarm and History – tap this symbol

and the alarm history will be visible

on the PLC screen

7. SCS – multiple cells will be shown as slides

shifting in a sequence with enlarged displays

8. Set up for

•date&time

•communicationwithsoftware

•calibrationoffset

The oven has a touch controlled screen. A touch pen will be included.

Note: Do not use sharp objects to touch the screen.

This can cause damage on the screen.

8

4

3

2

5

1

67

Figure 1 – The arrow marks the

connection for compressed air

supply, which is found on the back

of the oven.

3

Elastocon Manual – Cell Ageing Oven EB 36

2.2.1 Temperature and test time setting

Tap on the temperature actual value to set the test

temperature,seegure2.2.1.a.

On the next screen tap on the set value box on the rigth side

of the SetTtext,seegure2.2.1.b.

Anumerickeyboardwillshow(seegure2.2.1.c).Typein

thesettemperaturewiththenumerickeyboardandnish

with a tap on the return button.

Whilestillonthisscreen(seegure2.2.1.d),thetesttime

can also be set in hours and minutes and the test time

started to count down.

Hoursandminutesareseparatedintwodierentboxes.

Tollinthehourstapintheboxontherightsideofthetext

Test time [xxxx h].

A numeric keyboard will show. Type in the time in hours

followed by a tap on the return button.

To set the test time minutes repeat the same proceedure but

instead of a tap on the xxxxh box, tap on the xxxxm box

To start the test time count down at this point, tap on the

hour glass symbol.

The time will now start countdown. This time can

only be changed when the hour glass symbol to the

right is stopped. To stop the test time count down,

tap and hold the hour glass symbol pressed for >3 seconds.

A stopped test time count down will indicate with a red

stretch over the hour glass symbol.

When the test time is stopped the test time in hours and

minutes can now be changed.

The count down time can be stopped and started at any time.

The test time will return to the last time entered every time

the test time is stopped.

Figure 2.2.1.a – Temperature setting.

Figure 2.2.1.b – Temperature setting.

Figure 2.2.1.c – Temperature setting.

Figure 2.2.1.d – Test time.

4

Elastocon Manual – Cell Ageing Oven EB 36

2.2.2 Test name

Fromthemainscreen,taponthenameeldthat

correspondstotheovencellchannel(seegure2.2.2.a).

Type the test name from the touch screen keyboard (see

gure2.2.2.b). One test name row on the screen can hold up

to 40 characters.

1. Use the white arrow buttons on the upper left corner to

swapbetweendierentkeyboardcharacterlayouts.

2. Tap on the Enterbuttontonalizethetestnameinput.

3. To re-enter any character on the same test name row,

it is possible to correct any character in the test name with

a tap on any of the white left or right arrow buttons in the

lower left and right corner on the screen.

4. To cancel any input changes, tap on the ESC button and

return to the previous screen.

2.2.3 Power failure

Power failure during a test

If the test time is running when a power failure occurs, the

oven temperature and test time counters will continue from

the time when the power failure occurred, when the power is

resumed.

Power failure indicator

When the power is resumed after a power failure during

a test with temperature control at set point and test timer

running, the screen will lit up a power failure button.

Tap on the Power Failure button to see more information

andtoresetthepowerfailure,seegure2.2.3.a.

Anewscreenwillshow,seegure2.2.3.b.

This feature will give the operator information about

duration of the power failure and temperature deviation

caused by the power failure. The power failure button will

remain until the button Clear & Exit is tapped.

2.2.4 Set up screen (user)

Password

A password is needed to enter the set up mode.

Tap on the Setup button on the main screen to enter the

passwordscreenforsetup,seegure2.2.4.a.

Default password is: 1111

Figure 2.2.3.a – Power failure.

Figure 2.2.3b – Power failure.

Figure 2.2.4.a – Password.

Figure 2.2.2.a – Test name.

Figure 2.2.2.b – Test name.

5

Elastocon Manual – Cell Ageing Oven EB 36

IP-address

In the Set up mode an IP-address can be typed in to establish

a communication with a PC-software e.g. monitoring

program. Tap on the IP-addr.eldtoenteranIP-address,

seegure2.2.4.b.

The IP-addr.eldisdividedintosmallerelds.

Theovenmainpowermustbeswitchedoandon(restart)

for the IP settings to refresh and initiate.

Temperature offset

Inthesetupmodetheosetisadjustedaccordingto

calibration. When a re-calibration is done, values may have

to be adjusted again.

Anindividualosetvaluecanbeaddedtoboththe

temperature-indicator and -controller.

Standby temperature

The operator can in this Set up also preset a standby

temperature. That means when the test timer has reached

0:00, the oven will be set to this pre-set temperature. To

access the standby temperature setting, tap on the control

box below Stdby,seegure2.2.4.c.

A zero value in this control means that it is not active and

after the test timer timeup the oven will remain at the same

temperature as during the test.

A higher value than zero represents the temperature

set value. Eg. if the operator sets the standby control to 30,

the oven will go to 30 °C after the test time has reached the

end.Minimumsetvalue(SV)fortheovenis30°C,seegure

2.2.4.d.

Theovenhasnocooling.Thetemperaturewilljustcoolo

naturally. The cooling time depends on the room ambient

temperature.

Real time clock

Tap on the real time clock control to set time and date,

seegure2.2.4.e.

This is the system time and date and this time/date stamp

will be included to all alarm and time critical information

visible on the screen.

Use the numeric keyboard to set a new time and date.

Figure 2.2.4.b – IP-address.

Figure 2.2.4.c – Standby temperature.

Figure 2.2.4.d – Standby temperature.

Figure 2.2.4.e – Real time clock

6

Elastocon Manual – Cell Ageing Oven EB 36

2.2.5 Alarm

Alarm is activated at:

•hightemperatureinthetestchamber,+1°Cfromsetvalue

•lowtemperatureinthetestchamber,-1°Cfromsetvalue

•hightemperatureofthecontroller,+5°Cfromsetvalue1)

1) This alarm will be reset automatically when the temperature is within tolerance from set value again.

Error code Problem cause Remedy

001–006 Oven cell is too warm. The alarm will be reset when the alarm

Cell 1–6 has been acknowledged and the cell

has cooled down.

007–012 Temperaturedierencebetween Waituntilthetemperatureiswithin

Cell 1–6 set value and process value ± 1 °C. range to acknowledge the alarm.

013 Lowpressurefromairpump. Checktheairpumplterandfunction.

014 Shinko Communication Timeout. Contact support.

015 Low battery. Replace backup battery in OPLC

(contact support).

016–021 Loop break controller #. Broken temperatur sensor,

Cell 1–6 call for service.

022–027 Temperaturedierence Acknowledgethealarm.

Cell 1–6 between set value of controller When temperature is within range

andactualvalue+5°C. thealarmwillbereset.Ifthealarm

is not reset contact support.

Coloured lines on PV and SV display indicates alarm status.

•AredlineabovePVdisplay=PVtemperaturediers+1°CfromSVtemperature.

•AlightbluelinebelowPV=PVtemperaturesdiers-1°CfromSVtemperature.

•AredlineaboveSV=SVdiers+5°Cfromactualcontrollertemperature.

•AgreenlinebelowSV=PVtemperatureiswithin±1°CfromSVtemperature.

SV temp. di. alarm to general alarm collection list and ashing alarm button

will only be active for running channels (active count down meter).

7

Elastocon Manual – Cell Ageing Oven EB 36

Alarmwillactivateabuzzerand/oraashingredAlarmbutton.

Thebuzzercanbeswitchedonandobyataponthebuzzer

symbol.

Ifthealarmbuttonstartstoash,gothroughthechecklistin

this chapter to identify the alarm and address the problem for

proper action.

Buzzer on Buzzer o

Acknowledge any alarm

To acknowledge any alarm, tap on the button Alarm.

Figure 2.2.5.a. All active alarms can be seen on this screen. Press

the magnifying glass to the right side of the alarm ID 00 in the

alarm group list to view all active alarms in that group.

This oven will present all active alarms in the group named

ID 00.

All the alarms in this group are divided into two levels

depending on how serious the alarm is.

First level will reset the alarm automatically, but still requires

an acknowledgement to be cleared from the alarm list.

Second level must always be acknowledged by the operator

manually.

Figure 2.2.5.b. To acknowledge an alarm, press the magnifying

glass to the right of the chosen alarm.

Figure 2.2.5.c. Press the button Ack and the alarm will be reset.

Any alarm that is reset automatically will remain in the alarm

list until a normal condition is met. The red Alarm button will

howeverswitchfromashingtoaxedstate.

Alarm that still persists will show up again after the

acknowledge procedure.

Press the Esc button several times to return to main screen.

The History button will show a record of all previous alarm.

Figure 2.2.5.a

Figure 2.2.5.b

Figure 2.2.5.c

8

Elastocon Manual – Cell Ageing Oven EB 36

2.2.6 Set the air flow rate

According to standards the air has to be changed during

thetest.AS/NZS1660.2.3requiresanairowof0,25

± 0,025 m3/h.

The cells in the oven have a volume of 2,4 l/cell.

Thisgivesthefollowingowofairthroughtheowmeters:

air ow rate

m3/h l/min

0,225 3,7

0,25 4,2

0,275 4,6

Readtheowoftheowmetersatthecenteroftheoats.

Theoatsshallrotateslowlytoshowthecorrectreading.

Note:Iftheoatsdoesnotrotateproperlycheckiftheoven

is placed horizontally.

2.3 Start the test

When the test temperature is reached, take up the test piece

holders and place your samples on the pins, then return the

sample holders in the cells. Be careful when placing the lid

of the test piece holder, to achieve a good contact with the

aluminium block of the oven.

9

Elastocon Manual – Cell Ageing Oven EB 36

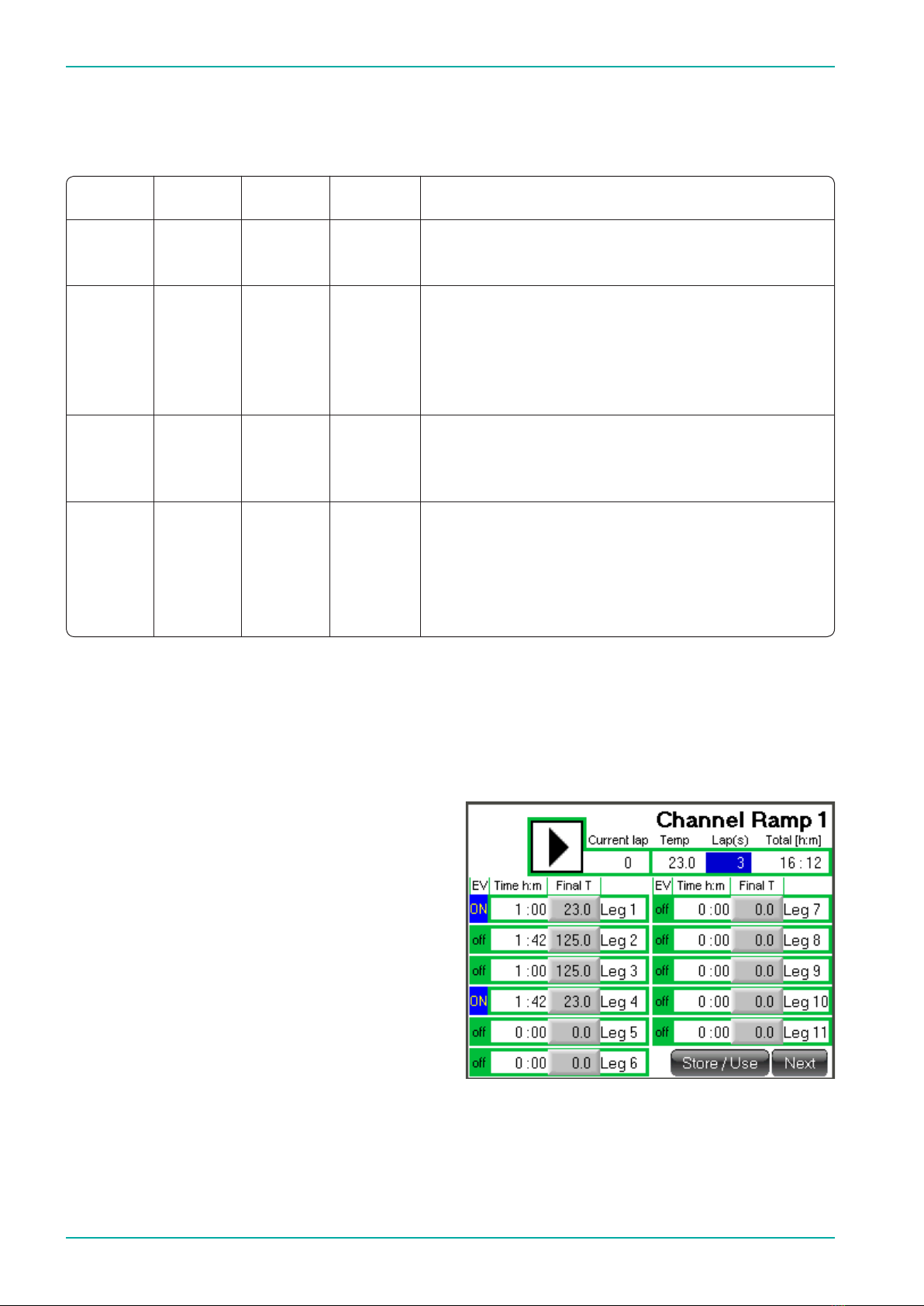

Figure 3

3. Programming of ramp with cycling temperatures

Programming of cycling

temperatures/ramp is an additional

option.

If this addition is included in the oven

the ramp button will be visible on the

main screen.

A temperature cycle is divided into

segments. Each segment is known in

this chapter as a ramp.

The ramp can be set within the same

temperatureintervalasspeciedfor

the oven. The ramp is built up by 2 break

points known as legs. There are 50 legs

available to build ramps and create a full

temperature cycle. See illustration on the next page

(Leg-Ramp-Cycle).

Each leg can be used to set a new temperature or

maintain the same temperature over a time period

(duration). Duration up to 999 hours and 59 minutes,

can be set to each leg.

Ramp button

Press the ramp button to enter the ramp function.

This button can be found on the main screen.

Legs

Ovens with more than one individually controlled

temperature cell or chamber will have 50 legs

available for each temperature cell or chamber.

Each leg consists of a time control (Time h:m) and

one temperature set point control (Final Temp). An

optionalbutton[ON/o]isincludedtosomeovens.

The ON/o buttons will be described further on.

Leg at start of temperature cycle

If the temperature in the header (Temp) for the

instrument is equal to the temperature set point in

leg 1, that same temperature will be kept over the

time duration set in leg 1.

On the other hand, if the temperature set value for

theovenislowerorhigherthanthersttemperature

set point in leg 1, the temperature will increase/

decrease towards the temperature set point typed in

the leg 1 control. The temperature increase/decrease-

speed will be calculated to last over the time duration

set in leg 1.

10

Elastocon Manual – Cell Ageing Oven EB 36

3.1 Leg when temperature cycle

is running

Whentherampisstarted,eachleglledwith

information will be processed. Legs with time settings

0:00 will not be processed and will be skipped.

If the temperature set value in a leg (Final Temp) is

equal to the temperature set point in the following

leg, the same temperature will be kept over the time

duration set in the following leg.

On the other hand, if the temperature set value for

the leg is lower or higher compared with the following

leg, the temperature will increase/decrease towards

the temperature set point typed in the following leg

control. The temperature increase/decrease -speed

will be calculated to last over the time duration set in

the following leg.

Ramp speed tolerances can be found in the speci-

cationsfortheinstrument.

The essential part of the leg

function is that if the following

legissetwithadierent

temperature (set value) than

the previous leg, a ramp in

temperature will be created.

The duration for the ramp

is always controlled by the

following leg.

Button next

Press the button Next to show additional 13 legs

available for the same temperature cell/chamber.

There are three Next screens. A total of 50 legs are

available.

Ramp

Cycle

Leg

11

Elastocon Manual – Cell Ageing Oven EB 36

Button [ON/off] (optional)

This button is available on some instruments that

require any type of mechanical action such as open/

close valves for additional cooling or heating. These

buttons are not visible if the instrument does not

have this option. The button is included to each leg

clusterandwillonlytakeactionwhenthespecicleg

is running and a time has been set for that leg.

Pressthebuttontogiveitaxstate.

ON= willactivatetheoutput(valveorcontrolwillbe

switched on when this leg is running).

o= noactionwillbetakenandtheoutputwill

remaino(valveorcontrolwillbeswitchedo

when this leg is running).

12

Elastocon Manual – Cell Ageing Oven EB 36

Ramp view header

Theheaderislocatedontherstrampscreen.The

header consists of one Play (start) button, Current

lap, Temp, Laps and Total [h:m].

The PLAY (start) button will execute the full

temperature cycle(s). To start the temperature cycle,

press the button PLAY. The play button will change it

appearance to a stop button.

An additional button will now also appear. This

button is the PAUSE button. Press the Pause button

to pause the ramp. In this state the temperature will

stop at the current processed set value. Press the

Pause button again and the temperature ramp will

continue.

To stop the ongoing cycle, press and hold the STOP

button pressed until the process is stopped (about

3 seconds).

Current lap is an indicator.This indicator

will show the current lap that is beeing

processed.

When the temperature cycle is started, the

Current lap indicator will show the current

processing lap.

The Temp control is the same control

as the set value (SV) control on the main

screen of the instrument.

This control will also act as an indicator

when the temperature cycle is started. The

operator can then follow the temperature in

this control as the cycle proceeds.

The Lap(s) is a control where the operator

can set up a number of repetitions for the

cycle.

Total [h:m] will calculate the total time of the

temperature cycle. The time settings for each leg will

be summed up. This time value is then multiplied by

the number of laps typed in the header control laps

to give the total time for the temperature cycle(s).

The Total [h:m] indicator will show the remaining

time for the full temperature cycle(s), when the

temperature cycle is running.

For some software versions, the total time cannot

show more than 9999 hours. In these cases, the

indicator will show xxxx. The function will remain

normal, but the total time is not possible to show.

Play

Pause Stop

13

Elastocon Manual – Cell Ageing Oven EB 36

3.2 How to Store/Use

a programmed ramp

The total ramp generated can be stored into a

memory Bank.

There are six individual memory banks to choose

from.

Any stored ramp can be used for any heater cell/

chamber in the same oven, if the oven has more

than 1 heater cell/chamber.

The ramp program is write-protected and must be

temporary unlocked to edit the ramp data or store a

programmedramptole.

ES 07-II

Locked state is indicated with the word Locked on the

main screen.

Any other oven

Locked state is only indicated by disabled input

controls on the ramp screen.

In the locked state, any pre-stored ramp can still be

selected when the ramp screen is opened. Refer to

point USE in this chapter.

The ramp edit mode will remain open until the ramp

screen is closed and 1 minute has passed.

Store

Noticethatthelenameforthestoredrampisxed

andthelenamesarealways“RampDat1forBank1”,

“RampDat2forbank2”andsoon.

Thestorebuttonwillsavethecurrentrampintoale

on the onboard SD micro card.

Iftheleislocked,thenreadthedescriptionbelow

from point 1.

Iftheleisun-locked,thenreadthedescription

below from point 5.

1. From the main screen, press the button Setup.

2. Enterpassword1111+Enter.

3. Press the button Options (not for instrument

EB 17).

4. Tick the box Temporary unlock Ramp Store/Use

button.

5. Return to the main screen and press the RAMP

button.

6. Prepare the ramp as wanted with temperature and

time.

The temporary unlock will stay unlocked while

stepping between any of the four Channel Ramp#

screens.

When changing to another screen except these,

the temporary unlock will be cancelled and after

2 minutes the Store/Use button will then be

locked automatically.

7. Press the button Store/Use.

8. If any memory Bank is empty, type in a new

lenameandpressitsStore button.

If a memory Bank is occupied, Press its Store

buttonandchooseto“overwrite”theoldle.

Anewlenamecanbegivenatalltimebefore

pressing the Store button.

14

Elastocon Manual – Cell Ageing Oven EB 36

Use

The Use button will connect any of the ramps stored

in any of the six memory banks to the Channel ramp

in use.

If the oven has more than one temperature cell/

chamber, any of these cells/chambers can be

connected to any of the memory banks.

1. From the Ramp screen press the button Store/

Use.

2. Press the button Use on any of the memory Banks.

3. Press the physical key ESC to return to the Ramp

screen.

4. TheleselectedwillnowbeloadedtotheChannel

in use.

If the oven has more than one cell or chamber

a matrix will be visible on the right side of the

Store/Use buttons.

This matrix will show each channel and if it is

connected to a ramp.

The maximum number of cells/chambers is six.

The example below shows that oven cell 1 was edited

(Administrate Ramp for Channe1) and ramp in

“Bank1”iscurrentlyinuseforthisovencellandsois

the oven cell 6.

Ovencell2isusingrampdatafrom“Bank2”andso

is oven cell 4, oven cell 3 is using ramp data from

“Bank3”,ovencell5isusingrampdatafrom“Bank5”.

15

Elastocon Manual – Cell Ageing Oven EB 36

Quick guide to initiate a ramp

(temperature cycle) and run it.

1. From the main instrument windows press the

ramp button symbol.

2. Fill in the header controls Temp and Laps.

Temp is the standby temperature before the ramp

(temperature cycling) is started and Laps

multiplies the number of cycles to run.

3. Fill in the Time and Final temp for a number of

legs to build all individual ramps in a full

temperature cycle. Nine legs are available in the

rstrampscreen.Another13legscanbeinitiated

in the next ramp screen. Press the button Next to

enter the next ramp window. Four screens are

available. First screen has 11 legs and the following

screens have 13 legs per screen. 50 legs in total.

Event buttons [EV]

(visible on instruments with this option)

To activate the event output, click and set the

event ON for each leg that is supposed to activate

the event output. Instruments with the LTP option

will open the cooling water valve on any leg that

has this option set to ON. This option is only

availableonthersttemperaturecell/chamber,

if the instrument has more than one temperature

cell/chamber.

4. When the full cycle has been programmed with all

legs necessary, the total time will be calculated and

shown in the header indicator Total [h:m].

5. The temperature cycle can now be started. To start

the temperature cycle, press the header button

PLAY (Start).

6. The ramp symbol will start to blink on the main

screen, when the main screen is restored

automatically after two minutes or if the operator

presses the ESC key below the screen to restore

the main screen.

16

Elastocon Manual – Cell Ageing Oven EB 36

Example of a temperature cycle:

Header Temp is set to 23 °C (or the standby temperature of your oven).

Time Temp Option Description

Leg 1 1:00 23 ON ‘ Temp will be kept at 23 °C for 1 hour.

Option is ON to run an optional event.

Leg2 1:42 125 o ‘ During1hand42minthetemperaturewillrise

to 125 °C. That represents a ramp speed of

1°C/min.125-23=102->102minutes

=1hand42minutes.

Optionisotoholdanoptionalevent.

Leg3 1:00 125 o ‘ Thetemperaturewillbekeptat125°C

for 1 hour.

Optionisotoholdanoptionalevent.

Leg 4 1:42 23 ON ‘ During 1 h and 42 min the temperature will drop

from 125 °C to 23 °C. That represents a ramp speed

of1°C/min.125-23=102->102minutes

=1hand42minutes.

Option is ON to run an optional event.

Repeat this cycle three times: When leg 4 is

completed, the cycle will start over on leg 1. The total

time for all cycles will be 16 hours and 12 minutes.

The number of laps and remaining time can be

followed on the indicators Current lap and Total

[h:m]. After this time the ramp will stop and the

temperature will remain on the last leg temperature

set value if no standby temperature was set. In this

example the oven will keep 23 °C when the ramp is

complete.

This is how the ramp window should look like

according to the example above.

It is possible set a standby temperature, if the last leg

has a high temperature set point and the operator

would like to end the temperature cycle with a low

temperature. This can be done from the Setup screen.

See chapter 2.2.4 Set up screen (Standby

temperature).

17

Elastocon Manual – Cell Ageing Oven EB 36

6. Troubleshooting

When the oven does not work properly, check the following.

Problem Problem cause Remedy

No power. No main power. The main fuse, 6,3 AT, is placed

in the connector for the mains lead

on the back of the oven.

Black screen No power to screen. Open up the cover on the right side

on power up. of the oven and check fuse F3 (2 AF).

Refer to electrical drawings.

Alarmbuttonashing. Anyalarm. Seechapt2.2.5Alarm.

Oven cell stirrer No power to stirrer. Make sure that the electric connector

notturning. isinsertedforthespecicstirrer.

Open up the cover on the right side of

the oven and check fuse F4 & F5 (2 AF).

Refer to electrical drawings.

Check electric schematics for fuses. Before changing a defective fuse,

check for any possible short circuit, causing the fuse to burn.

4. Temperature calibration

The instrument is adjusted and calibrated according to the

attachedcalibrationcerticateatthedelivery.

Calibration should be done annually.

5. Service and maintenance

The cell oven shall be cleaned on both the outside and inside,

at regular intervals. The oven can be cleaned with water and

a detergent or ethanol on the outside.

On the inside, most dirt is accumulated on the inside of the

upper lid, by volatiles from the samples condensing. The

lid can be cleaned with a suitable solvent such as ethanol or

white spirit.

Themostsensitivepartsoftheovenaretheairlterandthe

air pump, which should be checked at least once a year.

7. Sa fet y

Note: Use gloves when the samples are placed in the

oven or removed from the oven.

Important! For the best performance of the

instrument, we recommend the following working

environment:

• Standardlaboratorytemperatureofeither

23 °C ±2° or 27 °C ±2°.

• Humiditynotmorethan90%RH

– non condensing.

• Otherenvironmentalaspects:Pollutiondegree2

– Laboratory environment.

18

Elastocon Manual – Cell Ageing Oven EB 36

8. Technical specification

EB 36

Temperaturerange,°C: +40to+200

Temp.control, +40to+100°C,°C: ±0,5

+101to+200°C,°C: ±1,0

Temp. variation in time, °C: ± 0,25

Temp.variationinspace,%: ±0,5

Temperature sensors: Pt 100, 1/3 DIN

No. of temperatures: 4

No. of cells: 4

Paddle speed, rpm: 60

Airow,m3/h: 0,25 ± 0,025

Useful volume, l: 4 × 2,4

Dimensions, inner, dia × h, mm: 100 × 300

Dimensions, external, w × h × d, mm: 760 × 620 × 510

Weight, kg: 58

Voltage, V/phase/freq: 220–240/1/50

Power, W: 900

Standards: AS-NZS 1660.2.3

19

Elastocon Manual – Cell Ageing Oven EB 36

Common specifications:

• TheovensarecontrolledfromaPLC(witha

colour touch screen).

• Specialdesignwithcontrolledairowrate.

• Thecasingconsistsofsteel,paintedwithpowder

paint in bluegreen colour.

• Theinnercellsaremadeofaluminium.

• Temperaturecontrollerwith0,1°Csetpoint(PLC).

• Temperatureindicatorwithsensorineachcell

(PLC).

• Fixedovertemperaturefuse.

• Flowmeterswithneedlevalves,forsetting

theairowrate.

• Alarmforlowairpressure(PLC).

• Coolingchannelsinthecasingforlowsurface

temperature.

• Temperaturecontrolledcoolingfanforthe

electronics cabinet.

• Indicationofpowerfailure(PLC).

• Run-timemeter(PLC).

• Countdowntimer(PLC).

• Microlterfortheairwhichremovesallparticles

over0,01μm.

Optional accessories

EB-P Ramp function for temperature setting

in the PLC.

EC 11 Monitoring software.

ED 04 Computer, PC.

Network cable.

Elastocon AB

Tvinnargatan 25 •SE-507 30 Brämhult •Sweden

www.elastocon.com

Support

+46333233934

Table of contents

Other Elastocon Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Waters

Waters Xevo G2 QTof Operator's, overview and maintenance guide

Buchi

Buchi S-300 installation manual

Shel lab

Shel lab SMI2-2 Installation & operation manual

BioLAB

BioLAB BCBS-103 Operation manual

SPETEC

SPETEC SuSi FMS Series Translation of the original operating instructions

Buchi

Buchi Rotavapor R-200 operating instructions