Elastocon Gehman Tester ET02-II User manual

Manual

Gehman Tester ET 02-II

© 2016–2020, Elastocon AB, SWEDEN

Content

0. Use p. 3

1. Installation of the Gehman Tester p. 3

2. Freezing software p. 5

3. Using the Gehman Tester p. 10

4. Temperature calibration p. 17

5. Service and maintenance p. 17

6. Troubleshooting p. 17

7. Safety p. 19

8. Technicalspecication p. 19

Technical documentation supplied on USB flash drive

ma-et02-II_04_2009

Elastocon AB •Tvinnargatan 25 •SE-507 30 Brämhult •Sweden

2

Elastocon Manual – Gehman Tester ET 02-II

Addition

Combined TR, Gehman

and Brittleness Tester

When using our combined instrument there are some things

that needs to be done before starting the test.

• Change the rig manually by turning it clockwise or anti

clockwise and lock it with the locking device.

• Change to the right method (TR , Gehman or Brittleness) in

the software under “edit” and “method”.

This manual continues to describe the Gehman Tester only.

For other instruments, please refer to the manual for each

instrument.

Technical specification

for combined instrument

Width, mm: 750 (connection of liquid nitrogen

on the left side requires free space)

Height, mm: 1610

Depth, mm: 870

Weight, kg: 116 (Combination ET01-II/ET02-II)

3

Elastocon Manual – Gehman Tester ET 02-II

0. Use

Instrumenttodeterminetherelativestinesscharacteristicsof

vulcanized or thermoplastic rubbers, also called the Gehman

procedure. The test is done according to ISO 1432, ASTM D1053

method A, or technical equivalent standards.

1. Installation of the Gehman Tester

1.1 Unpacking

Unpack the instrument carefully. The following items are included:

• Gehman Tester with rig.

• This manual.

• 6 metal guides, one for each station (also transport protection).

• 2 cables (one data cable and one power cord).

• OneUSBashdrivewithFreezingsoftware,thismanual

inPDFformat,andauniquecalibrationandlicensele.

• Cryogenic vessel for liquid nitrogen and hose for connection

to the Gehman Tester (optional).

Note: Remove the metal guides from each station and attach

theclampingdeviceinstead,seegure1.1.Savetheguides,

as they are needed when changing torsion wires. Figure 1.1

4

Elastocon Manual – Gehman Tester ET 02-II

1.2 Installation

Ifthemainplugdoesnottyouroutlet,cutthecableand

replace with a suitable grounded plug. The cable colours means:

Brown = live, Blue = neutral and Yellow/Green = ground. This

change should be done by an authorized person.

Note: Remember to compare the outlet voltage and the

voltage labeled on the instrument. It is entirely the users

responsibility that the instrument is connected to the

correct voltage.

Place the Gehman Tester and the computer on a stable and

horizontal bench.

Connect the following:

– Connect the Gehman Tester to a grounded mains outlet,

according to the type label on the Gehman Tester.

–ConnecttheGehmanTestertoanairsupplywithalterand

water trap of min/max 7/8 Bar pressure. Connect a dia 10 mm

reinforcedairhose,seegure1.2.

– Connect the Ethernet cable between Gehman Tester and the

computer’s LAN connection. See chapter 2.1.

If the automatic cooling system is supplied, connect the

Cryogenic vessel to the Gehman Tester with the supplied

exiblemetalhosebyconnectingthehoseendto“Liquid

Nitrogen inlet” on the Gehman Tester.

Also connect a silicone hose to the “Nitrogen Vapour Exhaust”

connector. This hose should not be longer than 5 m and the

open end must be connected to a fume hood or directly to an

outdoor environment.

Note: It is of great importance that all waste gas are led

out from the “vapour exhaust” connector at the backside

of the Gehman Tester to an outdoor environment. This is to

prevent high concentration of nitrogen gas in the room.

– To connect a printer, see the manual for the printer.

Figure 1.2

5

Elastocon Manual – Gehman Tester ET 02-II

Figure 2.1a

Figure 2.1b

Figure 2.1c

2. Freezing software

2.1 Installation

LAN settings

The Gehman Tester uses IPv4, which is an addressing system of

communication by Ethernet.

For proper communication between the Gehman Tester and the

PC the connection must be set correctly according to how the

Gehman Tester is connected. Follow the right options below.

Local connection is preferable to avoid communication

problems, when using the instrument, if the network is down.

Local connection (cable connection between the computer

and the instrument):

Go to the network settings in Windows and select the

local connection that is connected to Gehman Tester. If

your computer only has one LAN port, there is only a local

connection,

seegure2.1a.

Right-click the icon and select “Properties”.

When the properties comes up, highlight the “Internet

Protocol Version 4 (TCP / IPv4)” and press the “Properties”

button,seegure2.1b.

Then select the option “Use the following IP address”.

Enter the IP address 192.168.10.90

SubnetMaskwillbelledinautomaticallyto255.255.255.0,

seegure2.1c.

LAN connection (connecting instrument to a LAN with

dynamicallyassignedorxedIPnumbers)

The computer and Gehman Tester must be adapted to

the network by a network administrator to avoid address

conict.

The Gehman Tester comes with the following settings.

Specify this for a network administrator to connect the

equipment in the network:

IP 192.168.10.250

Subnet Mask 255.255.255.0

Gateway 192.168.10.3

6

Elastocon Manual – Gehman Tester ET 02-II

Install the Freezing software

(if not already pre-installed)

1.InserttheUSBashdriveinanemptyUSBport.

GotoWindowsExplorerselectthele“start.exe”.

2. Next to the “Install Programs” button select “Freezing” and

then press

the “Install Programs” to install the program.

Theprogramandotherleswillbeinstalledintheapplication

directory Elastocon Freezing along with calibration data.

A working directory will be created with the path Elastocon

Data\

Gehman Data).

The program’s settings will be stored in the system directories

for Windows.

2.2 Install calibration file

Launch the software Freezing.

Ifnocalibrationlehasbeeninstalled,anew

window will appear on the screen.

The window will ask the operator for a calibration

le(*.cal).Thiscalibrationlecontainsbothall

necessary calibration data for all the stations and

the product license information.

Thecalibrationlecanbefoundontheinstallation

USBashdrive.InserttheFreezing installation

USBashdrive,ifnotyetloaded.Havingthe

window“Installcalibrationle”onthescreen,

browsetothefolder“Calibrationprole”onthe

installationUSBashdrive.Thereisonlyonelestoredinthis

folderandthelenameisuniqueforyourcompany.

Selectthecalibrationlewiththeuniquelenameandpressthe

button “Open”.

The software Freezing will now launch and your company

proleandcalibrationwillbeloaded.

If the software is to be used for demonstration purpose only,

simply click on the button ”Abort”. The software will now enter

a demo mode. The program will not attempt to communicate

with the instrument in demo mode.

To re-establish communication with the instrument, go to the

“Edit” menu and select “Communication Preferences”.

See label on the instrument next to the Ethernet connection for

proper communication settings.

Figure 2.2

7

Elastocon Manual – Gehman Tester ET 02-II

2.2.1 Change calibration profile

The instrument needs to be calibrated annually. If the

calibration deviates too much from any calibration instrument

used, a correction must be made.

Thecurrentcalibrationlecanbeloadedintoinacalibration

software and the calibration can be adjusted. This software

canbefoundontheinstallationUSBashdriveandcanbe

launcheddirectlyfromtheUSBashdrive(FrezCal.exe).

In the software FrezCalthelicense/calibrationlecanbe

opened for adjustment.

ThecalibrationlecanbefoundintheWindowssoftware

directory Elastocon Freezing and subdirectory Cal.

Whentheadjustmentsarenished,thelemustbestoredwith

anewlename.

Atypicalcalibrationlenameisbuiltupasfollow:

<Company name YYMMDD Gehman.cal>

Where YYMMDD is the actual calibration date. Ex. File name

would be: Elastocon AB 20160101 Gehman.cal

Itisveryimportantthatthenewcalibrationleisstoredin

the same folder as the

current.

Thenewlemustnow

be loaded in the Freezing

software to be able to

work.

Launch the software

Freezing and click with

the left mouse button on

thetag“Calibration”,seegure2.2.1a.

Press the “Browse” button.

Selectthenewcalibrationleyouhavecreatedandpressthe

“Save”button,seegure2.2.1b.

When the dialogue “Reload?” comes up, select the “Yes” button.

The software will now inform you that you have selected a new

prole,seegure2.2.1b.

Restartthesoftwareandmakesurethatyourproleisshown

onthe“splashscreen”,seegure2.2.1c.

Figure 2.2.1a

Figure 2.2.1c

Figure 2.2.1b

8

Elastocon Manual – Gehman Tester ET 02-II

2.3 Software commands and settings

File menu (Alt+A) figure 2.3a

New = Start a new measurement (Ctrl+N).

Open = Open an old measurement (Ctrl+O).

Close =Closeameasurementle.

Print test results = Printing of the report. Prints both the RM-

values and the graph.

EXIT = Ends the Freezing software (Ctrl+Q).

Edit menu (Alt+E) figure 2.3b

Method = Set TR or Gehman standard method (if available).

Calculations = Select the RM-values you want to evaluate from

the test data. On historical data you can change this to evaluate

other RM-values. Calculations can also be inserted, eg 70-10

(Ctrl+C).

See chapter 2.4.

Communication Centre = Set the communication between

the controller and the computer. Can also be used to tune the

communication between the Gehman Tester and computer.

Working directory =Changethepathtothetestles(Ctrl+W).

Save setup = Save pre-settings to a disk (Ctrl + Shift + S).

Operate menu (Alt+O) figure 2.3c

Start measurements = Start a measurement initiated with new

(Ctrl+S).

Abort measurement = Abort running test (s).

Turn all stations to full angle = Turns all stations 180°.

Return all stations to Zero = Turns all stations to the 0° position.

Windows menu (Alt+W) figure 2.3d

Full size = Maximize Freezing software on screen. (Ctrl + /).

Diagram settings = Adjust diagram settings.

Reverse axis = Reverse the × and y diagram axis.

Current axis range = Set axis range to stored values (Ctrl+U).

Help menu (Alt+H) figure 2.3e

About = Information about the software, version etc. Tip strips

will also appear on mouse events and is context sensitive.

Figure 2.3e

Figure 2.3a

Figure 2.3b

Figure 2.3c

Figure 2.3d

9

Elastocon Manual – Gehman Tester ET 02-II

2.4 Calculations

Go to the “Edit” menu and select “Calculations”,

seegure2.4.

RM Editor

Select the RM data if you would like to evaluate.

RM Editor shows the present values for evaluation.

To add a new RM value:

Enter the new value in the “New value” box and press the

button “Add” or press the [F3] key on your keyboard.

To replace a RM value in the ”RM Editor” list:

Enter the new value in the “New value” box and click with

the left mouse button on any value in the “RM editor” list.

The list value should be marked in blue or black.

Then press the button “Replace” or press the [F2] key on your

keyboard.

To remove a present value from the “RM Editor” list:

Click with the left mouse button on any value. It is possible to

hold the Shift key pressed while selecting one or several values.

The value(s) should be marked in blue or black.

Then press the button “Remove” or press the [F4] key on your

keyboard.

To add a RM constant to the arithmetic function:

Mark any value in the “RM editor” and press the button

“Constant” or press the [F5] key on your keyboard.

Arithmetic function

Make a calculation with the RM values in the “RM Editor”.

Values within “-signs are RM constants. It is then possible to

make a mathematic expression in the “Arithmetic function”

eld.Youcanalsodescribetheexpressionwithanameinthe

“Header”eld(max8chr).

Here is an example: You wish to make the calculation

of RM2 - RM10

The expression should look like this:

(“2” - “10”)

To add this calculation to the report, simply click with the

mouse on the radio button next to the “Arithmetic function”.

Thefunctionwillbeshownintheprevieweldabove.

Figure 2.4

10

Elastocon Manual – Gehman Tester ET 02-II

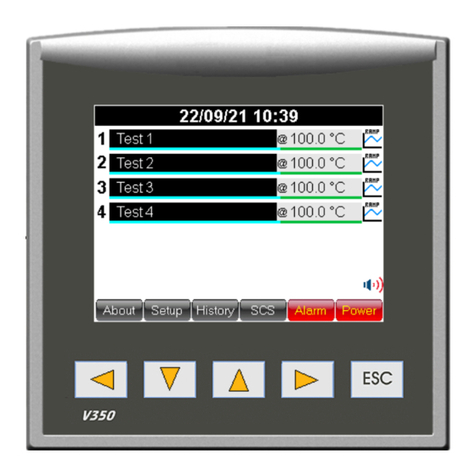

3. Using the Gehman Tester

Switch on the power to the Gehman Tester and the computer (in

this order). The touch display will make a self test and then show the

temperature in the bath. The process value is in red. Start the software

Elastocon Freezing.

If no error messages shows up in the software, continue with 3.1.

3.1 Preparations for testing

3.1.1 Mounting the Torsion wires

1. Removethe2platesthatnormallyxtherubbersampleduring

tests. Remove upper and lower plates.

2. Insert the 0° aluminium template where the rubber sample

normallyts.Insertbothscrews,butdoNOTtightenthescrews.

The template must remain free to move.

3. Put the 0.25 mm feeler gauge between the lower air bearing gap.

4. Make sure the upper rod and the lower clamp is

in parallel. Push the upper rod upward, so the

feeler gauge is being pressed and tighten the

2 screws on the aluminum template. Make sure

the rod stays in the upper position, by friction.

5. Put in the torsional wire from the top trough the

upper mechanical part of the rig and down to

the rod.

6. Holdandverticallycenterthewire,sothatthe

wiretsforbothupperandlowersetscrew.

Dierentwirescanhavedierentlength.

7. Tighten the lower setscrew on the wire.

8. Pull the torsional wire gently upwards and

tighten the upper setscrew.

IMPORTANT! Make sure not to twist the wire when tightening.

Just pull the wire straight up.

9. Take out the feeler gauge. Make sure that the rod has not moved

down. The feeler gauge distance must remain.

10. Press the pre-set button in the software and make sure the value is

being pre-set to 0.

11

Elastocon Manual – Gehman Tester ET 02-II

11. Remove the aluminium template. Look at the position in the

software as the template has been removed. A small

deviation from 0° angle is acceptable. About 5°. Any higher

deviation must be corrected and the procedure must be

repeated.

12. Perform a full twist from the software (menu: Operate

– Turn all stations to full angle). Make sure that the rod is

hangingfreely(oatingonair).Theremustbenofriction

eitherin0°positionoratfullangletwist.Theairwillow

for about 10 seconds after the stations have been returned

to zero. Check for friction at 0° point, during this time.

13. Turn back the rod and make sure to get a position close to

the same angle in point 11.

Note: When performing the friction test in air, the rod can

starttooscillateandwhentheairowiscutotherodwill

be blocked in any interval of the oscillation amplitude. It is

then recommended to stop any oscillation by hand, before

theairowiscuto(within10sec).

Rubber sample and liquid will slow down any oscillation

during tests.

14. Repeat the same procedure for all wire changes.

3.1.2 Fill the container with cooling liquid

Whentherigisintheupperposition,llthecontainerwitha

suitable liquid (e.g. ethanol). Add room tempered cooling liquid

(eg. 18 °C/65 °F) up to min/max 50/60 mm from the top of the

container and check that the circulation pump works properly

when the Gehman Tester is switched on.

Note: Evaporation and the cooling will decrease the liquid

level during the test. Therefore check the level before each

test and add additional liquid if required.

Always keep the level at 50–60 mm at room temperature

(approx. 18–20° C/65–68 °F). A hint is to look on the red

display on the Gehman Tester while pouring the liquid into

the container. This display shows the actual temperature.

For chilled ethanol the tolerance of the liquid level is

70–80 mm at approx. -80 °C/-112°F.

12

Elastocon Manual – Gehman Tester ET 02-II

3.1.3 Cooling of the liquid

If manual cooling is used (carbon dioxide) set

the controller to -100 °C in the software from

thetag”temperature”,seegure3.1.3.Thisis

to avoid heating during the cooling.

Note: If carbon dioxide ice is used, crush

it well and do not add to much, as this may

delay the heating.

If automatic cooling with liquid nitrogen is used (option), set

the controller to the start temperature, e.g. -73 °C.

Note: After a test the Gehman Tester will automatically

start to cool down to the set start temperature. See the

Edit menu and the tag ”temperature” for other settings.

The communication with the computer is still active even

ifthecoolingisshuto.

Start the cooling for -73 or -75 °C, guidance can be found in

ISO 3383. Normally crushed dry ice (solid carbon dioxide)

or liquid nitrogen is used. Liquid nitrogen is used with the

automatic cooling system, through a cooling coil inside the bath.

Ifpre-cooledEthanolisused,llthebathascloseaspossibleto

teststart.Makesureyouwillnotllmoreliquidthenuptoapp.

80 mm from the top.

Apply a pressure on the cryogenic vessel to get the liquid

nitrogen into the Gehman Tester. This can be done by using a

self-pressurizing cryogenic vessel or by connecting dry nitrogen

gas to the vessel with a pressure of about 0.8–1.5 Bar (8–15 psi).

Note: Havetherigraisedduringthecoolingperiodtoavoid

ice formation on the rods.

Hints for using Gehman Tester without the automatic

cooling system.

1. Prepare the test by mounting test pieces in the test stations

andcreatenewmeasurementlesforeachofthetest

stations in the Freezing software.

2. Set the temperature to -100 °C.

3. To improve the cooling, pour about 2–3 liters pre-cooled

liquid (-80 °C) in to the container and leave the liquid for

about 5 minutes.

Draintheliquidagainfromthecontainerandllupwith

new pre-cooled liquid to the correct level.

4. Make sure that the rods are locked, but that the test station’s

locking caps are under the locking pins.

5. Stretch the test pieces for elongation, start the measurement

and immediately lower the rig in the liquid.

The test time will start counting down and the test starts

automatically.

Figure 3.1.3

13

Elastocon Manual – Gehman Tester ET 02-II

3.2 Starting a test

3.2.1 Initializing a test

Mount the test pieces in the clamps. Be careful and do not press

to much on the upper clamp, since this may damage the rod.

The best way is to hold the upper clamp steady with one hand

and mount the test piece with the other hand. Do not use any

sharp item to press the test piece since this may damage the

wedge,seegure3.2.1a.

How to use the template for a 25 mm free sample length

A steel pin of approx. 15 × 1,5 mm tied on to a nylon string will

be found in the package for the Gehman tester. This pin is used

on the lower clamping device to achieve a 25 mm free hanging

lenght for the mounted test piece.

Seegure3.2.1b.

1Small allen screw to adjust clamping force.

Use the screw driver from the package.

2Upper clamping rod.

Locker plate with M4 allen screw. Use the screw driver

from the package.

3Lower clamping device is a part movable up and

down.

4Insert the steel pin under the lower clamp to achieve a

free lengt for the test piece of approx. 25 mm.

1. Begin with station 1 and mount the test piece into the

upper clamping rod and secure it with the locker plate.

Begin with station 1 and move on to the next station.

Mount and secure all the samples in the upper clamp

rst.

2. Now begin with station 1 again and pull up its lower

clamping device slightly and insert the 15 × 1,5 mm

steel

pin in the opening that creates for the lower clamp.

3. Now mount the test pice into its lower clamping and

secure it with the locker plate. Then remove the steel

pin from the lower clamp.

4. Now perform the same proceedure on each test stations.

5. Use the small allen key on the 3 mm allen screw on each

upper and lower locker plate to adjust the clamping force.

Figure 3.2.1b

Figure 3.2.1a

1

2

3

4

14

Elastocon Manual – Gehman Tester ET 02-II

In the Freezing software, select “New” in the “File”

menu.Fillinalenameforyourtest(youhaveto

giveeverytestpieceauniquelename),seegure

3.2.1c.

Then press the button “Save”. A new dialog box

appearswhereyoullinthetestdata.

Identification

First give your test a name in “Sample ID” and then

eventuallysomecommentsinthenoteeld,see

gure3.2.1d.

Station selection

Choose a test station with a click of the mouse. Test

station 1 is the one to the left on the rig.

End conditions

Choose the test ending conditions by a clicking on the button

at the corresponding end condition (Time, Temperature etc.)

e.g.RM2.Morethanoneconditioncanbechosen.Therst

condition met will end the test for this station.

Torsional wire

Choose the torsion wire under “torsional wire” (e.g. 2.8 mNm).

Canbedierentforeachstation.Thelistedvaluesarereal

calibration values.

Sample dimensions

Type in the sample dimensions. Lenght, width and thickness.

Create new measurements for all stations required. You may

use from one up to six stations in the same test procedure.

3.2.2 Test at 23 °C

To start a measurement at 23 °C go to the “Operate”

menu and choose “Start measurements”, or press

Ctrl+S. An extra setting for 23 °C appears.

Selecttestinairorinliquid,seegure3.2.2a.

Select the kind of test preferred. The instrument

automaticallyndsthezeropositionforthetestpieces

when the text “System is ready, test continued” shows

up, move on to “the 23 °C test in air, the 23 °C test

inliquid”.Thiswillbeshownasaashingtext.Do

nothinguntiltheashingstops.

The 23 °C test in air

Havetherigraised.Measuretheairtemperatureclosetothetestpiecesand

type the result in the box “Air temperature for 23 °C test”. Change the “Data

acquisition delay” e.g. 10 second and/or “Additional time for twist motion”

e.g.1 second, if necessary. Press the button “Continue”. The 23 °C test will

now start. The “data acquisition delay” time is now counting down (not

shown on screen) to zero. Continue on chapter “Save or resume 23 °C test”.

Figure 3.2.1d

Figure 3.2.1c

Figure 3.2.2a

15

Elastocon Manual – Gehman Tester ET 02-II

Figure 3.2.2b

The 23 °C test in liquid

Havetherigraised.Manuallytypethestarttemperaturein

the box “Start temperature for LIQUID 23 °C test”. Change the

“Data acquisition delay” e.g. 10 second and/or “Additional time

for twist motion” e.g. 1 second, if necessary.

The label of process temperature will change to “lower rig now”

when the temperature has reached the preset temperature.

Lower the rig and the 23 °C test will now start. The “data

acquisition delay” time is now counting down (not shown on

screen) to zero.

Save or resume 23 °C test.

A new dialog box appears after the data acquisition delay, see

gure3.2.2c.

Thedialogshowstwooptions,“Savetole”and“Resume”.It

also has the possibility to change torsion wire. An information

box tells you if the test was within range. The “Resume” button

will be lit if the test is out of range (120–170°). To re-measure

this station, select a new torsion wire and press “Resume”, else

press“Savetole”.

Howeveritispossibletopress“Savetole”evenifthetestis

out of range, but this is not according to the Gehman standard.

If more than one station is activated (Initialized) a new dialog

box appears. Follow the same procedure as previously in the

text. This procedure will continue until all “initialized” stations

areapprovedwith“Savetole”.Stationsdiscardedwith

“Resume” button will result in a new dialog box telling you

tochangetorsionwire.Seegure3.2.2d.

Note: If any station was out of range, do nothing

before the text below has been read.

The numbers of each station corresponds to the numbers

listedinthedialogbox.ChangethesewiresandTHEN

press OK. Follow procedure in chapter 3.1.1 It is important

NOT to press the OK button until all wires are replaced and

tightened correctly. After this procedure the instrument will

make a self test and readjust the zero position for the stations

resumed. When the adjustment is complete a new 23 °C test will

be done immediately.

The “resumed” set of test(s) will be represented in the dialog

box “Gehman 23 °C test result”. Follow the same procedure as

previously described in this text.

Go to chapter 3.2.3 Low temperature test, when all 23 °C tests

areapprovedwith“Savetole”.

Figure 3.2.2c

Figure 3.2.2d

16

Elastocon Manual – Gehman Tester ET 02-II

3.2.3 Low temperature test

If the 23 °C test was performed in LIQUID, raise the rig to the

upper position.

Anewdialogappears,seegure3.2.3a.PressOK.

The dialog box “Start procedure (23 °C test)” will change to

“Start procedure (Low temperature test)”, if the 23 °C test has

been performed correctly.

After 23 °C test in:

Air

The start temperature was probably set as described in

chapter 3.1.3 Cooling of the liquid. It is however possible

to change the temperature in the box “Start temperature”,

e.g -73°C.

Liquid

Type the start temperature in the box “Start temperature”,

e.g -73°C.

Setthe“Conditiontime”(delaybeforerstmeasurement),set

the “Temperature ramp” and “Twist interval”.

The actual temperature will be shown under “waiting for start

temp” and the label will change to “Temp. ready lower rig now”

when the preset temperature has reached the start temperature.

Lower the rig and the countdown for the “Condition time” starts

and will be shown under ”Condition time left”.

Note: It is very important that No other programmes are

running on the computer at the same time as the Freezing

software is collecting data from the Gehman Tester.

The Freezing software is working with some time critical

operations and needs all system resources, see minimum

requirements for Freezing.

Thetestwillautomaticallystopwhentherstendconditionis

met. This is done separately for each test station.

Whenallstationsarenishedadialogboxappears.

The actual status for all software commands is shown in the

lowerrighthandcornerofthesoftware,seegure3.2.3c.

Note: Whenallstationsarenished,theprogramshows“All

measurements are ended”. Press OK and the instrument starts

to cool to the pre-set temperature.

To make a new test, raise the rig and remove the specimens.

Close all measurements in the software Freezing and go to

chapter 3.2.1.

When the Gehman Tester is not in use drain all of the liquid and

store it in a safe place.

Figure 3.2.3a

Figure 3.2.3c

17

Elastocon Manual – Gehman Tester ET 02-II

4. Temperature calibration

The controller and sensor are adjusted at delivery and calibrated

accordingtotheattachedcerticate.Calibrationshouldbedone

annually.

5. Service and maintenance

Empty the container when not using the Gehman Tester.

To clean the container and remove test pieces etc. from the bottom,

remove the plate holding the motor and pump. Now you can lift up

the grid in the bottom of the container and clean the bottom. This

procedure is not recomended to do unless the bottom surface is

extremly littered and dirty. The grid itself will catch most broken or

lost test pieces.

Note: Be careful not to damage the temperature

sensor when removing or reattaching the grid.

It is important to always keep the instrument clean to prolong the

lifetime of it.

6. Troubleshooting

If the instrument does not function as expected, try to match the

symptom with any of the descriptions below.

No communication with the instrument. If this occurred suddenly,

it is most likely a lose or damaged data cable. Check the cable between

the instrument and the computer. Also be sure that the instrument

is swiched on. A blown fuse could have caused a power down on the

instrument.

No power at all.Switchothemainswitch.Removethepowercord

from the mains inlet. Pull out the fuse holder and check the two fuses.

The value should be 6,3 AT for a 230–240 VAC instrument and 10

AT for a 100–120 VAC instrument. Replacement fuse must be of a

ceramic kind. Replace any broken fuses, pull back the fuse holder and

attach the main coard. Switch the mains back on.

No power to the panel instruments. Switch of the main power and

remove the power coard from the instrument. Remove the hatch from

the right hand side of the instrument (two screws). Locate the fuse F3

(2 AF) with help of the schematics (schematics can be found on the

USBashdrivefortheinstrument).Replacethefusewithanewand

try again. Always use the same value for a replacement fuse.

No power to rig sensors. Switch of the main power and remove the

power coard from the instrument. Remove the hatch from the right

hand side of the instrument (two screws). Locate the fuse F4 (2 AF)

withhelpoftheschematics(schematicscanbefoundontheUSBash

drive for the instrument). Replace the fuse with a new and try again.

Always use the same value for a replacement fuse.

18

Elastocon Manual – Gehman Tester ET 02-II

No power to the pneumatic valves or cryogenic valve.

Switch of the main power and remove the power coard from the

instrument.

Remove the hatch from the right hand side of the instrument

(two screws).

Locate the fuse F5 (4 AF) with help of the schematics

(schematicscanbefoundontheUSBashdriveforthecircuit

drawings). Replace the fuse with a new and try again. Always

use the same value for a replacement fuse.

6.1 Alarm

A few problems will be displayed on the touch screen.

A description is shown below.

Anyactivealarmwillbeindicatedasaashingalarmbutton.

Over temperature in bath. The over temperature protection is

activated.Iftheuidinsidethecontainerisabove30°C/86°F,

lettheuidgodownintemperature.Thenlocatethe“overtemp

reset”-button on the left side of the instrument. The button is

located inside the punched hole of the steel chassie.

Use a small screwdriver an press back the green button. Turn

theinstrumentofromthemainswitch.Waitforabout5

seconds and turn the instrument back on.

Error code Problem cause Remedy

000 No power on fuse F4. Replace fuse F4.

013 Failure on agitator pump. Contact support.

014 Temperature Communication Timeout. Contact support.

015 Backup battery low. Replace battery in the touch screen

(contact support).

028 No power on fuse F5. Replace fuse F5.

042–045 Internal communication problem. Contact support.

046 Over temperature in bath See remedy below.

19

Elastocon Manual – Gehman Tester ET 02-II

7. Sa fet y

Warning! Be careful when handling the liquid, the dry ice or

liquid nitrogen. Wear protective clothing and safety glasses.

Warning! We strongly recommend to arrange a ventilation to

take care of the vapours from the liquid.

Warning!Keepyourngersawayfromtherigwhenyouraiseor

lower

the rig, to avoid getting pinched.

Warning! See to that used Nitrogen gas is taken care of. There

is a hose connection on the backside of the the machine marked

EXHAUST.Werecommendtoconnectthisoutlettoventilation.

Important! For the best performance of the instrument, we

recommend the following working environment:

• Standard laboratory temperature of either 23 °C ± 2°

or 27 °C ± 2 °.

• Humiditynotmorethan90%RH–noncondensing.

• Other environmental aspects: Pollution degree 2

– Laboratory environment.

8. Technical specification

Temperature control

Temperature range, °C: -80 to +30

Accuracy, °C: ± 0,5

Resolution, °C: ± 0,1

Sensor: Pt 100, 1/3 DIN

Length measurement

Indicators, no: 6 pc digital encoders

Resolution, mm: 0,1

Measuring range, °: 0 to 182 1)

Test rig

Rig material: Stainless steel and aluminium

Min/max test samples, l × w × t, mm: 40 ± 2,5 × 3 ± 0,2 × 2 ± 0,2

Test stations: 6

Other specications

Dimensions, external, b × h × d, mm: 680 × 1 010 (1 260) 2) × 710

Weight, kg: approx 90

Cooling liquid volume, l: about 8

Voltage,V: 220–240VAC50/60Hz(alt.110–120VAC)

Power, W: 600

Air supply, Bar: 4–6

Computer connection: Ethernet

Standards: ISO 1432, ASTM D 1053

1) Testing range adjustable from 0-182°. Adjusted at 0-180°.

2) Test rig in raised position.

Elastocon Manual – Gehman Tester ET 02-II

Elastocon AB

Tvinnargatan 25 •SE-507 30 Brämhult •Sweden

www.elastocon.com

Support

+46 33 323 39 34

Table of contents

Other Elastocon Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

VITACOM

VITACOM LAMP-UV-PR02 instruction manual

Sutter Instrument

Sutter Instrument MP-225A Operation manual

BioCare Medical

BioCare Medical Decloaking Chamber Plus manual

NoiseKen

NoiseKen SWCS-931SD instruction manual

Grant

Grant UVT-B-AR operating instructions

Thermo Scientific

Thermo Scientific Sorvall WX+ instruction manual