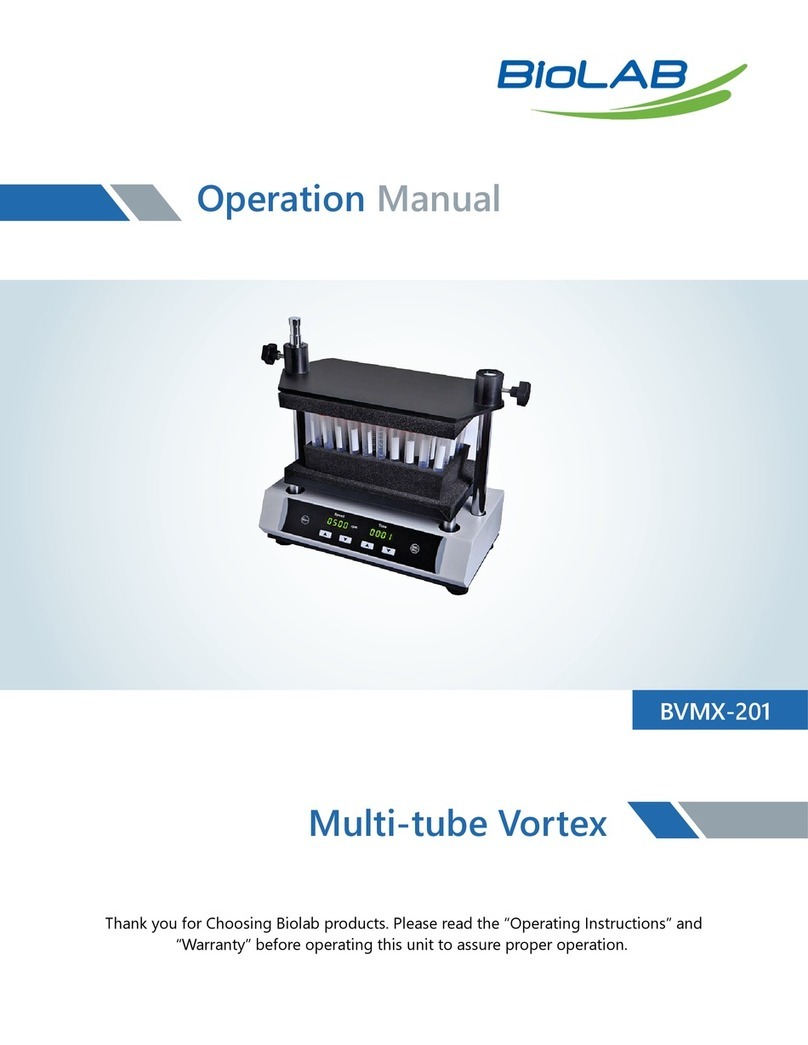

Biological Safety Cabinet Class I BCBS-103

www.biolabscientific.com 13

2.3 Operating Considerations & Operating Procedures

2.3.1 Operating Consideration

1) Before AC power connecting, make sure input voltage is correct and stable. The rated load of

main power socket should be higher than cabinet consumption. BCBS-103 adopt grounded plug,

which only could be used with grounded socket. This is a kind of safety device. If the plug cannot be

inserted into the socket, please ask electrician to install grounded socket.

2) The weight of items placed in the cabinet should be no more than 23Kg/25×25cm2

3) Samples placed in parallel: Samples should be placed in the cabinet parallelly to avoid cross-

contamination between samples.

4) In order to avoid samples being sucked into the negative passage or the blower, do not place soft

and slight samples (for example: soft tissue) on the surface during experiment.

5) Avoid vibration: avoid using vibration equipment inside the cabinet. Vibration would cause

particulate matter shake o from lter membrane, causing lower cleanliness of operating area.

6) No ame: No ame is allowed inside the cabinet. Using of re will lead to airow disorder, and lter

damage. If sterilization is required during the experiment, infrared sterilizer is highly recommended.

7) HEPA lter life: With the usage time increasing, dust and bacteria accumulate inside HEPA lter.

Filter Resistance is getting bigger, when it reaches the maximum point, there will be audible alarm.

Please replace new HEPA lter, otherwise it will aect the safety performance of the equipment.

Interior components shouldn’t be abandoned at random when the equipment is maintained or

scraped. There are biological hazards of components, please processed based on local laws and

regulations.

8) Blower and underside steel plate are static pressure, back door is dam-board of negative pressure

air passage, which is sealed strictly in factory. The operator is not allowed to remove or loose screws

of those parts. If necessary, please contact service personal.

9) The maximum storage period is one year. If the period is more than one year, performance test

should be done by technical sta. Then it could be put into operation if qualied.

Serious declaration: we will take no responsibility for risks caused by improper operation and

man-made damages!

2.3.2 Operating Procedures

a. Connect the same AC power supply as required of equipment;

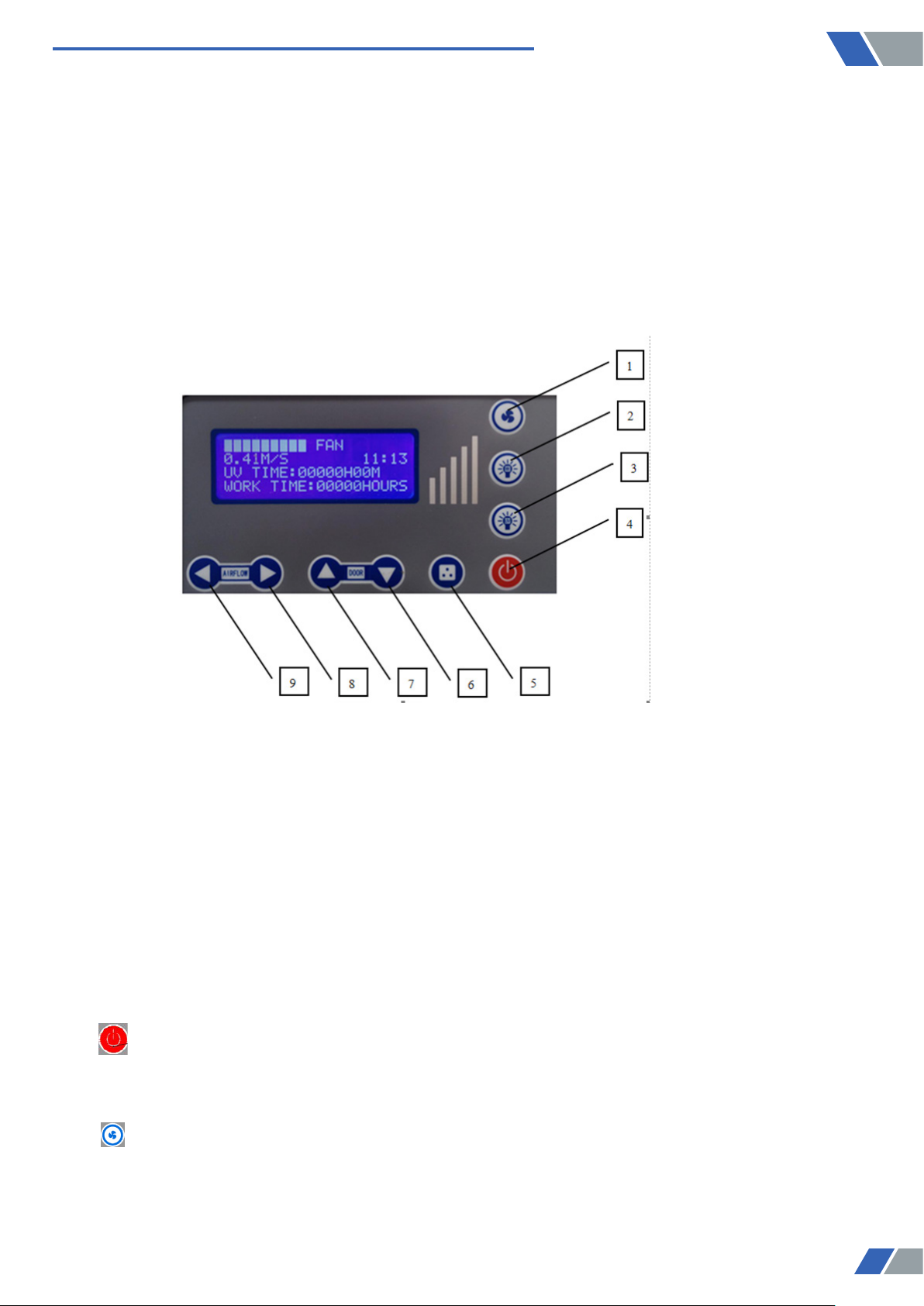

b. Open the ship type switch, electrify the equipment. Pressing the relevant function button

(Introduction and operation of function buttons, please check 2.2.2 ) to check if the function

buttons are accordance with operating result and check the blower start and air-ow, uorescent

lamp and UV lamp based on the above Technical Parameters.

c. Before using, please make the front window down to bottom and sterilize the cabinet for more

than 30 minutes by UV lamp.