Content

1.0 Notes on the Manual ......................................................................................................................3

2.0 Safety................................................................................................................................................3

2.1 General Instructions...................................................................................................................3

2.2 Warning......................................................................................................................................3

2.3 Repair .........................................................................................................................................3

2.4 Safety Instructions...................................................................................................................... 3

3.0 Transportation and Installation .....................................................................................................4

3.1 Packing .......................................................................................................................................4

3.2 Transportation............................................................................................................................4

3.3 Storage .......................................................................................................................................4

3.4 Supply List ..................................................................................................................................4

3.5 Ambient Temperature................................................................................................................5

3.6 Air Humidity ...............................................................................................................................5

3.7 Power Connection...................................................................................................................... 5

4.0 Technical Specifications.................................................................................................................5

4.1 Introduction of Function ............................................................................................................5

4.2 Electrical Parameters..................................................................................................................6

4.3 Feed Size.....................................................................................................................................6

4.4 Collecting Bucket........................................................................................................................6

4.5 Instrument Size ..........................................................................................................................6

4.6 Weight........................................................................................................................................6

4.7Floor Space..................................................................................................................................6

5.0 Instrument Operation .....................................................................................................................7

5.1 Instrument Units(Fig 5.1.1~Fig 5.1.3)...................................................................................7

5.2 Units Function List......................................................................................................................8

5.3 Open/Close Grinding Chamber Door (Fig 5.3.1)...................................................................8

5.4 Install/Disassemble the Rotor Beater Grinding Set Accessories(Fig 5.4.1~5.4.6)................9

5.5 Collecting Bucket Installation (Fig 5.5)................................................................................10

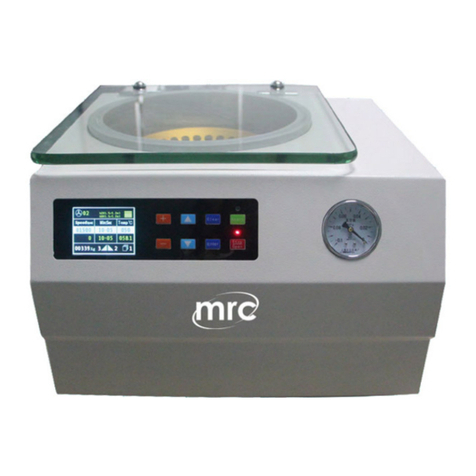

5.6 Control Panel(Fig 5.6) ...................................................................................11

5.7 Control Panel Function List ......................................................................................................11

5.8 Feed Sample Materials.............................................................................................................11

5.9 Preparation Before Grinding ....................................................................................................12

5.10 Start the Instrument...............................................................................................................12

5.11 Stop the Instrument...............................................................................................................12

5.12 Using the Cyclone...................................................................................................................12

5.13 Install the Cyclone..................................................................................................................13

5.14 Install the Vibratory Feeder VF200.........................................................................................14

6.0 Routine...........................................................................................................................................16

6.1 Clean.........................................................................................................................................16

6.2 Safety Switch and Safety Inspections.......................................................................................16

6.3 Maintenance ............................................................................................................................17

6.4 Accessories...............................................................................................................................17