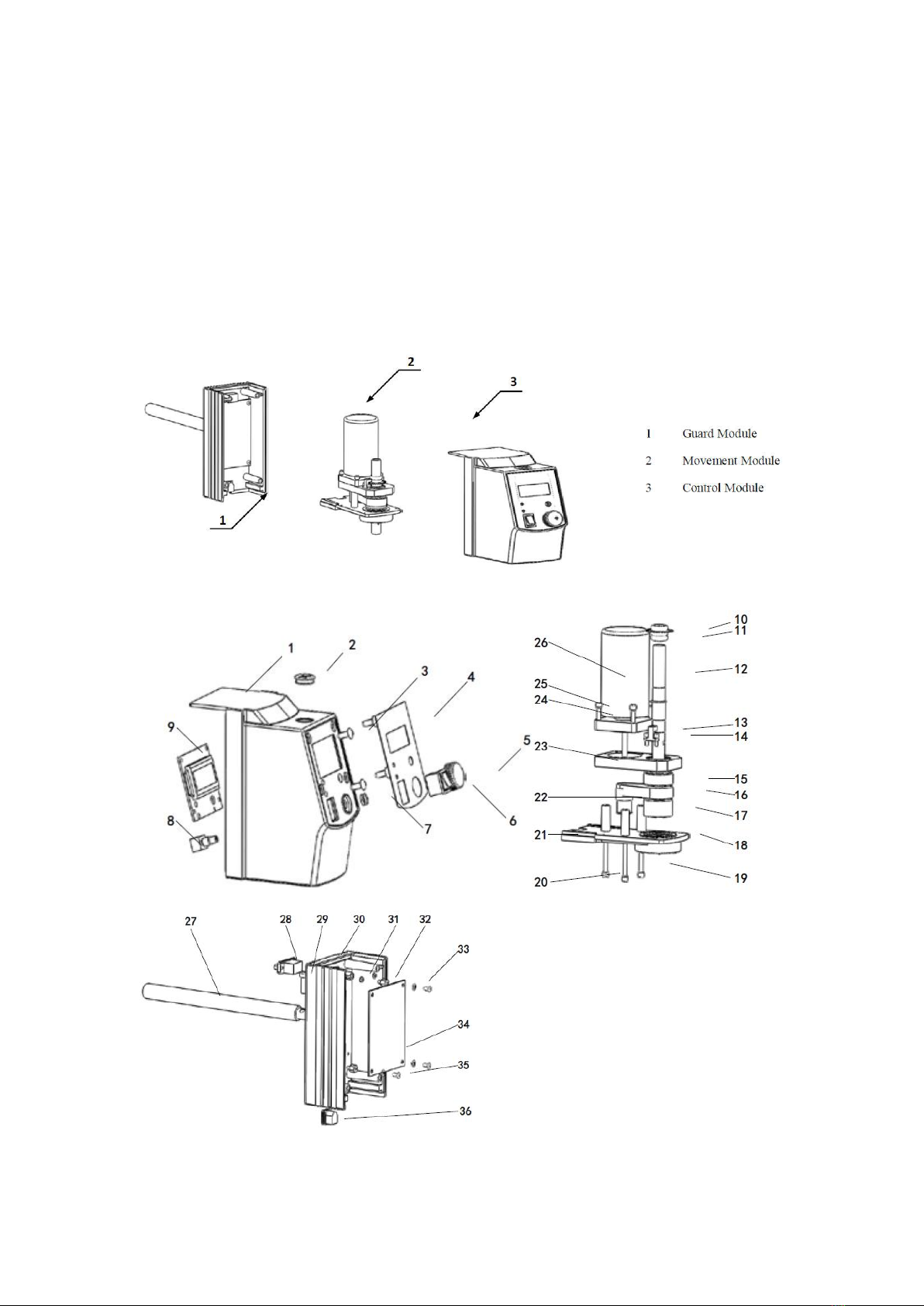

3

1 Front Guard 2 Rubber Cap 3 Nail 4 Membrane

5 Knob 6 Power Switch 7 Knob Lock 8 Knob Switch

9 Master Control Board

10 Coded Disc 11 Rubber Ring 12 Shaft

13 Photoelectric switch

14 M3*10 Socket Hexagon Screw 15 Bearing

16 Belt

17 Spindle Pulley 18 Bearing 19 M4*35 Socket Hexagon Screw

20 Ø 4 Elastic Pad 21 Lower Support Plate

22 Motor Pulley 23 Motor Bearing Support

24 M4*15 Socket Hexagon Screw 25Ø 4 Elastic Pad 26 Motor

27 Rail 28 RS232 Interface 29 M5*16 Socket Hexagon Screw

30 Rear Guard 31 M3 Hexagon Nut 32 M3*6 Copper Stud 33 Ø Ceramic Gaskets

34 Driven Board 35 M3*6 Pan Head Screw 36 Power Outlet

Fig. 4 illustrates the structural components of OS40 (20)-Pro, and Fig. 5 is the Exploded View of

OS40 (20)-Pro. Guard module includes front guard, Membrane, knob, power switch, rubber cap,

LCD PCB, knob switch, and PCB clamp and so on. Control modules are consisted of rear guard,

Driven Board, power outlet, RS232 interface and bar and so on. The movement module is

composed of motor, coded disc, shaft, motor pulley, bearing pulley, bearing, belt, photoelectric

switch, lower support plate and so on.

Stirring: Motor drives shaft to rotate though pulley, and further the shaft drives stirring

impeller fixed on it to rotate. Thus, the target sample is stirred.

Speed feedback: the motor speed is accurately measured by the coded disc fixed on the Shaft

along with photoelectric switch and a feedback is given. (OS40(20)-Pro)

LCD display: LCD PCB is connected to Driven Board and displays user’s settings and current

equipment operation information.(OS40(20)-Pro)

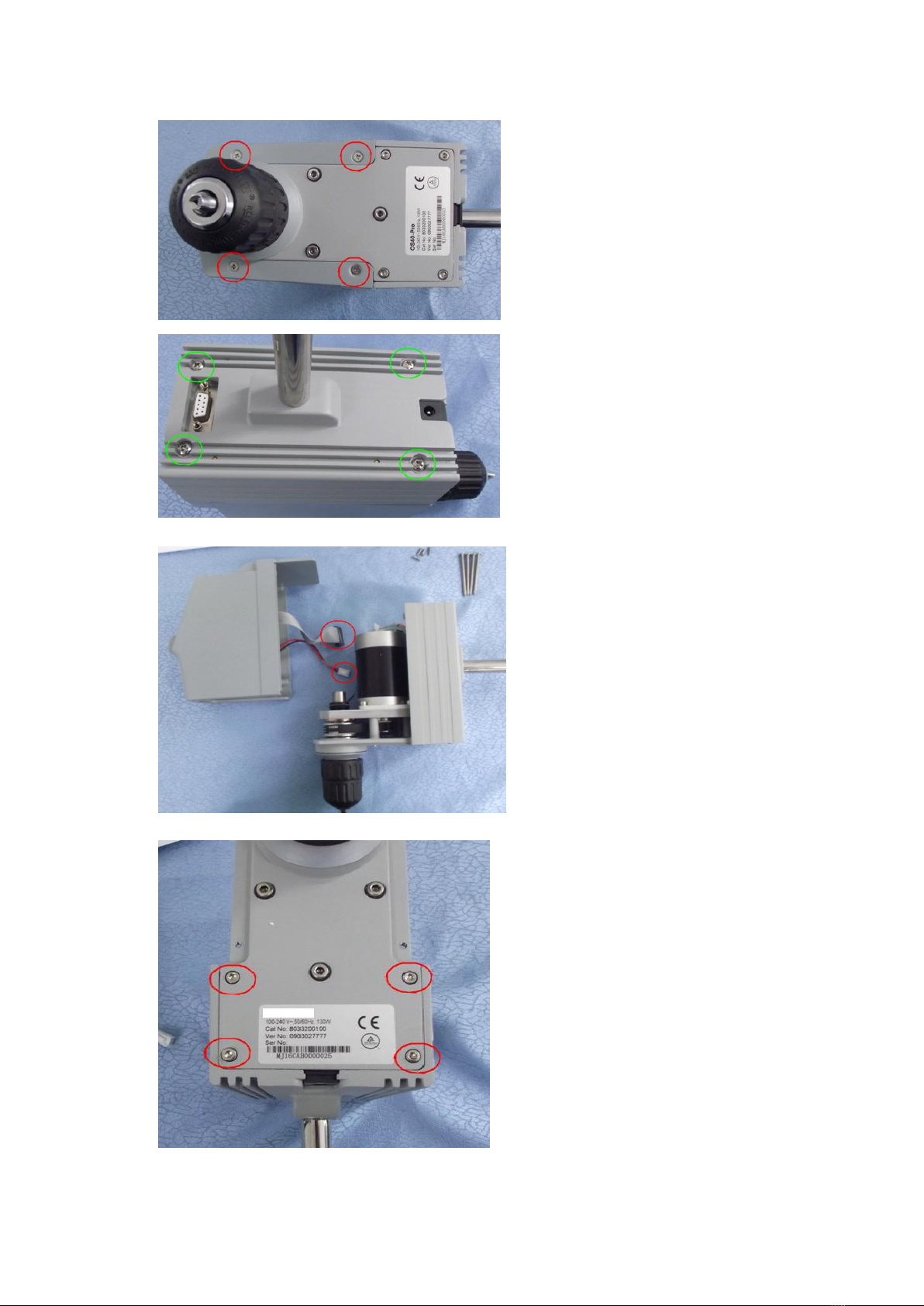

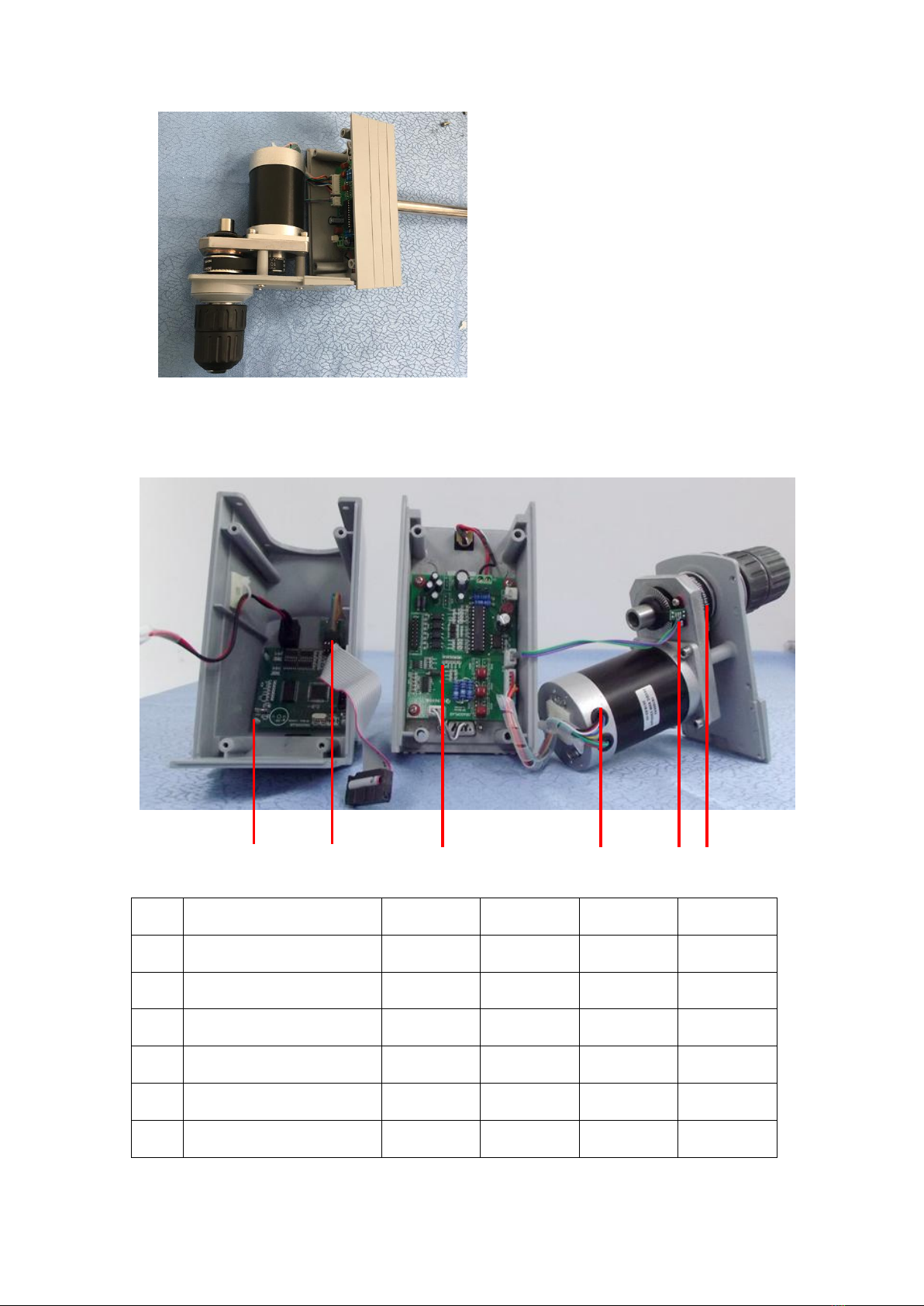

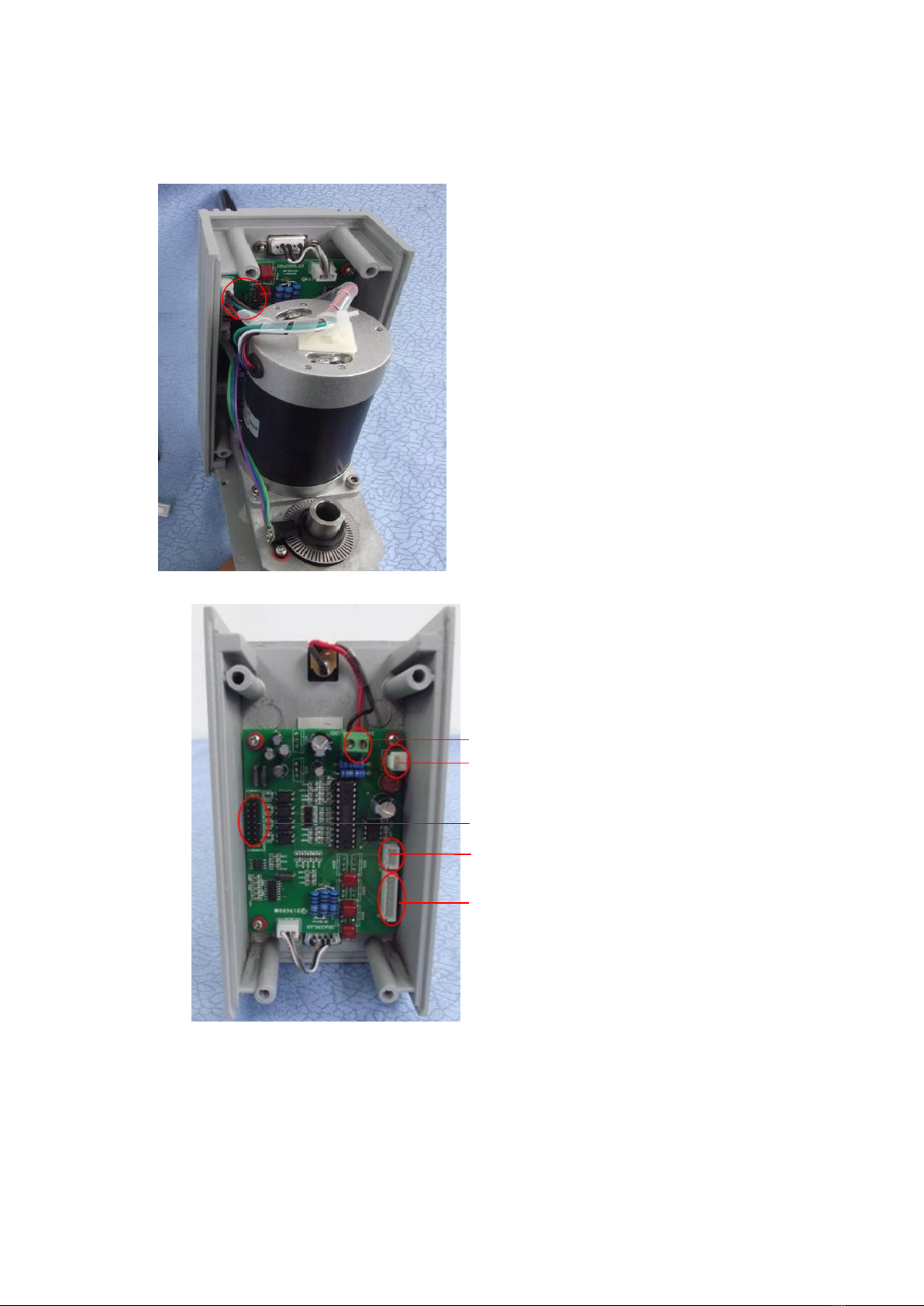

Chapter 2: Removal and Installation of Instrument

When instrument failure occurs, first, you should conduct a failure analysis; if the failure is caused

by the damage of instrument hardware, the related component must be repaired or replaced. Here

are the relevant contents of the replacement and disassembly of instrument.

2.1 Removal

Tool:Cross screwdriver