09/2011 - Art. Nr. 4200 1040 7900A 3

Important information

Burners

N6 and N7 GL-RZ3/LFL

are

designed for the combustion of natural

gas and light oil. The design and

function of the burners comply with

EN676 and EN 267. They are designed

for use with systems that are approved

for the use of burners in accordance with

EN 676 and EN 267.. To use the burner

with heat generators in conformity with

Pressure Equipment Directive 97/23/

EU, special burner components are

required (not supplied with standard

equipment). Before using the burner

with equipment of this type, the

equipment characteristics must be

checked. Burners that comply with

Pressure Equipment Directive 97/23/EU

come with a declaration of conformity to

this effect and are labelled on the identi-

fication plate. Any other type of applica-

tion requires the approval of ELCO. The

burner may only be used in accordance

with the instructions set out in this docu-

mentation and the relevant technical

data. If not used properly, it could cause

damage to property and the environ-

ment and personal injury. Furthermore,

the burner would no longer be CE com-

pliant. Installation, commissioning and

maintenance may only be carried out by

authorised specialists and all applicable

guidelines and regulations must be

complied with.

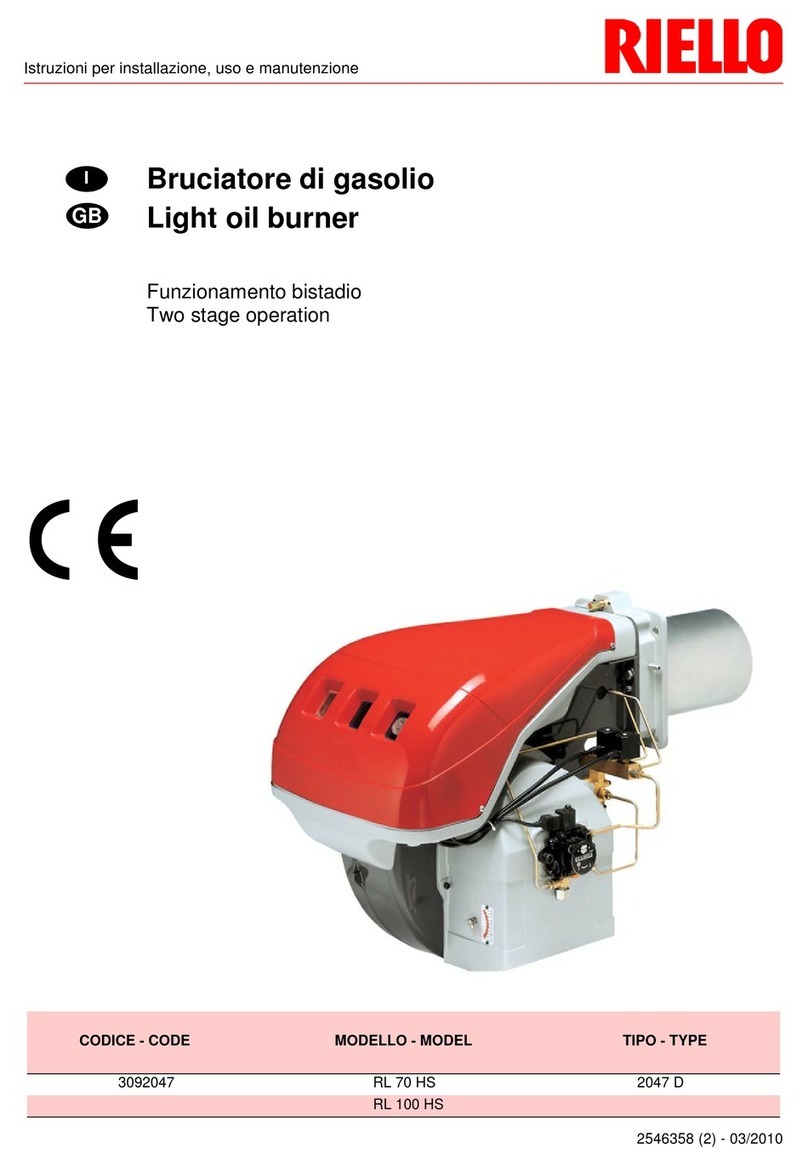

Burner description

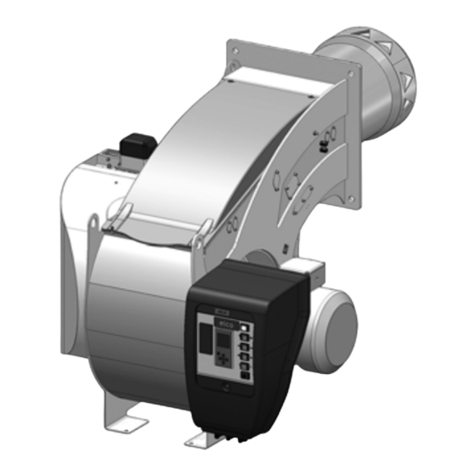

The burners

N6 and N7 GL-RZ3/LFL

are

progressive, fully automatic mechanical

monoblock-type burners for gas and 3-

stage for fuel oil. Emissions rates may

differ, depending on combustion

chamber dimensions, combustion

chamber load and the furnace (three-

pass boilers, boilers with reverse firing).

For specifying warranty values, the con-

ditions for the measuring equipment, tol-

erances and humidity must be observed.

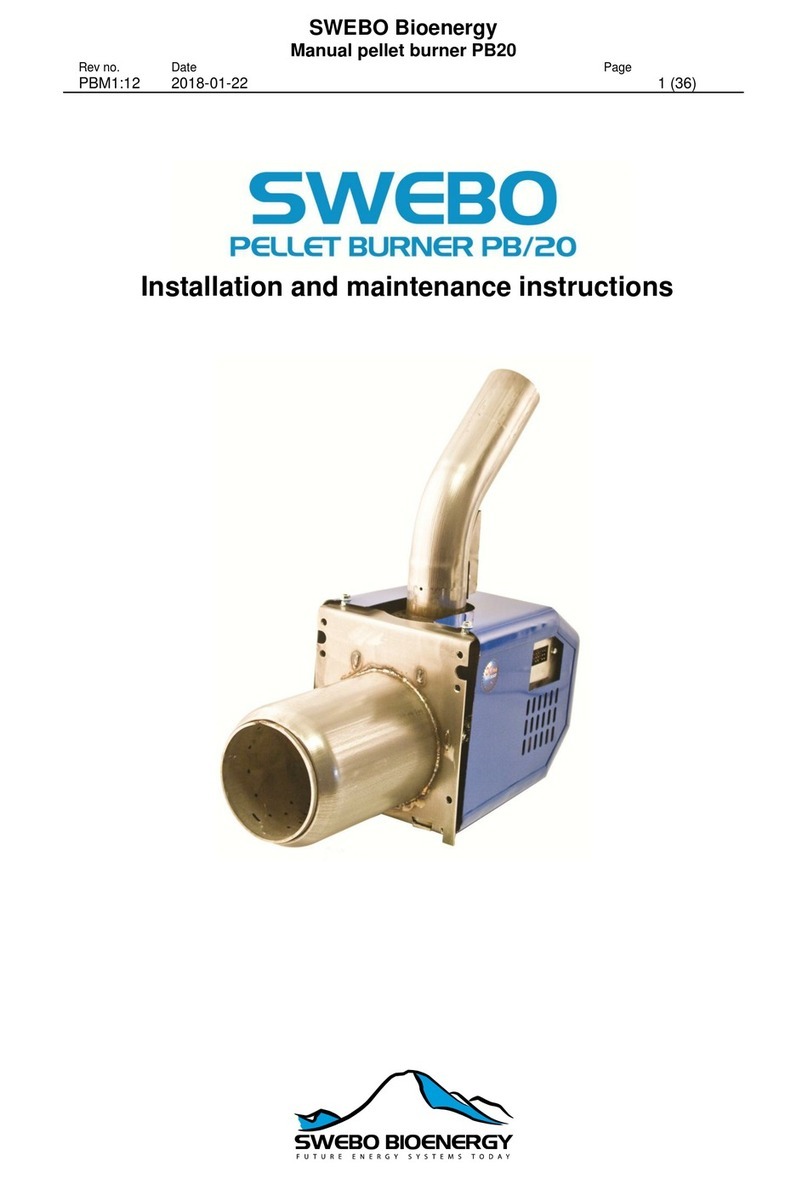

Scope of delivery

The burner is supplied packaged in

three boxes on a pallet:

- Burner with:

- integrated switch cabinet

- flange seal and securing screws

- operating instructions, circuit

diagram and spare parts list

- Burner head

- Compact gas train with gas filter

Before commissioning, a check must be

carried out to ensure that the product

delivered complies with the scope of

delivery.

The following standards should be

observed in order to ensure safe, envi-

ronmentally sound and energy-efficient

operation:

EN 226

Connection of fuel oil and forced-

draught gas burners with fan to a heat

generator

EN 60335-1, -2-102

Specification for safety of household

and similar electrical appliances, partic-

ular requirements for gas burning appli-

ances

DIN EN 60204-1

Safety of machinery. Electrical

equipment of machines

DIN EN 50156-1

Electrical equipment for furnaces

Gas lines

When installing the gas lines and trains,

the general directives and guidelines, as

well as the following national regula-

tions, must be observed:

CH: - SVGW-Gasleitsätze G1

- Vorschriften der kantonalen

Instanzen (SVGW Gas Direc-

tives G1 - Cantonal specifi-

cations) (e.g. fire authority

specifications)

DE: - DVGW-TVR/TRGI

Installation location

The burner must not be used in rooms

with aggressive vapours (e.g. hair spray,

tetrachloroethylene, carbon tetrachlo-

ride), high levels of dust or high air

humidity (e.g. laundry rooms). The limi-

tations of use set out in the technical

data must be complied with.

Adequate provision must be made for

the supply of combustion air. Given

standard conditions, the combustion air

requirement may be calculated as

follows:

Vl [Nm³/h] = QF [kW] *1.25 [Nm³/(h*kW)]

We can accept no warranty liability

whatsoever for loss, damage or injury

caused by any of the following:

- inappropriate use

- incorrect installation and/or repair on

the part of the buyer or any third party,

including the fitting of non-original

parts

Final delivery and instructions for

use

The furnace fitter must supply the

operator of the system with operating

and maintenance instructions on or

before final delivery. These instructions

should be displayed in a prominent

location at the point of installation of the

heat generator. They should include the

address and telephone number of the

nearest customer service centre.

Notes for the operator

The system should be inspected by a

specialist at least once a year. It is

advisable to take out a maintenance

contract to guarantee regular servicing.

Warning:

When in operation, the burner produces

an electromagnetic field. In certain cir-

cumstances, this field could affect

medical implants (e.g. pacemakers).

Before working with the machine,

anyone who has a medical implant

should consult their doctor and the man-

ufacturer of the medical implant in order

to reduce the risk of serious or fatal

injury.

Transport \ packaging \ storage

Safety measures

The burner and accessories must be

transported and stored using suitable

lifting equipment, means of transport

and tools. The safety instructions must

be complied with.

Transport

Depending on the size and weight of

packaging, burners and accessories

must be transported manually or with the

use of suitable aids. The transport

instructions on the packaging must be

complied with. The burner must be

properly secured for transport. If

measures to secure the burner have not

been taken at the factory, suitable

measures to secure it during transporta-

tion must be taken.

Packaging

The burner and accessories are placed

on a wooden pallet and shrink-wrapped.

When unpacking the product, suitable

lifting equipment and tools must be used

to remove the screw connections and

clamping devices between the burner

and the packaging. Suitable protective

clothing must be worn (gloves, safety

shoes).

Storage

In order to protect the burner from envi-

ronmental influences, it must be placed

in a dry, locked room when stored tem-

porarily. For the maximum storage tem-

peratures, please refer to the technical

data sheet.

Disposal The current local leg-

islation must be

complied with without

fail.

General information

Important notes