elco FS200 IM User manual

Manual

ELCO FS200

IM FS2-GW-DP00

Order No.: ELCO FS2-GW-DP00

This manual is part of the documentation package

with order number ELCO FS200_IM and relevant for:

Product Order number as of state:

HW FW

IM FS200 FS2-GW-DP00 01 2.03

Manual ELCO Intelligent I/O-FS200 About this manual

Subject to change to cater for technical progress.

The information contained in this manual is supplied without warranties.

The information is subject to change without notice.

© Copyright 2011, ELCO(Tianjin)ELECTRONIC CO,.LTD.

Tel.: +86 (22) 23888288/23788282

Fax.: +86 (22) 23788399

http://www.elco-holding.com.cn

Hotline:+86 (22) 23788282

All rights reserved

The contents of this manual were verified with respect to the hard- and

software.

However, we assume no responsibility for any discrepancies or errors. The

information in this manual is verified on a regular basis and any required

corrections will be included in subsequent editions.

Suggestions for improvement are always welcome.

ELCO and FS200

are registered trademarks of ELCO(Tianjin)ELECTRONICS CO,.LTD.

SPEED7

is a registered trademark of profichip GmbH

SIMATIC, STEP and S7-300

are registered trademarks of Siemens AG.

Any other trademarks referred to in the text are the trademarks of the

respective owner and we acknowledge their registration.

Disclaimer of

liability

Trademarks

No.12,4th XEDA Branch Road,Xiqing Economic Development Area,

Tianjin 300385,P.R.China

Tel.: +86 (22) 23888288/23788282

About this manual

Subject to change to cater for technical progress.

About this manual

This manual describes the FS200 bus coupler for Profibus DP of

commissioning and operation.

Chapter 1: Basics and Assembly

found.

Chapter 2: Hardware description

Here the hardware components of the FS200 are more described.

You will find the technical data at the end of this chapter.

Chapter 3: Deployment

This chapter describes the usage of the FS200 with Profibus. After

a short introduction you may find here every information about assembly,

project engineering and diagnostic. The chapter closes with the description

of the firmware update.

Overview

Manual ELCO Intelligent I/O-FS200

the System intelligent I/O from ELCO.

Here you may find every information for

The focus of this chapter is on the introduction of the ELCO Intelligent I/O

Besides the dimensions the general technical data of System FS200 will

be

FS200. Here you will find the information required to assemble and

wire a controller system consisting of System FS200 components.

Manual ELCO intelligent I/O-FS200 Contents

i

Contents

User considerations.................................................................................1

Safety information....................................................................................2

Chapter 1 Basics and Assembly .....................................................1-1

Safety Information for Users................................................................. 1-2

System conception............................................................................... 1-3

Dimensions .......................................................................................... 1-6

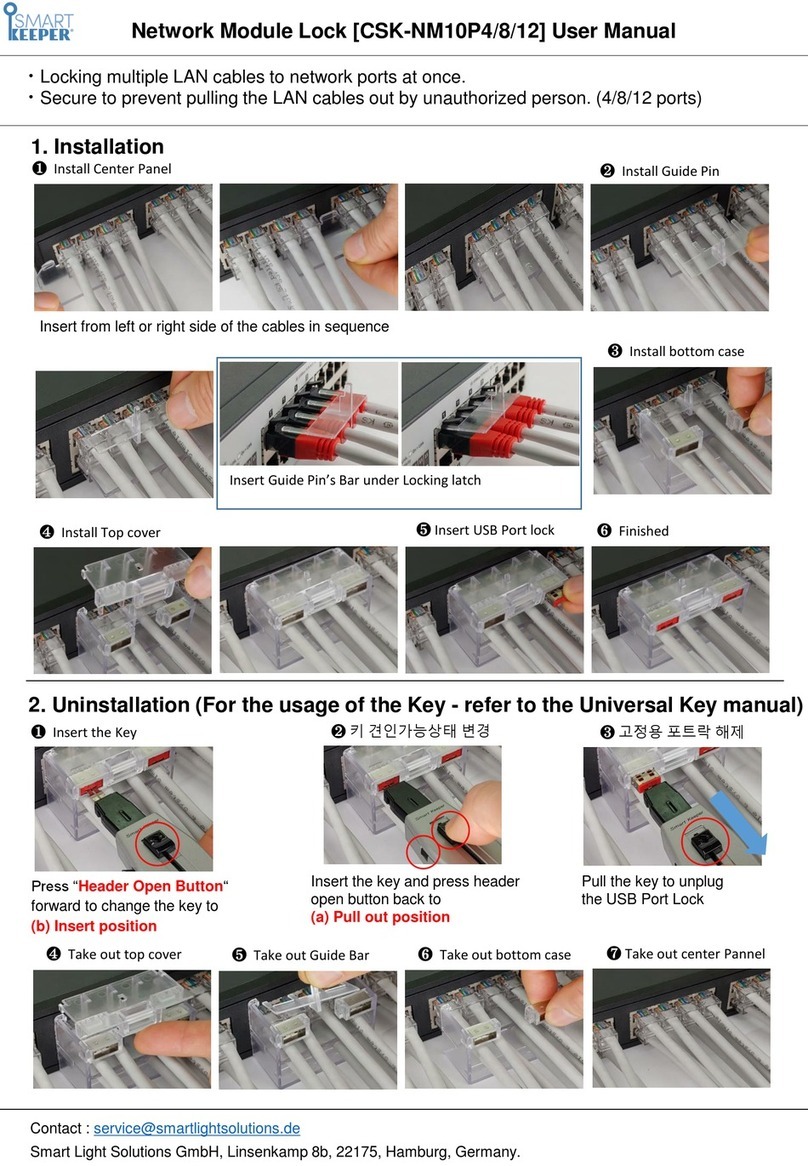

Installation............................................................................................ 1-7

Wiring................................................................................................. 1-11

Installation guidelines ......................................................................... 1-14

General data ...................................................................................... 1-17

Chapter 2 Hardware description .....................................................2-1

Properties............................................................................................. 2-2

Structure .............................................................................................. 2-3

Technical data...................................................................................... 2-6

Chapter 3 Deployment .....................................................................3-1

Basics .................................................................................................. 3-2

Project engineering ............................................................................ 3-10

DP-V1 services .................................................................................. 3-13

DP-V1 - I&M data ............................................................................... 3-15

Profibus installation guidelines ........................................................... 3-17

Diagnostic functions ........................................................................... 3-20

Firmware update ................................................................................ 3-28

Contents

ii

Manual ELCO intelligent I/O-FS200

Manual ELCO Intelligent I/O-FS200 User considerations

1

User considerations

This manual describes the FS2-GW-DP00 of the Intelligent I/O from ELCO. It

contains a description of the structure, project engineering and

deployment.

The manual is targeted at users who have a background in automation

technology.

The manual consists of chapters. Every chapter provides a self-contained

description of a specific topic.

The following guides are available in the manual:

• an overall table of contents at the beginning of the manual

• an overview of the topics for every chapter

The manual is available in:

• printed form, on paper

• in electronic form as PDF-file (Adobe Acrobat Reader)

Important passages in the text are highlighted by following icons and

headings:

Danger!

Immediate or likely danger.

Personal injury is possible.

Attention!

Damages to property is likely if these warnings are not heeded.

Note!

Supplementary information and useful tips.

Objective and

contents

Target audience

Structure of the

manual

Guide to the

document

Availability

Icons

Headings

Safety information

2

Safety information

The Intelligent I/O FS200 is constructed and produced for:

• communication and process control

• general control and automation applications

• industrial applications

• operation within the environmental conditions specified in the technical

data

• installation into a cubicle

Danger!

This device is not certified for applications in

• in explosive environments (EX-zone)

The manual must be available to all personnel in the

• project design department

• installation department

• commissioning

• operation

The following conditions must be met before using or commissioning

the components described in this manual:

• Modification to the process control system should only be carried out

when the system has been disconnected from power!

• Installation and modifications only by properly trained personnel

• The national rules and regulations of the respective country must be

satisfied (installation, safety, EMC ...)

National rules and regulations apply to the disposal of the unit!

Applications

conforming with

specifications

Documentation

Disposal

Manual ELCO Intelligent I/O-FS200

Chapter 1 Basics and Assembly

1-1

Chapter 1 Basics and Assembly

The focus of this chapter is on the introduction of the ELCO FS200.

Here you will find the information required to assemble and wire a

controller system consisting of FS200 components.

Besides the dimensions the general technical data of FS200 will be

found.

Topic Page

Chapter 1 Basics and Assembly .....................................................1-1

Safety Information for Users................................................................. 1-2

System conception............................................................................... 1-3

Dimensions .......................................................................................... 1-6

Installation............................................................................................ 1-7

Wiring................................................................................................. 1-11

Installation guidelines ......................................................................... 1-14

General data ...................................................................................... 1-17

Overview

Content

Manual ELCO Intelligent I/O-FS200

Chapter 1 Basics and Assembly

1-2

Safety Information for Users

ELCO modules make use of highly integrated components in MOS-

Technology. These components are extremely sensitive to over-voltages

that can occur during electrostatic discharges.

The following symbol is attached to modules that can be destroyed by

electrostatic discharges.

The Symbol is located on the module, the module rack or on packing

material and it indicates the presence of electrostatic sensitive equipment.

It is possible that electrostatic sensitive equipment is destroyed by energies

and voltages that are far less than the human threshold of perception.

These voltages can occur where persons do not discharge themselves

before handling electrostatic sensitive modules and they can damage

components thereby, causing the module to become inoperable or

unusable.

Modules that have been damaged by electrostatic discharges can fail after

a temperature change, mechanical shock or changes in the electrical load.

Only the consequent implementation of protection devices and meticulous

attention to the applicable rules and regulations for handling the respective

equipment can prevent failures of electrostatic sensitive modules.

Modules must be shipped in the original packing material.

When you are conducting measurements on electrostatic sensitive

modules you should take the following precautions:

• Floating instruments must be discharged before use.

• Instruments must be grounded.

Modifying electrostatic sensitive modules you should only use soldering

irons with grounded tips.

Attention!

Personnel and instruments should be grounded when working on

electrostatic sensitive modules.

Handling of

electrostatic

sensitive modules

Shipping of

modules

Measurements and

alterations on

electrostatic

sensitive modules

Manual ELCO Intelligent I/O-FS200

Manual ELCO Intelligent I/O-FS200 Chapter 1 Basics and Assembly

1-3

System conception

ELCO FS200 is a modular automation system for assembly on a 35mm

mounting rail. By means of the peripheral modules with 2, 4 or 8 channels

this system may properly be adapted matching to your automation tasks.

The wiring complexity is low, because the supply of the DC 24V power

section is integrated to the backplane bus and defective modules may be

replaced with standing wiring.

By deployment of the power modules in contrasting colors within the

system, further isolated areas may be defined for the DC 24V power

section supply.

The FS200 consists of the following components:

• Bus coupler

• Periphery modules

• Power modules

• Accessories

With a bus coupler bus interface and power

module is integrated to one casing. With the bus

interface you get access to a subordinated bus

system.

Via the integrated power module for power supply

the bus interface is supplied as well as the

electronic of the connected periphery modules.

The DC 24 power section supply for the linked

periphery modules is established via a further

connection.

By installing of up to 64 periphery modules at the

bus coupler, these are electrically connected, this

means these are assigned to the backplane bus,

the electronic modules are power supplied and

each periphery module is connected to the DC

24V power section supply.

Overview

Components

Bus coupler

Chapter 1 Basics and Assembly

Manual ELCO Intelligent I/O-FS200

1-4

Each periphery module consists of a terminal and an electronic module.

[1]

[2]

[1]

[2]

Terminal module

Electronic module

The terminal module serves to carry the electronic

module, contains the backplane bus with power supply

for the electronic, the DC 24V power section supply and

the staircase-shaped terminal for wiring.

Additionally the terminal module has a locking system

for fixing at a mounting rail.

By means of this locking system your FS200 may

be assembled outside of your switchgear cabinet to be

later mounted there as whole system.

The functionality of a FS200 periphery module is defined

by the electronic module, which is mounted to the

terminal module by a save sliding mechanism.

With an error the defective module may be exchanged

for a functional module with standing installation.

By an integrated coding only the modules may be

plugged, which may be combined.

At the front side there are LEDs for status indication.

For simple wiring each module shows a corresponding

connection diagram at the front and at the side.

In the FS200 the power supply is established by

power modules. These are either integrated to the bus

coupler or may be installed between the periphery

modules to define isolated areas of the DC 24V power

section supply.

For better recognition the color of the power modules

are contrasting to the periphery modules.

Periphery modules

Terminal module

Electronic module

Power module

Chapter 1 Basics and Assembly

1-5

The shield bus carrier serves to carry the shield bus to

connect cable shields.

Shield bus carriers, shield bus and shield fixings are not

in the scope of delivery. They are only available as

accessories.

The shield bus carrier is mounted underneath the

terminal of the terminal module.

With a flat mounting rail for adaption to a flat mounting

rail you may remove the spacer of the shield bus carrier.

With each bus coupler, to protect the backplane bus

connectors, there is a mounted bus cover in the scope

of delivery.

You have to remove the bus cover of the bus coupler

before mounting a FS200 module.

For the protection of the backplane bus connector you

should always mount the bus cover at the last module of

your system again.

Accessories

Shield bus carrier

Bus cover

Manual ELCO Intelligent I/O-FS200

Chapter 1 Basics and Assembly Manual ELCO Intelligent I/O-FS200

1-6

Dimensions

104

109

76.5 48.5

104

109

76.5

15

133

12.5

58

62 12.5

Dimensions in mm

Dimensions

bus coupler

Dimensions

periphery module

Dimensions

electronic module

Manual ELCO Intelligent I/O-FS200 Chapter 1 Basics and Assembly

1-7

Installation

There is a locking lever at the top side of the terminal module. For

mounting and de-mounting this locking lever is to turn upwards until this

engages audible.

Now the module may be pulled forward.

For mounting plug the module to the module installed before and push the

module to the mounting rail guided by the strips at the upper and lower side

of the module.

The module is fixed to the mounting rail by pushing downwards the locking

lever.

The modules may either separately be mounted to the mounting rail or as

block. Here is to be considered that each locking lever is opened.

Clack

1 2 3

For mounting between 2 modules and for the exchange of a defective

electronic module, the electronic module may be pulled forward after

pressing the unlocking lever at the lower side of the module.

For installation plug the electronic module guided by the strips at the lower

side until this engages audible to the terminal module.

1. Press

2. Pull

Clack

Functional

principle

Mounting

terminal module

Mounting

electronic

module

Chapter 1 Basics and Assembly

Manual ELCO Intelligent I/O-FS200

1-8

The modules were directly be mounted to the mounting rail and so

connected to the backplane bus and the power supply for the electronic

and power section.

Up to 64 modules may be mounted. Please consider here that the sum

current of the electronic power supply does not exceed the maximum value

of 3A.

• Mount the mounting rail! Please consider that a clearance from the

middle of the mounting rail of at least 80mm above and 60mm below,

respectively 80mm by deployment of shield bus carriers, exist.

80mm

80mm

60mm65mm

• Start at the left side with the head module (e.g. bus coupler). For this

turn both locking lever upwards, put the head module to the mounting

rail and turn both locking lever downwards.

• Before mounting the periphery modules you have to remove the bus

cover at the right side of the Head module by pulling it forward. Keep the

cover for later mounting.

1 2

Mounting

Proceeding

Mounting

mounting rail

Mounting

Head module

(e.g. bus coupler)

Chapter 1 Basics and Assembly

1-9

• Mount the periphery modules you want.

1 2

Clack

3

• After mounting the whole system, to protect the backplane bus

connectors the bus cover may now be mounted at the last module

The shield bus carrier (available as accessory) serves to carry the shield

bus to connect cable shields. The shield bus carrier is mounted underneath

the terminal of the terminal module. With a flat mounting rail for adaption to

a flat mounting rail you may remove the spacer of the shield bus carrier.

Clack

Mounting

periphery module

Mounting the

bus cover

Mounting

shield bus carrier

Manual ELCO Intelligent I/O-FS200

Chapter 1 Basics and Assembly

Manual ELCO Intelligent I/O-FS200

1-10

With the mounting of a FS200 module respectively of a group of FS200

modules between two modules for mounting reasons you have always to

remove the electronic module of the just mounted right module. After that it

may be plugged again.

To mount the module put it to the gap between the both modules and push

it, guided by the stripes at both sides, to the mounting rail.

12 3 4

With mounting respectively de-mounting of a module group you also have

to remove the electronic module of the just mounted right module! After

mounting it may be plugged again.

For mounting respectively de-mounting the locking lever of the modules of

the block must be turned upwards.

To mount the group of modules put them to the gap between the both

modules and push it, guided by the stripes at both sides, to the mounting

rail.

After mounting the block turn each locking lever of the modules

downwards.

Clack

Mounting

between 2

modules

1 module group

between 2 modules

Manual ELCO Intelligent I/O-FS200 Chapter 1 Basics and Assembly

1-11

Wiring

DC24V

0V

DC24V

0V

1

2

DC24V max. 10A

SysDC5V max. 3A

[1] DC 24V Power section supply I/O area

[2] DC 24V Electronic power supply bus coupler and I/O area

Note!

Power section and electronic power section supply are internally protected

against higher voltage by fuses. The fuses are within the power module. If

one fuse released, its electronic module must be exchanged!

It is recommended to protect the power section supply with a fast 10A fuse

and the electronic power supply with a fast 4A fuse.

Standard wiring

Chapter 1 Basics and Assembly

Manual ELCO Intelligent I/O-FS200

1-12

If the 10A for the power section supply is no longer sufficient, you may use

the power module from ELCO with the order number FS2-PS-AB00.

So you have also the possibility to define isolated groups.

The following figure should illustrate the usage of the power modules.

007-1AB00

Sys DC 5V: ---

DC 24V: 10A

007-1AB00

Sys DC 5V: ---

DC 24V: 10A

DC24V

0V

DC24V

0V

DC24V max. 10A

SysDC5V max. 3A

DC24V max. 10A DC24V max. 10A

DC24V

0V

DC24V

0V

1

2

1 1

[1] DC 24V Power section supply I/O area

[2] DC 24V Electronic power supply bus coupler and I/O area

Definition of

isolated groups

Manual ELCO Intelligent I/O-FS200 Chapter 1 Basics and Assembly

1-13

To attach the shield the mounting of shield bus carriers are necessary.

The shield bus carrier (available as accessory) serves to carry the shield

bus to connect cable shields.

The shield bus carrier is mounted underneath the terminal of the terminal

module. With a flat mounting rail for adaption to a flat mounting rail you

may remove the spacer of the shield bus carrier.

After mounting the shield bus carrier with the shield bus, the cables with

the accordingly stripped cable screen may be attached and fixed by the

shield clamp.

Clack

1

2

3

4

[1] Shield bus carrier

[2] Shield bus

[3] Shield clamp

[4] Cable shield

Shield attachment

Table of contents

Other elco Control Unit manuals

Popular Control Unit manuals by other brands

BERMAD

BERMAD 42T Installation operation & maintenance

Nordson

Nordson Tribomatic II Customer product manual

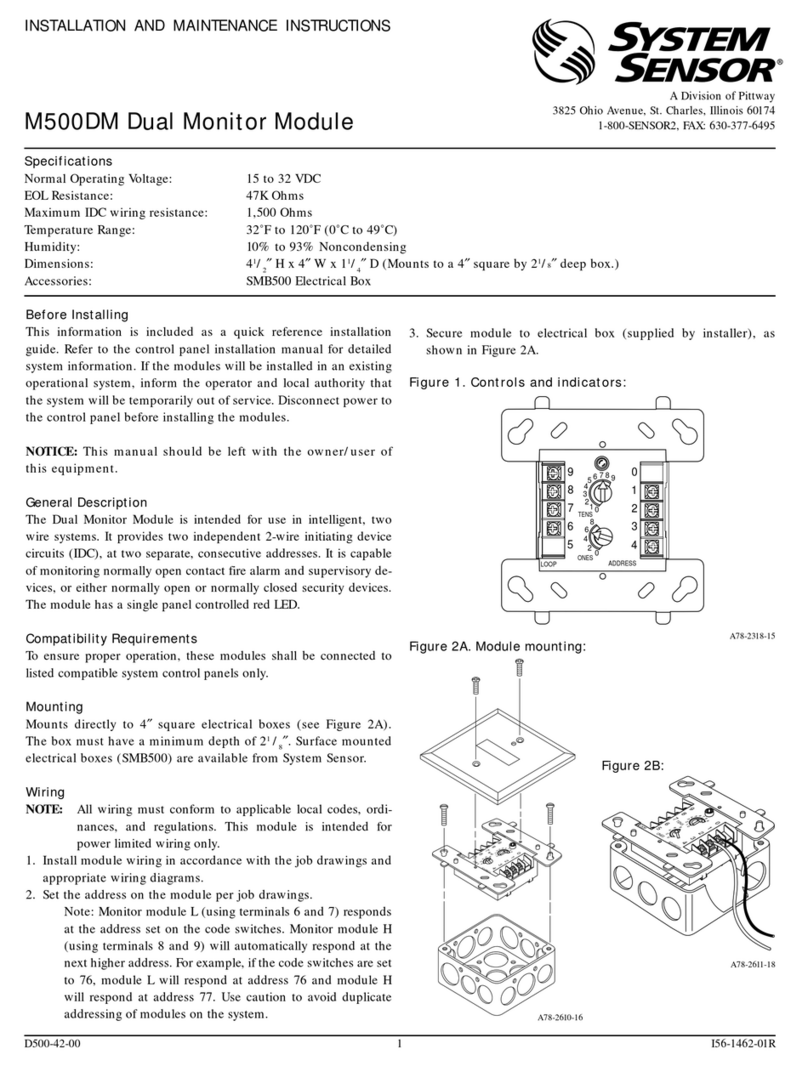

Pittway

Pittway SYSTEM SENSOR M500DM Installation and maintenance instructions

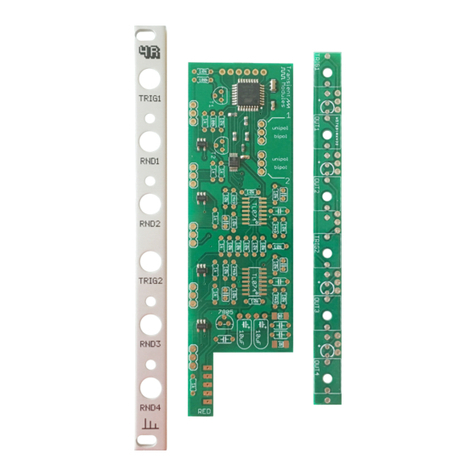

Transient Modules

Transient Modules 4R Build manual

Domestia

Domestia DMC-012-003 S manual

Axetris

Axetris LGD Compact Integration guide