Page 3 of 12

4. Installation

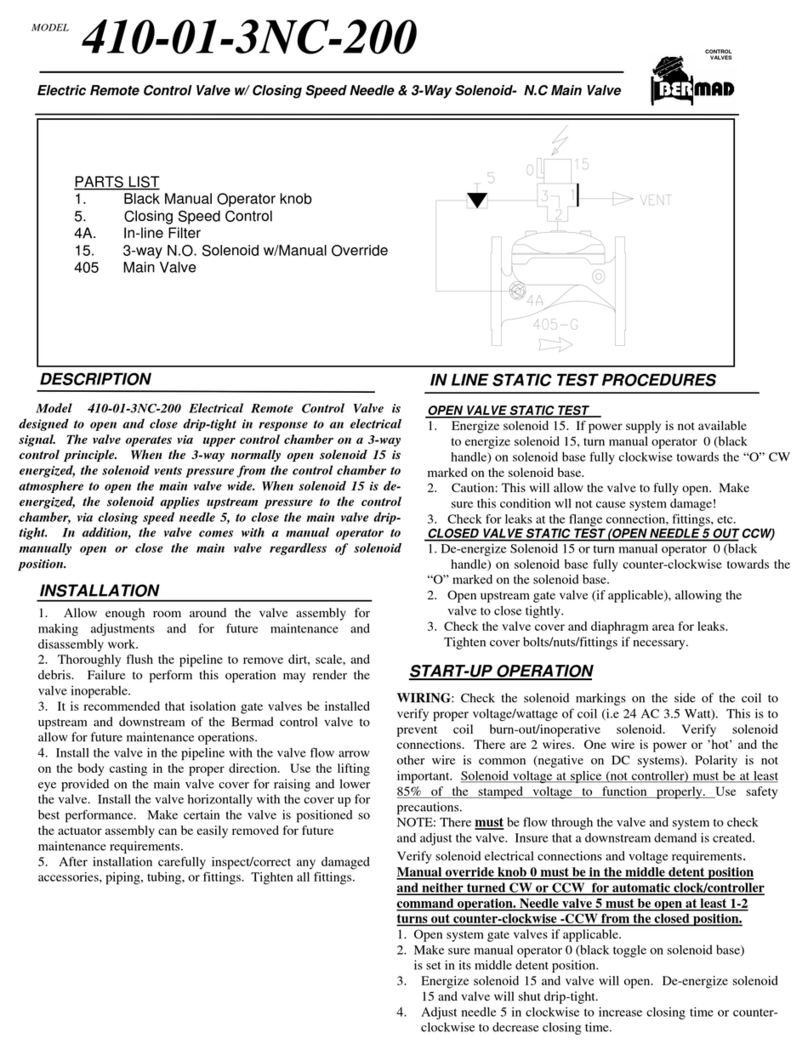

4.1 Allow enough room around the Bermad 42T pressure reducing valve assembly for any adjustments and future

maintenance/disassembly work.

4.2 Before the valve is installed, flush the pipeline to remove any dirt, scale, debris, etc. Failure to do this might result in the

valve being rendered inoperable.

4.3 UL-listed and FM approved indicating isolation valves should be installed upstream and downstream of the Bermad 42T

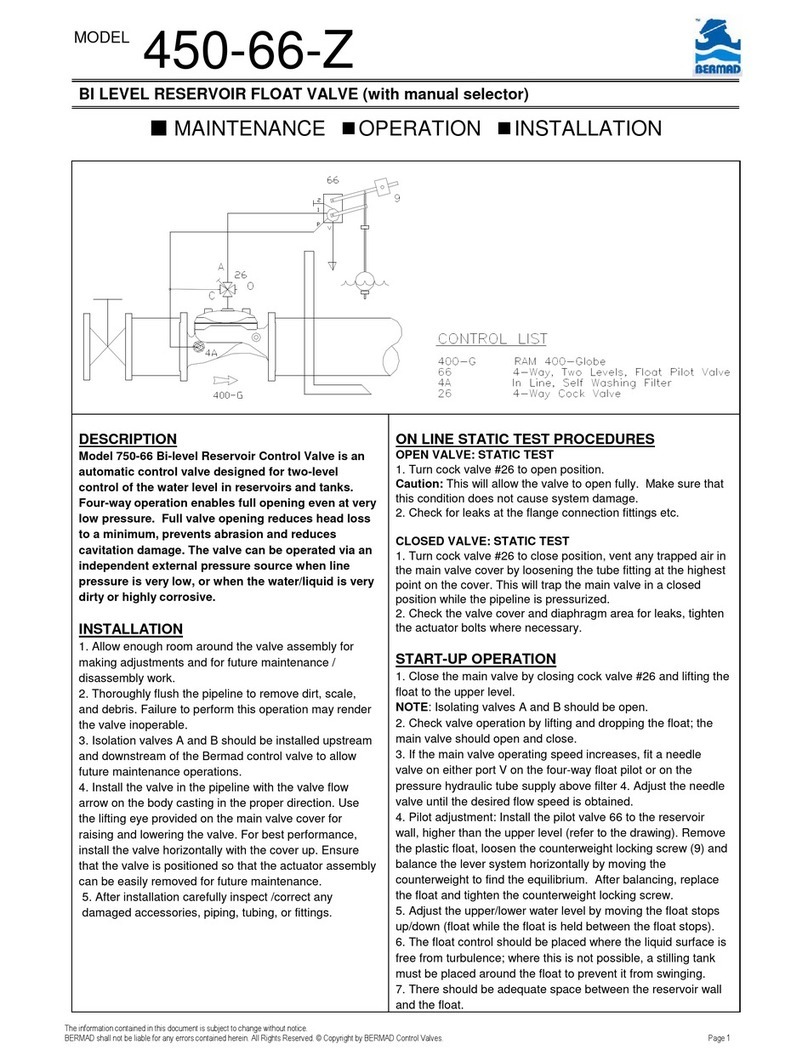

pressure-reducing valve to allow future maintenance, see fig. 1.

4.4 Using the lifting eye provided on the main valve cover for lifting and lowering the valve. Install the valve in the pipeline with

the valve flow arrow on the body casing in the proper direction.

Note: A small diameter bypass pressure-reducing valve may be required when large diameter pressure-reducing valve is used, to

accommodate low flow conditions such as those created by the flow of a hose connection or a single sprinkler.

4.5 The Bermad 42T pressure-reducing valve is suitable for horizontal or vertical installation. Ensure that the valve is positioned

so that the cover is facing upwards and can be easily removed for future maintenance.

4.6 After installation, carefully inspect/correct any damaged accessories, piping, tubing, or fittings.

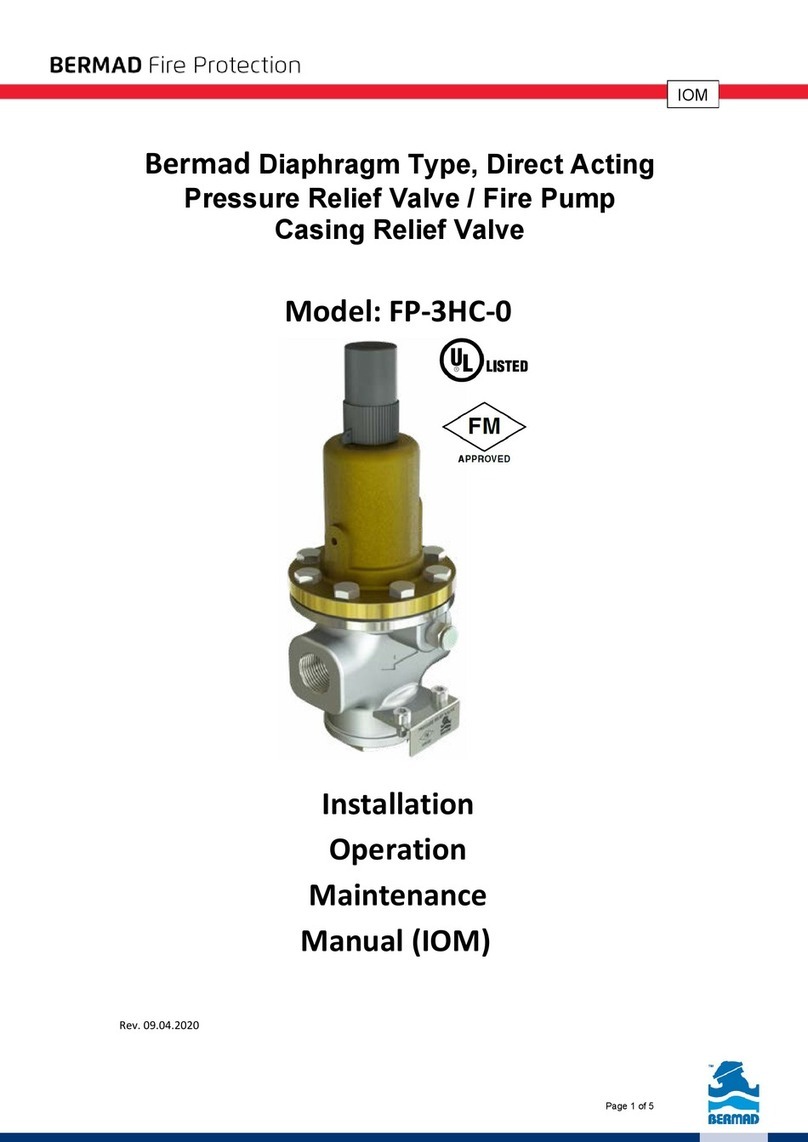

4.7 A UL-listed and FM approved pressure relief valve with a proper size must be installed with every pressure control valve.

Note: The pressure relief valve shall be set to open at 0.5 – 1.0 bar (8 – 16 psi) above the 400Y pilot valve setting.

4.8 Install a listed pressure gauge on both the upstream & downstream of the Pressure Control Valve; see fig. 1 for indicated

installation.

4.9 Install the Bermad 42T pressure-reducing valve in accordance with the Standard for Installation of Fire Sprinkler Systems,

NFPA 13, or the Standard for Installation of Standpipe and Hose System, NFPA 14, as appropriate. The Bermad 42T pressure-

reducing valve is to be tested after installation in accordance with NFPA 13.

4.10 The Bermad 42T pressure-reducing valve is to be inspected, tested and maintained in accordance with the Standard for the

Inspection, Testing and Maintenance of Water-Based Fire Protection Systems, NFPA 25.

5. Factory Fitted Options

5.1 Valve Position Indicator (code I): This option provides the means for Visual indication of the Main Valve Position at all times

5.2 Valve Position Limit Switch (code S or S9): For Remote Indication of the Valve Position.

5.3 Large Control Filter (code F): Provides extra filtration capacity for the water supplied to the pilot system, it is recommended

for cases where there is any doubt as to the level of particulate matter in the water.

5.4 Valve Seat Ring (code T): Corrosion Resistant Seat Ring Inserted to the main valve.

5.5 Non Return Feature (code 20): Allows the valve to prevent return flow by adding check valves to the 42T pilot system, see

fig. 2B for operation principle and item 7 and 3B item 5 for specific arrangement.

5.6 Closing Speed Control (code 01): Allows valve

reaction speed adjustment, see fig. 2A / 2B item 3.

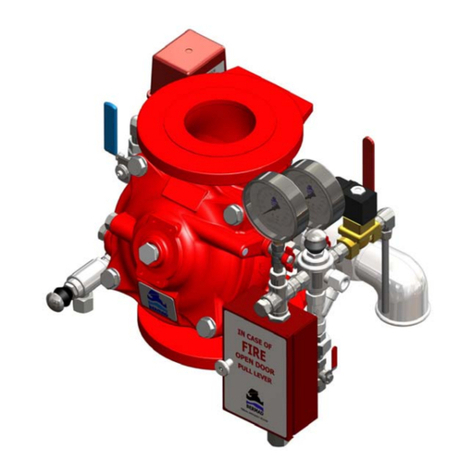

Figure 1B: Single Line Installation

Sprinkler System Pressure Reduction

Reduces a high, unstable pressure supply to a preset,

stable system pressure

Sets the sprinkler pressure to suit the system design

For zonal pressure control

Hose System Pressure Reduction

Reduces a high/unstable pressure supply to suit fire

hose pressure

Limits fire hose pressure to 7 bar (100 psi) to meet

NFPA 14 regulations for maximum allowable hose

pressure supply

Two-Stage Pressure Reduction

High pressure reduction ratio, when pressure

differential is more than 12 bar/175 psi

Redundancy Backup Pressure Reducing

Backup valve inline to a master valve to secure pressure

rating at all times.

NFPA-14 requires that failure of a single device does not

allow pressure increase above the pressure rating