Electro-Air SC-924A Manual

OPERATION & MAINTENANCE MANUAL

MODEL SC-924A

SELF-CONTAINED

ELECTRONIC AIR CLEANER

IMPORTANT: PLEASE READ MANUAL BEFORE OPERATING UNIT

Certified for shock and electrical fire hazard only.

INTRODUCTION

DESCRIPTION

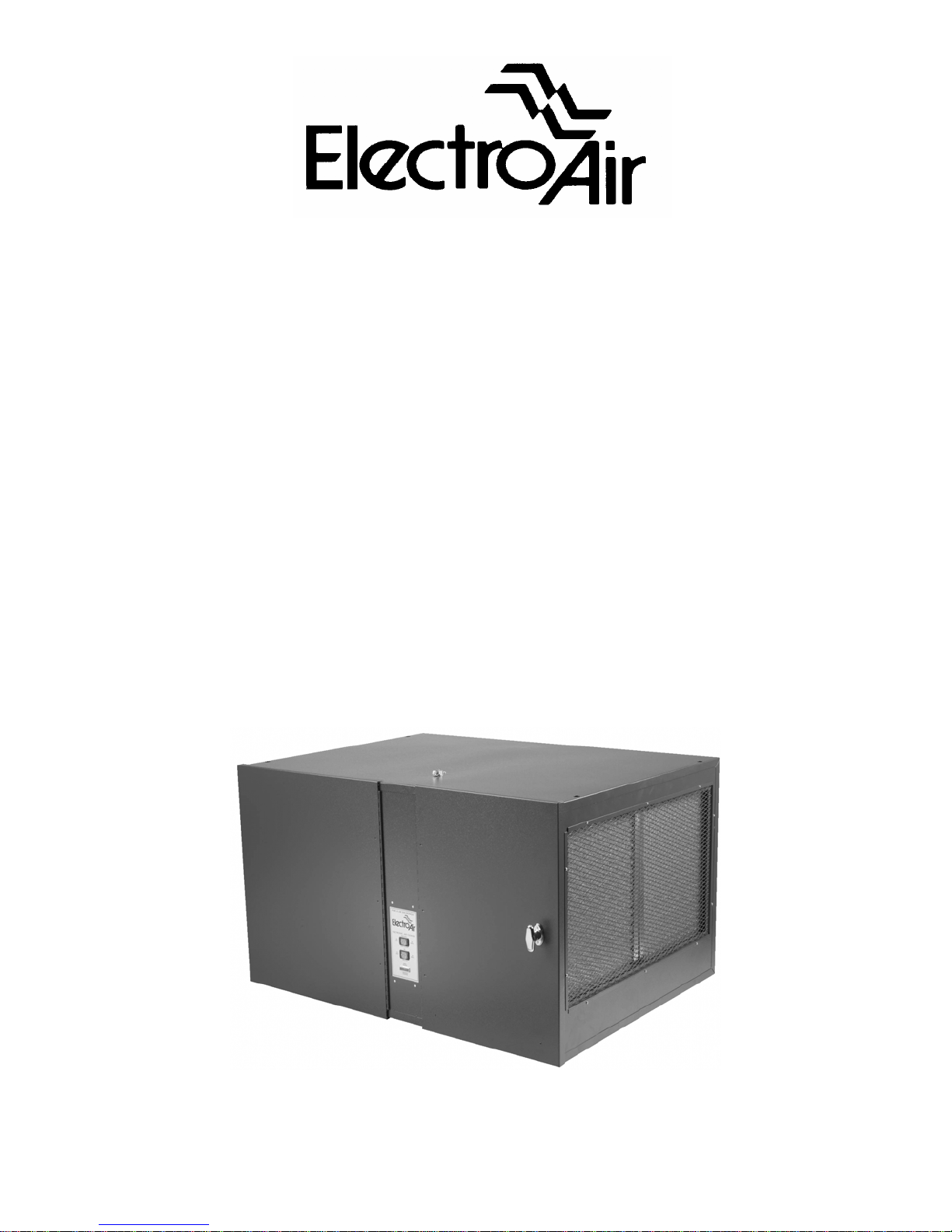

The SC Series Electronic Air Cleaners are self-contained

units comprised of collecting cell(s), electrical

compartment, blower and motor assembly, complete

cabinet housing, prefilter(s) and after filter(s) or optional

carbon filter(s).

There are two sizes available:

Model SC-910: up to 1100 CFM capacity at 90%

efficiency

Model SC-924: up to 2100 CFM capacity at 90%

efficiency

The efficiency of the above units are rated on the removal

of particulate matter down to .01 micron including welding

fumes, automotive grinding dust, oil mist and carbon

black dust. On larger particulate matter such as .03

micron, it is possible for efficiencies to reach as high as

99%. This is based on the ASHRAE standard Dust Spot

Test.

HOW IT WORKS

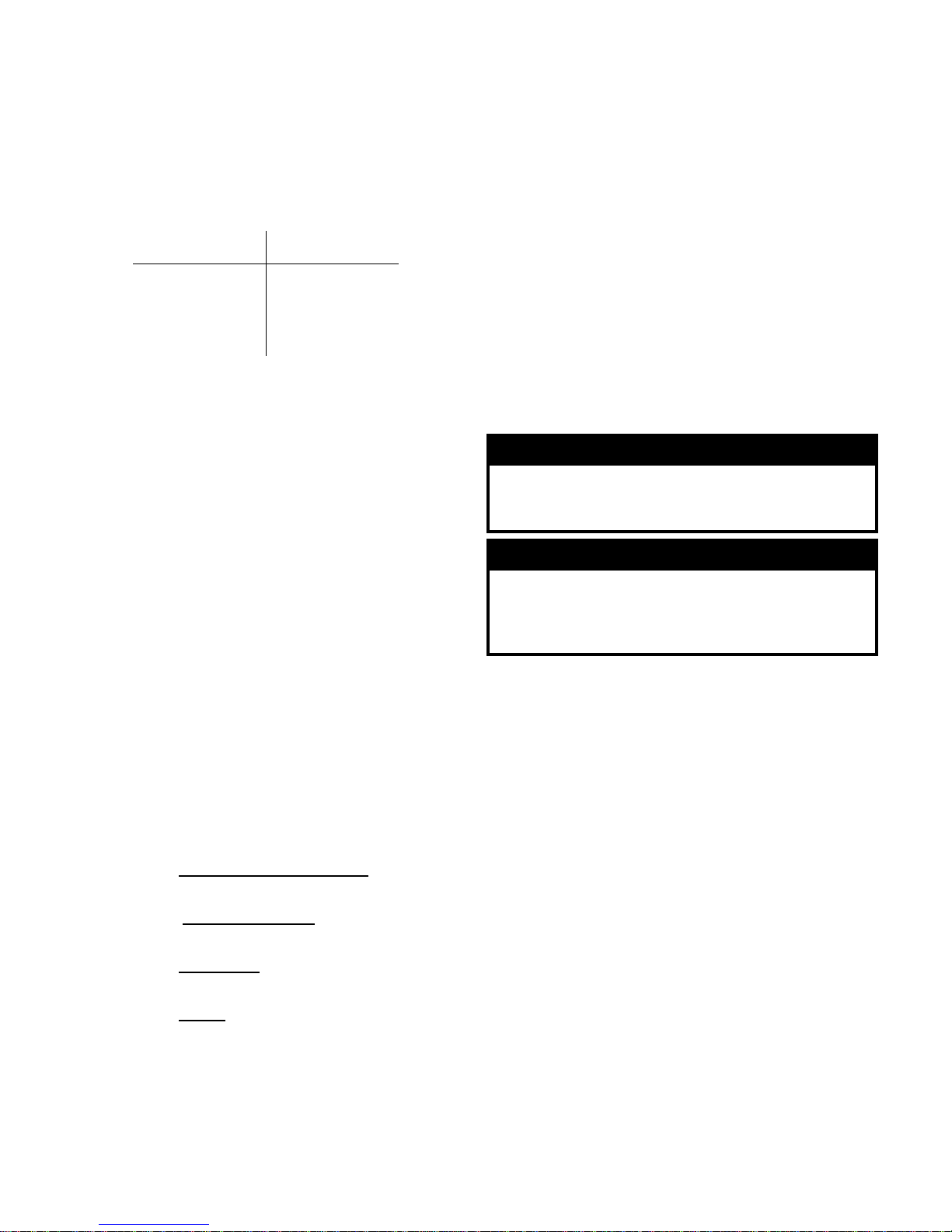

The Electronic Air Cleaner operates on the principle of

"Electrostatic Precipitation". Millions of airborne pollutants

are drawn in through the intake grill on the front of the air

cleaner and first pass through a prefilter where large

particles are caught. Next, smaller particles move to a

two-stage electrostatic collecting cell where they are

given a powerful positive charge by the ionizing wires.

Charged particles then move into the collecting area

where they are attracted to a series of alternately charged

and grounded plates. Pollutants are held on the plates

like a magnet until washed away during cleaning. Clean

air is then dispersed through the exhaust grill.

MAJOR COMPONENTS

CABINET

The cabinet is constructed of 18 gauge steel finished in a

scratch-resistant, electrostatic powder coated finish. The

unit has an interlocked cell access door, and two blower

access doors. The removeable intake grill is 20 gauge

expanded metal screen. Air is discharged through a 4-

way directional defuser. Weld nuts to accept 1/2 in.

threaded rods are incorporated into the cabinet top to

facilitate hanging the unit.

PREFILTERS

The washable prefilter measuring 16 x 20 in (40.6 x 50.8

cm) is constructed of multi-layers of aluminum mesh for

maximum filtration of large particles.

AFTER FILTER

The after filter measuring 16 x 20 in (40.6 x 50.8 cm) is

constructed of multi-layers of aluminum mesh for filtration

of agglomerated dust, and to maintain back pressure.

COLLECTING CELL

The two part collecting cell include support brackets,

collecting plates, support tubing, insulators, end plates,

spring contact, access handles, and separate ionizing

section; ionizing wires, ionizing wire support.

MOTOR & BLOWER

The motor is 3/4 HP TEFC, 1725 RPM. The blower is a

double inlet, centrifugal type with a forward inclined

wheel.

ELECTRICAL COMPARTMENT

The control panel on the front of the unit contains the two

lighted rocker switches to control the motor and power

board, and a performance indicator light, indicating high

voltage.

The high voltage power board is located in a separate

removable steel box mounted below the blower motor.

The power board is an open printed circuit board with an

adjustable output. The direct current output is 10,000

volts @ 3.5 mA. It is fused at 1.5 amps. A large value

resistor bank will bleed off the high voltage from the cell

when the unit has been turned off.

Quick disconnects on the board allow easy removal for

troubleshooting or repairs. The Performance Indicator

Light should be on during normal operation. The light

will flicker with arcing in the cell or extinguish if the cell,

ionizer or power board is shorted.

The cell access door is equipped with a safety interlock

switch to cut the power to the unit when the door is

Electrostatic Precipitation

2 Prefilter

1 Dirty Air

3 Ionizing Section

4 Collecting Cell Plates

6 Clean Air

5 After Filter or

Carbon Filter

(optional)

opened.

AIR VELOCITY

Air velocity is critical to operation of the unit and should

not exceed 500 FPM. Do not adjust drive to exceed this

velocity.

EXTERNAL STATIC

These units are not normally set up for ducting. Should

ducting be necessary, consult the factory regarding

blower and motor combinations.

SIZING AND LOCATION

The following are the general guidelines for sizing and

location of units.

GENERAL AIR CLEANING

Sizing of equipment is based on the recirculation of clean

air in the contained area. Determine the total cubic

footage of the area to be cleaned. Determine the number

of air changes that would be appropriate. This total is the

actual CFM necessary. Divide this figure by the capacity

of the SC unit that will be used and this determines the

number of units required.

Example: Body Shop

Desired air recirculation = 10 air changes/hr

Size of room (L x W x H) = 100 x 75 x 20 ft

Maximum CFM of SC-924 = 2100 CFM

L x W x H X Air Changes/Hour = Total CFM

60

Total CFM = No. of units

Maximum CFM of Air Cleaner

150,000 x 10 = 25,000 CFM

60

25,000 = 11.9 = 12 units

2,100

In the example above, 12 units should be placed so that a

uniform air flow pattern is developed. A good air flow will

ensure good cleaning.

MAINTENANCE SCHEDULE

The collecting cell,s ionizers, prefilters and after filters

must be cleaned on a regular basis for the unit to function

at its peak efficiency. The frequency of cleaning will vary

from one environment to another. For instance, in a

welding shop you may be required to wash the cell every

3 days to 2 weeks depending on the work load of the unit.

Every environment will be different. Inspect the unit

frequently until you determine the right washing schedule

for your particular application.

If your unit is equipped with an activated carbon filter it

will need to be refilled, depending on the environment,

every 3 - 6 months. Do not wash the carbon filter as this

will render it useless.

WASHING INSTRUCTIONS

1. Turn both the fan and power supply switches OFF

and wait 15 seconds for high voltage to dissipate.

2. Open the cell access door and remove the collecting

cells, ionizers, prefilters and after filters.

3. If the cell plates are heavily coated it may be

necessary to spray the cells with hot water to remove

the excess contaminate before applying detergent.

Allow excess water to drain off the cell before

applying detergent.

4. Place the cell and ionizer in a tub and spray

completely with DAX Detergent, allowing detergent

to run down both sides of the plates and ionizing fins.

Let sit for 5 minutes.

5. Rinse the cell well with hot water (140ºF / 60ºC

maximum).

6. If dirt remains on plates, let the cell soak in hot soapy

water for 30 minutes, then repeat the washing

instructions listed above. Never use any instrument

to clean the cell, as this may damage the ionizing

wires or cell plates.

7. An alternate method to clean the cell and ionizer is to

soak them in a tub of Dax for 10-15 minutes. The Dax

can be reused numerous times as long as the cell is

CAUTION

The cell plates are sharp. Handle with care. Take care

not to damage the cell by hitting the cell plates. The

cell plate spacing is critical for proper operation of the

unit.

CAUTION

Avoid washing the cell or ionizer with a high pressure

cleaner as this may cause damage to the cell plates

or fins.

SC-924

Intake Velocity 500 FPM

Discharge Velocity 2100 FPM

Internal Static .25 in WG

kept from sitting in the sludge which will collect in the

bottom of the tub. Never allow the cell or ionizer to

sit longer than 15 minutes in the DAX or they will

discolour. The tub should be covered when not in

use to prevent evaporation.

8. Spray the prefilter and after filter with DAX Detergent

and rinse well, applying water pressure against the

air flow direction. This pushes contaminate out of the

filter instead of forcing it through the filter..

9. To dry the cell and ionizer, tilt on a 45º angle against

wall with the direction arrow pointing sideways. Allow

to dry completely for at least 8 - 10 hours.

10. When the cells, ionizers, prefilters and after filters are

dry, install them back into the cabinet. The arrow on

the cell and ionizing section should point toward

the blower. The spring contact should line up

with the fibreboard on the back wall of the

cabinet. Close the door. If the cells arc when the fan

and power supply switches are turned on or if the

performance indicator light does not come on, then

the cells may still be wet. Allow more time for drying.

You can leave the cell and ionizer in the unit, turn the

fan switch ON and leave the power supply switch

turned OFF.

A cell placed in the air cleaner incorrectly can

burn out the power board.

11. The high voltage contact boards inside the cabinet

need to be cleaned on a regular basis to insure a

good contact with the cell and to prevent

accumulation of contaminate behind the contact

board. Clean the contact disc and surrounding red

contact board with a dry cloth while the accumulation

behind the contact can be removed with dry

compressed air. Complete access to the back of the

contact boards can be made from the outside of the

cabinet by removing the small panels on the back

side of the unit. The high voltage wires near the

contact boards should be wiped when the contacts

are cleaned and inspected annually by a qualified

service technician for deterioration.

12. The accumulated contaminate under the cells and in

the blower compartment should be removed at least

twice a year with a vacuum. Dry compressed air can

be used to remove the dust in the switch box and

power box which houses the high voltage power

supply. Do not apply air pressure too close to the

components as this may damage them. Build up of

contaminates on the blower wheel and housing can

also be cleaned with dry compressed air. The motor

should also be blown off with dry compressed air or

vacuumed, particularly around the cooling fan intake

at the back of the motor.

CLEANING AND SERVICE

The use of DAX Detergent is recommended for cleaning

as it is a heavy duty solution used expressly for removal

of accumulated pollutants on cell plates. If used as

directed, DAX will not harm aluminum or steel if used as

directed. Any problem arising out of the use of another

cleaning agent will void the warranty.

DAX Detergent is available in 1 gallon (4.5 L) and 4.4

gallon (20L) containers, as well as 45 gallon drums (205

L).

SERVICE MAINTENANCE

1. Determine if the air cleaner is performing properly by

seeing that:

• Fan switch is ON

• Power Supply switch is ON

• Performance indicator light is ON

2. The performance indicator light, when lit, shows that

the power board is functioning properly and should be

lit during normal operation. The light will flicker with

arcing in the cell or extinguish if the cell, ionizer or

power board is shorted.

3. If the performance indicator light fails to light, check

the cells to ensure they have been installed properly.

4. If the light still does not come on, remove the cells

and ionizers and close the door. Turn the unit on. If

the light now comes on inspect the cells or ionizers

for damage or water. Check the high voltage wires for

deterioration. Do not run the unit for more that 1

minute with the cell and ionizer removed. If the

light still is not on then the problem could be in the

light or the power board. Check the fuse on the power

board for continuity.

5. A simple test to ensure that the cell is in correctly and

there is high voltage to the cell is to take a long

plastic handle screwdriver and short the cell between

the frame of air cleaner and bolt head on the

porcelain insulators. Check both the cell and ionizer

for a spark. The fan and power supply switches

should be ON. Be sure to activate the safety interlock

switch before checking the voltage. CAUTION: You

are dealing with high voltage.

6. If in doubt and if cell is not collecting any carbon, tars

or body shop dust, then consult your dealer or factory

service center. The installing dealer should have

sufficient knowledge to determine any problems.

WARNING

Wear protective goggles, dust mask and gloves when

cleaning the inside of the cabinet. Always turn both the

fan and power supply switches OFF and turn OFF the

main breaker and lock out the unit before cleaning.

EA-924A-MAN.PUB

07/08

LIMITED ONE YEAR WARRANTY

Your Electronic Air Cleaner is guaranteed for one (1) year from the date of original purchase, against

electrical and mechanical defects in material and workmanship, under normal use and maintenance, which

will be repaired or replaced without charge, upon inspection by an authorized service center. The warranty

does not include the prefilter, after filter, carbon filter or ionizing wires.

This guarantee is in lieu of any other warranty, either expressed or implied.

ELECTRO-AIR CANADA will not be responsible for:

1. Normal maintenance as outlined in the Operation & Maintenance Manual including cleaning of electronic

collecting cells and/or replacement of carbon filters.

2. Damage or repairs required as a consequence of faulty installation or application by others.

3. Damage or repairs needed as a consequence of any misapplication, negligent handling, improper

servicing, unauthorized alteration, or improper operations.

4. Failure to start due to voltage conditions, blown fuses, open circuit breakers or other damages due to

the inadequacy or interruption of electrical service.

5. Damage as a result of floods, winds, fires, lightning, accidents, corrosive atmosphere, or other

conditions beyond the control of ELECTRO-AIR CANADA.

6. Parts not supplied or designated by ELECTRO-AIR CANADA.

7. ELECTRO-AIR CANADA products installed outside the continental Canada, U.S.A., Alaska, and Hawaii.

8. Any personal injury, special indirect or consequential property or commercial damage of any nature

whatsoever.

If warranty service is required, send the part(s) prepaid to your dealer or nearest authorized service center,

with a proof of purchase. Ensure that sufficient packing material is used. If part(s) arrive damaged due to

improper packaging, warranty will be void. Please enclose a note explaining the nature of your difficulty.

Model No. Serial No.

Date of Purchase Dealer Name

Owner’s Company Name & Address

RETAIN THIS CERTIFICATE WITH YOUR VALUABLE DOCUMENTS

Electro-Air Canada

351 North Rivermede Road

Concord, Ontario, Canada L4K 3N2

Toll Free: 1-800-267-8305

Phone: (416) 213-5636 Fax: (416) 213-5593

Email: info@fiveseasonsaircleaners.com

Table of contents

Other Electro-Air Air Cleaner manuals

Electro-Air

Electro-Air EAHEPA550-3 User manual

Electro-Air

Electro-Air EASASD-10ASC User manual

Electro-Air

Electro-Air MPRS1000 SOURCER Manual

Electro-Air

Electro-Air DM900UV-VO-WHT-VS User manual

Electro-Air

Electro-Air EAHEPA600M-3 User manual

Electro-Air

Electro-Air UST 16C26S-010 User manual

Electro-Air

Electro-Air EANC1620-A User manual

Electro-Air

Electro-Air 10C26S-010 User manual

Electro-Air

Electro-Air EAHEPA350 User manual

Electro-Air

Electro-Air EAP900 User manual