Electro-Air 10C26S-010 User manual

Part No. 37-6068B

Replaces 37-6068A

0021

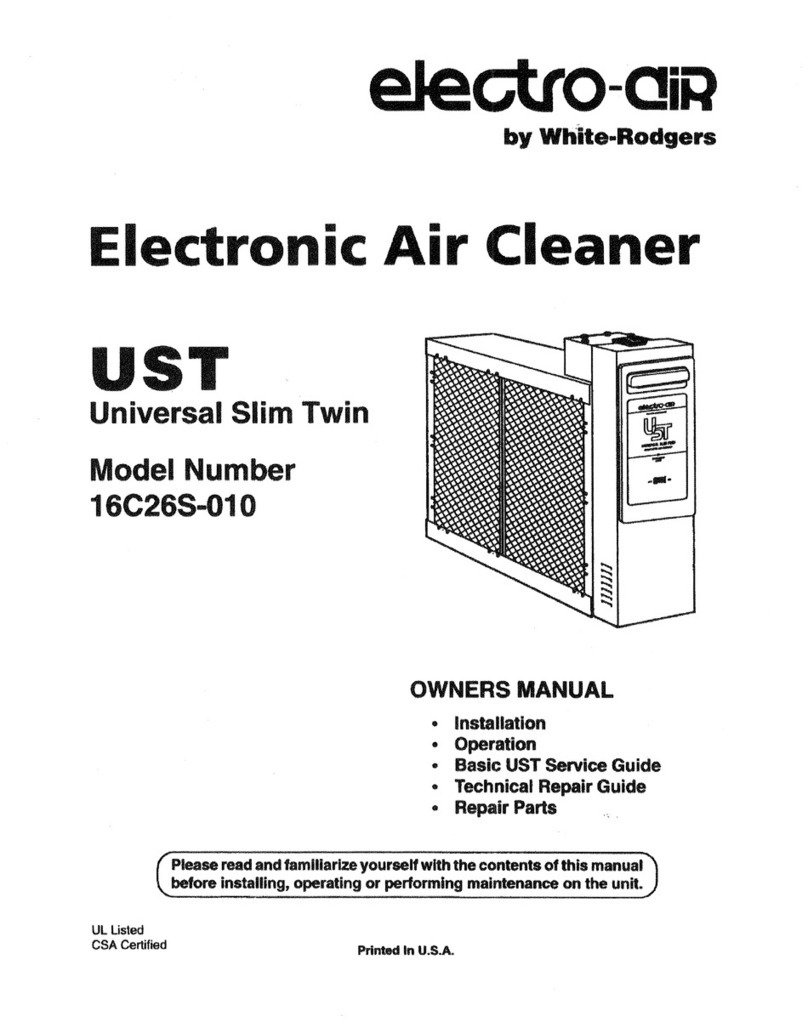

SST

Super Slim Twin

Model Number

10C26S-010

14C26S-010

16C28S-010

20C26S-010

OWNERS MANUAL

•Installation

•Operation

•Basic SST Service Guide

•Technical Repair Guide

•Repair Parts

Electronic Air Cleaner

Printed In U.S.A.

UL Listed

CSA Certified

by White-Rodgers

Please read and familiarize yourself with the contents of this manual

before installing, operating or performing maintenance on the unit.

WHITE-RODGERS

SUPER SLIM TWIN

ELECTRONIC AIR CLEANER

OPERATING

LIGHT

OFF ON

2

RULES FOR SAFE

INSTALLATION

AND OPERATION

Please read instructions before installing and using the

Electronic Air Cleaner. This will help you obtain the full

benefitfromtheElectronicAirCleaneryouhaveselected.

WARNING

!

ELECTROCUTION HAZARD

Shutoffpoweratfusepanelbefore

servicing.

Failure to do so could result in

serious personal injury or death.

WARNING

!

Donotattempt installationofthisunit unless you

are familiar with the necessary tools, equipment,

utility connections and potential hazards.

Installation should be performed only by a quali-

fied service provider.

Failure to do so could result in reduced perfor-

mance of the unit, serious personal injury or

death.

1. Read the Owners Manual and the Rules for Safe

Operation carefully. Failure to follow these rules and

instructions could cause a malfunction of filter or

unsatisfactory service.

2. Follow a regular service and maintenance schedule

for efficient operation.

WARNING

!

Installation of this unit must comply with local

electric codes or other applicable codes.

Review and understand local codes prior to in-

stallation.

Failure to do so could result in serious personal

injury or death.

CAUTION

!

CABINET AND CELLS MAY CON-

TAIN SHARP EDGES.

Usecarewhenservicingunitorhan-

dling cells.

Failure to do so could result in mi-

nor personal injury.

TABLE OF CONTENTS

Rules for Safe Installation and Operation....... 2

How the Air Cleaner Works ............................ 3

Construction of the Air Cleaner....................... 3

Preinstallation ................................................. 4

Installation....................................................... 6

Wiring Instructions .......................................... 7

Operation ........................................................ 8

Maintenance and Washing ............................. 8

Specifications.................................................. 9

Basic SST Service Guide ............................. 10

Technical Repair Guide ................................ 11

Repair Parts .................................................. 14

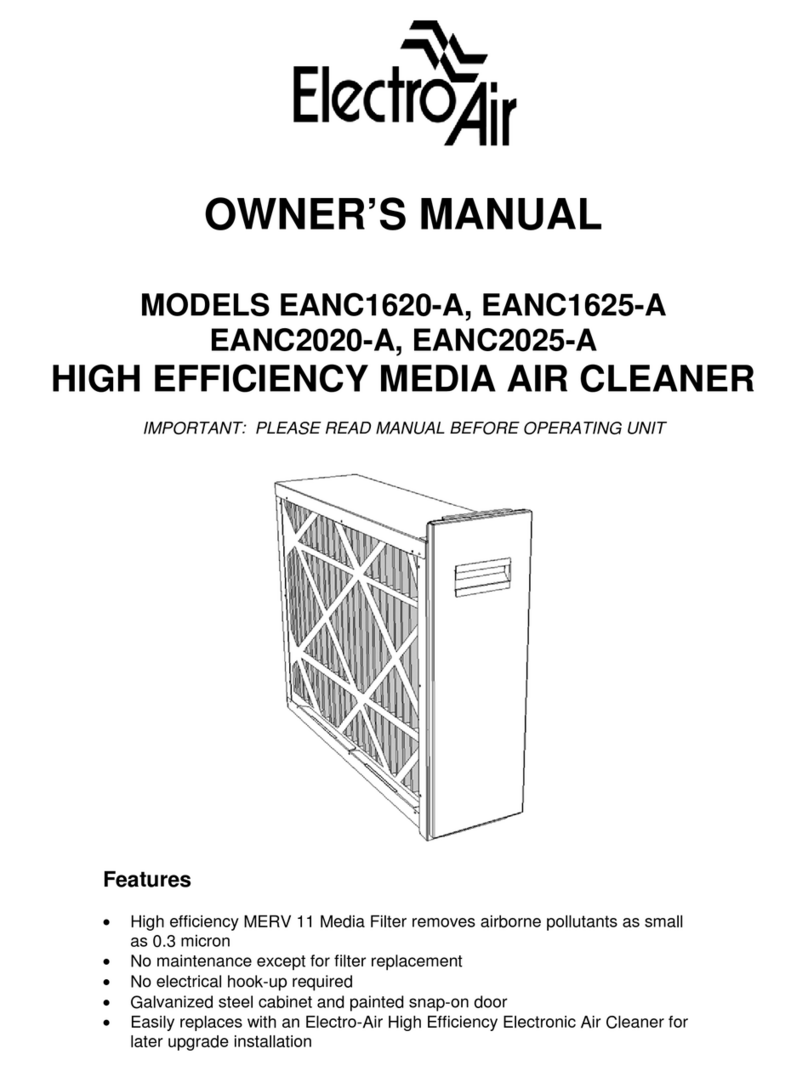

DID YOU GET THE RIGHT SIZE AIR

CLEANER

Model 10C26S-010 is designed for heating or cooling

blowersdelivering600to1200cubicfeetofairperminute

(cfm.)

Model 14C26S-010 is designed for heating or cooling

blowers delivering 1000 to 1600 cfm.

Model 16C28S-010 is designed for heating or cooling

blowers delivering 1000 to 2000 cfm.

Model 20C26S-010 is designed for heating or cooling

blowers delivering 1600 to 2200 cfm.

See specifications on page 9.

BASIC TOOL REQUIRED

Tin Snip

Screwdriver

Rule or Tape Measure

Drill

3

HOW THE AIR CLEANER

WORKS

Dirt particles flowing through the ducts (Figure 1) first

enters the pre-filters (A) where large particles (hair, lint,

etc.) are trapped. Smaller particles (smoke, dust, pollen,

etc.) pass through these pre-filters and enter the ionizing

section (B). Here each tiny particle receives a positive

electrical charge. These charged particles then enter the

collecting section (C). This section consists of a series of

aluminum plates which are alternately charged negative

and positive.

The positive charge of the particles cause them to be

repelled by the positive plates and attracted to the nega-

tive plates where they are collected . . . just as a magnet

attracts iron filings.

Clean-filtered air re-enters the supply duct system.

CONSTRUCTION OF THE

AIR CLEANER

Not only is your air cleaner easy to install, it is also easy

to operate and maintain. Its basic components, and their

functions, are as follows: (See Figure 2)

Cabinet - mounts to existing duct work and houses the

collecting cells and pre-filters.

Collecting Cells - are made in two sections and perform

theactualcollecting of dust, dirt,andother impu-

rities from the air. They contain the ionizing and

collection sections described above.

Eachcellmustbeinstalledwiththeionizingwires

on the air entering side. Each cell must be ori-

ented with the handles and contact button (Fig-

ure 2) toward the operator.

Pre-filters - are in two sections which are interchange-

able. They serve as a pre-filter to trap large

particles such as hair and lint before they can

enter the cell sections.

Power Pack- contains operating and power on lights as

well as the solid state components that convert

the 120 volt power supply to the high-voltage,

direct current required for the collecting cell.

ABC

Dirty Air In Clean Air Out

Figure 1

Cabinet Pre-Filters Handle

Contact

Button Contact

Button

Collecting Cells

Power Pack

Figure 2

4

PREINSTALLATION

tions. Turn cells upside down (with the same end facing

thecabinet opening). Thiswill locate the ionizingwires at

theright,andbothcontactbuttonsandcellhandleswillbe

facing the power door. Air flow direction must agree with

arrow embossed on end of collecting cells.

After installing the cell sections, install pre-filters in cabi-

nettracks on theright. This willagain place thepre-filters

on the air entering side (on the same side as ionizing

wires).

LOCATING THE AIR FILTER

Your air filter must be mounted in the return air duct of a

central forced-air system, on the air entering side of your

furnace. (See Figure 3 for example.)

Select a location that meets the following:

1. The face of the cell will be at a right angle to the air

stream.

2. Allow the following clearances to permit removal of

cells and pre-filters: (See Figures 4 and 5)

Model 10C26S-010 - 14 inches

Model 14C26S-010 - 15 inches

Model 16C28S-010 - 14 inches

Model 20C26S-010 - 15 inches

For complete dimension data refer to Figure 5.

3. The air filter is not to be placed in the discharge of

either the heating or cooling unit.

4. IMPORTANT: If atomizing spray type humidifier is

used, it must be installed downstream from the air

filter.

If your furnace duct system has a pre-installed boot,

discard front cover of boot and slide the air cleaner

component inside the boot. (Applies to 14C26S-010 and

20C26S-010.)

If furnace opening cannot be enlarged to required size, a

transition sheet metal section must be used. Transition

must be planned for each job. Reduction should not be

more than 4 inches per linear foot, approximately 20

angular degrees (Figure 3).

DIRECTION OF AIR FLOW THROUGH THE

AIR CLEANER

Your air cleaner is shipped from the factory with air flow

from left-to-right. If this air flow is suitable for the installa-

tion, no further changes need to be made (Figure 4). For

right-to-left air flow, remove both pre-filter and cell sec-

Air Flow

Furnace

Opening

Not to Exceed 20°

Air Flow

Electronic

Air Cleaner

Opening

Electronic

Air Cleaner

Furnace Transition Section

(if Needed)

Figure 3

Cabinet

(Interchangeable)

Collecting Cell (Interchangeable)

Collecting Cell

Outlet Box Power Pack

Handle

Contact

Button Contact

Button

Pre-Filters

(Interchangeable) See text for Cell

Removal Clearance

Figure 4

6 7/8"

A

B

E

D

F

C

Knockouts for

3/4" Conduit

(three sides)

10C26S-010 24 3/4 21 5/16 18 5/8 13 9/16 16 7/16 19 1/16

14C26S-010 29 11/16 26 1/4 23 5/8 13 9/16 16 7/16 19 1/16

16C28S-010 25 1/2 21 5/16 18 5/8 17 3/4 20 5/8 23 3/8

20C26S-010 29 11/16 26 1/4 23 5/8 17 3/4 20 5/8 23 3/8

MODEL NO. A B C D E F

Figure 5

5

TYPICAL MOUNTING POSITIONS

BASEMENT FURNACE

(LOWBOY) (Figure 6)

Cleaner is mounted hori-

zontally in return plenum,

just above furnace.

COUNTERFLOW

FURNACE (Figure 7)

Cleaner is mounted horizon-

tallyinreturn duct orplenum,

just above furnace.

HIGHBOY FURNACE

(Figure 8)

Side installation. Cleaner

is mounted vertically,

where return air enters

side inlet of furnace.

OFFSET INSTALLATION

(Figure 10)

Typical use of duct offset to match air filter opening.

If duct connection to furnace allows less than nine

inches for mounting the air cleaner, shorten the

lateral trunk, or attach an offset fitting to the elbow.

HORIZONTAL FURNACE

(Figure 11)

Cleaner is mounted vertically

inthereturnductnearfurnace.

Air Flow

Rear View

Figure 6

Air Flow

Rear View

Figure 7

Air Flow

Figure 8

Air Flow

Figure 9

At Least

9 Inches

Less than

7 Inches Offset

Figure 10

Air Flow

Figure 11

HIGHBOY FURNACE

(Figure 9)

Installation beneath furnace.

Cleanermountshorizontally,

where return air enters from

below. Raise furnace and in-

stall beneath base.

6

INSTALLATION

REMOVE OLD FILTER AND DISCARD

(Figure 12)

NOTE:Thisfiltermaybemountedinthefurnacecompart-

ment.

CLEAN BLOWER COMPARTMENT

It is suggested that the furnace blower compartment,

blowerandblowerhousingbecleanedtoensurecleanair

circulation.

INSTALLATION

The following is a typical installation of the air cleaner on

a “Highboy” furnace (Figure 8).

1. Placetheairfiltercleaneronthefloor.Standitupright

withthepowerdoorfacingyou(Figure4).Ifahorizon-

talinstallation isbeing planned,lay the cleaner on its

side,thiswillhelpyoutovisualizetherelativelocation

of all parts.

Allowamplespaceforwiringandservicingthepower

supply box (Figure 13).

2. Releasethelatch,removethe powerpack(bygrasp-

ing handle and pulling power pack away from cabi-

net) and set it aside. Remove the collecting cells and

pre-filters. Set pre-filters and cells aside in a safe

location until the cabinet is installed.

3. Set the cabinet next to the furnace. If necessary,

enlarge the opening in the furnace (if possible) to

match the opening in the cabinet.

If the furnace opening cannot be enlarged, a transi-

tion fitting should be used. (Figure 3).

Thecabinetcanbeattacheddirectly(Figure 13), ora

starting collar can first be fitted to the furnace inlet. A

butt or slip joint can be used.

Securely attach the cabinet to furnace inlet, using at

least two of the mounting holes on each side of the

cabinet.

4. Usingbuttjoint,attachductwork(normallyanelbow)

to the upstream side of air cleaner cabinet. (Note the

useofthesheetmetalturningvanesinsidetheelbow

to improve air distribution over the face of the cells.)

(Figure 14)

NOTE: An optional method of attaching duct work to the

cabinetistomodifythecabinet(Figure15)bybendingthe

tabs outward at a 90°angle and attaching duct work to

tabs.

Transition Fittings

Iftheairductdoesnotfitthecabinetopening,atransition

fitting should be used. Gradual transitions are preferred

for greatest efficiency. Not more than four inches per

linear foot (approximately 20°angle) should be allowed

(Figure 3).

5. Connecttheverticalductsectiontotheelbow.Wedge

a wood block between floor and elbow for support

(Figure 16).

6. Seal all joints in the return air system downstream

from the air cleaner with duct tape to prevent dust

from entering the air stream. Tape is usually applied

ontheoutsideofducts,butmayalsobeappliedonthe

inside, or both.

Figure 12

Figure 13

Duct Frame Power

Supply

Box

Mounting

Holes

Air Flow Turning

Vanes

Figure 14

Optional method

(Bend tabs outward at 90°angle)

Figure 15

7

WIRING INSTRUCTIONS

7. Withthe cabinet installed,the air cleanercan now be

wired to electrical input source.

WARNING

!

Installation of this unit must comply with local

electric codes or other applicable codes.

Review and understand local codes prior to in-

stallation.

Failure to do so could result in serious personal

injury or death.

8. Since this air cleaner unit has an air flow monitor

installed, it does not require electrical wiring through

thefurnacecontrols.Thisunitrequiresa120VAC 60

Hz input circuit. A 20 amp circuit is more than ad-

equate.

9. Remove junction box cover and install the required

bushing into the 3/4 in. Knock out. With the supply

voltage turned off, route three (3) wires into junction

box for connections. (See Fig. 17.)

Insure all wires are clamped, wire connectors prop-

erly installed and grommets used to prevent wire

abrasion.

10. With the cabinet Installed, reinstall pre-filter(s) and

collecting cell(s) (Figure 19).

NOTE: The contact button and handles on the cell

mustbefacing you andionizingwires must beonthe

air intake side.

11. Install the power pack as follows:

Engage the lip on lower inside edge of power pack in

the flange on cabinet and carefully close the power

pack,makingsurethattheelectricalconnectorprongs

on the power pack enter the slots in the socket on

cabinet. When the power pack is fully in place, en-

gage the latch and snap it closed.

Vertical

Section

Tape All

Joints

Wood Block

Figure 16

Hot

Neutral

Grounding

Conductor

Front View

Figure 17

Floor

Conduit

Duct

Electronic

Air Cleaner

Figure 18

Cabinet Pre-Filters Handle

Contact

Button Contact

Button

Collecting Cells

Power Pack

Figure 19

8

OPERATION

1. With the 120 VAC power turned on at the circuit

breakerforthefurnace,pushtheaircleanerON-OFF

switch to the “ON” position (Figure 20).

2. With the furnace blower running, the air cleaner will

be operating. An arcing or “snapping” sound may be

heard. This will occur occasionally, however the unit

is operating properly.

3. With the furnace blower running, the Operating Light

should be ON. If the Operating Light is not ON this

signifies that the cells need washing, or that trouble

exists in the unit.

If, after washing the cells, the Operating Light stays off,

the cell could be wet, improperly placed in the cabinet or

may need servicing.

NOTE: An occasional flicker of the light accompanied by

harmless sparking or snapping noise may occur. This is

caused by trapping large particles of dirt. If arcing is

continuous, the cells should be washed or checked for

service problems see Basic SST Service Guide.

4. Remove the cell(s) and pre-filter(s) from cabinet.

Using a solution of warm water and low sudsing

detergent, soak cell(s) and pre-filter(s) for 20 to 30

minutes.

NOTE: Ionizing wires may become coated causing

loss of cleaning ability by the collecting cell. Using a

damp cloth, wipe each ionizing wire, exercising care

not to damage them.

5. Removethecell(s)andpre-filter(s) from solutionand

rinse thoroughly with clean water.

6 Allow cell(s) and pre-filter(s) to drip dry for a mini-

mum of 2 hours. Cell(s) and pre-filter(s) may be

tipped at a slight angle to expedite the drip-dry pro-

cess.

7. Reinstall the cell(s) and pre-filter(s) in the cabinet.

8. Replace the power pack. Turn furnace fan on. After

30 minutes push ON-OFF switch on the power pack

to the “ON” position.

A moderate amount of arcing or “snapping” may

occur at this time, which will indicate that the cell(s)

are still damp. If the noise is objectionable, push the

ON-OFF switch to the “OFF” position and allow

additional time for cell(s) and pre-filter(s) to dry. In

some cases the Operating Light will remain OFF

duringthisinitialactivationoftheaircleaner,andthis

wouldindicate thatthe cell(s)are not completely dry.

The Operating Light should remain ON while the

furnace fan is running once the drying is complete.

MAINTENANCE AND

WASHING

CAUTION

!

CABINET AND CELLS MAY CON-

TAIN SHARP EDGES.

Usecarewhenservicingunitorhan-

dling cells.

Failure to do so could result in mi-

nor personal injury.

For maximum efficiency your air cleaner cell(s) and pre-

filter(s) should be inspected once a month and cleaned

when necessary. Cleaning will usually be required every

one to three months, depending upon the particular

householdcircumstances.Whencleaning isrequiredthe

following procedure should be used:

CLEANING THE CELLS

1. Turn the air moving system “OFF.”

2. Push the ON-OFF switch on the power pack to the

“OFF”position(Figure20).Wait15secondsandboth

the power pack and the collecting cell(s) will be

automatically discharged.

3. Release the latch on top of power pack and pull the

power pack straight away from cabinet at the top.

Then lift pack out of ledge at bottom edge of cabinet.

Set power pack aside.

Operating

Light

On-Off

Switch

Figure 20

9

REPLACING AN IONIZING WIRE

If an ionizing wire should break, it can be replaced as

follows:

1. Remove all pieces of broken wire. Make sure sup-

ports at each end are in good condition and not bent

out of shape.

2. Hook the new wire onto the support at one end.

3. Hold your finger against the support at the other end

(Figure21)andholdtheionizingwirebetweenthumb

and forefinger as shown or use needle nose pliers.

Press inward on spring support. Hook end of wire

over small tab at end of support and release. Make

sure wire is securely anchored at each end.

Support

Ionizing

Wire

Figure 21

Rated Capacity 600 - 1200 cfm 1000 - 1600 cfm 1000 - 2000 cfm 1600 - 2200 cfm

Max. Pressure Drop .08 in. W.G. .08 in. W.G. .12 in. W.G. .09 in. W.G.

Cell Weight (2) 7 lbs. each (2) 9 lbs. each (2) 9 lbs. each (2) 9 lbs. each

Power Pack Weight 9 lbs. 9 lbs. 10 lbs. 10 lbs.

Unit Weight 35 lbs. 42 lbs. 38 lbs. 45 lbs.

Power Consumption 40 Watts (Max) 40 Watts (Max) 40 Watts (Max) 40 Watts (Max)

Electrical Input 120 VAC 60 hz. 120 VAC 60 hz. 120 VAC 60 hz. 120 VAC 60 hz.

Electrical Output 1.0 Ma 1.2 Ma 1.5 Ma 1.7 Ma

@ 6450 VDC (nom)

Max. Ozone Output .05 ppm .05 ppm .05 ppm .05 ppm

Temperature Rating 40°F to 125°F40°F to 125°F40°F to 125°F40°F to 125°F

SPECIFICATIONS 10C26S-010 14C26S-010 16C28S-010 20C26S-010

SPECIFICATIONS

10

SERVICE INDICATION SERVICE CHECKS

ON/OFF switch “ON” Unit functioning Normally

Blower ON

Operating Light ON

ON/OFF switch “ON” 1. Power is not being supplied to air cleaner.

Blower ON A. Check fuse or circuit breaker.

Operating Light OFF B. Ensure power pack is properly installed and latched.

2. Collecting cell shorted - Turn power Off - Remove power pack - Remove

collecting cells - Replace power pack - Restore power (ensure blower is

operating).

A. If Operating Light comes ON check cells for bent plates, loose ionizing

wire(s) or cracked insulator(s).

B. If Operating Light remains OFF, malfunction is in the power pack. (See

power supply Checkout Procedure).

ON/OFF Switch “ON” 1. Air flow sensor contaminated/misaligned

Blower OFF A. Remove power pack and clear contamination inside black bushing around

Operating Light ON the small sensor element.

B. Ensure small sensor element is centered in bushing.

2. Air sensor left in bypassed condition after servicing.**

3. Faulty air flow sensor panel.

Excessive arcing during 1. Wet collecting cell.

normal operation - A. Allow cell(s) to dry after cleaning before applying power.

Operating Light may blink 2. Damaged collecting cell(s).

A. Remove cell(s) and inspect for bent plates, loose ionizing wire(s), cracked

insulator(s), etc.

3. Collecting cells dirty.

A. Clean cells as instructed in this manual.

4. Faulty power supply (see power supply checkout procedure)

**NOTE: Your air cleaner is equipped with an air flow sensor (switch) which turns the unit ON and OFF in re-

sponse to the system blower. It may have been “wired out” during a service check and inadvertently left in this

condition

BASIC SST SERVICE GUIDE

This guide will cover most homeowner complaints. If, after checking the items listed, the unit still fails to operate

properly, contact the nearest Authorized Service Center.

11

TECHNICAL REPAIR GUIDE

All voltage measurements indicated can be made with a

high voltage D.C. probe and a general purpose volt ohm

meter. For example: Simpson 260 or equivalent.

For test purposes, the air flow switch may be “wired out”

of the system. This will eliminate the need for air flow

across the sensing thermistor to energize the power

supply (see Fig 23).

NOTE: All tests to be performed with the Ozone Reduc-

tion Jumper intact.

NOTE: When servicing the power pack components, all

wiring must be routed to factory specifications.

WARNING

!

Do not attempt repair of this unit unless you are

familiarwiththenecessarytools,equipment,util-

ity connections and potential hazards.

Repair should be performed only by a qualified

service provider.

Failure to do so could result in reduced perfor-

mance of the unit, serious personal injury or

death.

This guide contains service checks to assist service

personnelin locating and correcting anymalfunction that

might occur to render the air cleaner ineffective or inop-

erative. The air cleaner has been designed with replace-

ablecomponents,suchasthehigh-voltagepowersupply

andairflowswitch.Thisallowstheservicemantoreplace

a faulty component rather than attempt repairs of such

components in the field.

The solid-state power supply is not

designed for individual component part

replacement and must be replaced as

a complete "snap-in" unit.

Input voltage: 120 VAC 60 Hz.

Output to light: 1.5 to 2.5 VDC

H.V. Output: 6450 VDC (nom)

Collecting Cell

Specifications

Power Supply

Specifications

1000 cfm - 1.0 Ma @ 6450VDC

1400 cfm - 1.2 Ma @ 6450 VDC

1600 cfm - 1.5 Ma @ 6450 VDC

2000 cfm - 1.7 Ma @ 6450 VDC

Operating

Light

Power

Supply

Cell Contact

& Insulator

ON/OFF

Switch

Cover Assembly

AirFlow Switch

Power Pack

Assembly

L1

120 VAC

Connector

Wht

Wht

Gnd Red

Blk

Blk

Wht/Brn Wht

Blk

Blu

Wht/Brn

Wht

Blk

Blu

L2

Figure 22

12

POWER SUPPLY

CHECKOUT PROCEDURE

1. Turn power switch to the “OFF” position and remove

the power pack from cabinet.

2. Locateairflowswitchand removepowerpackcover.

Disconnect the three-pin plastic connector.

3. Jumper the two female pins (white wire to white-

brown wire) as shown in Fig. 23.

Jumper Lead

Female Pins

Male Pin

Plastic Connector

Method of jumping lead wires of

connector plug from air flow switch.

Figure 23

4. Place power pack on a well insulated workbench.

Connect meter negative (-) lead to the sheet metal

chassis and the high voltage probe to high voltage

contact on back cover of power pack. Connect AC

power to power pack using an extension cord and

turn power switch to the “ON” position. Keep hands

and tools away from high voltage contact.

5. If Operating Light comes ON and output voltage is

between6100 and 6800VDC, power supplyis good.

6. If voltage is good but Operating Light does not come

on, replace Operating Light.

CELL TEST

1. Place collecting cell on a well insulated workbench

with the cell contact button pointing upward.

2. Select a power pack (with air flow switch bypassed

and ozone reduction jumper intact) that reads be-

tween6100and 6800 VDCatthe cell contactwithno

cell attached.

3. Place power pack on top of collecting cell ensuring

that there is proper contact between the cell contact

on the power pack contact.

4. Using a standard extension cord, apply 120 VAC to

power pack. Turn power switch to “ON” position.

5. Connect meter negative (-) lead to metal frame of

collecting cell. Use high voltage probe to measure

voltageatcollectingcellionizerorcellplates.Voltage

should be 6100 to 6800 VDC.

NOTE:Anew“out-of-box”cellmaycausethevoltage

to be lower than normal for a short period of time. To

obtain a more accurate measurement, “age” the cell

by applying high voltage to the cell for 15 to 30

minutes.

6 If voltage is below 6100 VDC, check cell for foreign

objects, bowed/bent/loose plates, broken ionizing

wires or cracked insulators. Wash cells if required. If

OperatingLightremainsOFF,replacecollectingcell.

AIR FLOW MONITOR TEST

1. Connect a multimeter set to read 120 VAC to power

supply terminals marked “LINE.”

2. Connect 120 VAC to power pack plug, turn power

switch “ON.”

3. Blow on thermistor at air flow monitor. 120 VAC

should appear at multimeter. Stop blowing and volt-

age should disappear in 10 - 15 seconds.

4. If voltage did not appear (Step 3), disconnect power

to power pack. Locate air flow switch and remove

power pack cover. Disconnect the three-pin plastic

connector.Jumper the twofemale pins (white wireto

white-brown wire) as shown in Fig. 23. Reconnect

power to power pack. Turn power switch “ON.”

A. If 120 VAC appears at multimeter, replace air

flow monitor.

B. If120 VAC doesnot appear on multimeter,prob-

lem is other than air flow monitor. Recheck all

primary wiring.

NOTE: The air flow monitor is designed to operate in the

temperature range of 65°to 120°F. Operation outside

this range is not recommended.

13

OZONE REDUCTION

Allelectronicaircleanerstypicallyproduceasmall

amount of ozone that is within established limits.

Some customers may notice an odor especially at

high altitudes or low air flow rates.

This power supply has a “hairpin” shaped jumper

wire labeled W1 (see Fig 24) that can be cut and

separated in case of such complaints. This will

cause the power supply to limit the maximum

operating power to a lower level.

LINE

WHT/BRN BLK

W1

E3 E2

Ozone Reduction Jumper

Cut and separate

Ozone Reduction

Jumper

Figure 24

14

123

4

5

5

6

237

8

9

18

5

14

13

10

11

12

REPAIR PARTS

15

ITEM

NO. DESCRIPTION PART NUMBER

10C26S-010 14C26S-010 16C28S-010 20C26S-010

1 Cabinet N/A N/A N/A N/A

2 Pre-Filter • F825-0431 • F825-0432 • F825-0337 • F825-0338

3 Collecting Cell • F811-0398 • F811-0397 • F811-0321 • F811-0319

4 Junction Box Cover F838-0072 F838-0072 F838-0072 F838-0072

5 * Screw #6 x 3/8 ------ ------ ------ ------

6 Connector, Female F818-0053 F818-0053 F818-0053 F818-0053

7 Power Pack Assembly F858-0919 F858-0919 F858-0920 F858-0920

8 Cell Handle F832-0039 F832-0039 F832-0039 F832-0039

9 Ionizing Wire F843-0484 F843-0484 F843-0500 F843-0500

10 Light F844-0130 F844-0130 F844-0131 F844-0131

11 Switch F876-0202 F876-0202 F876-0202 F876-0202

12 Power Pack, Cabinet Only N/A N/A N/A N/A

13 Connector, Male F827-0026 F827-0026 F827-0026 F827-0026

14 Power Supply F858-1000 F858-1000 F858-1000 F858-1000

15 Cover, Power Pack F820-0098 F820-0098 F820-0220 F820-0220

16 † Manual 37-6068 37-6068 37-6068 37-6068

17 † Charcoal Filter (with mounting clips) F825-0466 • F825-0467 • F825-0468 • F825-0469

18 Air Flow Switch (w/Mtg.Hdwr) F859-0380 F859-0380 F859-0380 F859-0380

* Standard Hardware Item

• Two (2) Required

† Not Shown

REPAIR PARTS

PARTS LIST FOR ELECTRONIC AIR CLEANERS

When ordering repair parts, always give the following information as

shown in this list.

1. The PART NUMBER

2. The PART DESCRIPTION

3. The MODEL NUMBER

4. The NAME OF ITEM - ElectronicAir Cleaner.

Always order by “PART NUMBER” . . . Not by “ITEM NUMBER”

White-Rodgers Division, Emerson Electric Co.

9797 Reavis Road, St. Louis, MO 63123-5398

314-577-1300 • FAX 314-577-1517

www.white-rodgers.com

Controlling America’s Indoor Comfort

NOTICE TO CONSUMERS

White-Rodgers

Electronic Air Cleaner

Dear Consumer;

White-Rodgers would like to thank you for purchasing a White-Rodgers Electronic Air

Cleaner or product containing a White-Rodgers Electronic Air Cleaner. Although White-

Rodgers does not extend a warranty directly to consumers, White-Rodgers does extend a

warranty to Wholesalers and Original Equipment Manufacturers who use White-Rodgers

Products. To obtain more information about how your Wholesaler or Original Equipment

Manufacturer’s warranty may benefit you, please contact your Wholesaler or Original

Equipment Manufacturer.

Sincerely,

White-Rodgers

This manual suits for next models

3

Table of contents

Other Electro-Air Air Cleaner manuals

Electro-Air

Electro-Air EAHEPA450 User manual

Electro-Air

Electro-Air EASASD-10ASC User manual

Electro-Air

Electro-Air EANC1620-A User manual

Electro-Air

Electro-Air MPRS1000 SOURCER Manual

Electro-Air

Electro-Air EAHEPA550-3 User manual

Electro-Air

Electro-Air SC-924A Manual

Electro-Air

Electro-Air SC-500 05C11E-01002 User manual

Electro-Air

Electro-Air EASA900VS User manual

Electro-Air

Electro-Air EAHEPA650 User manual

Electro-Air

Electro-Air EAHEPA600M-3 User manual