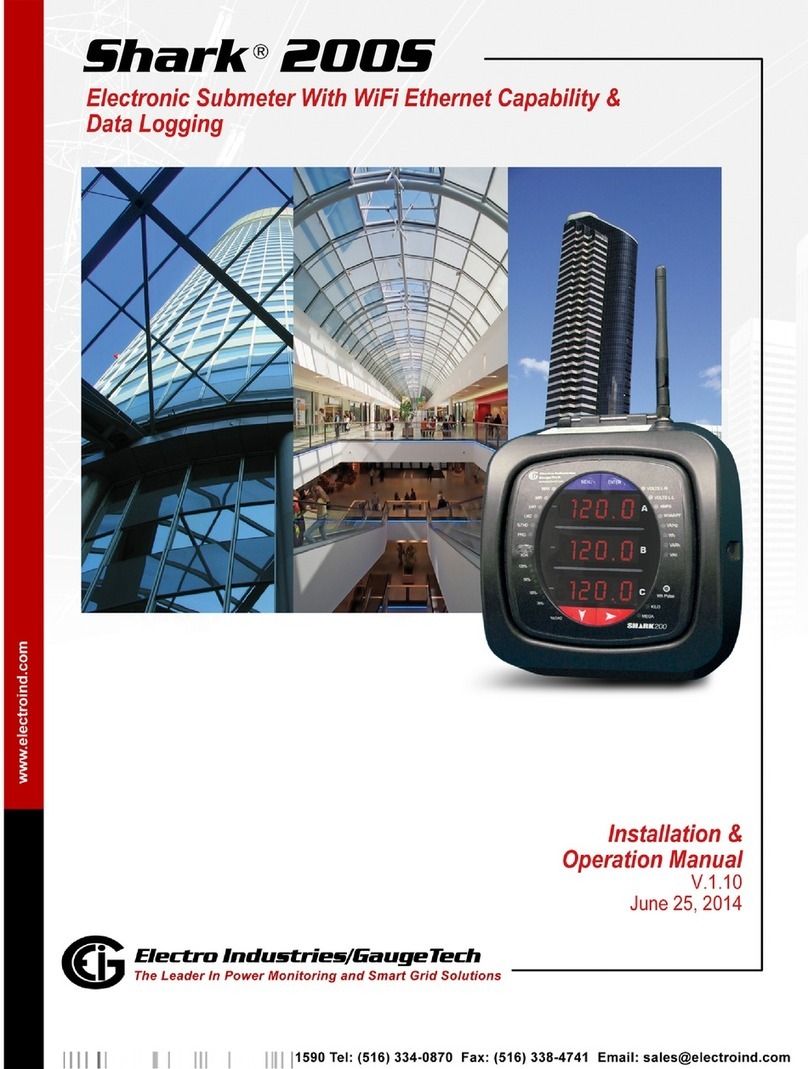

Electro Industries Shark 100S User manual

Other manuals for Shark 100S

1

This manual suits for next models

1

Other Electro Industries Measuring Instrument manuals

Electro Industries

Electro Industries Shark 200 User manual

Electro Industries

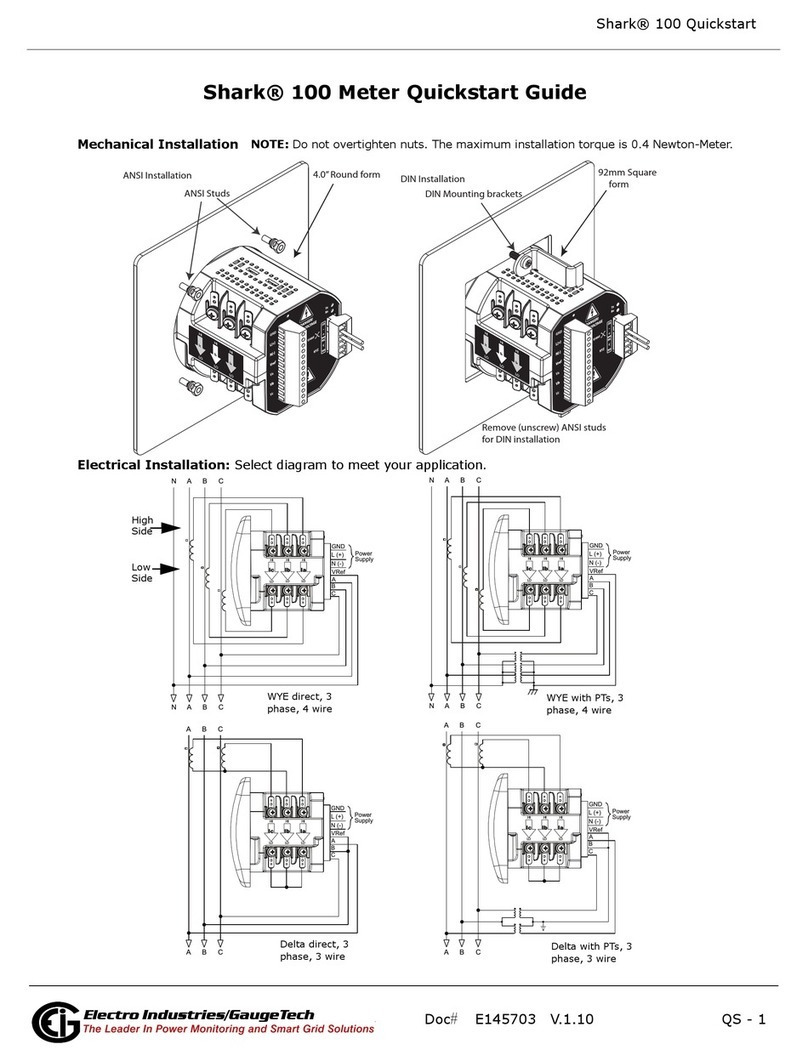

Electro Industries Shark 100 User manual

Electro Industries

Electro Industries Shark 200S Administrator Guide

Electro Industries

Electro Industries Nexus 1262 User manual

Electro Industries

Electro Industries 1252 User manual

Electro Industries

Electro Industries Shark 200 User manual

Electro Industries

Electro Industries WARMFLO WF-ANZ7 User manual

Electro Industries

Electro Industries Shark ST40 User manual

Electro Industries

Electro Industries Shark 100 User manual

Electro Industries

Electro Industries Shark 100S User manual

Popular Measuring Instrument manuals by other brands

DAKOTA ULTRASONICS

DAKOTA ULTRASONICS ZX-3 Operation manual

Extech Instruments

Extech Instruments ExStik DO600 user manual

BRUEL & KJAER

BRUEL & KJAER 4448 Field guide

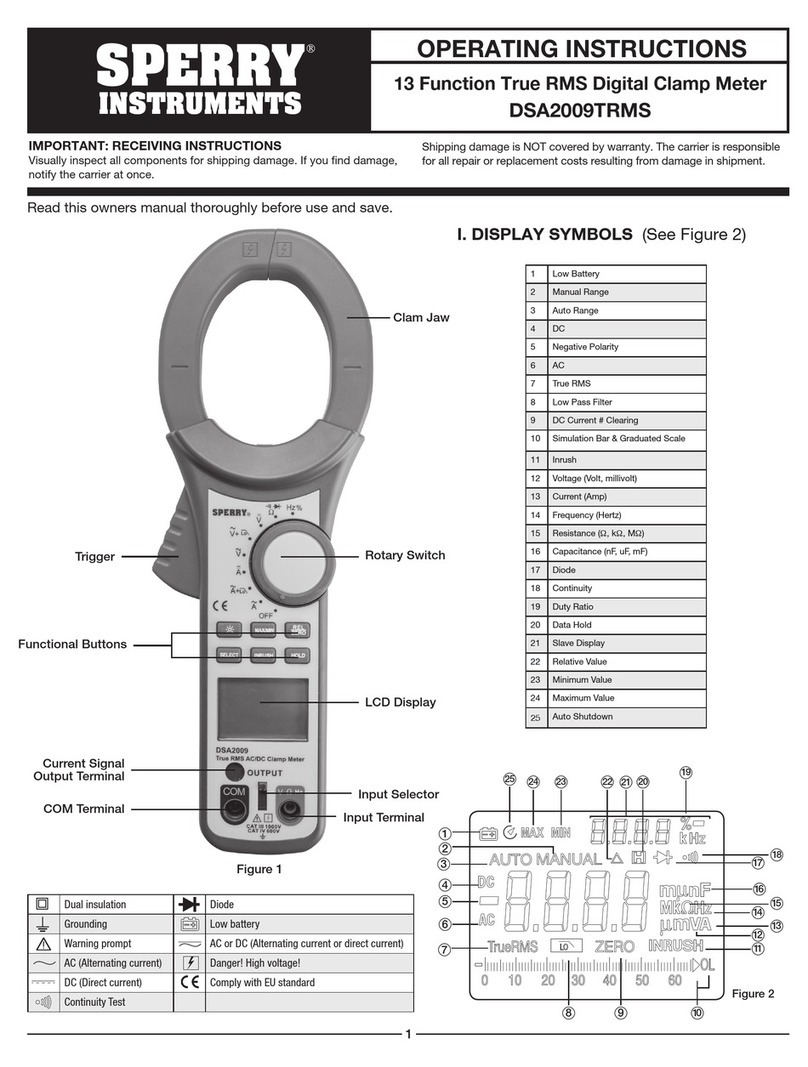

Sperry instruments

Sperry instruments DSA2009TRMS operating instructions

Triplett

Triplett EM400 user manual

BRUEL & KJAER

BRUEL & KJAER 4152 Instructions and applications

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS TURBIDIMETER TN-100 WATERPROOF PORTABLE... instruction manual

ABB

ABB COPA-XM 3000 Series instruction manual

Siemens

Siemens sitrans PROBE LU Quick start manual

Perel

Perel E305EM5 quick start guide

VOLTCRAFT

VOLTCRAFT 2109292 operating instructions

La Crosse Technology

La Crosse Technology WS9501 Operation manual