4

Full Description of Switch Functions

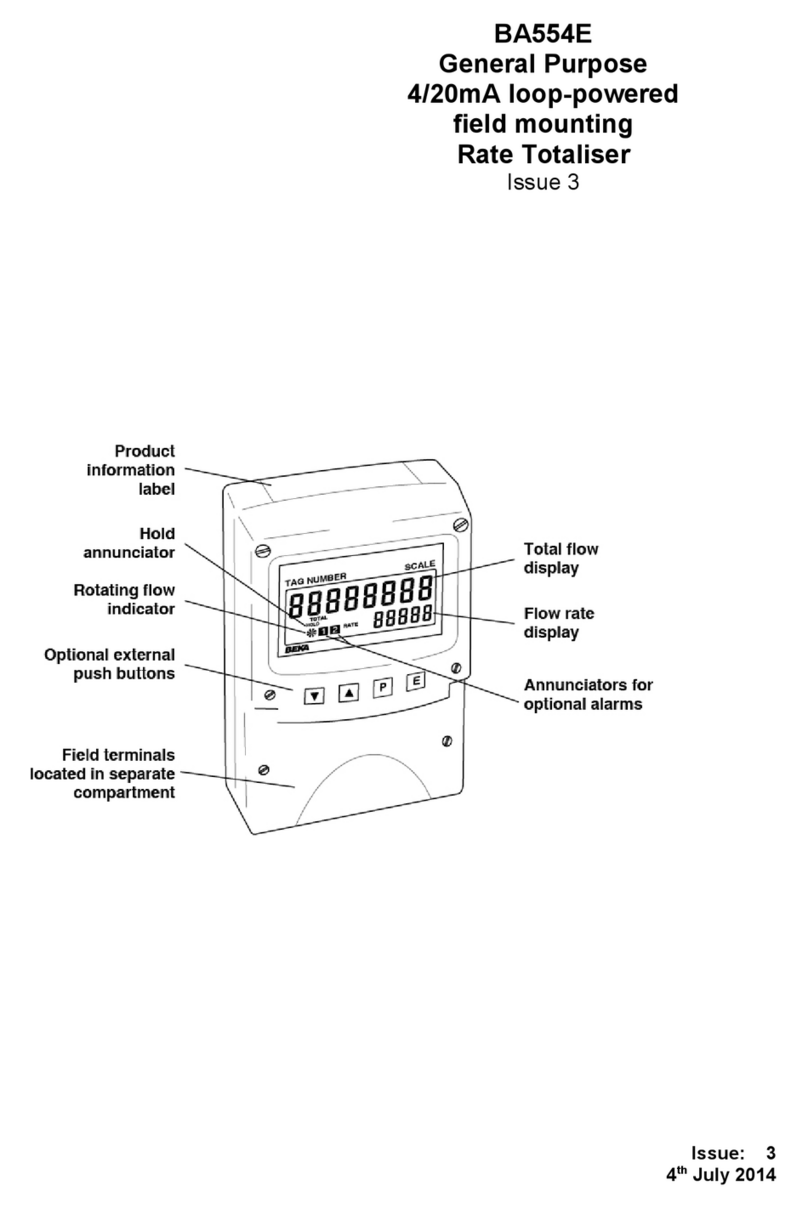

PWhile this button is pushed the rate

display will show the input current in

mA, or as a percentage of the

instrument span depending upon how

the instrument has been programmed.

When the button is released the normal

display in engineering units will return.

The function of this push-button may be

modified when alarms are fitted to the

instrument.

Down While this button is pushed the

instrument will show the calibrated rate

display with 4mA input - usually zero for

flow applications. When the button is

released the flow rate will again be

displayed.

Up While this button is pushed the

instrument will show the calibrated rate

display with 20mA input. When the

button is released the flow rate will

again be displayed.

E+ Down While these buttons are pushed the

total display will show the least

significant eight digits of the grand total,

and the grand total annunciator will be

activated.

E+Up While these two buttons are pushed the

total display will show the most

significant eight digits of the grand total

and the grand total annunciator will be

activated.

Down Resets the total display to zero

+Up when these two push-buttons are

operated simultaneously.

Selectable function from programme

menu.

See section 6.15

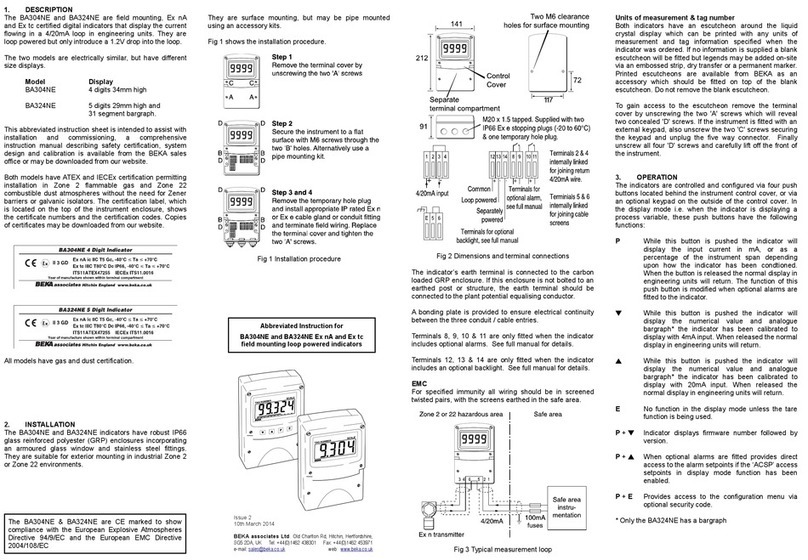

2.2 Displays

The BA354D has two digital displays and

associated annunciators, plus a flow indicator as

shown on page 1.

Rate Shows the flow rate on the smaller

Display five digit display.

Total Shows the total flow on the larger

display eight digit display. Is set to zero when

reset is operated.

Flow This disc in the lower left hand

indicator corner of the display 'rotates' when the

input current exceeds 4mA.

INTRINSIC SAFETY CERTIFICATION

3.1 ATEX certificate

The BA354D has been issued with an EC-Type

Examination Certificate by Notified Body ITS

Intertek Testing and Certification confirming

compliance with the European ATEX Directive

94/9/EC for Group II, Category 1, gas and dust

atmospheres, EEx ia IIC T5. The instrument

bears the Community Mark and, subject to local

codes of practice, may be installed in any of the

European Economic Area (EEA) member

countries. ATEX certificates are also acceptable

for installations in Switzerland.

This manual describes installations in explosive

gas atmospheres which conform with BS

EN60079:Part14:2003 Electrical Installation in

Hazardous Areas. When designing systems for

installation outside the UK, the local Code of

Practice should be consulted.

For the use in the presence of combustible dust,

please refer to Appendix 1 which describes

installations complying with BS EN 50281-1-

2:1999. Please note that dust certification is an

option which must be specified when the

instrument is ordered.

3.2 4/20mA input

In Europe, sources of energy which do not

generate more than 1.5V; 100mA and 25mW are,

for intrinsic safety purposes, considered to be

simple apparatus (Clause 5.4 of EN50 020:1994).

Although the BA354D indicator does not itself

comply with the requirements for simple apparatus,

the EC-Type Examination Certificate specifies that

under fault conditions the voltage, current and

power at the 4/20mA input terminals 1 and 3 will

not exceed those specified for simple apparatus in

Clause 5.4 of EN50020:1994. This allows the

BA354D 4/20mA input terminals to be connected

into any intrinsically safe circuit protected by a

Zener barrier or galvanic isolator without the need

for additional certification, providing the output

parameters of the circuit do not exceed:

Uo 30V dc

Io 200mA dc

Po 0.85W

The BA354D EC-Type Examination Certificate

specifies that the maximum equivalent capacitance

and inductance between the two 4/20mA input

terminals 1 and 3 is:

Ci 20nF

Li 10µH