Electrolux TS-5121 User manual

Other Electrolux Dryer manuals

Electrolux

Electrolux EW2H328R2 User manual

Electrolux

Electrolux EDI 96150 W User manual

Electrolux

Electrolux TE1120 User manual

Electrolux

Electrolux T3900 User manual

Electrolux

Electrolux EFDE210TIW User manual

Electrolux

Electrolux TW SL EEV User manual

Electrolux

Electrolux EWED65H SS User manual

Electrolux

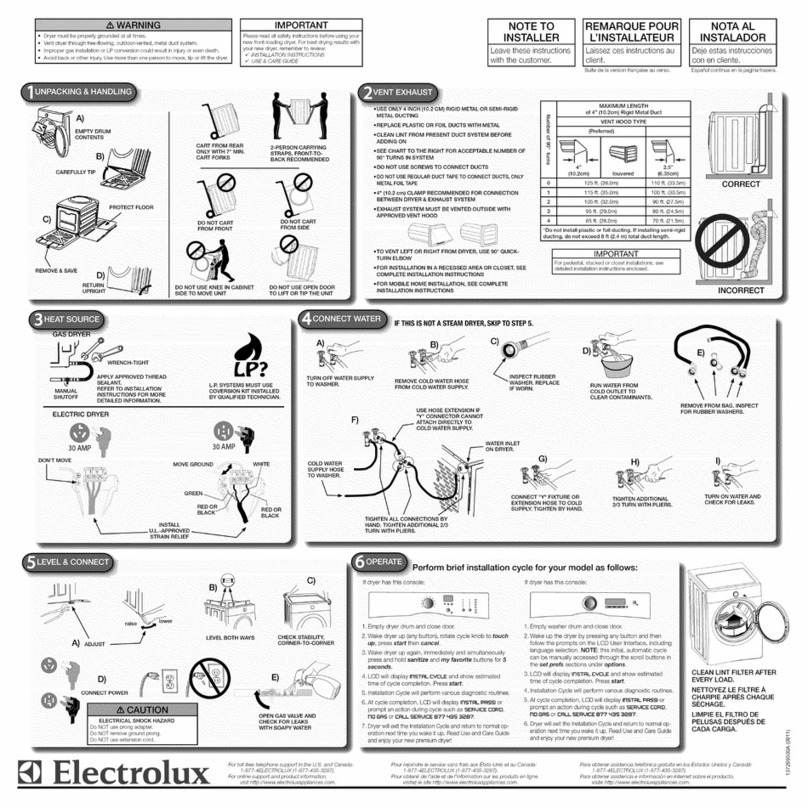

Electrolux EIGD55HIW - 27" Gas Dryer Installation instructions

Electrolux

Electrolux IQ-Touch EIMGD60LSS0 User manual

Electrolux

Electrolux EDC804P5WB User manual

Electrolux

Electrolux EFMG617STT User manual

Electrolux

Electrolux EDH3284PDW User manual

Electrolux

Electrolux EDC 504M User manual

Electrolux

Electrolux EW8H458BP User manual

Electrolux

Electrolux T4650 User manual

Electrolux

Electrolux EW2C327R1 User manual

Electrolux

Electrolux EWMED70J IW User manual

Electrolux

Electrolux T4290 Owner's manual

Electrolux

Electrolux EDC67550W User manual

Electrolux

Electrolux DC3500TWR User manual

Popular Dryer manuals by other brands

Kenmore

Kenmore 8041 - 5.8 cu. Ft. Capacity Electric Dryer installation instructions

Frigidaire

Frigidaire CAQE7077KW0 use & care

Bosch

Bosch WTX8HKM9SN User manual and installation instructions

Sharp

Sharp KD-NHH9S7GW2-PL user manual

Samsung

Samsung DV431AEPXAC user manual

Speed Queen

Speed Queen ADE3TRW5431AW01 Specifications