Module d'acquisition température

Temperature Measuring Module

No. 5311249-00/01 fe

ELEKTRONISCHE REGELUNGEN GMBH D-68766 Hockenheim, germany

Schwetzinger Str. 103

Telefon (+49)(0) 62 05 / 2009-0

Telefax (+49)(0) 62 05 / 2009-39

Technischer (+49)(0) 62 05 / 2009-25

Service (+49)(0) 62 05 / 2009-27

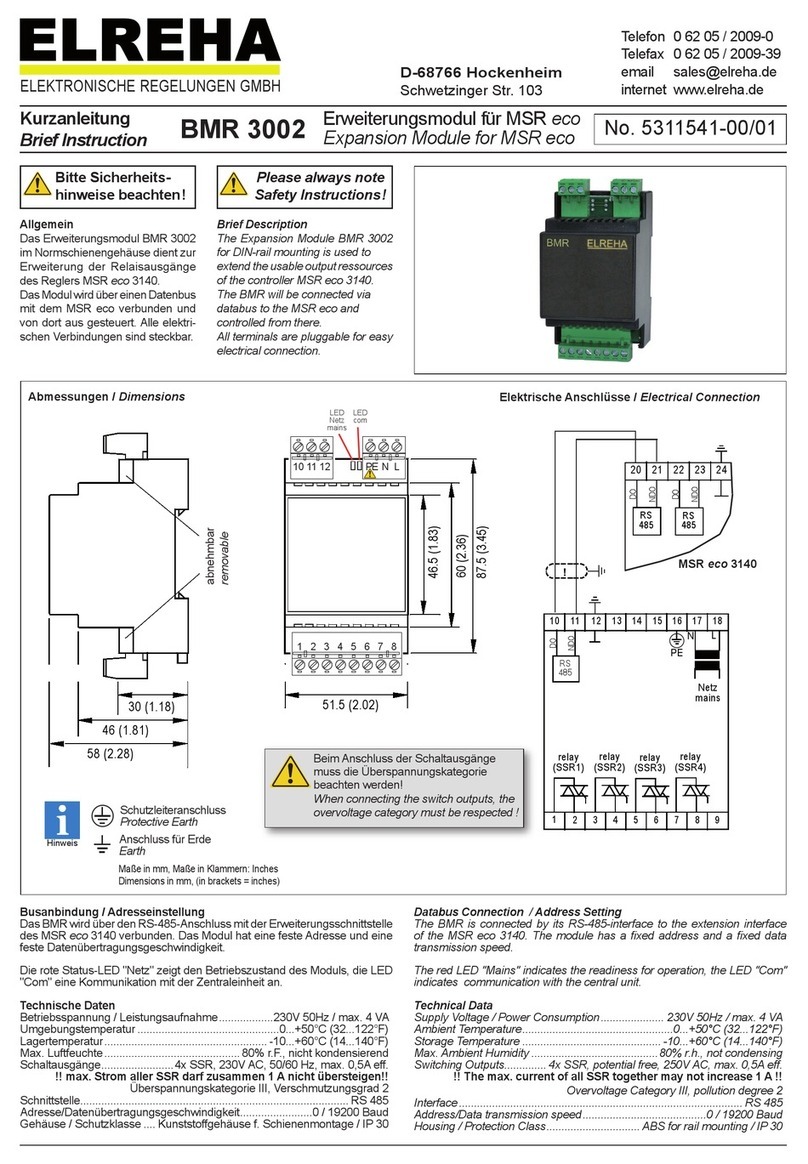

BMT 2101

Description

• Boîtier d'acquisition pour montage mural

• Connexions pour 4 sondes de température

type TF 201ou TF 501 (PT1000)

• Lecture et paramétrage via interface

RS-485

• Relais d'alarme en option pour trans-

mission défauts de température ou de

sonde

• Diagnostique interne par LED

• Prévu pour augmenter l'acquisition de

points de mesure dans un réseau de

régulateurs existant ou pour créer un

système d'enregistrement et surveillance

complet avec le SMZ en tête.

Brief Description

• Temperature Sensor Module for wall

mounting

• Connection for 4x TF 201 or

4x TF 501-Sensors

• Can be programmed and read via

RS-485-interface

• Optional alarm relay allows forwarding of

error messages like temperature too high/

low, sensor malfunction

• Internal diagnostic LEDs

• Designed to extend controller networks by

additional sensor inputs or to assemble

extensive data logger systems using SMZ

Frontends

Données techniques

Alimentation .................230V AC / 50-60Hz, env. 3 VA

Sonde de température.4x TF 201 ou 4x TF 501,

impossible de mélanger les 2 types !

Plage de mesure..........-100,0°C...+100.0°C (avec TF 501, Pt1000)

-50,0°C...+50,0°C (avec TF 201)

Interface ......................RS-485, reconnaissance automatique de la

vitesse de transmission de 1200 / 2400 / 4800 /

9600 / 19200 / 28800 / 57600 19200 baud

T°C fonctionnement .....-25...+50°C

Humiditéambiante........85% h.r. non condensée

Connexions.................. Bornes à vis 1,5 mm²

Presses-étoupes pour entrée des câbles

Boîtier ...........................Plastique, montage mural

Protection.....................IP54

Option

Relais d'alarme ............Inverseur libre de tt pot., 8A rés, 3A ind./230VAC

Connexions.................. Bornes à vis 1,5 mm²

Technical Data

Supply Voltage ..................230V AC / 50-60 Hz, appr. 3 VA

Temperature Sensors.......4x TF 201 or TF 501, not mixed

Temperature Range..........-100,0°C...+100,0°C (with Pt1000)

-50,0°C...+50,0°C (with TF 201)

Interface ............................RS-485, automatic baudrate recognition

for 1200 / 2400 / 4800 / 9600 / 19200 / 28800/

57600 baud

Operating Temperature ....-25...+50°C (-22...+122°F)

Ambient Humidity .............max. 85% r.H. not condensing

Electrical Connection ...... screw terminal 1,5 mm²

cable insertion via PG-glands

Housing ............................ plastic, wall mounting

Protection ......................... IP 54 / Nema 3, 3S, 13

optional

Relay Output .....................SPDT-contact, pot.free,

8A res, 3A ind. 230VAC

Connection ....................... screw terminal 1,5 mm²

Paramètres interrogeables et réglables via l'interface RS-485

Mesure 1-4...................-100,0°C...+100.0°C, Résolution 0,1K

Version programme .....ex. BMT 1.0

Type de sonde .............TF 501 (Pt1000, usine) / TF 201 (PTC2000)

Nom de l'appareil ..........16 caractères maxi. (usine "BMT")

Paramètrage pour chaque sonde

Sonde connectée.........oui / non (usine = oui)

Alarme basse...............-100,0°C...+100.0°C (usine -100,0°C)

Alarme haute................-100,0°C...+100.0°C (usine +100,0°C)

Retard d'alarme ............0...240 min (usine 5 min)

Correction ....................± 10,0K (usine 0,0K)

Nom de sonde ..............16 caractères maxi. (usine "sensor x")

Parameters, readable and programmable via interface

Actual Temperature 1-4 .... -100,0°C...+100.0°C, resolution 0,1K

Program Version ............... e.g. BMT 1.0

Sensor Type ...................... TF501 (Pt1000, default) / TF 201 (PTC)

Unit Name .......................... max. 16 characters (default "BMT")

Parameters of each Sensor

Sensor ............................... on / off (default = on)

Lower Alarm Limit.............. -100,0°C...+100.0°C (default -100,0°C)

Upper Alarm Limit.............. -100,0°C...+100.0°C (default +100,0°C)

Alarm Delay ....................... 0...240 min (default 5 min)

Sensor Correction ............. ± 10,0K (default 0,0K)

Sensor Name..................... max. 16 characters (default "sensor x")

DO

Databus

RS-485, E-Link

BMT 2101BMT 2101

GND

NDO

DO

NDO

GND

DO

NDO

GND

BMT 2101

Exemple d'application

Application Example