Electrothermal STEM RS1000 User manual

Page 1 of 24

RS1000 Instruction Book M7239. Issue 4.3

RS1000 REACTION STATION

PS80010 & PS80033

Page 2 of 24

RS1000 Instruction Book M7239. Issue 4.3

INSTRUCTION BOOK

Please take your time to read this Instructions book in order to understand the safe and

correct use of your new Bibby Scientific product.

It is recommended the Responsible Body for use of this equipment reads this

Instruction book and ensures the user(s) are suitably trained in its operation.

CONTENTS

Section 1

Introduction

Page

3

Section 2

Symbols and using this Instruction book

Page

4

Section 3

Safety Information.

Page

5

Section 4

Unpacking and Contents

Page

7

Section 5

Installation

Page

8

Section 6

Environmental Protection.

Page

9

Section 7

Product Operation.

Page

10

Section 8

Technical Specification.

Page

17

Section 9

Maintenance

Page

19

Section 10

Customer Support

Page

21

Section 11

Spares and Accessories

Page

22

Section 12

EC declaration of Conformity

Page

24

Appendix A

Decontamination Certificate.

Page

23

©The copyright of this instruction book is the property of Bibby Scientific Limited. This instruction book is supplied by

Bibby Scientific Limited on the express understanding that it is to be used solely for the purpose for which it is

supplied. It may not be copied, used or disclosed to others in whole or part for any purpose except as authorised in

writing by Bibby Scientific Limited. Bibby Scientific Limited reserves the right to alter, change or modify this document

without prior notification.

In the interest of continued development Bibby Scientific Limited reserve the right to alter or modify

the design and /or assembly process of their products without prior notification.

This product is manufactured in Great Britian by Electrothermal, part of the Bibby Scientific Group of

companies.

Bibby Scientific Limited.

Beacon Road,

Stone,

Staffordshire ST15 0SA,

Great Britain.

Tel: +44(0)1785 812121

Fax: +44(0)1785 810405

Note: All illustrations in this document are for reference only

Page 3 of 24

RS1000 Instruction Book M7239. Issue 4.3

1.

INTRODUCTION.

1.1. This product is designed to meet the demands of today’s modern laboratory and has been

meticulously designed to provide years of service when used as described in the following

pages. This product is a 10-positioned heat and stir reaction station designed for use with

24 or 25 mm diameter glass vessels. (Variant dependant).

1.2. At the heart of this product is an innovative, firmware package designed to provide

enhanced, accurate temperature control of the block or vessel. Temperature is sensed by a

high precision platinum sensor embedded within the vessel block. A microprocessor

constantly monitors temperature change many times per second. The products

temperature range is from ambient to 150°C.

1.3. Linked DC motors provide optimum speed control and sensitivity to drive the stir facility.

High performance magnetic sensors carefully measure speed control via a feedback loop

controlled by quartz oscillator and a microprocessor. The stir speed range is 400 –

2000rpm.

1.4. The vessel block is aluminium with a Teflon coating. The raised case walling reduces heat

loss, which improves energy efficiency and adds to the protection of the user.

Page 4 of 24

RS1000 Instruction Book M7239. Issue 4.3

2.

SYMBOLS AND USING THIS INSTRUCTION BOOK.

2.1. Throughout this Instruction book the following symbols are shown

to identify conditions which pose a hazard to the user or to identify actions that should be

observed. These symbols are also shown on the product, or its packaging. When a symbol

is shown next to a paragraph or statement it is recommended the user takes particular note

of that instruction in order to prevent damage to the equipment or to prevent injury to one’s

self or other people.

The Responsible Body and the Operator should read and be familiar with this

Instruction book in order preserve the protection afforded by the equipment.

To prevent injury or equipment damage it is the manufacturer’s recommendation that

all persons using this equipment are suitably trained before use.

2.2. Symbols defined.

Caution, risk of danger. See note

or adjacent symbol.

This symbol denotes the use of the

heating function

Protective conductor terminal to

be earthed. (Do not loosen or

disconnect).

This symbol denotes this section of

the fascia is designated for the control

of the stirring function.

Caution / risk of electric shock

This symbol denotes this section of

the facia is designated for the setting

and control of the temperature

Recyclable Packing Material

These symbols are designated for the

left and right arrow functions when

setting the product

Do not dispose of product in

normal domestic waste.

These symbols are designated for the

up and down arrow functions when

setting the product

Caution. Hot surface.

Bio Chemical Hazard. Caution

required. Will require

decontamination.

Refer to Instruction book.

Page 5 of 24

RS1000 Instruction Book M7239. Issue 4.3

3.

SAFETY INFORMATION.

This product has been designed for safe operation when used as detailed in accordance with the

Manufacturer’s instructions.

NOTE: Failure to use this equipment in accordance with the manufactures operating instructions

may compromise your basic safety protection afforded by the equipment and may invalidate the

warranty / guarantee. The warranty / guarantee does not cover damaged caused by faulty

installation or misuse of the equipment

3.1. Prevention of Fire and Electric Shock.

To prevent a risk of fire or electric shock,

DO NOT

open your product case

without authorisation. Only Qualified Service Personnel should attempt to

repair this product.

Replace fuses only with the type as listed in section, ‘Technical

Specifications and Parts and Accessories’ (See fuse type and rating).

Ensure the Mains Power Supply conforms to rating found on the data plate

located on the right hand side of this product.

Never

Operate this equipment without connection to earth / ground.

Ensure the mains supply voltage is correctly earthed / grounded in

accordance with current area legislation.

3.2. General Safe Operating Practice.

Always follow good laboratory practice when using this equipment. Give

due recognition to your company’s safety and legislative health & safety

procedures and all associated legislation applicable to your areas of

operation. Check laboratory procedures for substances being heated and

ensure all hazards (e.g. explosion, implosion or the release of toxic or

flammable gases) that might arise have been suitably addressed before

proceeding. When heating certain substances the liberation of hazardous

gases may require the use of a fume cupboard or other means of

extraction.

Do not

position the product so that it is difficult to disconnect from the

mains supply.

Do not touch the heating block or any glass vessel whilst in use.

Do not lean or stretch over equipment, glassware and fixings when in use.

Do not immerse unit in water or fluids.

Do not spill substances onto the heating block. If spillage does occur,

disconnect unit from mains supply and follow instructions as detailed in

Page 6 of 24

RS1000 Instruction Book M7239. Issue 4.3

Maintenance. (Section 9).

Do not cover this product whilst in use. Do not block or obstruct ventilation

slots / airways.

Do not leave equipment switched on without a charged flask(s).

It is not recommended to leave any heating apparatus unattended during

operation.

Only use Original Equipment manufacturers spares and accessories. Ref

Section 10.

This equipment will generate magnet fields. Keep all metal objects and

magnetic data devices (e.g. credit cards) away from the stirrer unit.

The equipment is not spark, flame or explosion proof and has not been

designed for use in hazardous areas in terms of BSEN 60079-14:1997.

Keep flammable, low flash point substances away from the apparatus.

Do not operate or handle any part of the product with wet hands.

Keep the Mains cord and moulded IEC plug and lead set away from the

heating surface.

Page 7 of 24

RS1000 Instruction Book M7239. Issue 4.3

4.

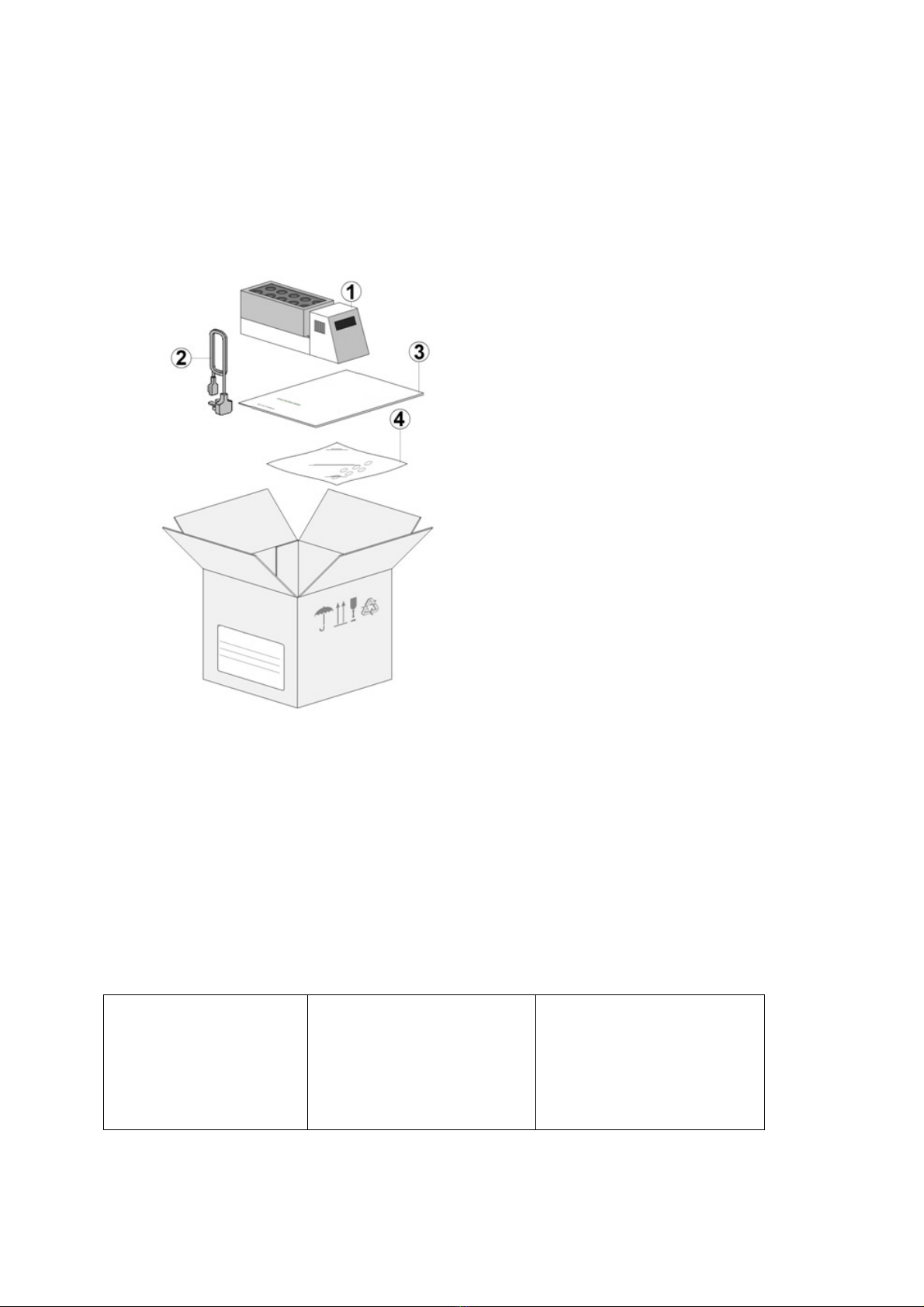

UNPACKING AND CONTENTS.

4.1. Please check the contents of your carton against the diagram.

Item Description Qty

1 RS1000 Product 1

2 Mains Cord and Lead set A/R

(illustration only)

3 Instruction book 1

4 Stir Bars (Pkt 10) 1

For future reference

please record your

products Serial and

Model Numbers.

Serial Number Unit Model/Cat Number

Page 8 of 24

RS1000 Instruction Book M7239. Issue 4.3

5.

INSTALLATION.

5.1.

Electrical safety and installation.

5.1.1.

This equipment is designed to be used safely under the following conditions:-

•Indoor use.

•Altitude up to 2000 meters.

•Temperatures between 5°C and 40°C.

•Maximum relative humidity 80% for temperatures up to 31°C decreasing linearly to

50% relative humidity at 40°C.

•Mains supply voltage fluctuations up to ±10% of the nominal voltage.

•Transient over voltages typically present on the mains supply

(Over voltage category II). Applicable rated pollution degree 2.

5.2.

This equipment must be earthed / grounded to a fixed earth / grounded mains

socket outlet. The mains supply is to earthed / grounded in accordance with current

legislation.

5.3.

Ensure only the correct rated mains input fuses are fitted. (Where applicable ensure the

correct Mains cord and moulded IEC plug and lead set fuse if fitted). See Technical

Specification Section 8 of this Instruction book.

5.4.

Check the voltage on the data label of this product. Ensure the rating conforms to your

local supply.

5.5.

It is recommended this product be connected to a mains supply source which

incorporated a RCD or GFCI device.

5.6.

Do not install this product or accessories on a surface which may become

wet or flooded.

5.7.

The unit is supplied with a Mains cord and moulded IEC plug and lead set wired as

follows.

Green / Yellow

or Green = Earth / Ground

Blue or White = Neutral

Brown or Black = Live / line hot.

Page 9 of 24

RS1000 Instruction Book M7239. Issue 4.3

5.8.

Install equipment is used on a clean, dry, non-combustible, solid work surface

with at least 300mm suitable clearance all around from other equipment / objects.

6.

ENVIRONMENTAL PROTECTION.

6.1.

Maximum consideration has been given to environmental issues within the design and

manufacturing process without compromising end product performance and value.

6.2.

Packaging materials have been selected such that they may be sorted for

recycling.

6.3.

At the end of your product and accessories life, it must not be discarded as

domestic waste. Ref: EU Directive 2002/96/EC on Waste Electrical and Electronic

Equipment Directive (WEEE). Please contact your distributor / supplier for further

information. For end users outside of the EU consult applicable regulations.

6.4.

This product should only be dismantled for recycling by an authorised recycling

company.

This product and accessories must be accompanied by a completed

Decontamination Certificate prior to any disposal. Copies of the Certificate are

available from your distributor of Bibby Scientific products, or you may copy and

enlarge from ‘Appendix A’ of this instruction book.

Page 10 of 24

RS1000 Instruction Book M7239. Issue 4.3

Bibby Scientific’s Electrothermal branded product range is registered with the Environment Agency under the name of as Electrothermal

Engineering Limited as being a producer of WEEE (Waste Electronic and Electrical Equipment) through b2b Compliance,an authorised waste

collection compliance scheme.

7.

PRODUCT OPERATION.

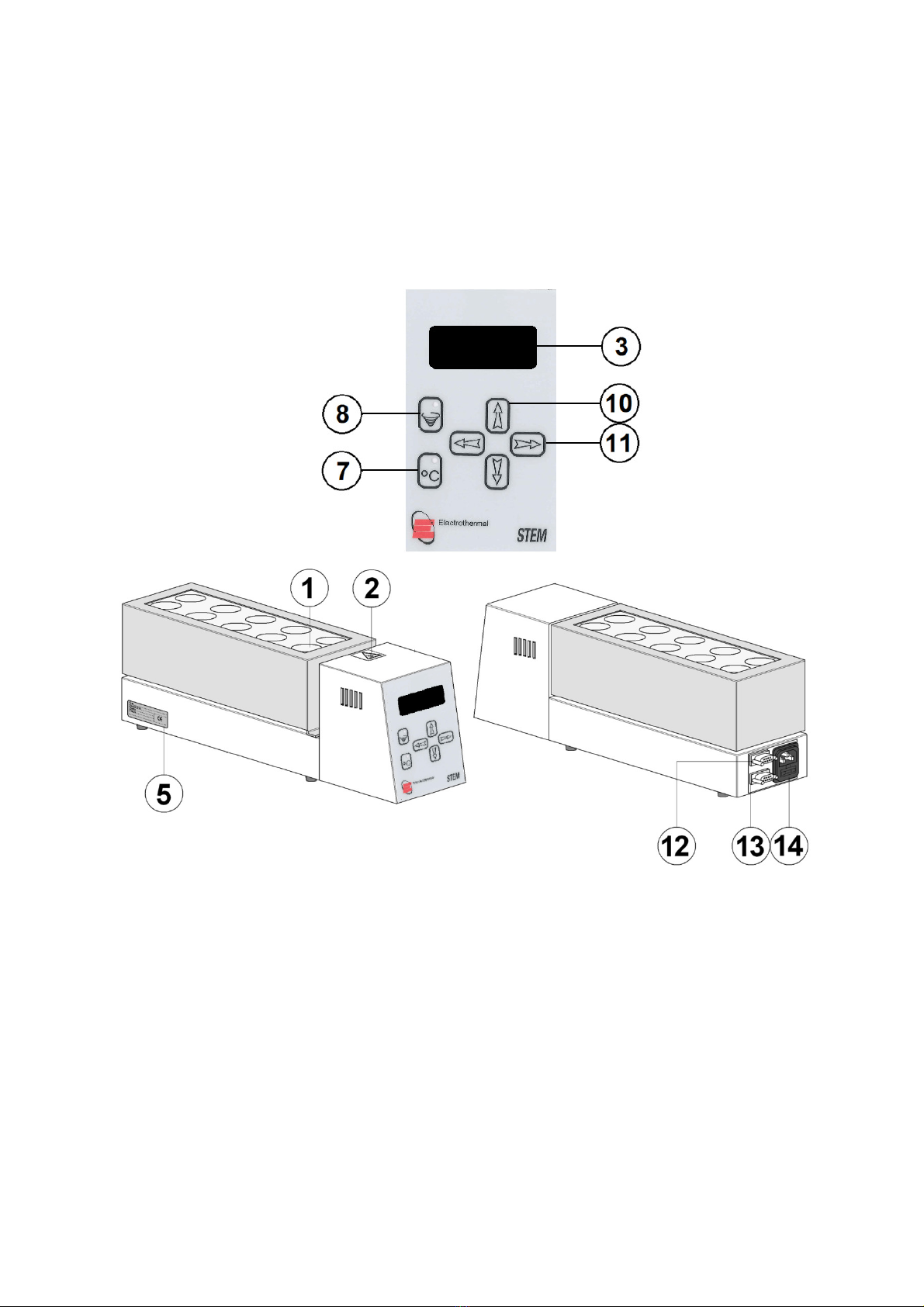

7.1. The illustration below shows the general layout of the RS1000.

1 Reaction block chamber

2 Hot Surface warning Label.

3 Display

5 Data Plate – Refer to for correct voltage.

7 Temperature on/off selection button

8 Stir facility on/off button

10 Up / Down arrow function select and set button

11 Left / Right arrow function select and set button

12 RS232 9-way connection socket.

13 RS485 9-way connection socket

14 IEC socket with fuse protection.

Page 11 of 24

RS1000 Instruction Book M7239. Issue 4.3

7.2. Plug the mains cord with the moulded IEC plug into the IEC socket of the unit. Connect the

mains plug to the correct voltage mains supply. Check data plate for correct voltage

input.

7.3. The display will peform a warm up and self check prior to displaying the present temperature

for the reaction block.

Sound Indication: - A short ‘Beep’ gives indication of parameter change. Long ‘Beep’ gives

warning of error.

7.4. Main Screen

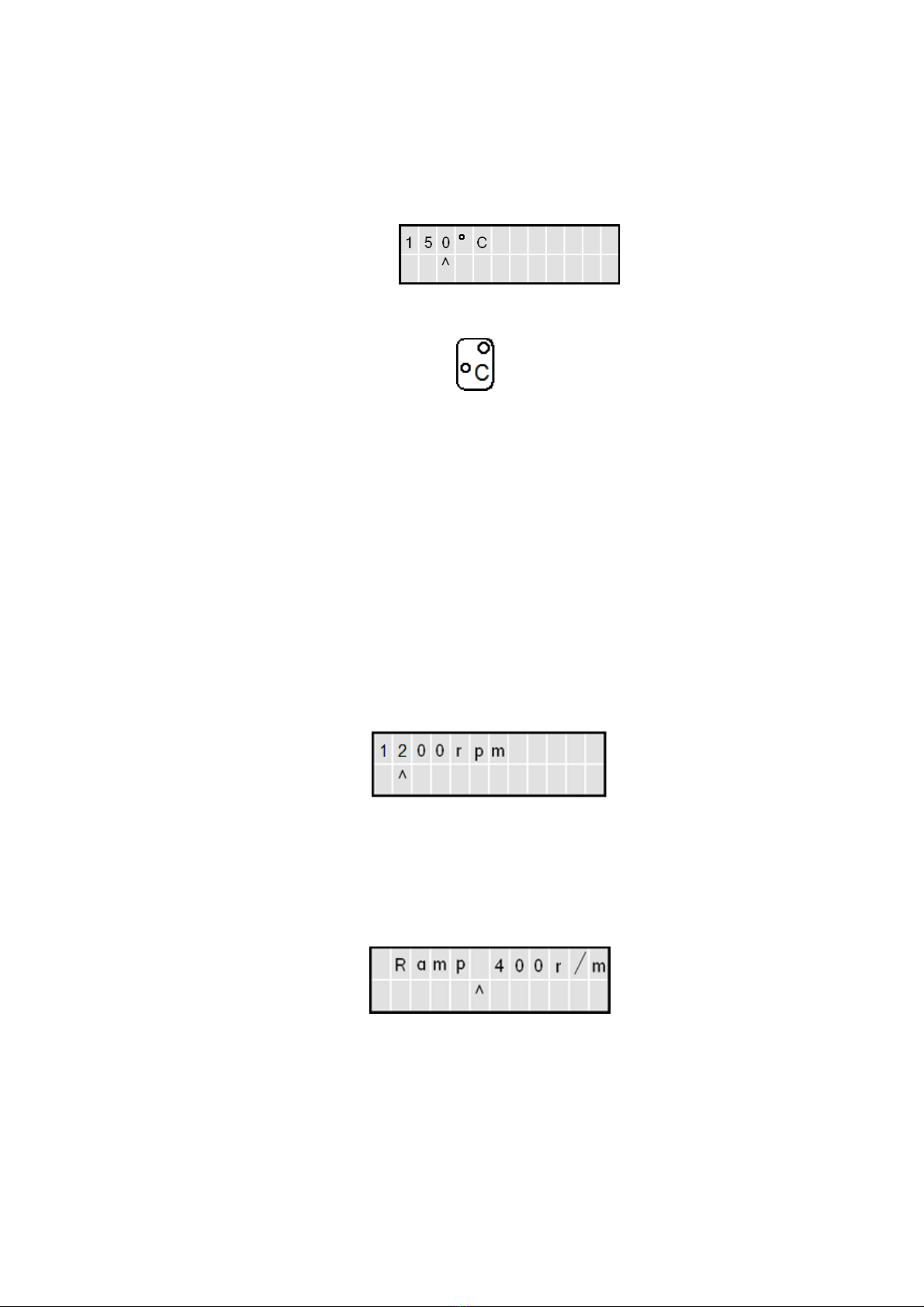

7.4.1.The following screen shot shows the actual block temperature. This is likely to be at

ambient temperature when the RS1000 is first powered up from cold. The “T” in the

display shows the mode for setting the temperature. The “S” in the display shows the

mode for setting the stir speed. The “t” in the display is used to set the count down time

left before the heating function is turned off. Actual block temperature is displayed in

degrees Centigrade. Stir speed is measured in RPM and shown with the “s” symbol

denoting Speed.

Note: If 10 seconds elapse without a key being pressed the display is to return to the

main display screen.

7.5. Setting and Operating the Heater Function

7.5.1.From the main display screen press the < key to go into Temp setting screen.

7.5.2.Press the ^or vto make the 100’s selection. Press the >key to go into 10’s set screen.

First time factory default setting to be 5

°

C.

Last user setting will be displayed.

Page 12 of 24

RS1000 Instruction Book M7239. Issue 4.3

7.5.3.Press the ^or vto make the units selection. Press the >to go back to main display

screen.

7.5.4.To commence heating press the heating button. To turn off the heating function press

the button one once again.

Note: The main display screen will always show the actual temperature of probe or block

PT100. During the heating process the red LED found in the center of the Heater on/off key

will flash. When the set temperature has been reached the flashing will stop and remain

constantly illuminated.

When adjusting the set temperature from a reached temperature to another, to accommodate

over / under temperature oscillation the LED will not recommence flashing until temperature

of ± 10°C off of the original set temperature has been made.

7.6. Stirrer Functions.

7.6.1. From the Main display screen press the > key to enter the Stir speed selection screen.

7.6.2.Press the > or < to make the 1000’ 100’ 10 and units selection. Press the ^ and v

buttons to select the values.

Note: The maximum settable stir speed value is 2000 rpm.

7.6.3.Press the > from the units setting to enter the stir speed ramp mode.

7.6.4.Using the > or < to make the 1000’ 100’ 10 and units selection. Press the ^ and v

buttons to select the ramp speed values.

Example: in the example, the stir speed will ramp up at the rate of 400rpm per minute. So if a

stir speed of 1200 rpm was set, it would take approximately 2 minutes to ramp from start to

1200rpm. Ie 400 to 1200 rpm in 2 minutes.

7.6.5. Repeatedly press the > button to exit the stir speed setting mode.

7.6.6. To commence stirring press the stir button. To stop stirring press the stir button once

again.

Page 13 of 24

RS1000 Instruction Book M7239. Issue 4.3

7.7. Timer set function.

The maximum time setting is 99 hours and 59 minutes.

Note: Once the timer has been set it will not commence count down until the Heater on/off

key is activated.

7.7.1.From the main display screen press the ^ key.

7.7.2.Press the ^or vto make the 10’s hours selection. Press the >key to go into unit hours

selection screen.

7.7.3. Press the ^or vto make the 10’s minutes selection. Press the >to go back to main

display screen.

Note: If 10 seconds elapse without a key being pressed the display is to return to the

main display screen.

7.7.4.With the timer set the front screen will display only count down hours until only minutes

are left on the time counter, then minutes are to be displayed. The front screens will

look like this. hdenotes hours and mdenotes minutes. When the time counter reaches

zero the heaters are turned off. The Heater on Red LED is extinguished and the main

display screen reverts to ^t. A 1 second beep is to be sounded when heaters are turned

off in timer mode.

Note: The timer will not commence count down until the set temperature has been

reached and the Red LED is constant.

Page 14 of 24

RS1000 Instruction Book M7239. Issue 4.3

7.8. Host PC Operation.

7.8.1.Disconnect the power to the unit.

7.8.2. Connect a lead between the host PC and the RS232 socket of the RS1000 unit.

7.8.3.When the unit is coupled to external software that is PC biased, the keypad will become

locked and access to the RS1000 menu will not be possible.

7.9. RS232 Operation.

7.9.1.When the unit is coupled to an external host robotic system that is either RS485 or

using GSIOC protocol through the RS485 socket the following screens are seen.

Page 15 of 24

RS1000 Instruction Book M7239. Issue 4.3

7.10. STEM

Protocol (RS232).

Stem command SET can be operated using RS232.

Unit address 40. Baud rate is 9600, N, 8, 1.

Command set as follows: -

LK*

Local Keypad (0 or 1)

SE

*

Stirrer enabled (0 or 1)

SR

*

Stir speed ramp rate (400 to 2000 per min)

SS

*

Stir Speed (RPM) (400 to 2000)

TE

*

Thermal control enabled (0 or 1)

TT*

Target temperature. (ºC). (0.0 to 150)

TR

*

Temperature Ramp rate (ºC/min) (0.0 to 5.0)

Note: For TR 0.0 indicates no control. *Denotes variable parameter

Query command set

QC

Request commanded variables

QF

Request system principal fixed values.

QM

Request measured data

Using a suitable terminal, type in and test some of the commands and query set,

STEM protocol.

Examples of STEM Command protocol used.

“<CR>” Is a carriage return character.

Type in: >40 SE1 #0000 <CR>

Response: <40.00 OK <CR>

Result: Stirrer enabled (LED for stirrer ON< RS600 will commence stirring).

Type in: >40 SE0 #0000 <CR>

Response: <40.00 OK <CR>

Result: Stirrer disabled (LED for stirrer OFF, RS600 will stop stirring).

Type in: >40 TT123,4 TE1 #0000

Response >40,00 OK <CR>

Result Target temperature set to 123, 4ºC, thermal control enabled (LED for

ON< temperature will begin to raise block temperature).

Type in: >40 SS2000 SE1 SR2 #0000 <CR>

Response: <40,00 OK <CR>

Result: Stirring enabled, stirring speed set to 2000 rev/min, Stirrer ramp rate

set to 2, (Stirring speed will steadily increase to 2000 rev/ min over 2

minutes).

Page 16 of 24

RS1000 Instruction Book M7239. Issue 4.3

GSIOC Interface module for RS1000.

The interface module is designed to comply with the specifications in the Gilson

document “GSIOC technical Manual” dated March 1999.

Buffered Commands:

Command Meaning.

T1 Turn on thermal control

T0 Turn off thermal control

S1 Turn on stirrer, start speed ramp-up

S0 Turn off stirrer, reset speed ramp.

P# Set temperature set point to #°C (Range 5 to 150°C)

V# Set stir speed target to # rpm (Range 400 to 2000)

R# Set stir ramp control to # rpm/min (Range 0 to 2000 – 0 means no

ramp control).

L1 Lock local keypad

L2 Unlock local keypad

Z# Set GSIOC address

Immediate commands

Command Meaning. Return Value.

$ Reset unit $

W Report current temperature # (# is temperature in °C).

Q Report set temperature set

point

# (# is set point in °C).

A Report for stir speed # (# is set speed in rpm).

B Report set ramp time # (# is set ramp time in seconds).

S Report status xy X is the ‘ready’ status; it will be “1”

if the unit is not ready to accept a

command and “0” if the unit is

ready. Y is the ‘error’ status; it will

be “12 if the last command was

not accepted, otherwise it will be

“0”

K Report keypad lock status x X is “1” for locked, and “0” for not

locked.

Notes:

•Before taking control of the unit using GSIOC, the ‘L1’ command must be sent to lock the local keypad.

When control is released, ‘L0’ may be sent to unlock the keypad and allow manual control.

Page 17 of 24

RS1000 Instruction Book M7239. Issue 4.3

•Numbers, represented by “#” are decimal numbers of up to four digits.

8.

TECHNICAL SPECIFICATIONS.

8.1. Specification.

Mains Supply Power. 230V-AC or 115/100V-AC @ 50/60Hz

Mains Power Lead set (UK) 13A

BS1362

3 core earthed / ground. 2 meters long

Moulded IEC plug and Lead set – supply cord H0 V V-F-

Replace only with equivalent cable.

Mains Power Lead set (Europe) 3 core earthed / ground. 2 meters long

Moulded IEC plug and Lead set – supply cord H0 V V-F-

Replace only with equivalent cable.

Mains Power Lead set (USA) 3 core earthed / ground. 2 meters long

Moulded IEC plug and Lead set – supply cord SJT VW

1- Replace only with equivalent cable.

Lead set plug fuse (UK – only) 13A

Power Consumption 600W

Operating Ambient Temperature 5°C to 40°C

Heating Temperature Range Ambient + 5 to 150°C

Display 2 x 12 back lit LED.

Fuse Type and Rating 230V~AC F5A Quick Blow 20mm

115 / 100V ~ AC F8A Quick Blow 20mm

Number of Vessel positions 10

Vessel diameter 24 / 25mm – may be reduced by the use of optional

adapter sleeves.

Well diameter 24.5 / 25.5mm

Stirring Rate Off and variable 400 to 2000 RPM.

Stirring speed accuracy ±0.5%.

Temperature stability ±1.0°C (Still air, under no load condition).

Interface RS232, RS485

Connection 9-way ‘D’ type socket / plug for connection to the serial

port of a laboratory computer or liquid handling system.

8.2. The Ingress protection rating for this product is classified as IPX1.

Page 18 of 24

RS1000 Instruction Book M7239. Issue 4.3

8.3. Weight. 4.0Kg without Glassware a Mains Cable.

8.4. Emissions Classification. (115V Only).

Warning! Any modification or changes made to this device, unless explicitly approved by

Bibby Scientific Limited, will invalidate the authorisation of this device. Operation of an

unauthorised device is prohibited under Section 302 of the Communications Act of 1934 as

amended, and Subpart 1 of Part 2 of Chapter 47 of the code of Federal Regulations.

NOTE: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interference at their expense.

NOTE: (230V) Product is found to comply with the limits of Class B digital device, pursuant to

part 15 of the FCC Rules.

Guidance notes.

Class A Digital Device.“A digital device that is marketed for use in a commercial, industrial

or business environment, exclusive of a device which is marketed for use by the general

public or is intended to be used in the home.”

Class B Digital Device.“A digital device that is marketed for use in a residential environment

notwithstanding use in commercial, business and industrial environments. Examples of such

devices included, but are not limited to, personal computers, calculators, and similar

electronics devices that are marketed for use by the general public

Page 19 of 24

RS1000 Instruction Book M7239. Issue 4.3

9.

MAINTENANCE.

9.1. General Information.

Unplug the unit from the mains voltage supply and allow it to cool before

undertaking any maintenance tasks.

Maintenance should only be carried out under the direction of the Responsible

Body, by a competent electrician. Failure to do so may result in damage to the product

and in extreme cases be a danger to the end user.

With proper care in operation this equipment has been designed to give many years of

reliable service. Contamination or general misuse will reduce the effective life of this product

and may cause a hazard.

Maintenance for the unit should include:

•Periodic electrical safety testing (an annual test is recommended as the minimum

requirement).

•Regular inspection for damage with particular attention to the mains lead and plug

set.

•Routine cleaning of the equipment should be undertaken using a clean cloth.

DO NOT USE SOLVENTS FOR CLEANING ANY PART OF THIS EQUIPMENT.

9.2. Internal Fuse Replacement.

The mains fuse holder is located at rear your product. Refer to Technical Specification, ‘Fuse

Rating’ for correct fuse type and rating. Turn your product off and remove it from the mains

supply. Open fuse draw and remove fuses. Fit replacement fuses and close the draw.

Page 20 of 24

RS1000 Instruction Book M7239. Issue 4.3

9.3. Servicing.

This product should be serviced by a Bibby Scientific Service Engineer or by an agent on

behalf of the manufacturer. If in doubt contact Customer Support. See Section 10.

9.4. Spillage and Decontamination.

In the event of spillage switch off and unplug this product from the mains electrical supply.

Wipe off all excess liquid from the reaction block and surrounding area using an absorbent

soft cloth. Allow sufficient time for any ingressed liquid to evaporate before commencing with

use.

If in doubt please consult Customer Support. Refer to section 10.

If the equipment has been exposed to contamination, the Responsible Body

is responsible for carrying out appropriate decontamination. If hazardous material has

been spilt on or inside the equipment, decontamination should only be undertaken

under the control of the Responsible Body with due recognition of possible hazards.

Before using any cleaning or decontamination method, the Responsible Body should

check with the manufacturer the proposed method will not damage the equipment.

Prior to further use, the Responsible Body shall check the electrical safety of the unit.

Only if all safety requirements are met can the unit be used again. The above

procedure is intended as a guide. Should spillage occur with a toxic or hazardous

fluid then special precautions may be necessary.

Decontamination Certificate.

Note: In the event of this equipment or any part of the unit becoming damaged, or requiring

service, the item(s) should be returned to the manufacturer for repair accompanied by a

decontamination certificate. Copies of the Certificate are available from

Distributor/Manufacturer. Appendix A of this instructions book may be copied and

enlarged.

At the end of life, this product must be accompanied by a Decontamination Certificate.

See section 6.3 and 6.4

Other Electrothermal Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

W&H Med

W&H Med lyla RIN-210-17 Instructions for use

Optika Italy

Optika Italy ACCESSORIES Series instruction manual

Velp Scientifica

Velp Scientifica RX3 instruction manual

Tableau

Tableau TX1 user guide

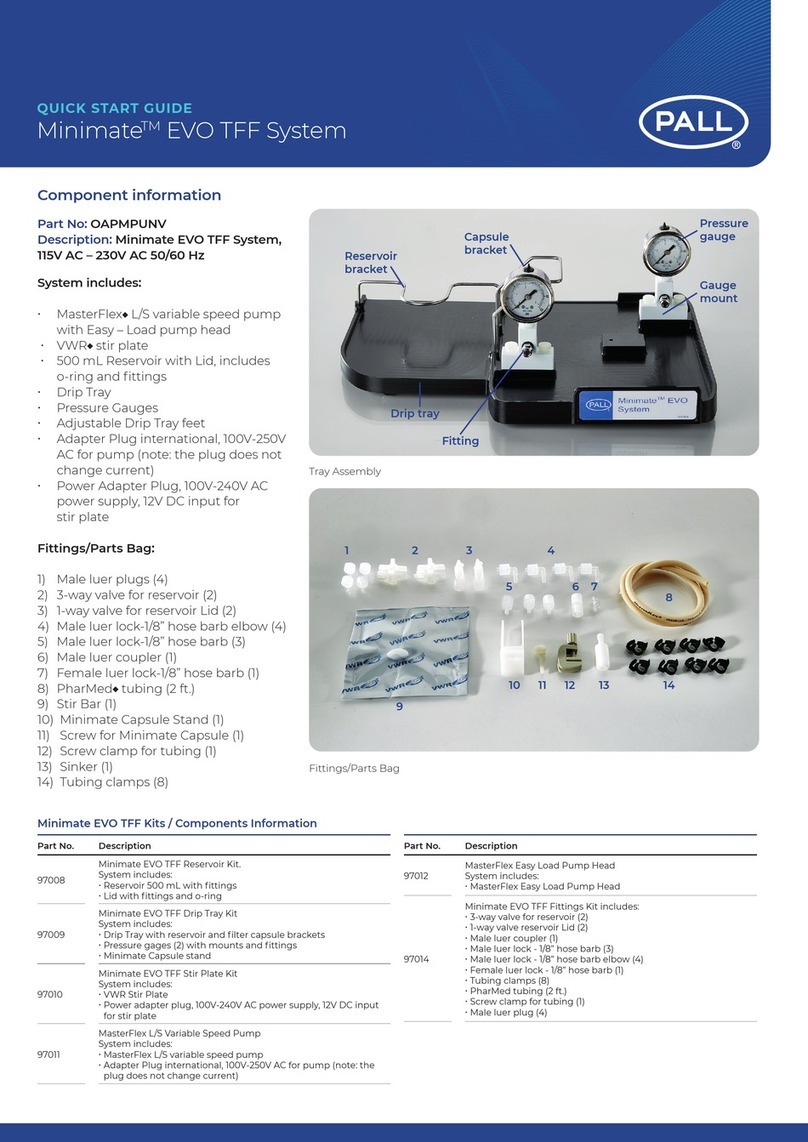

Pall

Pall Minimate EVO TFF quick start guide

Diesse

Diesse CHORUS TRIO CHORUS EXPANDER UPGRADE KIT installation guide