Corporate Headquarters

Port Washington, NY, USA

+1-800-717-7255 toll free (USA)

+1-516-484-5400 phone

European Headquarters

Fribourg, Switzerland

+41 (0)26 350 53 00 phone

Asia-Pacic Headquarters

Singapore

+65 6389 6500 phone

Visit us on the Web at www.pall.com/laboratory

Contact us at www.pall.com/contact

Pall Corporation has offices and plants throughout the world. To locate the Pall office

or distributor nearest you, visit www.pall.com/contact.

The information provided in this literature was reviewed for accuracy at the time of

publication. Product data may be subject to change without notice. For current

information consult your local Pall distributor or contact Pall directly.

GN21.0712

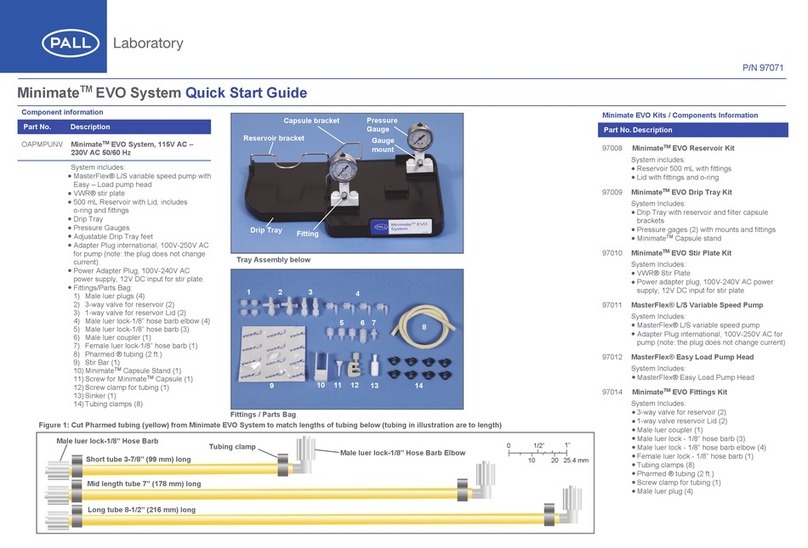

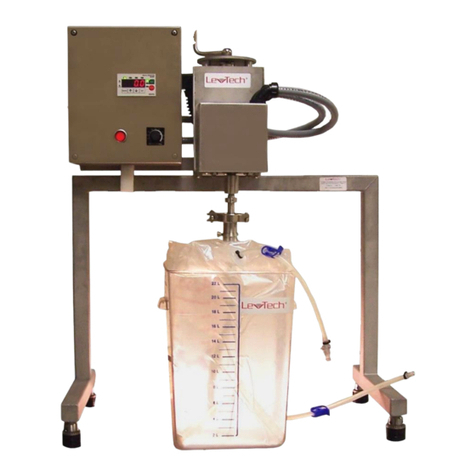

Figure 8

One way valve

Reservoir lid

Dialtration

vessel

Female luer – barb

(to ltrate port)

Filtrate

collection

vessel

14. Connect “short tube” to tting on front of gauge

mount and to 3-way valve on reservoir inlet. Attach

adjustable screw clamp to tube. Remove clamp

when not in use, tubing can deform over time

without uid passing through tubing. (See gure 7)

15. Cut a length of tubing from Minimate Capsule

packaging long enough to reach ltrate collection

vessel from ltrate port on lter capsule. Attach

tubing clamp and female luer-1/8” hose barb to tube

Connect tting to ltrate port and place open tube

end into ltrate receiver vessel. (See gure 8)

16. If performing dialtration, place lid onto reservoir.

Connect 1-way valves onto ttings on top of

reservoir. From the Minimate Capsule lter

packaging, cut a length of tubing to reach from

1-way valve on reservoir lid top to dialtration vessel

Attach male luer-1/8” hose barb elbow and tubing

clamp. Attach elbow to 1-way valve on lid and other

tube end into dialtration vessel, sinker at end of

tube optional. (See gure 8)

Operation

■Conrm all ttings are secure prior to running liquid

through system

■Refer to VWR stir plate operating manual for

operation of stir plate. Use of reverse mode is not

recommended on stir plate with Minimate EVO

TFF System. If stir bar stops rotating when increasing

stir plate speed, reduce speed until stir bar is

again spinning

■Refer to MasterFlex Pump and Pump Head

manuals for use

■Refer to Minimate Instructions for use for operation

of the TFF capsule

Figure 7

Retentate port

Screw

clamp

Short

tube

Mid

length

tube

Male luer coupler

(to feed port)

© Copyright 2022, Pall Corporation. Pall, , Centramate, Minimate, and Omega are

trademarks of Pall Corporation. ® Indicates a trademark registered in the USA. PharMed

is a register trademark of Saint-Gobain, VWR and Masterflex are registered trademarks of

Avantor, Inc. or affiliates.