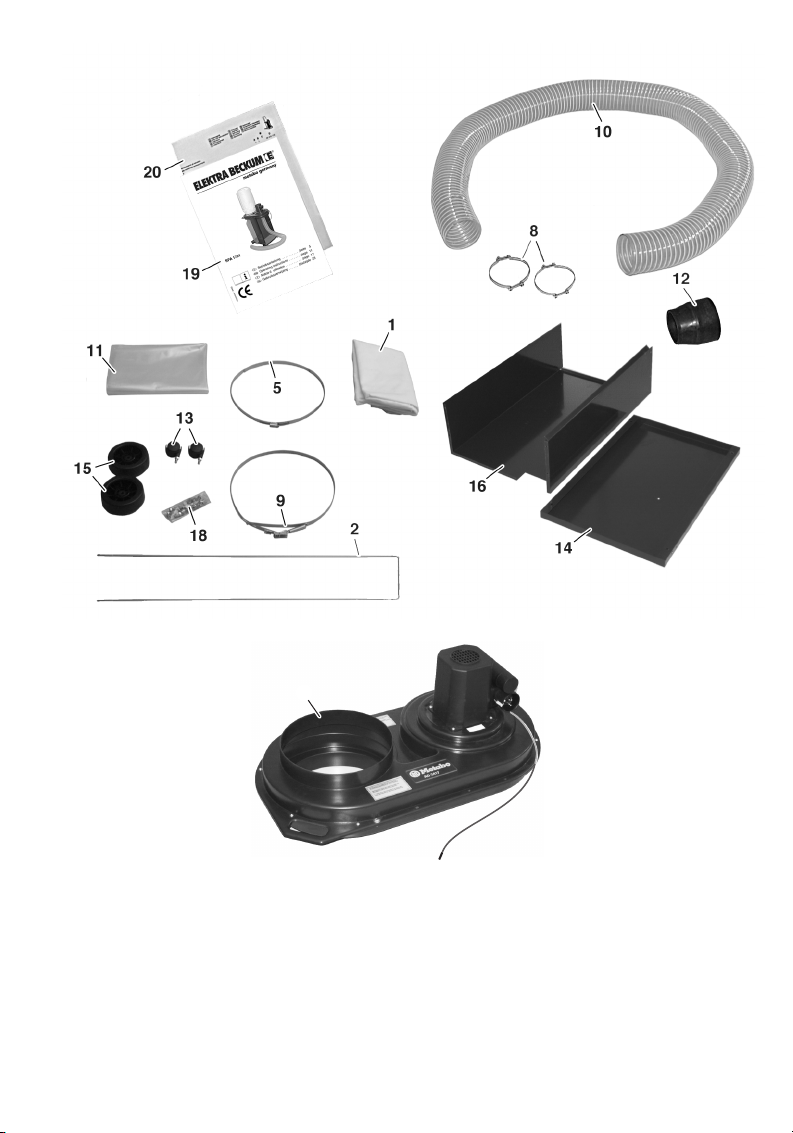

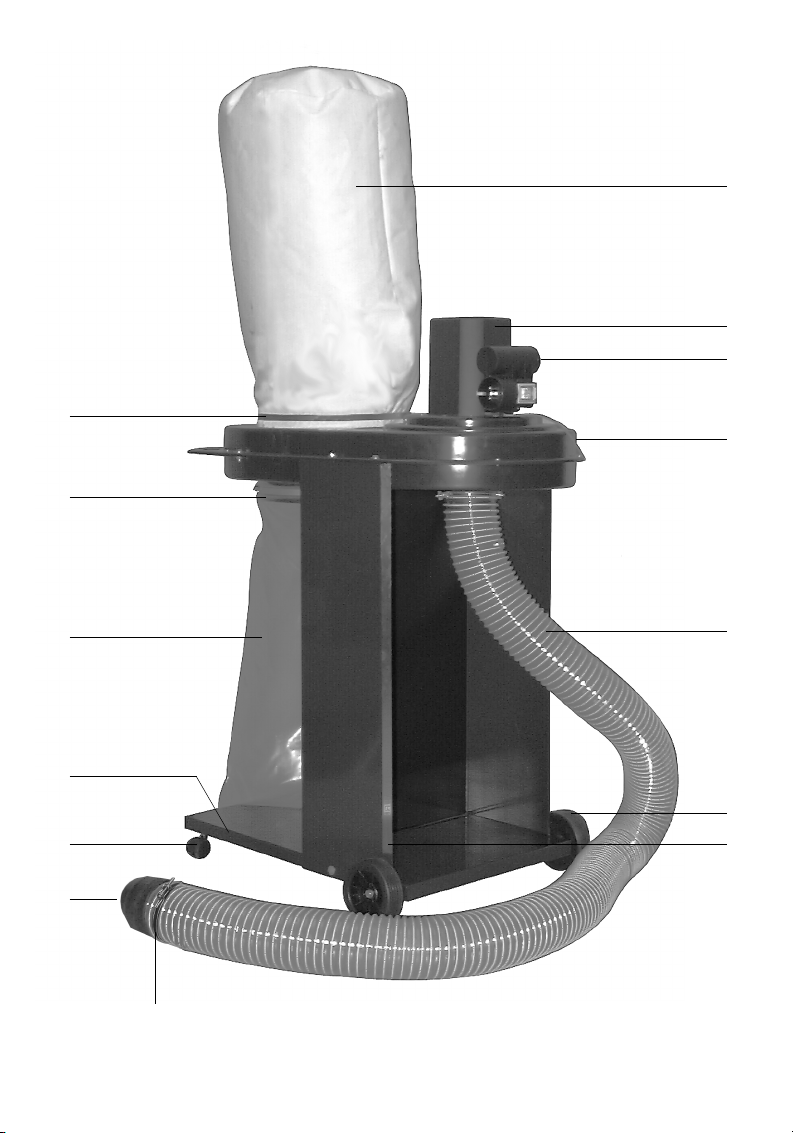

3 Appliance Components

1) Filter

3) 750 watt electric motor

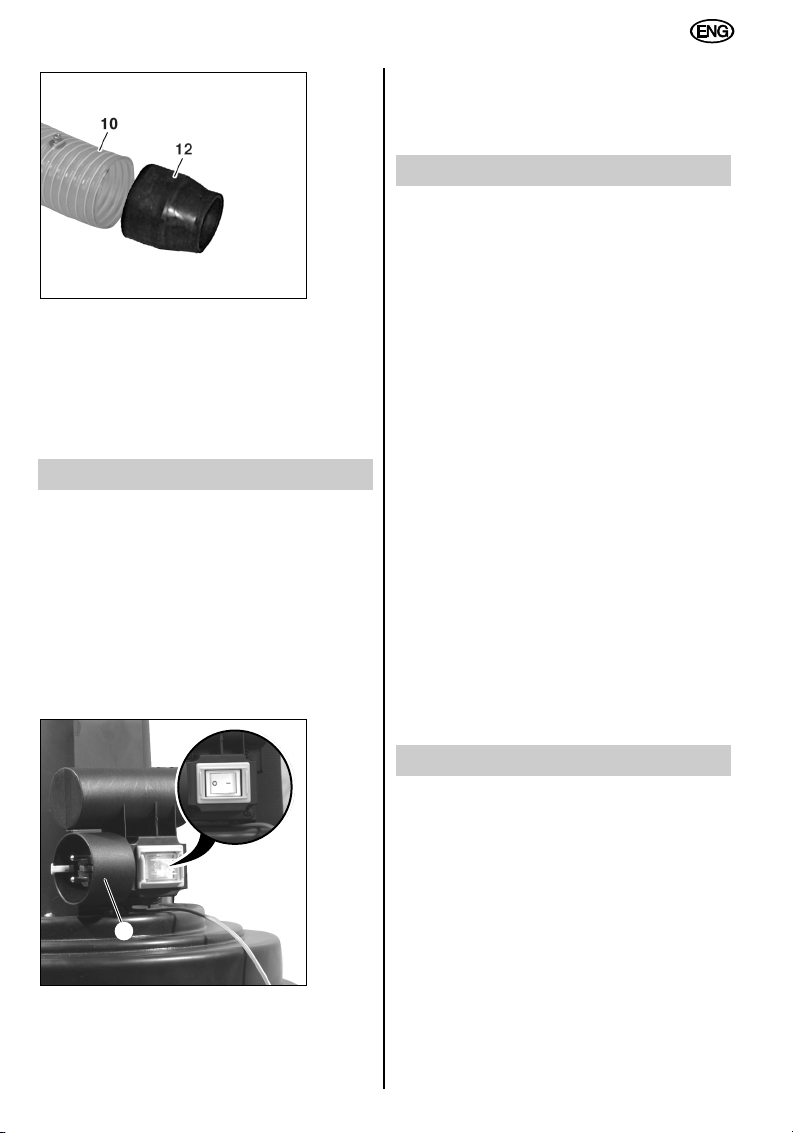

4) Combined switch/plug

5) Filter clamping band

6) Suction unit

8) Hose clamp

9) Chip bag clamping band

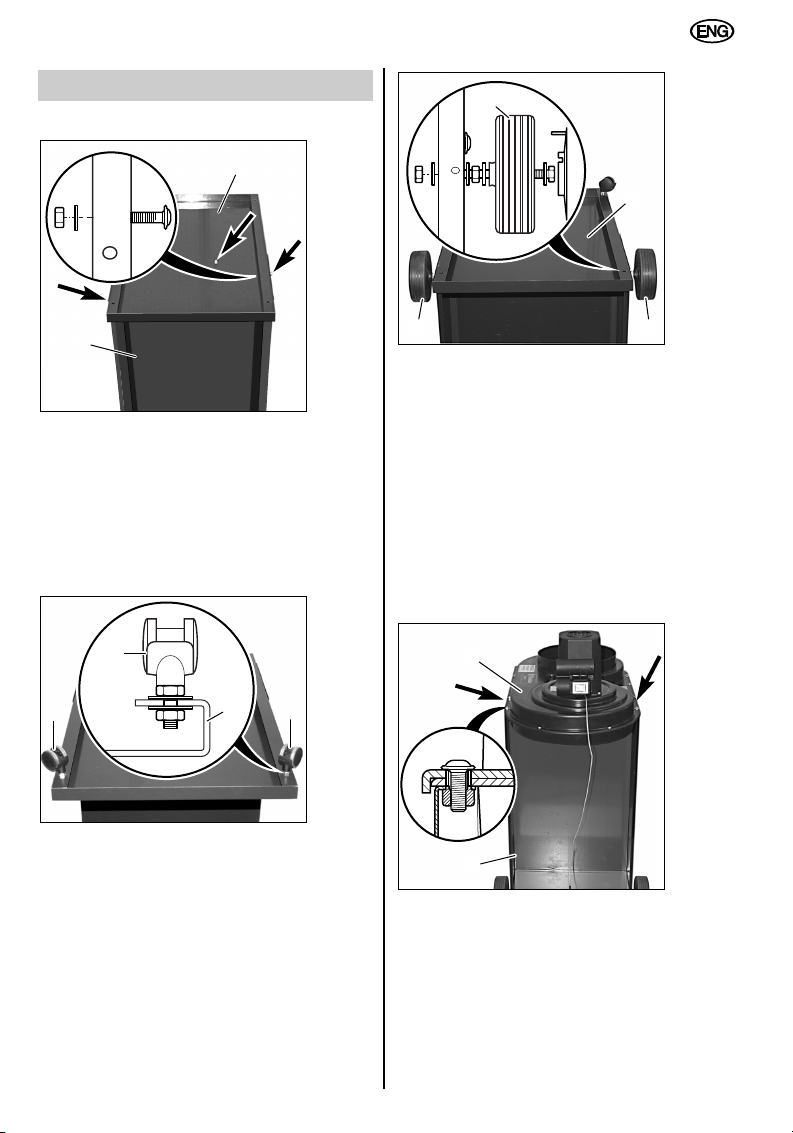

10) Suction hose

11) Chip bag

12) Connector

13) Castor

14) Base-plate

15) Wheel

16) Column

4 Safety Instructions

Read through these Operating

Instructions carefully and

thoroughly.

– The appliance must not be switched on until

it has been completely assembled.

– Extractor should only be operated if the

machine tools or cleaning nozzle are

connected.

– Solid bodies, e.g. pieces of wood (edge

longer than 10 mm), metal scraps and

stones etc. must not be vacuumed up.

Materials of this kind cause damage to the

fan impeller or the suction unit (rendering

guarantee claims null and void).

– Always disconnect the plug from the mains

supply before undertaking any maintenance

tasks, e.g. changing the bag, filter or hose,

so as to exclude any possibility of injury

caused by coming into contact with the

moving fan impeller.

– Keep the appliance dry. Do not vacuum up

any liquids.

– Do not use in any space where there is a

risk of explosion.

– Always check that the appliance is

operating properly before use.

– Do not use the appliance at temperatures

less than 0 °C. Do not vacuum up any

material which is at a temperature above

60 °C.

– The appliance must not be used by children

or any person who is not familiar with its

operation.

– Observe accident prevention and fire

prevention regulations.

– When changing the filter (1) or the chip bag

(11), a face-mask (filter-mask with particle

filter, filter class 2) must be worn to provide

protection from dust.

– Before changing the chip bag (11), tap the

filter (1) to dislodge deposits and clean.

– Where accessories are to be used, these

must be original manufacturer’s parts only.

The operator will render null and void any

claims arising if he uses the chip extractor

with anything other than original parts.

5 Proper Use

The chip extractor is designed for

extracting wood chips with a low

proportion of sawdust in connection

with wood-processing machines

(e.g. circular sawing machines, band

sawing machines, surface planing

and thicknessing machines and

vertical spindle moulding machines)

where these produce wood chips.

The appliance is not designed for vacuuming

up liquids. In addition, it should not be used for

the following materials: sharp-edged and

pointed objects (such as broken glass or nails)

or any material at a temperature above 60 °C.

The operator bears sole responsibility for any

damage caused by inappropriate use. The

generally recognised accident prevention

regulations and the “Safety Instructions” must

be observed.

The chip extractor is designed for non-

commercial use. Non-commercial use means

that the appliance is not used by employees,

persons undergoing professional training, in

schools, for domestic purposes, or by persons

in an employment relationship representing the

equivalent of work.

12

ENGLISH