ELEKTRA

Heating Cables

Installation

Stage 1: Heating cable’s

installation

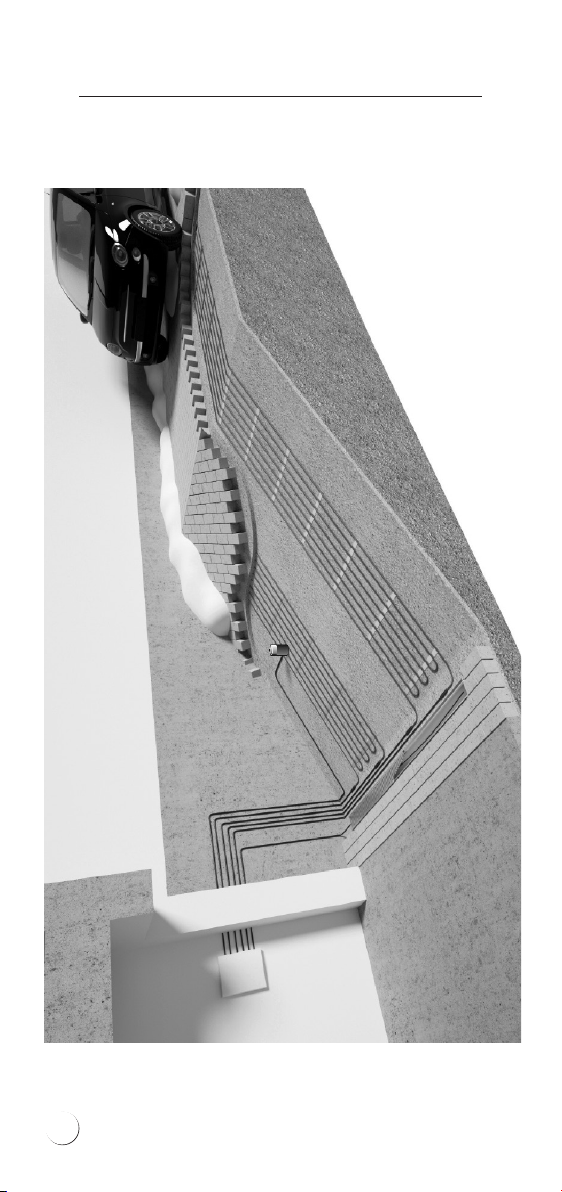

Before commencing the installation of the sys-

tem, it is required to assess the necessary heat

output per ft2(m2), as well as calculate the re-

quired spacing of the heating cable.

In order to calculate the required heating cable’s

spacing, apply the following formula:

a-a=S/L

where:

a-a: distances between cables,

S: surface area, for the surface heated with the heating cable,

L: heating cable’s length

To maintain xed positioning of the cable and

steady spacing conforming to the calculated

values, the cables need to be attached with the

ELEKTRA TME installation tape (the tape should

be positioned with the distances of 40 cm) or in-

stallation mesh of 2” x 2” (50 mm x 50 mm) grid,

made of Ø 0.08” (Ø 2 mm) wire.

TME installation tape

Additional temperature and moisture sensor can

be connected to this controller, which will enable

protection of two outdoor areas. Enables control

of two independent zones, e.g. garage driveway

and gutters, with one controller.

8