Contents

1 Introduction ................................................................................................4

1.1 Symbols used .......................................................4

1.2 Liabilities ...............................................................4

1.2.1 Manufacturer’s liability .............................................4

1.2.2 Installer’s liability .....................................................5

1.2.3 User’s liability ..........................................................5

1.3 Certifications .........................................................6

2Safety instructions and recommendations ..............................................7

2.1 Recommendations ................................................7

3Technical specifications ............................................................................8

3.1 Sensor characteristics .........................................8

4Installation ..................................................................................................9

4.1 Package list ...........................................................9

4.1.1 Standard delivery ....................................................9

4.1.2 Accessories .............................................................9

4.2 Installing the outside sensor ...............................9

4.2.1 Choice of the location ..............................................9

4.2.2 Connecting the outside sensor ..............................10

4.3 Fitting and connecting the control panel .........10

4.4 Electrical connections ........................................11

4.4.1 Connecting a direct heating circuit ........................11

4.4.2 Connection in cascade (with OpenTherm AD287)

option ....................................................................11

5 Commissioning ........................................................................................13

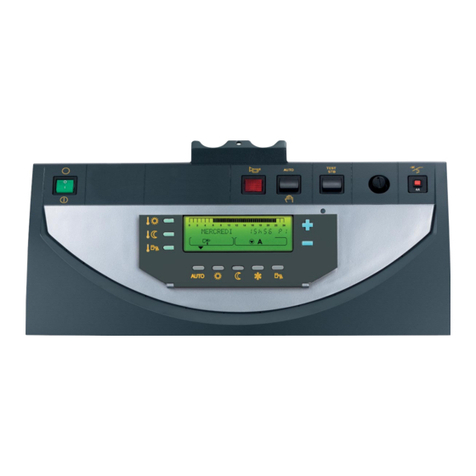

5.1 Control panel .......................................................13

5.1.1 Description of the keys ..........................................13

5.1.2 Description of the display ......................................14

5.2 Switch on the instrument panel ........................15

5.3 Reading out measured values ...........................16

5.3.1 Reading out measured values ..............................16

5.3.2 Readout from the hour counter and percentage of

successful starts ....................................................17

5.3.3 Status and sub-status ...........................................18

1260216 - 7600717-001-06