Elemer TM 5132 User manual

Подп. идата Взам

.

инв. №Инв. №дуб

л

.

Подп. идатаИнв . №подл.

THE RESEARCH AND PRODUCTION ENTERPRISE

SAFE MEANS AND SYSTEM

S

OF TECHNOLOGICAL MONOTORING

MULTICHANNEL THERMOMETER

ТМ 5132

OPERATION MANUAL

НКГЖ.405546.001-02РЭ

2

THE CONTENTS

1. Introduction...............................………….. 3

2. Specifications and operation......................... 3

2.1. Purpose of the article.....................……… 3

2.2. Technical characteristics..............………. 4

2.3. Design and operation.....................……… 7

2.4. Error message...................………………. 10

2.5. Marking and sealing............... ………….. 12

2.6. Packaging................................ ………….. 12

3. Employment of article according to purpose.. 13

3.1. Preparation of the article for operation...... 13

3.2. Employment of the article..................…….. 14

4. Method of testing………................................. 15

5. Technical maintenance................…………… 18

6. Storage…………………................................. 19

7. Transportation......................………………… 19

APPENDIXES: A. The electrical connections circuit. 20

B. Diagram of hooking up of MT

to a computer. 22

3

1. INTRODUCTION

1.1. The operation manual contains the items of information on design,

operating principle, performances of the multichannel thermometer MT 5132

(hereinafter - MT) and instructions indispensable for correct and safe

operation of the thermometer.

2. SPECIFICATIONS AND OPERATION

2.1. Purpose of the article

2.1.1. MT is intended for measuring and control of temperature and

other not electric magnitudes, converted into electric signals of power and

voltage of direct current or active resistance to direct current.

MT is employed in different manufacturing processes in industry and

agriculture.

2.1.2. MT is the multifunction microprocessor instrument and is

intended for operation both in an autonomous mode, and under control of a

computer program through the series interfacing.

The measuring channels of MT are intended for the configuration with

the unified input electric signals in the form of direct current of 0...5, 0…20 or

4... 20 мА, with thermo-converters of resistance (TR) and thermoelectric

converters (TC), as well as for measuring voltage of a direct current up to 100

mV and direct-current resistance up to 320 Ohm.

The dependence of the measured value on the input signal of MT may

be linear, with a function of averaging (damping), and for the input unitised

signal it may be with a function of root squaring as well.

MT is produced in two versions - with a fixed configuration or with a

variable one.

For the MT version with the fixed configuration the configuration of

MT is performed at the production plant. MT can not be reconfigured at ht

operation site. For the MT version with the fixed configuration there are

lacking micro switches at the rare panel. It should be noted that MT

configuration should be stated when making an order.

MT realises the function of signalling and automatic regulation of

monitored parameters.

4

For the MT version with the variable MT configuration there are micro

switches at the rare panel of MT with the help of which it is possible to

change configuration of MT.

The MT has no system signaling on input circuit opening.

The procedure of settings changing is protected from unauthorised

access.

2.1.3. MT has eight measuring channels and eight control channels

(commutation) by electric circuits.

MT is of the shield type- as for its design.

2.1.4. Pursuant to the GOST 12997-84:

considering stability to climatic influence when operating MT it corresponds

to the C3 group of production;

considering stability to mechanical shocks when operating MT

corresponds to LX group of production.

2.1.5. Pursuant to the GOST 14254-96 the degree of protection from

solid bodies and water getting inside is for

•Front panel IP54;

•Housing IP20;

2.2. Technical characteristics

2.2.1. The measuring ranges, input parameters and ranges of tolerable

basic reduced errors of measured values relative to НСХ with allowance for

configurations of measuring channels of MT provided in the tables 2.1 and

2.2.

The basic reduced error on the computer channel does not exceed the

basic reduced error of measured values.

2.2.2. Transient time of an operating mode does not exceed 30 min.

2.2.3. The limit of the additional tolerable error of MT caused by a

temperature variation of ambient air from the normal (20±5) ºC up to any

temperature within the range (minus 10… + 50) ºC for every 10 ºC of

temperature variation, does not exceed 0,5 of the limit of the basic tolerable

error.

2.2.4. The limit of the tolerable additional error of MT for the

configuration with TC, caused by a temperature variation of their free ends in

the range (minus 10 … + 50) ºC, does not exceed the limit of the tolerable

basic error.

2.2.5. The limit of the tolerable additional error of MT, caused by the

influence of high dampness (up to 95 % at 35ºC), does not exceed 0,5 of the

limit of the tolerable basic error.

5

2.2.6. The limit of the tolerable additional error caused by variation of

the power voltage from the nominal (220V) within the range (187 …242) does

not exceed 0,5 limit of the tolerable basis error.

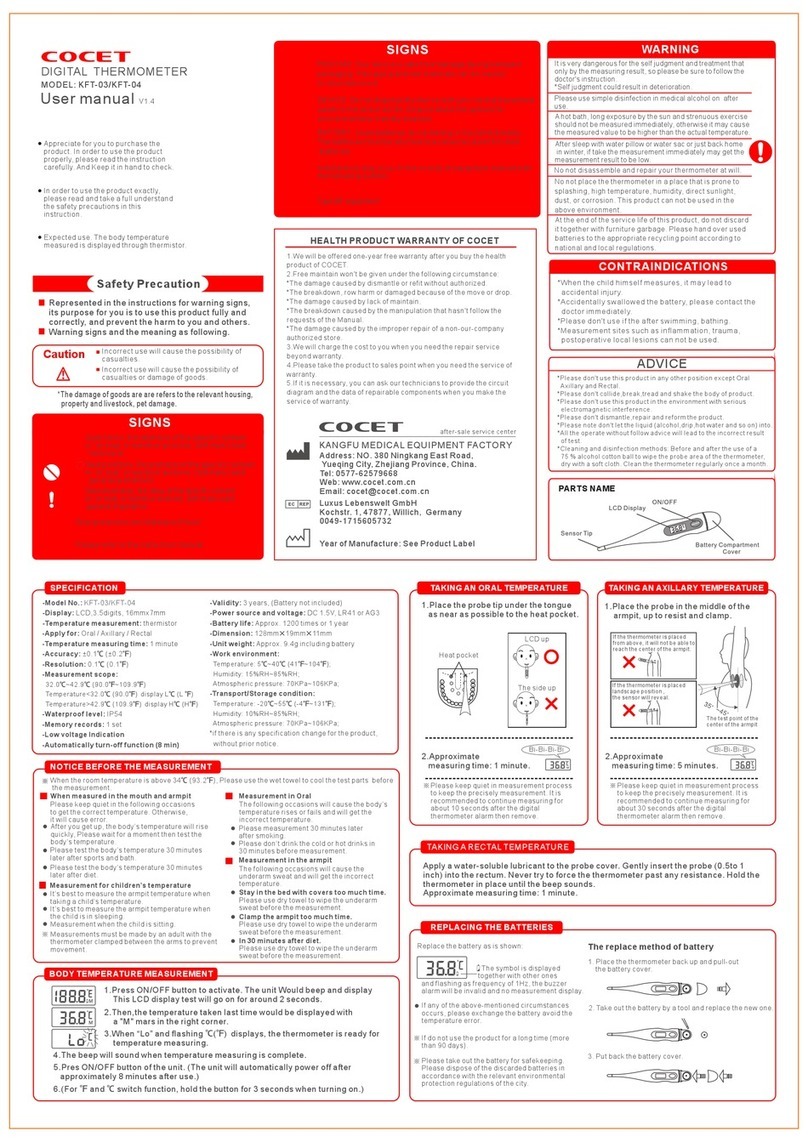

The table 2.1

Input parameters

According to НСХ

Type of the

primary

converter

W100

Range of

measurements,

ºС

input

resistance ,

KOhm

т.э.д.с.,

мV

input

resistance ,

KOhm

Limits

of tolerable

basic

reduced

error

relative

to НСХ, %

50M 39,23…92,78

100M 1,4280 78,45…185,55

50M 39,35…92,62

100M 1,4260

78,69..185,23

50П40,00…158,59

100П1,3910

-50….+600 80,00…317,17

Pt100 1,3850 -200…+600 18,52…313,71

±(0,25+*)

ТЖК (J) 0…+1200 0…69,536

ТХК (L) 0…+800 0…66,469

ТХА (K) 0…+1300 0…52,398

ТПП (S) 0…+1700 0…17,942

ТВР (A-1)

0…+2500

0…33,638

Not less then

100

±(0,5+*)

The table 2.2

Input parameters

Measured

value

Range of

measurement

Resistance

MOhm

Voltage, mV,

not more then

Maximum

current through

the measured

resistance, mA

Limits of

tolerable basic

reduced error

%

0…100

Voltage, MV 0…75 0,1 - -

0…20

4…20

Current mA

0…5

- 200 -

Resistance

Ohm 0..320 - - 0,7

±(0,25+*)

* One unit of the last discharge expressed in percentage from effective range.

6

2.2.7. The limit of tolerable additional error of MT, caused by the effect of

constant magnetic fields and (or) variation fields of the circuit frequency of up

to 400 А/мvoltage, does not exceed 0,5 limit of the tolerable basic error.

2.2.8. The limit of the tolerable additional error of MT during exposure to

vibration does not exceed the limit of tolerable basic error.

2.2.9. The area of determining of settings corresponds to measuring range.

2.2.10. The limit of the tolerable basic error of actuation of the signalling

system does not exceed the last displayed digit of measured value.

2.2.11. Individual point relays of signalling channels support

commutation:

•of alternating current system frequency:

-at the voltage of 250 V till 5 Аon resistive load ,

-at the voltage of 250 V till 2 Аon inductive load (cos

ϕ

≥0,4);

•of direct current:

-at the voltage of 250 V till 0,1 Аon resistive and inductive loads,

-at the voltage of 30 V till 2 Аon resistive and inductive loads.

Notes. On inductive load it is recommended to install spark suppression

circuits to the clamps of the instrument or to the inductive load

itself Spark suppression circuit should consist of series connected

реresistor 50…100 Ohm, 0,5 W and a capacitor 10…100 nF at the

voltage not less than 630 V.

2.2.12. The power supply of MT is carried out from alternating current

circuit with frequency (50±1) Hz and voltage of (220 +22 -33) V.

2.2.13. The power, consumed by MT from an alternating current circuit at

nominal voltage, does not exceed 20 V·А.

2.2.14. The insulation of electric circuits of MT between measuring

channels and relative to earthing clamp should hold out during 1 minute the

effect of testing voltage practically of sinusoidal shape with frequency from 45

up to 65 Hz:

- at normal conditions - 100 V and 1500 V accordingly;

-at the temperature of ambient air (35± 3) ºC and relative humidity

(95 ±3) % - 60 V and 900 V accordingly.

2.2.15. Electric resistance of insulation of current conducting circuits of

MT relative to its body and between the circuits themselves is not less then:

- 20 mOhm at the temperature of ambient air (20 ± 5) ºC and relative

humidity from 30 % up to 80 %;

- 5 mOhm at the temperature of ambient air (50±3) ºC and relative

humidity from 30 % up to 80 %;

7

- 1 mOhm at relative humidity (95± 3) % and temperature of ambient air

(35± 3) ºC .

2.2.16. MT is stable to the effect of temperature of ambient air variation

from minus 10 ºC up to +50 ºC.

2.2.17. Overall dimensions, mm, not more then:

the front desk - 96 х96;

mounting depth - 180;

slot in a board - 86 х86.

2.2.18. Mass, kg, not more than: 1,5.

2.3. Design and operation

2.3.1. MT is composed of:

- transformer power supply unit with linear regulators;

- pulse power supply unit with linear regulators;

- eight galvano- decoupled input amplifiers;

- double-link RC-filter (on each channel);

- module of an analog-to-digitial converter (ADC);

- microprocessor control unit ;

- indication module with a control keyboard;

- eight final controls;

- module of terminal blocks for external connections;

- interface module;

2.3.1.1. The transformer power supply unit converts mains voltage of

220 V and frequency of 50 Hz into direct stabilised voltages of ±5 V, ±8 V for

power supply of the microprocessor, of the interface, of ADC, and non-

stabilised voltage +24 V for power supply of the pulse power supply unit and of

the relay block. The switch of power supply is not envisaged, as MTs are

intended for operation in non-stop mode.

2.3.1.2. Two-element RC – filter provides high noise immunity of MT.

2.3.1.3 The analogue-to-digital converter will convert an input analogue

signal to the code acting(arriving) at a microprocessor box of control.

2.3.1.4. The microprocessor box of control executes following functions:

-calculates the current value of the measured value(according to data of

interrogation of ADC)

-controls indication module, i.e. displays the current value of the

measured value or the value of a setting on the indicator;

-interrogates the keyboard;

-controls the module of interface;

8

2.3.1.5. The module of the display and keyboard consists of:

- LED four-digit indicator of the measured value or setting;

- LED single-digit indicator of a channel number;

- eight solitary indicators of the relay condition;

- four solitary indicators of indication modes;

- one solitary indicator each: the indicator of parole input and the

indicator of settings editing;

- the button of settings variation (concealed);

- the button ">" of selection of mode/modification of an edited discharge;

- the button "^" and "V" of increase/decrease of a channel number or

variation of an edited discharge.

2.3.1.6. MT has two independent settings for each measuring channel,

which can be both upper, and lower, and can be connected to any executive

relay.

The executive relays are controlled by the microprocessor and operate

in accordance with the internal table of relay connections and settings of the

channels, which are edited by the user.

2.3.1.7. The module of the interface is intended for connection to the

computer. The circuits of MT connection to the computer - pursuant to the

appendix Б.

2.3.1.8. In the figure 2.1 the appearance of TM 5132 is presented.

Figure 2.1

2.3.2. On the front panel of MT are situated:

- the main display - four-digit LED indicator of a measured value or a

setting;

- additional display - single-digit LED indicator of a channel number;

9

- buttons "^" and "V", permitting to scan values of measurements or

settings, increasing or decreasing a channel number;

- the key ">", permitting to select one from four indication modes:

1) cyclic scanning of measurements on all channels;

2) scanning of measurements on any selected channel;

3) scanning of the setting 1 on any selected channel;

4) scanning of the setting 2 on any selected channel.

- The concealed push button of settings variation provides to the user a

possibility to change the values of settings with the aid of the

keyboard.

For changing of settings it is necessary to click and to retain the

concealed push button in the pushed -in state until flashing of the indicator

"PAROLE", then it is necessary with the help of keys ">", "^" и"V" to enter

the parole (the new parole is set only from the computer). If the parole was set

with an error, than MT turns to the mode of measurements indication

(condition of MT after energising). If the parole is set correctly, the indicator

“УСТ” is flashed and MT switches to the mode of settings editing. For

escaping from his mode it is necessary to click the concealed push button. The

key ">" will be used for selection of edited digit of settings. The "^" keys and

"V" will be used for increasing/decreasing of either flashing edited digit of a

setting, or for changing the number of setting/channel.

The setting of the configuration of TM is executed only from the computer.

2.3.2.1. The main display is intended for showing numeric values of

current measured parameters, settings as well as symbol messages about the

condition of MT (messages about errors).

2.3.2.2. The additional display is intended for showing of a channel

number.

2.3.2.3. The indicator "1" displays the state of the relay of the commuted

channel number 1. If the relay number 1 is switched on (the normally-opened

contacts are closed) then the indicator "1" - is flashed, if the relay is switched

off (contacts of the relay unlock the channel), then the indicator "1" - is not

flashed. Indicators "2" - "8" and relays 2 - 8 operate accordingly.

2.3.3. On the back panel of TM are situated:

- terminal blocks 2 series having 12 contacts for hooking up

thermoconverters;

- connector РП 14-30 for connecting of mains and external execution

units;

- earthing clamp;

- interface connector.

10

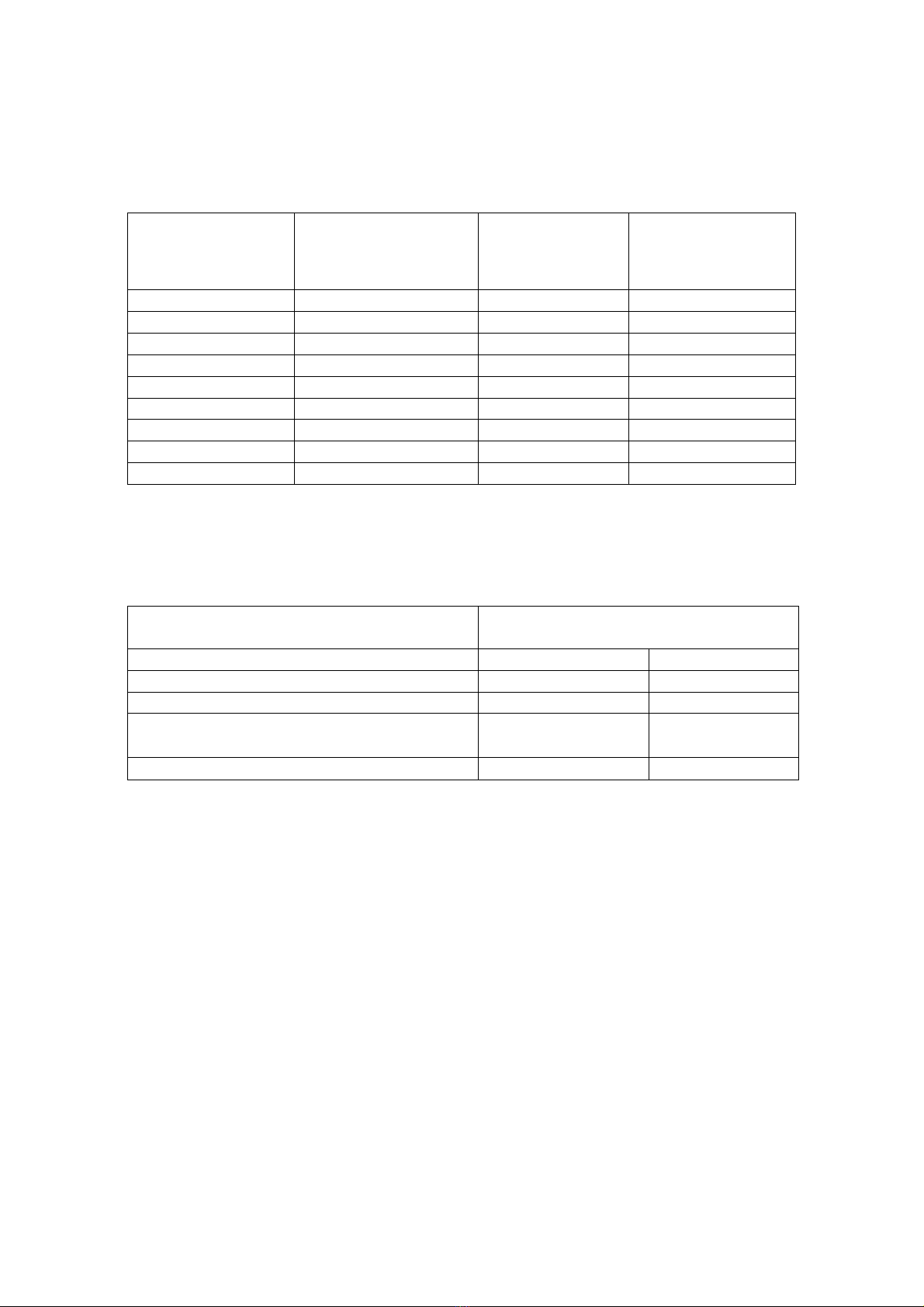

The table 2.3 – Designation of the contacts of connector РП14-30

Number of contacts

group for connection

of relays (external

actuating devices)

Group of contacts Normally-closed

contacts

Normally– opened

contacts

1 1a, 1b, 1c 1b, 1c 1a, 1b

2 2a, 2b, 2c 2b, 2c 2a, 2b

3 3a, 3b, 3c 3b, 3c 3a, 3b

4 4a, 4b, 4c 4b, 4c 4a, 4b

5 5a, 5b, 5c 5b, 5c 5a, 5b

6 6a, 6b, 6c 6b, 6c 6a, 6b

7 7a, 7b, 7c 7b, 7c 7a, 7b

8 8a, 8b, 8c 8b, 8c 8a, 8b

- -

Notes: Contacts 0a, 0c – for connection of TM to the circuit.

The table 2.4 - Correspondence of the position of micro switches on the back

panel of MT to different types of connected sensor devices.

Primary converter or input signal Position of corresponding micro switch

Upper (ON) lower

Thermoelectric converter 3 1,2,4

Direct current 1,2 3,4

Voltage of direct current 3 1,2,4

Thermo-converters of resistance

•double-wire connection circuit 3,4 1,2

•three-wire connection circuit 3,4 1,2

* For the MT version with variable configuration.

2.4 Error messages.

2.4.1.In case of any troubles or malfunctioning of MT on the main

display the error message is flashed. Possible errors, error messages, and

ways of their eliminations are provided in the table 2.5.

11

Table 2.5

Error code Malfunction Course Method of

elimination

“Err 0” Emergency condition of

the instrument

Malfunction of the

micro controller

Only in industrial

conditions

“Err 1” Emergency condition of

the instrument

Malfunction of the

micro controller

Only in industrial

conditions

“Err 2” Error in circuit

parameters

configurations

The network number

and messaging rate

with a computer is

set incorrectly

To set the network

number or messaging

rate with a computer

correctly when tuning

MT according to par.

3.2.1.2.16 and

3.2.1.2.17) of the

operator manual

“Err 4” Emergency condition of

the instrument

Malfunction of the

micro controller

Only in industrial

conditions

“Err 5” Rupture of all input

channels

When tuning MT all

input channels are

switched off,

incorrect MT

configurations.

Connect at least one

input channel when

tuning NT (see par.

3.2.1.2.2) of the

operator manual.

“-OU-” Variation of the signal

above the maximally

tolerable level of the

sub range

Input signal outside

the measuring sub

range

Provide for

correspondence of the

level of input signal to

sub range of

measurements

“-AL-” Variation of the signal

below the maximally

tolerable level of the

sub range

Input signal outside

the measuring sub

range or rupture of

the circuit of primary

converter.

Provide for

correspondence of the

level of input signal to

sub range of

measurements or

elimination of the

rupture of the circuit

of primary converter.

“----” Impossible to display a

parameter

Inconsistency of the

parameter value and

preset parameter

( see par.3.2.1.2 5) of

the operator Manual)

Decrease the

parameter “number of

digits after comma”

when tuning MT

" Err 0 ", " Err 1 ", " Err 4 " - error in internal memory of MT, the

cause is eliminated only in industrial conditions.

" Err 2 " - network number or speed of interchanging of the instrument

with the computer is incorrectly set.

" Err 5 " - there are no live channels.

12

Notes: In case of any errors with the codes “Err 0” … “Err 5” MT is

automatically assigned: number of the instrument – “0”, and the speed of

interchange – “9600”; after elimination of courses of malfunction, values of

these parameters are reinstated.

2.5. Marking and sealing

2.5.1. The marking corresponds to GOST 26828-86 Е, GOST

9181-74 Е, GOST 12.2.020-76 and drawing НКГЖ.405546.001-02СБ.

2.5.2. MT is sealed up by the representative of the QCD of the plant –

producer.

2.6. Packaging

2.6.1.Pacaging corresponds to GOST 23170-78E, GOST 9181-74 Еand

the drawing НКГЖ.405546.001-02УЧ and ensures complete safety of MT.

13

3. EMPLOYMENT OF ARTICLE ACCORDING TO PURPOSE

3.1. Preparation of the article for operation.

3.1.1. Safety measures instructions.

3.1.1.1. As to the method of protection of operators from electric

shocks MT corresponds to the class II according to GOST 12.2.007.0-75.

MT has a clamp of measuring earthing according to GOST 12.2.007.0-75.

Before the beginning of operation it is necessary to verify quality of earthing.

3.1.1.2. The primary converters are connected according to marking

when supply voltage is cut off.

3.1.1.3. When operating MT it is necessary to abide by requirements of

GOST 12.3.019-80, "Regulations of technical operation for electric devices of

consumers", "Regulations on the safety of operation of electric devices of

consumers " and "Rules of designing of electric devices. ПУЭ ", authorized by

Gosenergonadzor, it is also necessary to follow instructions on safety

regulations adopted by plants operating MT.

3.1.2. External inspection

3.1.2.1. When making external inspection, absence of mechanical

damage is established, correctness of marking, completeness is checked.

If there are any defects of coatings, affecting operation capacity of TM,

or discrepancies of completeness and marking, it is decided whether this MT

is possible to operate.

3.1.2.2. For each MT availability of the logbook with a mark of QCD is

cheked.

3.1.3. Assembly of an item.

3.1.3.1. For installation of MT it is necessary to have access to it from

the back side of the board. The sizes of the slot in the board should correspond

to item 2.2.17.

The order of installation:

- insert MT into the slot of a board;

- insert cramps into the body of MT;

- the front panel of MT is screwed to a board.

The electrical circuit of connections of MT with primary converters is

carried out via terminal blocks positioned on a back panel, and connections

14

with a web and commutation circuits - via РП 14-30 connector, according to

the figure A .1 of the Appendix A. The purpose of the contact connectors

Connections are performed in the form of cable ties.

Laying and terminating cables should meet the requirements acting

" Rules of designing of electric devices. ПУЭ ".

On the back panel there is a connector for hooking up of the computer

through the interface cable.

3.2. Employment of the artilce

3.2.1. Install MT on the instrumental board and lock safely.

3.2.2. Perform required connections of MT pursuant to

Appendixes A,Б.

3.2.3. Install micro-switches on the back panel in accordance to hooked

up thermoconverters and the table 2.4.( for versions of MT with variable

configurations)

3.2.4. If necessary - connect MT to the computer, load the

program of the configuration of MT, perform configuration of MT.

15

4. METHOD OF TESTING

4.1. MT is tested by bodies of the State Metrological Service or

Metrological Service of Consumers having the right of verification. The

requirements of verification, order, main stages of verification are stipulated

in ПР 50.2.006-94 "ГСИ. Verification of measuring facilities. Organisation

and procedure of verification" and in Recommendation "Methods of

verification МИ 2342-95".

Period of time between verifications is two years.

4.1.1. The basic reduced errors of measured values are determined

pursuant to the instructions provided in the item 5.5 of the recommendation

(for MT with input signals, corresponding configurations of verified MT).

4.1.2. Types and НСХ TR and TC for MT should correspond to the

ones provided in the present manual and meet the requirements of GOST

6651-94 and GOST Р8.585-2001 accordingly.

4.1.3. For tested MT, which HCX of the primary converter and ranges

(and the sub-ranges) of measurements correspond to those provided in the

recommendation, repeated points are indicated in the tables 5, 6 and 7 of the

recommendation.

Tested points of MT, with sub-ranges different from those provided in

the recommendation, are calculated pursuant to the item 5.5.1 of the

recommendation.

4.1.4. The basic reduced error of measured values, for the

configurations of MT with input electric signals in the form of voltage of

direct current, is determined in the points corresponding to 5, 25, 50, 75 and

95 % of the measurement range, by connecting a source of calibrated voltages

to the tested MT.

4.1.5. The basic reduced error of measured values for the MT

configurations with input electric signals in the form of direct current is

determined in verified points corresponding to 5,25.50,75 and 95 % of the

measurement range by connecting to the verified MT a source of calibrated

voltages.

4.1.6. For MT with input electric signals in the form of direct current of

0 … 5, 0 … 20 and 4 … 20 мА with root extracting dependence of measured

value of an input signal the basic reduced error is determined in the points

0,1; 1; 2; 3; 4; 5 мА - for range 0... 5 мА;

1; 5; 10; 15; 20 мА - for range 0... 20 мА;

4, 32; 8; 12; 16; 20 мА - for range 4... 20 мА.

16

True readings of the measured value At for the ranges of input signals

0... 5, 0…20 and 4... 20 мА are calculated from the formula (4.1), (4.2) and

(4.3) accordingly:

Аt = Амакс х√Iinput i (4.1)

√5

Аt = Амакс х√Iinput i (4.2) and

√20

Аt = Амакс х√Iinput i – 4 (4.3)

√16

Аt - True reading of measured value in the tested point;

Амакс - the upper limit of the range of measured value (is set during

configuration), the lower limit of the range of measured value is equal to 0;

Iinput i – the value of current in the input of the tested point;

5 мА, 20мА, 16 мА - ranges of input signals;

4 мА - lower limit of the range of an input signal for MT with

an input 4... 20 мА.

4.1.7. The basic reduced errors of measured values, determined from

the formula (5.1) of the recommendation should not exceed indicated in the

item 2.2.1 of the present operation manual.

4.1.8. Determination of the basic reduced error on the computer channel

is compared with determination of the basic reduced error of measured value.

The basic reduced error on the computer channel should not exceed the basic

reduced error of the measured value.

4.1.9. Determination of the basic error of the signalling system

operation.

4.1.9.1. Perform the configuration of MT for any type of an input

signal.

4.1.9.2. Set any values of two settings within the limits of measuring

range.

4.1.9.3. Perform the configuration of the logic of operation of all eight

relays in relation to programmed settings with allowance for possibilities of

opening of an input circuit.

17

4.1.9.4. Set a hysteresis on both settings.

4.1.9.5. Connect to clamps of relay channels of MT the indication

circuit of a closed /open conditions of channels (for example, circuits of light

emitting diodes power supply).

4.1.9.6. Change sequentially values of an input signal of MT from one

setting to another, make sure that all relays operate properly, both on

indication on the front panel of MT and on indicators connected to clumps of

channels.

4.1.9.7. The basic error of actuation of the signalling system should not

exceed the lowest digit of measured value for the following types of settings:

lower setting: U sett- signal is moderated;

Usett +Uhyst - signal is augmented;

upper setting: Usett - signal is augmented;

Usett - Uhyst - signal is moderated;

where Usett - value of settings;

Uhyst - value of hysteresis of setting.

18

5. TECHNICAL MAINTENANCE

5.1. Technical maintenance of MT is reduced to observance the

operating rules, stowage and transportation rules explained in the present

operation manual, to routine inspections, periodic checks and repair works.

5.2. The routine inspections are carried out in the order established at

the places of MT operation, but not less often then twice a year and include:

1) external examination;

2) inspection of holding power of communication lines of MT with

primary converters, absence of rapture of a grounding wire, holding power of

MT and grounding joint;

3) Functional test:

- self-calibration of MT;

- testing of electric resistance of insulation pursuant to the

Recommendation " The methods of control of MT 2342-95 ";

- testing of electric strength of insulation pursuant to the

Recommendation " The methods of control of MT 2342-95 ";

- testing of measuring precision of MT in points corresponding to 5, 50,

95 % of the range of measured values in accordance with the section 4 of the

present operation manual.

Under conditions of conducting a functional testing, when the

possibility of using of additional measuring aids is eliminated, MT is not

subject to inspection on precision of measuring. In this case only functioning

of MT is tested.

MT is considered functioning, if its readings roughly coincide with the

measured value.

5.3. Periodic testing of MT is performed not less often than once per

two years pursuant to the instructions, provided in the section 4 of the present

operation manual.

5.4. MT with faults which are beyond repair during routine

maintenance, or those ones that failed the periodic testing, are subject to

maintenance repair.

The repair of MT is made at the manufacturer’s enterprise under the

separate agreement.

19

6. STORAGE

6.1. The storage conditions for MT in transportation packing in a

warehouse of the manufacturer and consumer should correspond to conditions

of I GOST 15150-69.

Aggressive impurities should not be present in the air.

6.2. Disposition of MT in warehouses should ensure a free access to it.

6.3. MT should be stored on the racks.

6.4. Spacing interval between the walls, floor of a warehouse and MT

should be not less than 100 mm.

7. TRANSPORTATION

7.1. MT is transported by all types of transport in the covered

transportation vehicles. The attachment of containers in transportation

vehicles should be done according to the rules acting on the applicable types

of transport.

7.2. The conditions of transportation of MT should meet conditions 5

of GOST 15150-69 at the temperature of ambient air from minus 10 up to

+50°C with observance of protection measures from shocks and vibration.

7.3. MT should be transported packaged in parcels or piece by piece.

Transportation of MT in boxes should be performed in accordance with

the GOST 21929-76 requirements.

20

Appendix A

The electric diagram of MT 5132 connections

Connection of MT by the three-wire circuit

Connection of MT by the two-wire circuit

Connection of the thermoelectric couple

Connection of voltage source

Connection of current source

Figure A.1

GND

U

I

1

I

chann

1 2 3 4 5 6 7 8 9 0

c b a

1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4

Terminal blocks 1

series of 12 contacts

GND

U

I

GND

U

I

GND

U

I

II

chann

III

chann

IV

chann

Connector РП 14-30

5

2 6

3 7

4 8

GND

U

I

GND

U

I

GND

U

I

GND

U

I

V

канал

VI

канал

VII

канал

VIII

канал

K13

K1

K24

K1

2

Connector DB9 for

connection to a com

p

uter

I

U

GND

Rt

I

U

GND

Rt

I

U

GND

ТП

+

_

I

U

GND

Uin

_

+

I

U

GND

Iin

+

_

Table of contents