Table of contents

2 / 24 B-H86.0.04.DB201-1.0

Table of contents

1 Legal address of the manufacturer................................................................................................... 4

2 About this documentation ................................................................................................................. 5

2.1 Foreword............................................................................................................................................... 5

2.2 Purpose of the document...................................................................................................................... 5

2.3 Warranty ............................................................................................................................................... 5

2.4 Compliance with local laws and other legal regulations ....................................................................... 5

2.5 Correctness of content.......................................................................................................................... 6

2.6 Further information ............................................................................................................................... 6

3 Safety ................................................................................................................................................... 7

3.1 Explanation of safety symbols .............................................................................................................. 7

3.2 Foreseeable misuse ............................................................................................................................. 7

3.3 Safety instructions ................................................................................................................................ 7

3.4 Intended use ......................................................................................................................................... 8

3.5 Qualified personnel............................................................................................................................... 8

4 Description .......................................................................................................................................... 9

4.1 Scope of delivery .................................................................................................................................. 9

4.2 Job description...................................................................................................................................... 9

5 The product at a glance ................................................................................................................... 10

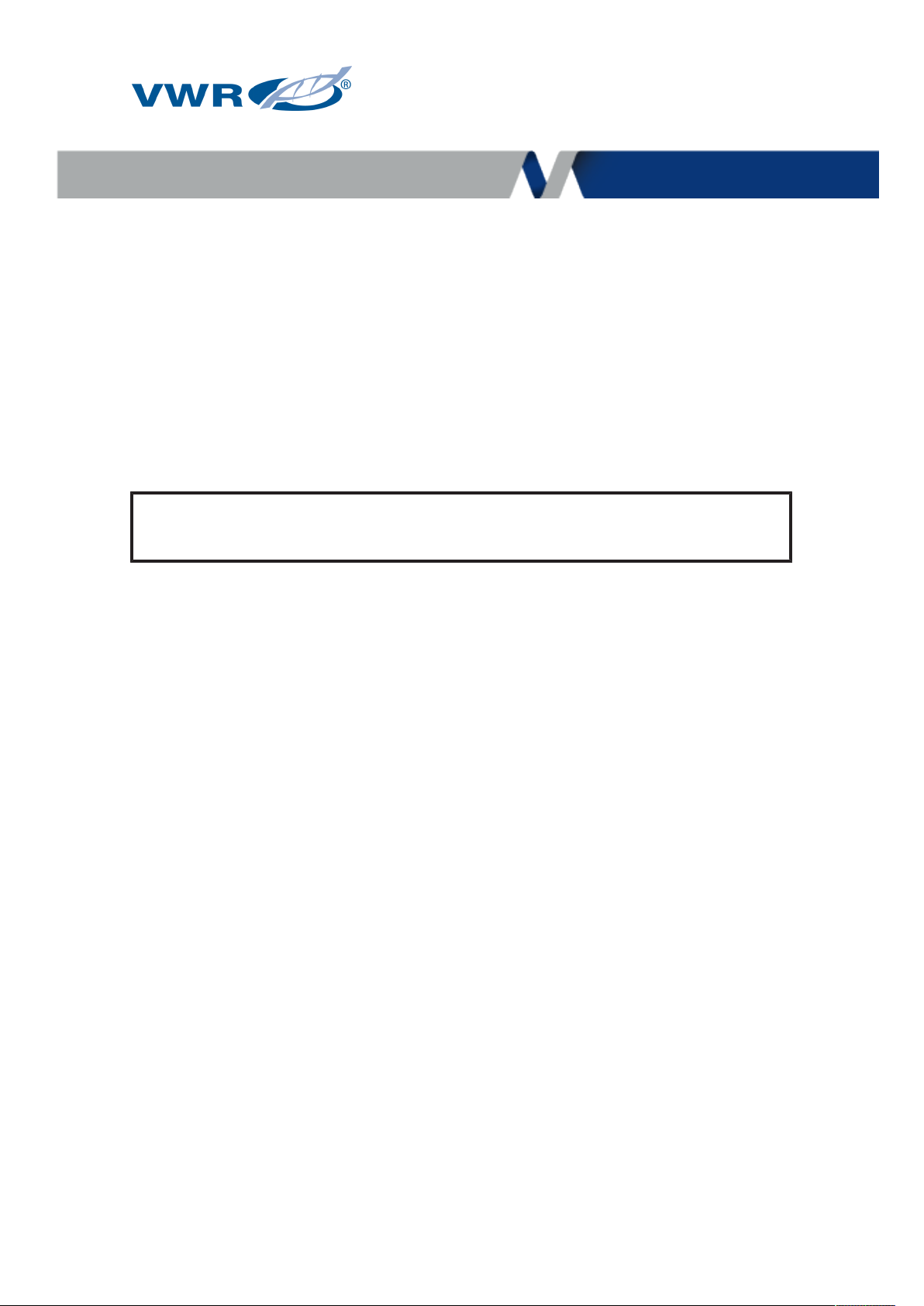

5.1 The TD310.......................................................................................................................................... 10

5.2 Display elements ................................................................................................................................ 10

5.3 Operating elements ............................................................................................................................ 10

5.4 Connections........................................................................................................................................ 10

5.5 Support stand ..................................................................................................................................... 11

6 Operation........................................................................................................................................... 12

6.1 Commissioning ................................................................................................................................... 12

6.1.1 Explanation ......................................................................................................................................... 12

6.2 Configuration ...................................................................................................................................... 12

6.2.1 Explanation ......................................................................................................................................... 12

6.2.2 Opening the configuration menu......................................................................................................... 12

6.2.3 Configuring parameters of the configuration menu............................................................................. 13

6.2.4 Opening the adjustment menu............................................................................................................ 14

6.2.5 Configuring parameters of the adjustment menu................................................................................ 14

7 Bases for measurement ................................................................................................................... 16

7.1 Sensor/device accuracy...................................................................................................................... 16

7.2 Possible measuring errors .................................................................................................................. 16

7.2.1 Immersion depth ................................................................................................................................. 16

7.2.2 Limit values......................................................................................................................................... 16

8 Maintenance ...................................................................................................................................... 17

8.1 Operating and maintenance notices ................................................................................................... 17

8.2 Battery ................................................................................................................................................ 17

8.2.1 Battery indicator.................................................................................................................................. 17

8.2.2 Changing battery ................................................................................................................................ 17

9 Error and system messages............................................................................................................ 19