E-2000M-W-X-Y-Z

W

0

1

2

3

Relay/SSR

No Relay

1 Relay

2 Relays

1 Pulse for SSR

1 Relay,1 Pulse for SSR

4

Y

0

Analog Output

1 Analog Output

No Output

X

1

0

Operating Voltage

20-60 V AC/20-85 V DC

85-265 V AC/85-375 V DC

Z

1

0

8.8.8.8

8.8.8.8

2000M

RL1 RL2 PRG F

Elimko

E-2000M

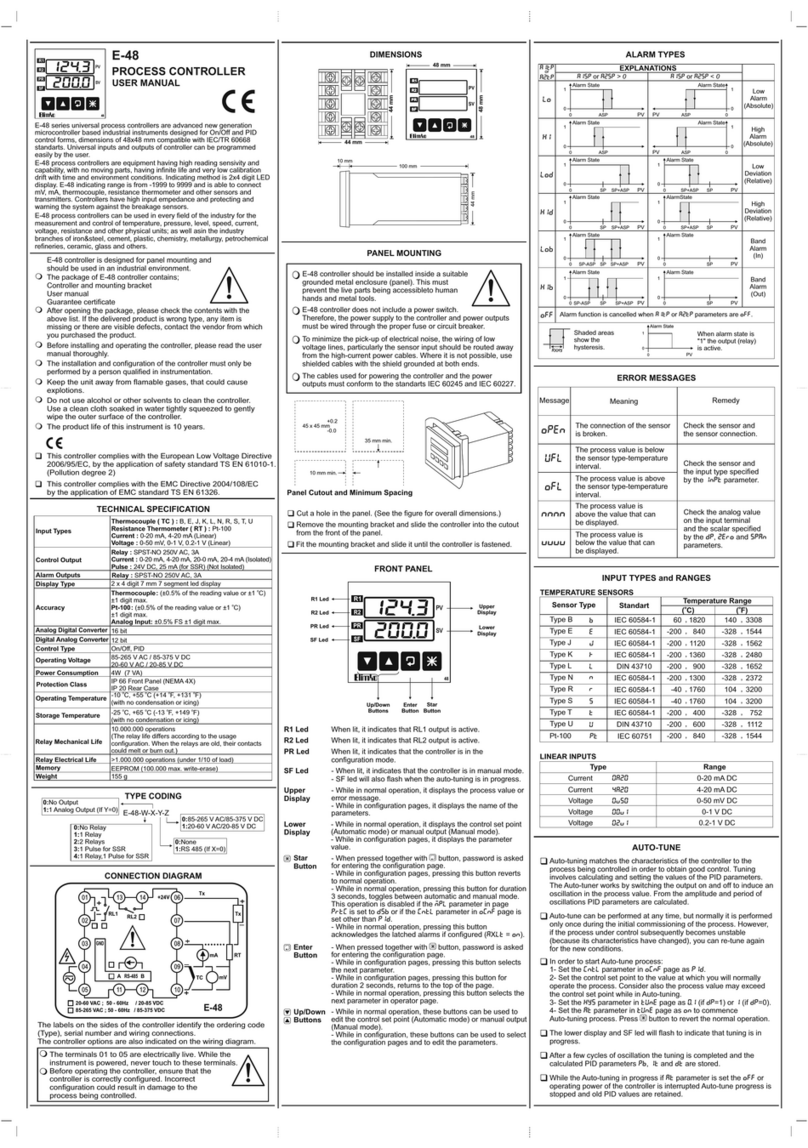

INPUT TYPES and RANGES

TEMPERATURE SENSORS

LINEAR INPUTS

Range

0-20 mA DC

Type

0-50 mV DC

0-1 V DC

0.2-1 V DC

4-20 mA DC

0a20

Current

0v50

Voltage

00v1

Voltage

02v1

Voltage

Current

4a20

Sensor Type Standart Temperature Range

o

( C) o

( F)

IEC584-1

IEC584-1

IEC584-1

IEC584-1

DIN43710

IEC584-1

IEC584-1

IEC584-1

IEC584-1

DIN43710

IEC751

Type B

Type E

Type J

Type K

Type L

Type N

Type R

Type S

Type T

Type U

Pt-100

B

E

J

K

L

N

R

S

T

U

Pt

60 1820

-200 840

-200 1120

-200 1360

-200 900

-200 1300

-40 1760

-40 1760

-200 400

-200 600

-200 840

140 3308

-328 1544

-328 1562

-328 2480

-328 1652

-328 2372

104 3200

-328 752

-328 1112

-328 1544

104 3200

AUTO-TUNE

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

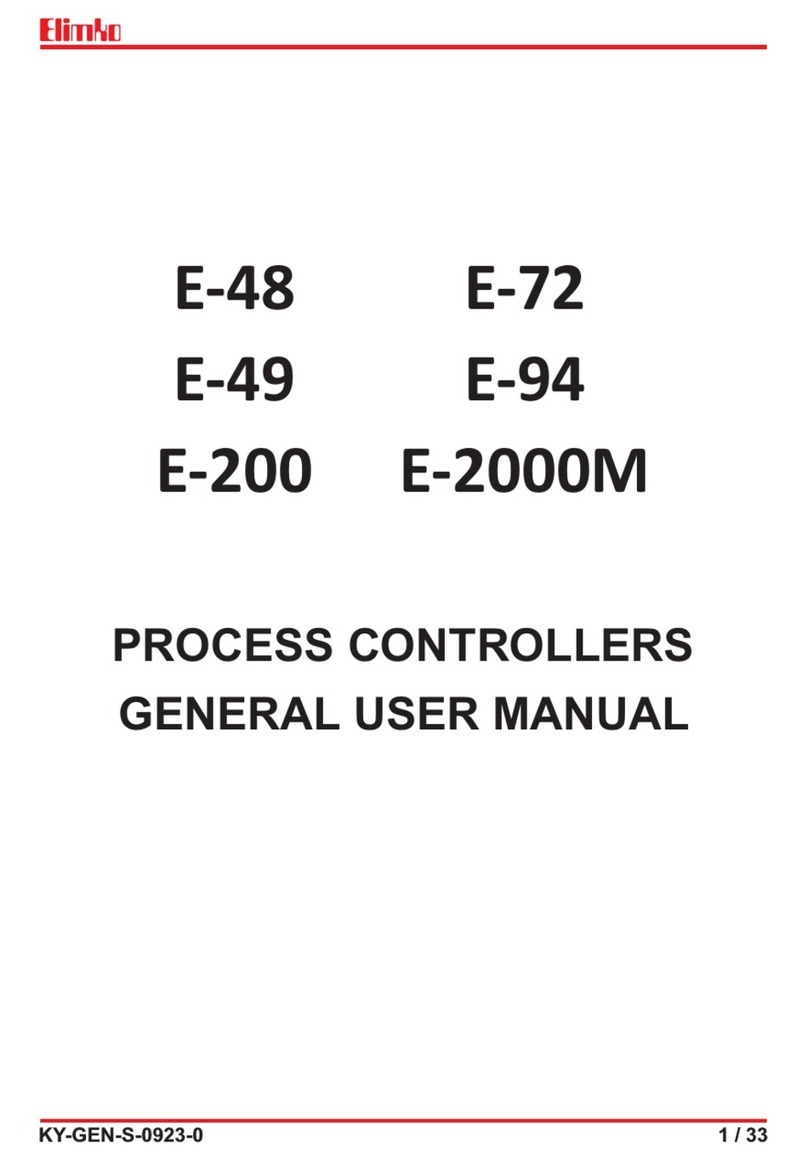

DIMENSIONS

2000M

RL1 RL2 PRG F

Elimko

96 mm

96 mm 6.5 mm

90.5 mm

50 mm

PANEL MOUNTING

FRONT PANEL

TYPE CODING

140

200

2000M

RL1 RL2 PRG F

Elimko

Up/Down

Buttons

Enter

Button

Star

Button

Lower

Display

Upper

Display

Leds

PROCESS CONTROLLER

USER MANUAL

E-2000M process controllers are equipment having high reading sensivity and

capability, with no moving parts, having infinite life and very low calibration

drift with time and environment conditions. Indicating method is 2x4 digit LED

display. E-2000M indicating range is from -1999 to 9999 and is able to connect

mV, mA, thermocouple, resistance thermometer and other sensors and

transmitters. Controllers have high input empedance and protecting and

warning the system against the breakage sensors.

E-2000M series universal process controllers are advanced new generation

microcontroller based industrial instruments designed for On/Off and PID

control forms, dimensions of 96X96 mm compatible with IEC 668 standarts.

Universal inputs and outputs of controller can be programmed easily by the

user.

E-2000M process controllers can be used in every field of the industry for the

measurement and control of temperature, pressure, level, speed, current,

voltage, resistance and other physical units; as well asin the industry

branches of iron&steel, cement, plastic, chemistry, metallurgy, petrochemical

refineries, ceramic, glass and others.

E-2000M controller is designed for panel mounting and

should be used in an industrial environment.

The package of E-2000M controller contains;

Controller

2 pieces of mounting clamps

User manual

Guarantee certificate

After opening the package, please check the contents with the

above list. If the delivered product is wrong type, any item is

missing or there are visible defects, contact the vendor from which

you purchased the product.

Before installing and operating the controller, please read the user

manual thoroughly.

The installation and configuration of the controller must only be

performed by a person qualified in instrumentation.

Keep the unit away from flamable gases, that could cause

explotions.

Do not use alcohol or other solvents to clean the controller.

Use a clean cloth soaked in water tightly squeezed to gently

wipe the outer surface of the controller.

The product life of this instrument is 10 years.

Relay : SPST-NO 250V AC, 3A

Current : 0-20 mA, 4-20 mA (Isolated)

Pulse : 24V DC, 25 mA (for SSR) (from RL1 output)

Thermocouple ( TC ) : B, E, J, K, L, N, R, S, T, U

Resistance Thermometer ( RT ) : Pt-100

Current : 0-20 mA, 4-20 mA (Linear)

Voltage : 0-50 mV, 0-1 V, 0.2-1 V (Linear)

Input Types

Control Output

Relay : SPST-NO 250V AC, 3A

2 x 4 digit 14 mm 7 segment led display

o

Thermocouple : (±0.5% of the reading value or ±1 C)

±1 digit max.

o

Pt-100 : (±0.5% of the reading value or ±1 C)

±1 digit max.

Analog Input: ±0.5% FS ±1 digit max.

16 bit

12 bit

On/Off, PID

85-265 V AC / 85-375 V DC

20-60 V AC / 20-85 V DC

4W (7 VA)

o o o o

-10 C, +55 C (+14 F, +131 F)

(with no condensation or icing)

o o o o

-25 C, +65 C (-13 F, +149 F)

(with no condensation or icing)

10.000.000 operations

(The relay life differs according to the usage

configuration. When the relays are old, their contacts

could melt or burn out.)

>1.000.000 operations (under 1/10 of load)

EEPROM (100.000 max. write-erase)

232 g

IP 65 Front Panel (NEMA 4X)

IP 20 Rear Case

Encloser Ratings

Alarm Outputs

Display Type

Accuracy

Analog Digital Converter

Digital Analog Converter

Control Type

Operating Voltage

Power Consumption

Operating Temperature

Storage Temperature

Relay Mechanical Life

Memory

Weight

Relay Electrical Life

TECHNICAL SPECIFICATION

WIRING CONNECTION

Operating

Voltage

1 2 3 4 5 6 7 8 9 10 11 12

24VDC

RL1 RL2

SSR

Analog

Output

RT

TC

mA

mV

The labels on the sides of the controller identify the ordering code

(Type), serial number and wiring connections.

The controller options are also indicated on the wiring diagram.

The terminals 01 to 06 are electrically live. While the

instrument is powered, never touch to these terminals.

Before operating the controller, ensure that the controller

is correctly configured. Incorrect configuration could

result in damage to the process being controlled.

E-2000M controller should be installed inside a

suitable grounded metal enclosure (panel). This must

prevent the live parts being accessible to human

hands and metal tools.

E-2000M controller does not include a power

switch. Therefore, the power supply to the

controller and power outputs must be wired through the proper fuse

or circuit breaker.

To minimize the pick-up of electrical noise, the wiring of low voltage

lines, particularly the sensor input should be routed away from the

high-current power cables. Where it is not possible, use shielded

cables with the shield grounded at both ends.

The cables used for powering the controller and the power outputs

must conform to the standarts IEC 60245 and IEC 60227.

min. 10 mm

min. 35 mm

+0.8

-0.0

92x92mm

Cut a hole in the panel. (See the figure

for overall dimensions.)

Slide the controller into the cutout from

the front of the panel.

Fit the mounting clamps to the controller,

ensuring the lugs are located in their

slots.

Fasten the mounting clamps using the

retaining screws.

- While in normal operation, it displays the process value or

error message.

- While in configuration pages, it displays the name of the

parameters.

Upper

Display

- While in normal operation, it displays the control set point

(Automatic mode) or manual output (Manual mode).

- While in configuration pages, it displays the parameter value.

Lower

Display

RL1 Led When lit, it indicates that RL1 output is active.

RL2 Led When lit, it indicates that RL2 output is active.

PRG Led When lit, it indicates that the controller is in the

configuration mode.

F Led - When lit, it indicates that the controller is in

manual mode.

- F led will also flash when the auto-tuning

is in progress.

Star

Button

- When pressed together with button, password is asked

for entering the configuration page.

- While in configuration pages, pressing this button reverts to

normal operation.

- While in normal operation, pressing this button for duration

3 seconds, toggles between automatic and manual mode. This

operation is disabled if the MPL parameter in page PRTC is

set to DSB or if the CNTL parameter in OCNF page is set other

than PID.

- While in normal operation, pressing this button acknowledges

the latched alarms if configured (AXLT = ON).

Enter

Button - When pressed together with button, password is asked for

entering the configuration page.

- While in configuration pages, pressing this button selects the

next parameter.

- While in configuration pages, pressing this button for duration

2 seconds, returns to the top of the page.

- While in normal operation, pressing this button selects the

next parameter in operator page.

Up/

Down

Buttons

- While in normal operation, these buttons can be used to

edit the control set point (Automatic mode) or manual output

(Manual mode).

- While in configuration, these buttons can be used to select

the configuration pages and to edit the parameters.

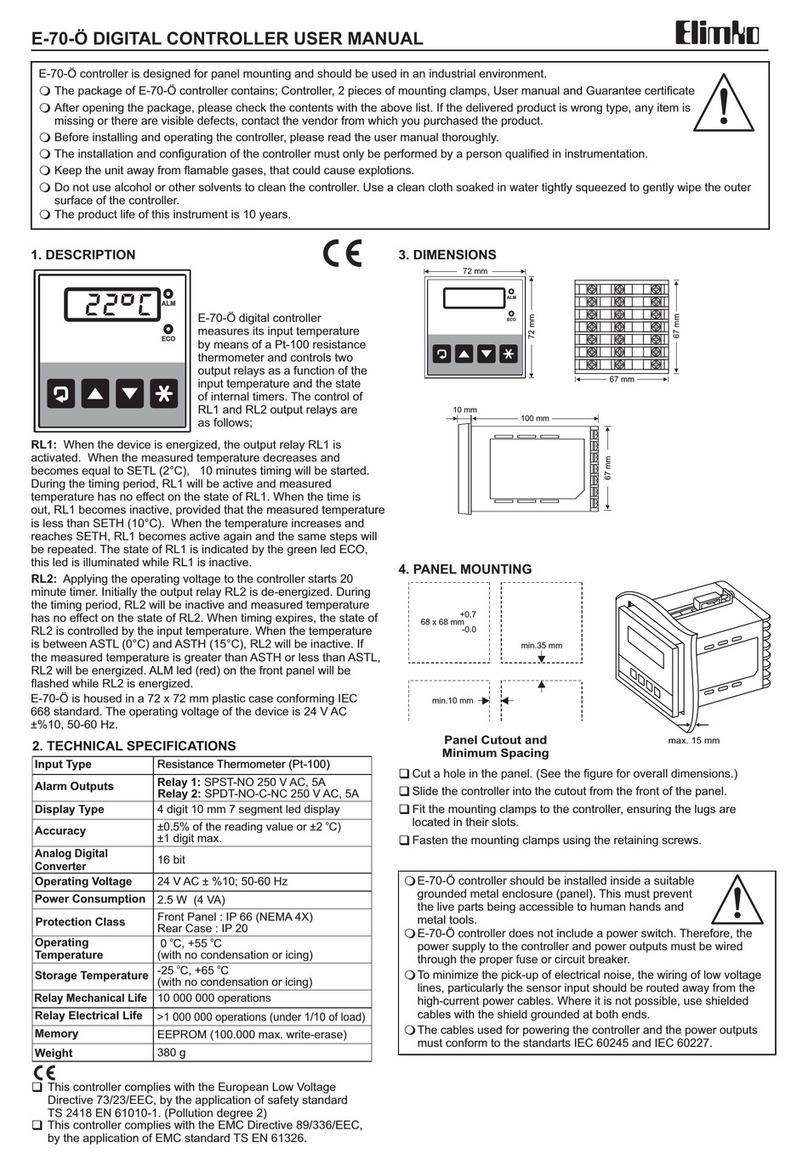

ALARM TYPES

EXPLANATIONS

A1SP or a2sp > 0

LO

HI

LOD

HID

LOB

HIB

OFF

1

ASP

PV

Alarm State

0

0

A1SP or a2sp < 0

A1tp

or

A2tp

Alarm State

PV

0

1

0

Alarm State Alarm State

PV

0

1

0

ASP

ASP

1

0

0

PV

ASP

Alarm State

1

0

0

SP SP+ASP

Alarm State

Alarm State

Alarm State

Alarm State

AlarmState

Alarm State

Alarm State

PV

PV

PV

PV

PV

PV

PV

1

0

0

SPSP+ASP

1

0

0

SP SP+ASP

0

SP

1

0

1

0

0

SP-ASP SP SP+ASP

1

0

0

SP

1

0

0

SP-ASP SP SP+ASP

1

0

0

SP

SP+ASP

AXHY

Alarm State

PV

1

0

0

Low

Alarm

(Absolute)

High

Alarm

(Absolute)

Low

Deviation

(Relative)

High

Deviation

(Relative)

Band

Alarm

(In)

Band

Alarm

(Out)

Alarm function is cancelled when A1tp or A2TP parameters are off.

Shaded areas

show the

hysteresis.

When alarm state is

"1" the output (relay)

is active.

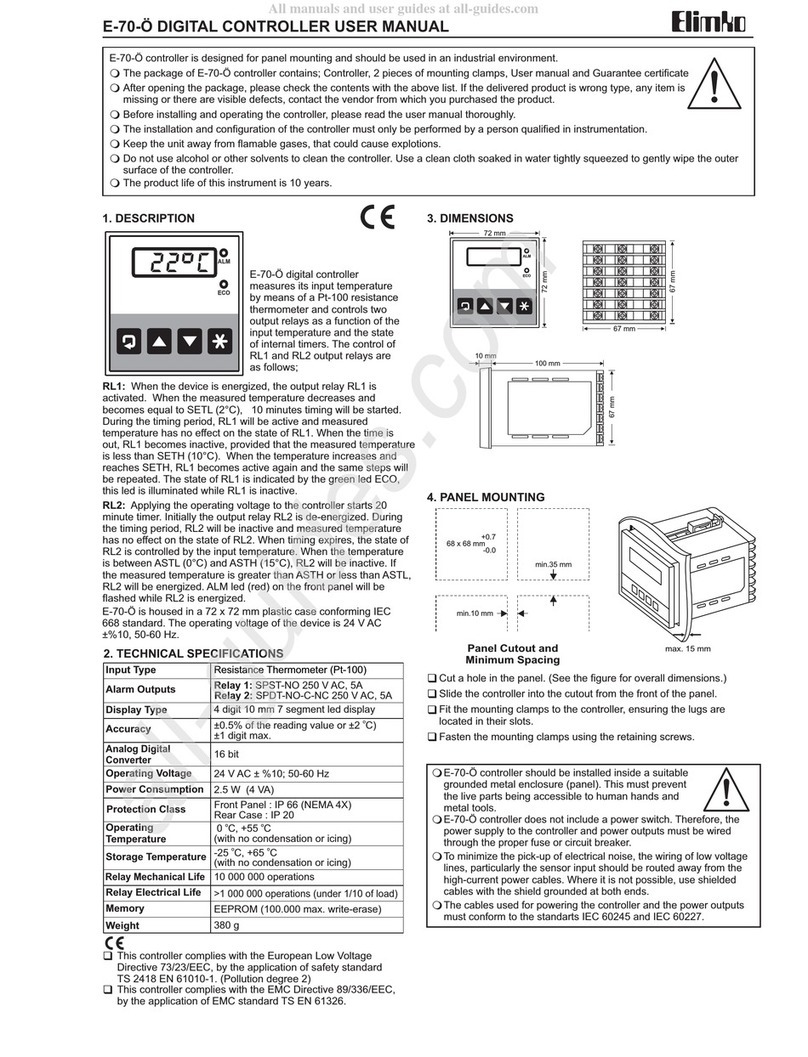

ERROR MESSAGES

Open

Ufl

Ofl

Nnnn

Vvvv

Message Meaning Remedy

The connection of the sensor

is broken.

The process value is below

the sensor type-temperature

interval.

The process value is above

the sensor type-temperature

interval.

The process value is

above the value that can

be displayed.

The process value is

below the value that can

be displayed.

Check the sensor and

the sensor connection.

Check the sensor and

the input type specified

by the INPT parameter.

Check the analog value

on the input terminal

and the scalar specified

by the Dp, Zero and span

parameters.

Auto-tuning matches the characteristics of the controller to the

process being controlled in order to obtain good control. Tuning

involves calculating and setting the values of the PID parameters.

The Auto-tuner works by switching the output on and off to induce an

oscillation in the process value. From the amplitude and period of

oscillations PID parameters are calculated.

Auto-tune can be performed at any time, but normally it is performed

only once during the initial commissioning of the process. However,

if the process under control subsequently becomes unstable

(because its characteristics have changed), you can re-tune again

for the new conditions.

In order to start Auto-tune process:

1- Set the CNTL parameter in OCNF page as PID.

2- Set the control set point to the value at which you will normally

operate the process. Consider also the process value may exceed

the control set point while in Auto-tuning.

3- Set the HYS parameter in TUNE page as 0.1 (if DP=1) or 1 (if DP=0).

4- Set the AT parameter in TUNE page as ON to commence

Auto-tuning process. Press button to revert the normal operation.

The lower display and F led will flash to indicate that tuning is in

progress.

After a few cycles of oscillation the tuning is completed and the

calculated PID parameters PB, IT and DT are stored.

While the Auto-tuning in progress if AT parameter is set the OFF or

operating power of the controller is interrupted Auto-tune progress is

stopped and old PID values are retained.

MANUAL TUNING

If for any reason Auto-tuning gives unsatisfactory results, the controller

can be tuned manually. There are a number of standard methods for

manual tuning. The one described here is the Ziegler-Nichols method.

With the process at its normal running temperature:

Set the IT, DT and HYS parameters in TUNE page as 0.

1-

If OCR parameter in page OCNF is set to RL1, then set the CT

parameter 2.

2-

Ignore the fact that the temperature may not settle precisely at the

set point.

3-

If the temperature is stable, reduce the proportional band PB so that

the temperature just starts to oscillate. If the temperature is already

oscillating, increase the proportional band until it just stops oscillating.

Allow enough time between each adjustment for the loop to stabilize.

Make a note of the proportional band value (B) and the period of

oscillation (T).

4-

Set the PB, IT and DT parameters values according to the calculations

given below.

5-

P

PI

PID

2xB

2.2xB

1.7xB

0

0.8xT

0.5xT

0

0

0.12xT

Type of

Control

Proportional

Band

(PB)

Integral

Time

(IT)

Derivative

Time

(DT)

This controller complies with the European Low Voltage

Directive 73/23/EEC, by the application of safety standard

TS 2418 EN 61010-1. (Pollution degree 2)

This controller complies with the EMC Directive 89/336/EEC,

by the application of EMC standard TS EN 61326.