Elimko

7 / 33KY-GEN-S-0923-0

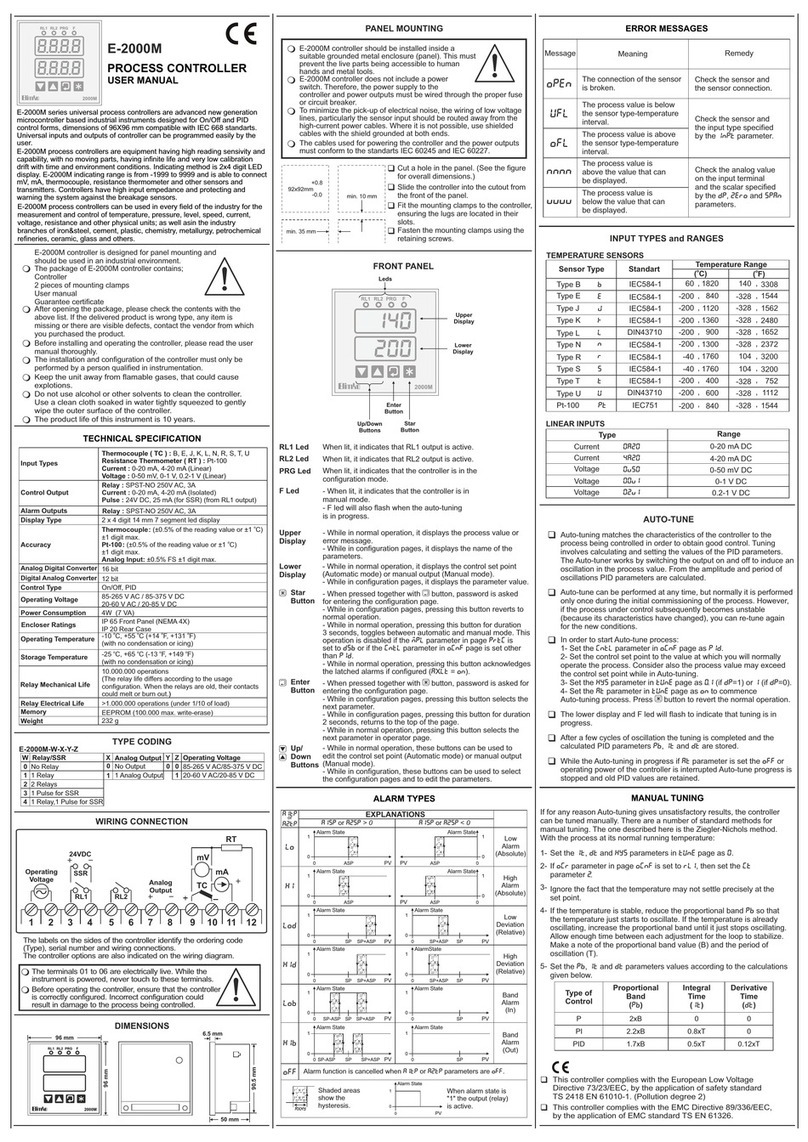

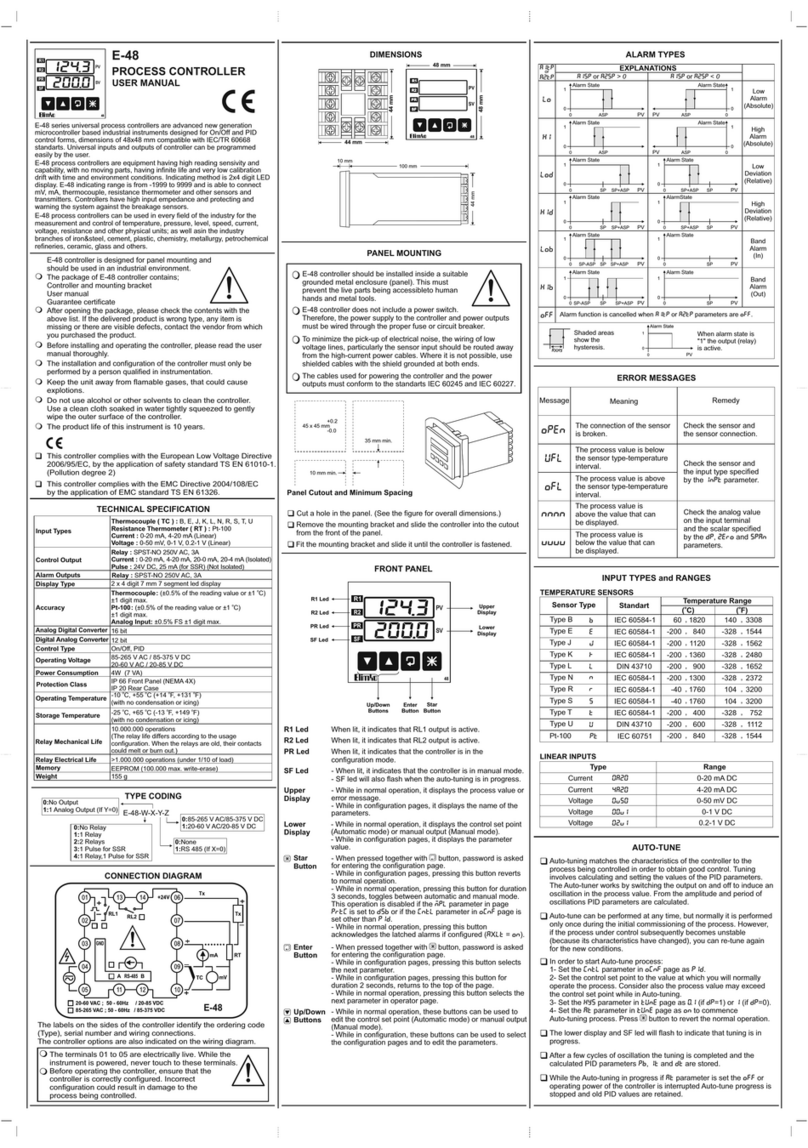

3.1. Process Screen and Operation Parameters

200.1

200.0 Process Screen Always

EU

Screen Definition Min Access

MaxUnit

Process Screen is the power on screen of the controllers and pressing 4 key

returns to this screen anytime. In this screen, upper display always shows process

value. Lower display shows either control set point or manual output value

depending on selected control mode. In automatic mode, control set point can be

adjusted between SPLL..SPHL and in manual control mode, the manual output

value can be adjusted between OLL..OHL using 12 keys. In manual control mode,

MN LED lights.

In Automatic Control Mode, if SETPaSPSR (Control Set Point Source) = PRFL and the

profile is not running, lower display shows PRFL message. After running the profile,

depending on the configured profile a changing and non adjustable control set point

is followed. Please see SETP configuration page for detailed profile configuration.

4 and 2 : Runs the profile.

4 and 1 : Stops the profile.

1 : Suspends the profile. Lower display flashes.

2 : Rerun the suspended profile.

In Automatic Control Mode, if SETPaSPSR (Control Set Point Source) = DINP, lower

display shows one of the digital input selectable control set point (SET1, SET2, SET3,

SET4) and adjustment is not allowed. Please see SETP configuration page for

detailed usage information.

In order to change control mode, first Process Screen is accessed by pressing 4

key and than 4 key is pressed and hold for at least 3 seconds . Alternatively,

Manuel Control Mode can be activated digitally by stimulating 1. digital input if

available. If the stimulation is removed, the controller returns to the automatic

control mode again. Mode selection is available only if OCNFaCTYP (Control Type) is

not NONE and OCNF aMNPR (Manuel Mode Selection) is ENB.

In Manual Control Mode, if OCNFaCTYP (Control Type) is BND (floating valve control)

, instead of a numeric output percentage, following messages are shown.

STP : None of the valve control output is active. Shown when no key is

pressed

OPN : Valve open output is active . 2 key activates valve open output.

CLS : Valve close output is active. 1 key activates valve close output.

aaa