UL LISTINGS AND INSTRUCTIONSUL LISTINGS AND INSTRUCTIONSUL LISTINGS AND INSTRUCTIONS

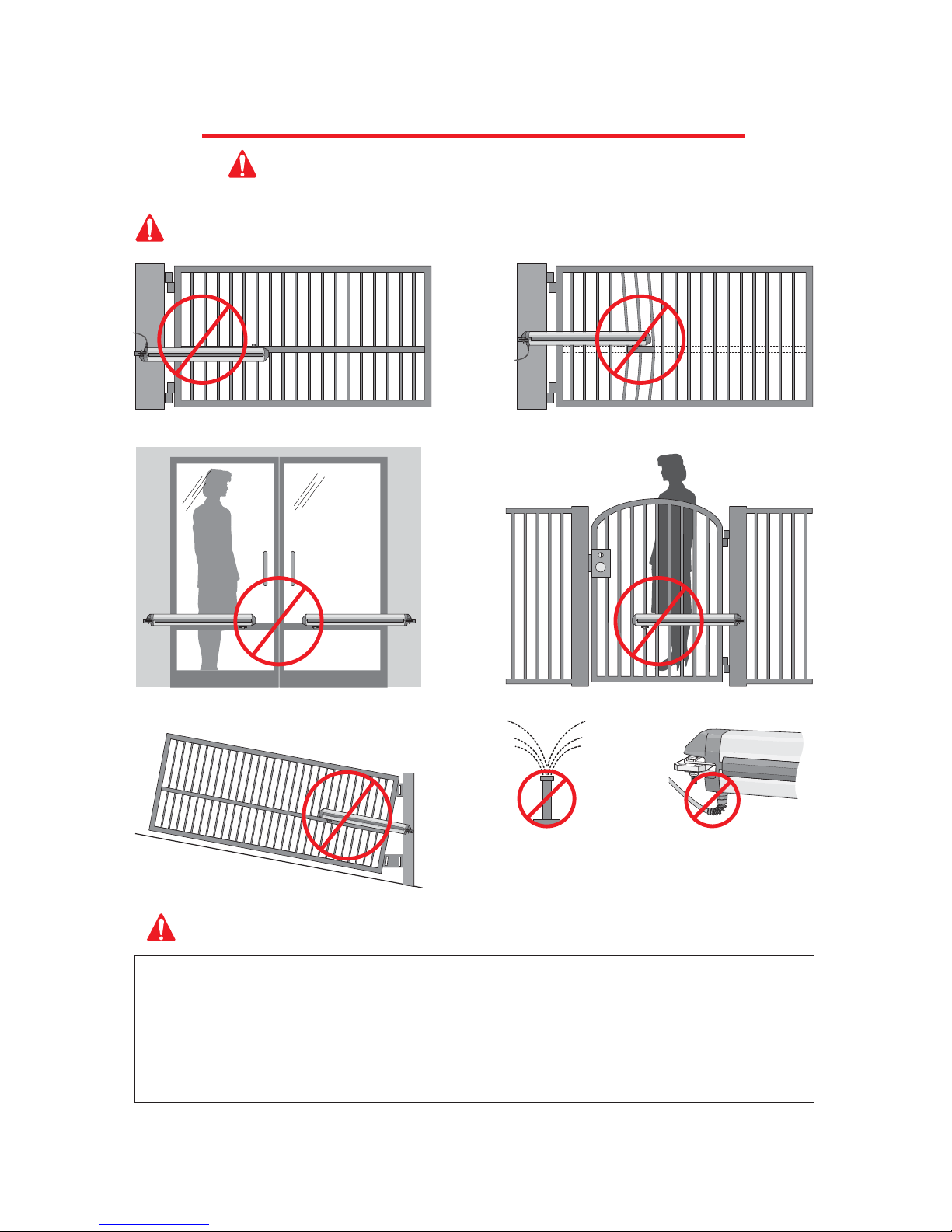

Gate – A moving barrier such as a swinging, sliding, raising lowering, rolling, or like, barrier,

that is a stand-alone passage barrier or is that portion of a wall or fence system that controls

entrance and/or egress by persons or vehicles and completes the perimeter of a defined

area.

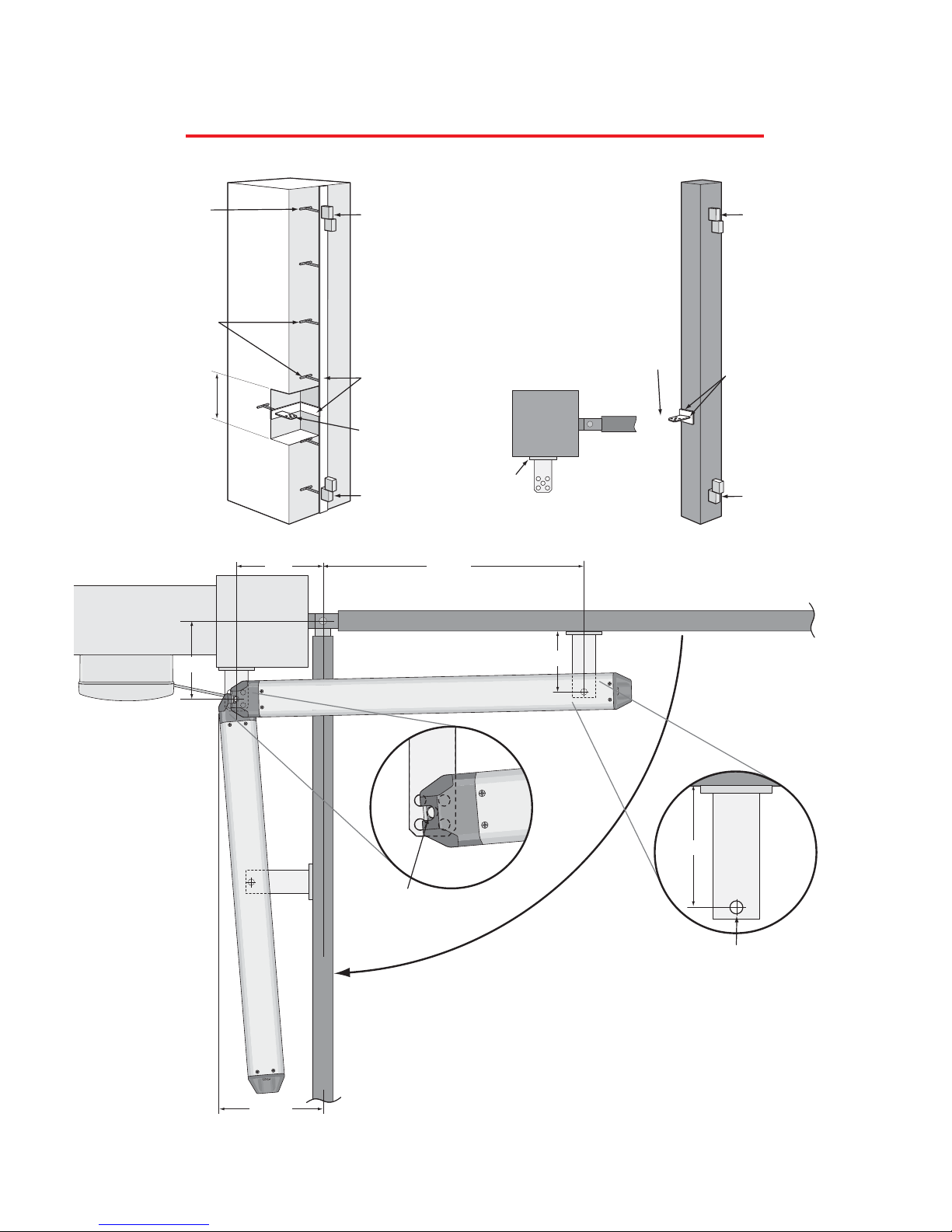

Vehicular horizontal slide-gate operator (or system) – A vehicular gate operator (or

system) that controls a gate which slides in a horizontal direction that is intended for use for

vehicular entrance or exit to a drive, parking lot, or the like.

Residential vehicular gate operator – Class I – A vehicular gate

operator (or system) intended for use in a home of one-to four

single family dwelling, or a garage or parking area associated

therewith.

Commercial/General access vehicular gate operator –

Class II – A vehicular gate operator (or system) intended for

use in a commercial location or building such as a multi-

family housing unit (five or more single family units) hotel,

garages, retail store or other building servicing the general

public.

Commercial/General access vehicular gate operator –

Class III – A vehicular gate operator (or system) intended for

use in a industrial location or building such as a factory or

loading dock area or other locations not intended to service

the general public.

Restricted access vehicular gate operator – Class IV – A

vehicular gate operator (or system) intended for use in a

guarded industrial location or building such as an airport

security area or other restricted access locations not

servicing the general public, in which unauthorized access is

prevented via supervision by security personnel.

5