The EWPC 961/S is a temperature

controller specifically designed for

refrigeration applications.

The instrument is equipped with a

RS-485 port for the purpose of con-

necting it into a Televis system.

GENERAL DESCRIPTION

The EWPC 961/S is a temperature con-

troller specifically designed for refrigeration

applications and provides time control for

off-cycle defrost management. It incorpo-

rates an output relay for compressor con-

trol and a PTC sensor input. Furthermore,

the instrument is equipped with a RS-485

port for the purpose of connecting it into a

Televis system. A number of parameters are

displayed alphanumerically to set up the in-

strument for each specific application.

The EWPC 961/S is supplied in the popu-

lar “32x74” ELIWELL housing.

OPERATION

The EWPC 961/S is designed to operate

strictly as a cooling control, which means

that the switching differential is positive: the

compressor cuts off at setpoint and is

started at a temperature of set plus differ-

ential. The on-board microprocessor pro-

vides several timing functions for the

defrost; the defrost cycle as well the de-

frost cycle duration are user selectable.

At the start of each defrost cycle, the com-

pressor is simply stopped, regardless of

the temperature control circuit.

In addition, the EWPC 961/S offers several

system protection features, all easy to un-

derstand and easy to program This instru-

ment is compatible with Televis software rel

2.4 or greater. In case its use with different

software releases is required contact your

supplier or Eliwell Customers’ Service.

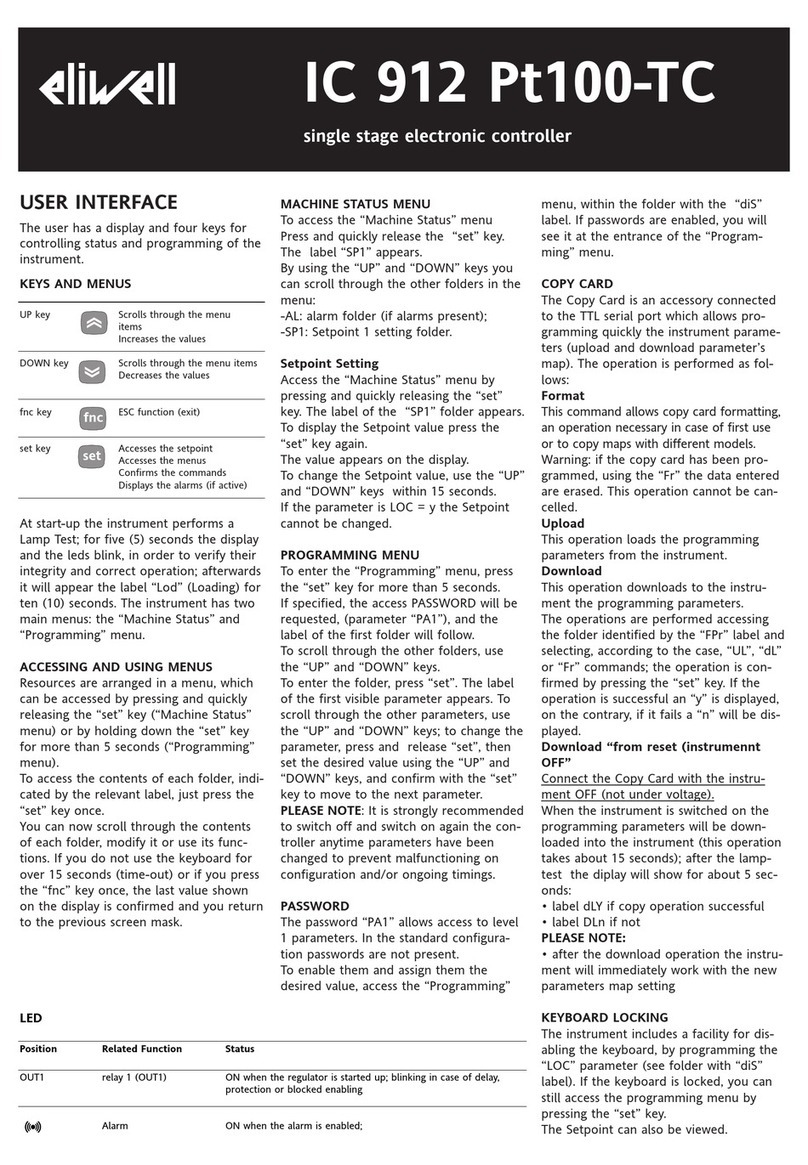

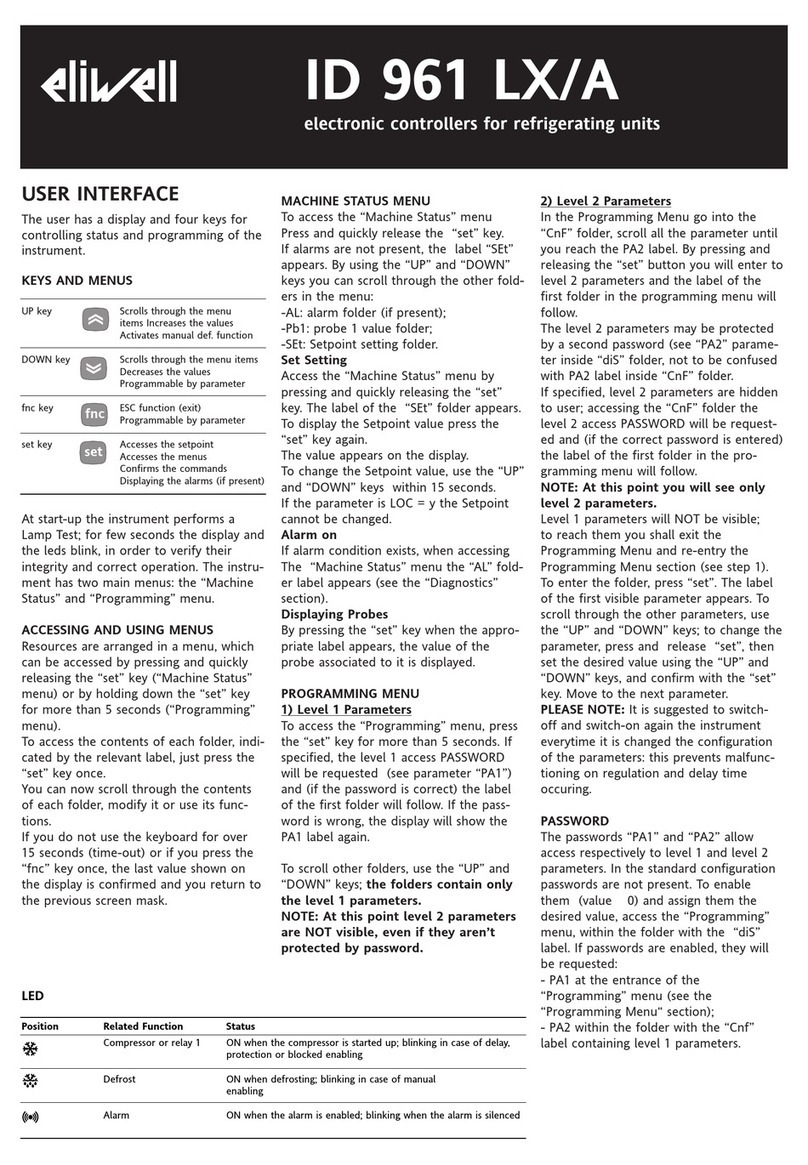

FRONT KEYPAD

SET: push and release to display the set-

point for 5 seconds. During this period the

“SET” status light is on and the setpoint

can be changed with the “UP” or “DOWN”

button only. The system will automatically

switch to normal display after 5 seconds

upon release of buttons and the new value

will be memorized.

UP: used to increase the setpoint value, as

well as the parameter when in program-

ming. When held down for a few seconds,

the change rate accelerates.

DOWN: same functions, except to de-

crease a value.

DEFROST: push to initiate a manual de-

frost cycle (override of programmed defrost

start; programmed time resets to zero).

Manual defrost can not be started while in

setpoint or in parameter programming

mode.

This button must be activated for 5 sec-

onds to start a defrost; the “DEF” status

light will come on and the compressor is

stopped.

Led “COMP”: status light of the internal

compressor relay. It is ON when the com-

pressor is ON.

Led “SET”: it is on during Setpoint display

and programming; it blinks during parame-

ter programming.

Led “DEF”: status light of the defrost. It is

on during automatic defrost; it blinks dur-

ing manual defrost.

PARAMETER PROGRAMMING

Programming is easily accessed by holding

the “SET” button down for more than

5 seconds; the first parameter is displayed

while the status light “SET” remains blink-

ing during the programming period.

Other parameters are accessed with the

“UP” and “DOWN” button. With the “SET”

button, the actual setting of each parame-

ter is displayed. To change a parameter

setting, push the “SET” plus the “UP” (or

“DOWN”). The system will automatically re-

turn to its normal operating mode a few

seconds after the programming procedure

is completed or interrupted.

DESCRIPTION OF PARAMETERS

diF: diFferential.

Switching differential (histeresis); it will al-

ways be set with positive value (make on

rise).

HOW IT IS MADE

• Dimensions: front 74x32 mm

(2.913x1.260"), depth 67 mm

(2.637")

• Mounting: flush panel mount with

mounting bracket

• Protection: the instrument front-

panel is waterproof IP65; an op-

tional snap-on cover can be

supplied to provide additional pro-

tection of the rear terminal block

• Connections: screw terminal block

(2.5 mm2; one wire each terminal

only, in compliance with VDE

norms)

• Display: 12.5 mm LED (0.50")

• Output: one (1) SPDT relay 8(3)A

250VA

• Input: PTC probe

• Serial connection: RS-485 serial

port for connection to the Televis

system

• Televis system compatibility: soft-

ware release 2.0.4 or greater

• Resolution: 1 °C (°F)

• Accuracy: better than 0.5% of full

scale

• Power supply: 12…24 VA/C

WHAT IT IS

EWPC 961/S

freezer control with Televis output