PAGE 2

97718C (Rev. E - 09/15)

ERS1*2F

Installation

For correct and safe installation, please read these instructions completely.

DANGER

• All Installation work must be performed by an authorized service personnel.

• Disconnect electrical supply serving the Installation area to reduce risk of electrocution.

• Unit not suitable for installations where water jets could be used.

WARNING

• Shut off water supply serving the Installation area to reduce risk of water damage.

• Installation area must have minimum required clearances and ventilation for safe operation.

• Never wire compressor directly to electrical supply.

CAUTION

• Hose-sets are not to be used for connecting to water mains.

• Tools/Items required but not provided.

o Safety Glasses

o Protective Gloves

o Hex drives.

o Water Shut-off Valve with 3/8" (9.5mm) compression outlet.

o Fasteners for wall type.

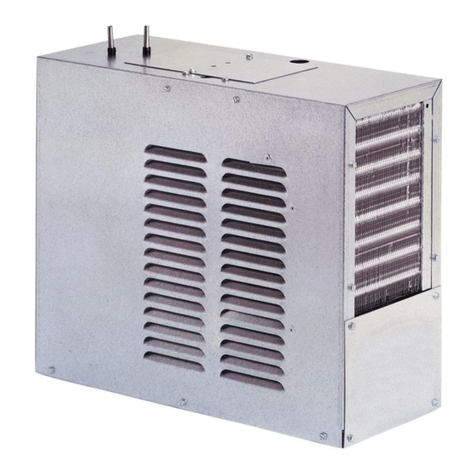

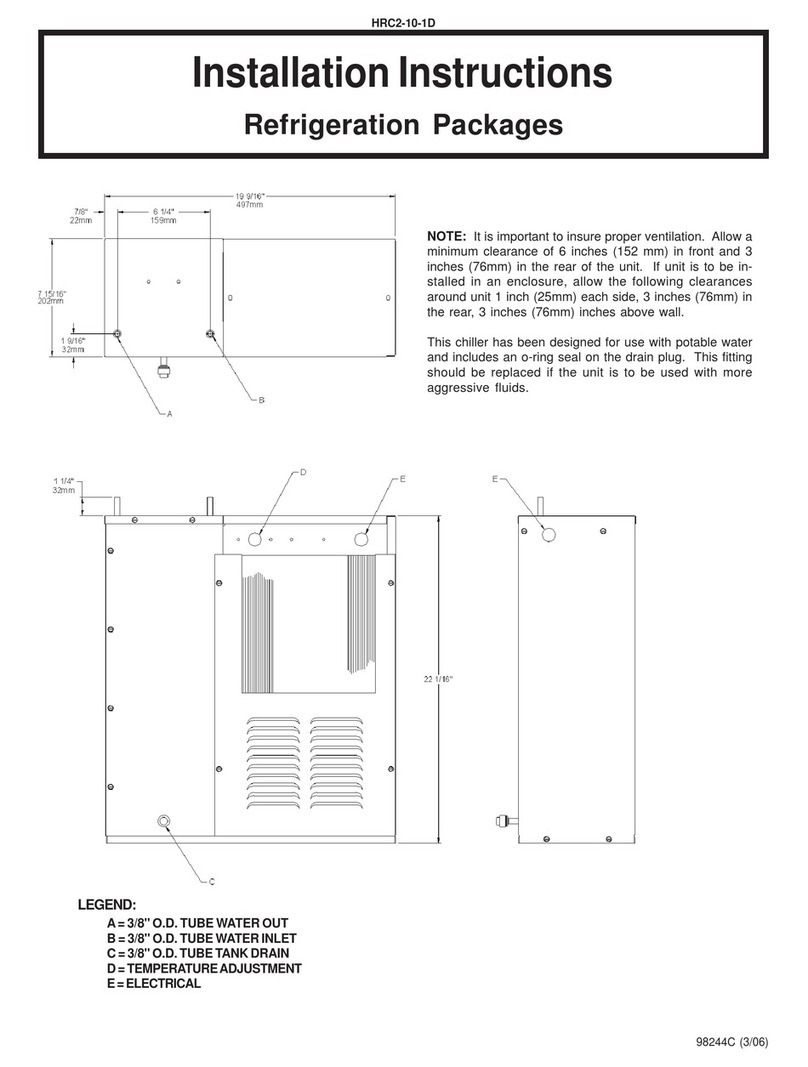

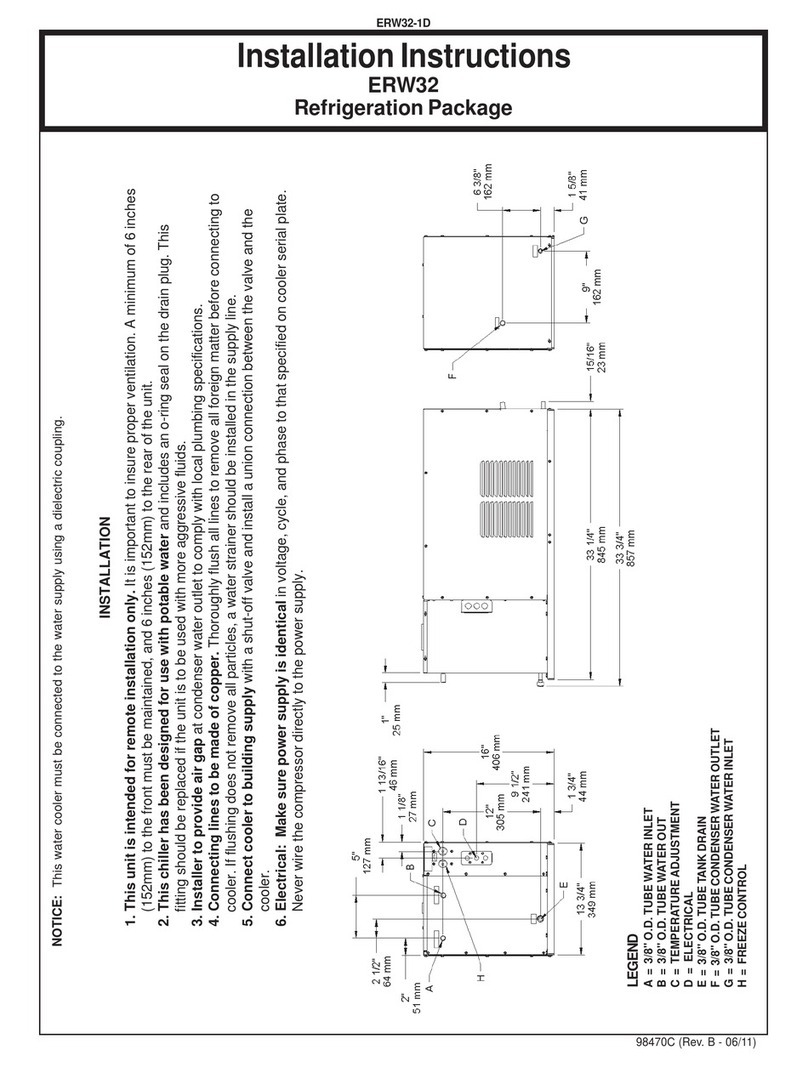

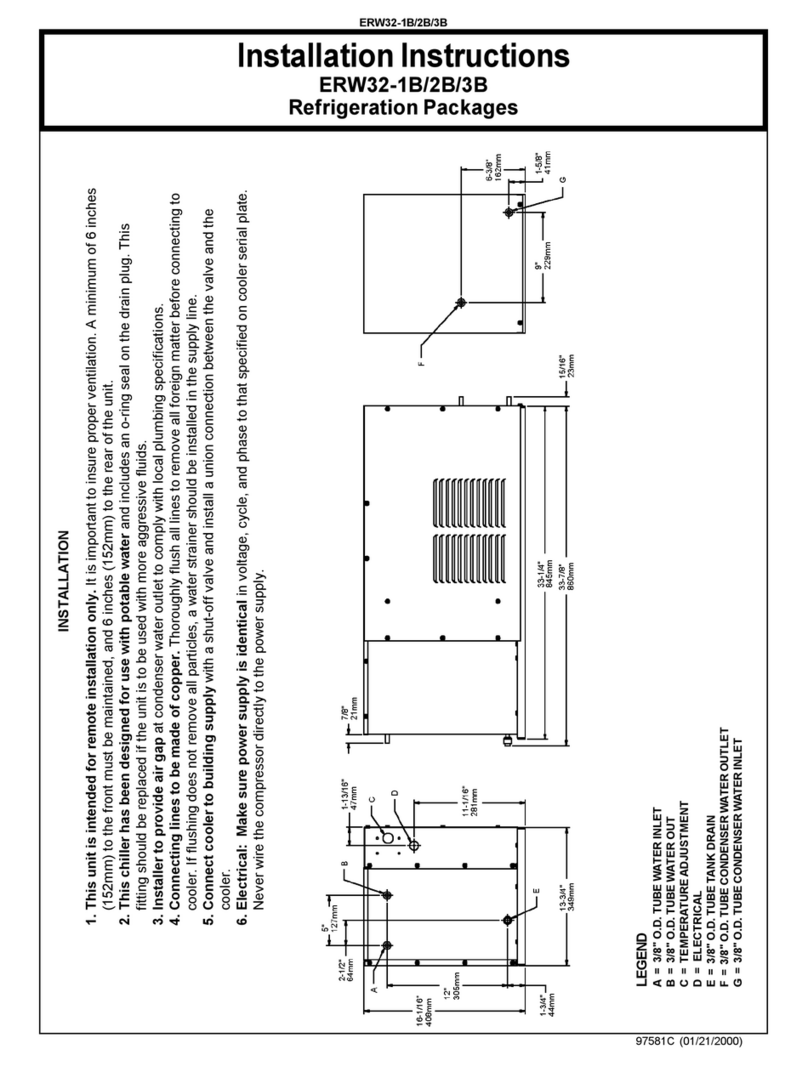

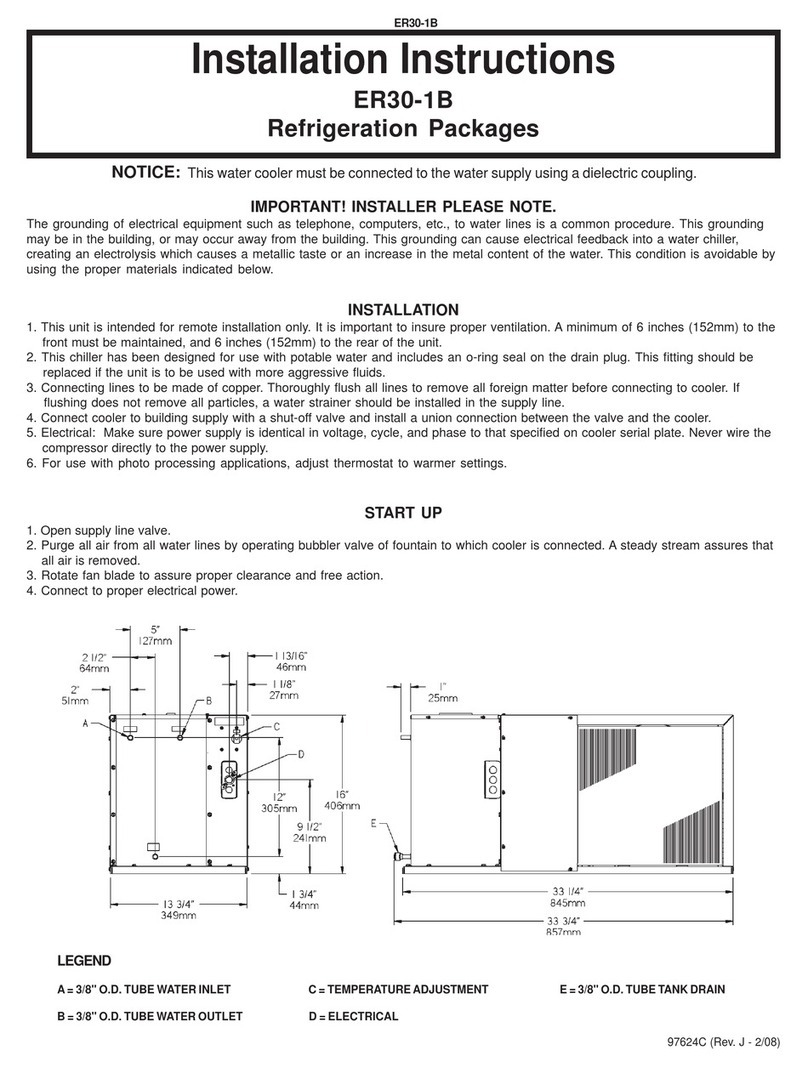

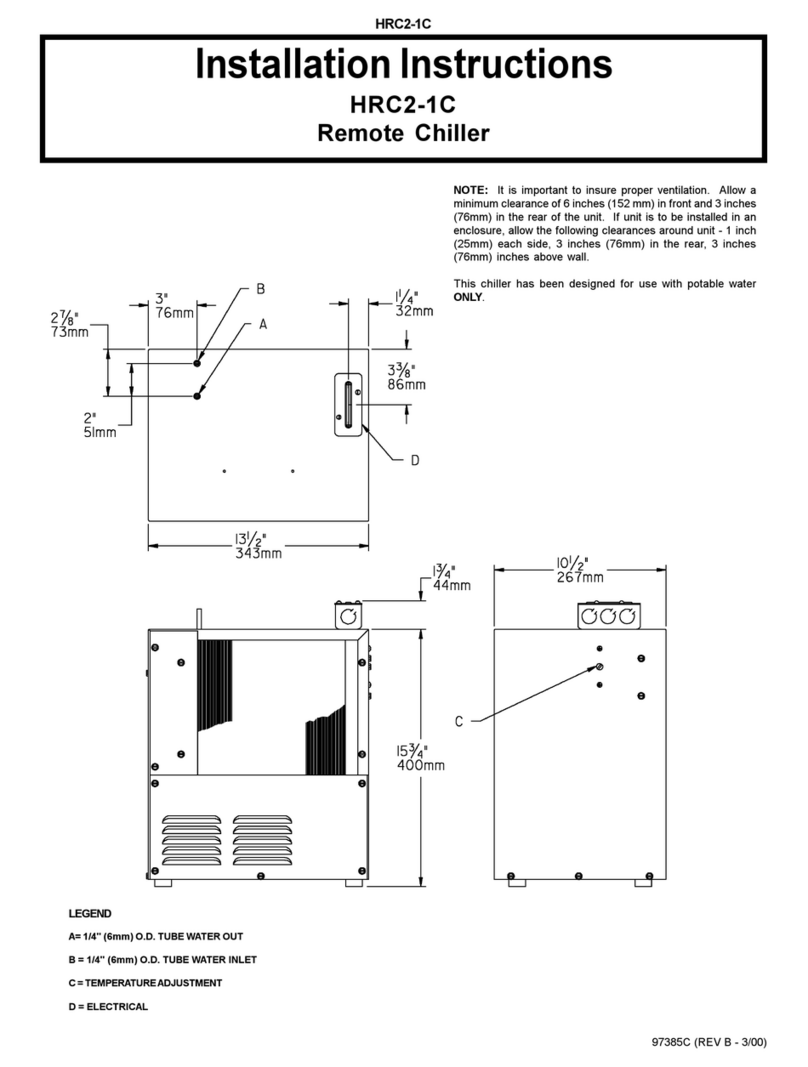

This unit can be installed underneath a commercial or industrial sink, in

a cabinet not less than 36" (914mm) wide (inside dimension). Two air

openings with a minimum of 40" square (1016mm/square) each, minimum

of 75% open area, must be provided in the cabinet. One opening must

be in the overhang of the toe space, the other opening near the top of the

cabinet. The remote unit must be installed with a minimum of 3"(76mm)

clearance between the unit and the rear wall of the cabinet. It can be in-

stalled ush against either side wall of the cabinet. The side louvers which

are not against the cabinet must not be blocked by objects located within

4" (102mm) of the louvers. In addition, a minimum of 1 to 2" (25 to 51mm)

clearance must be provided between the toe space air opening and front

of the unit.

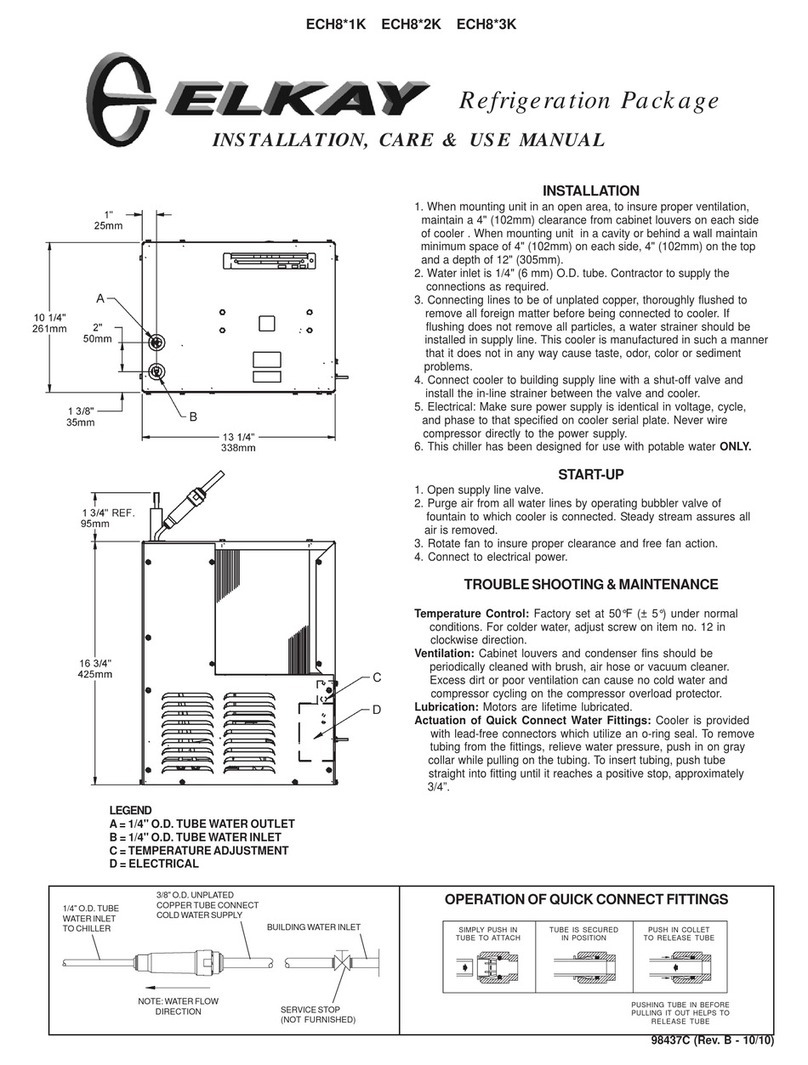

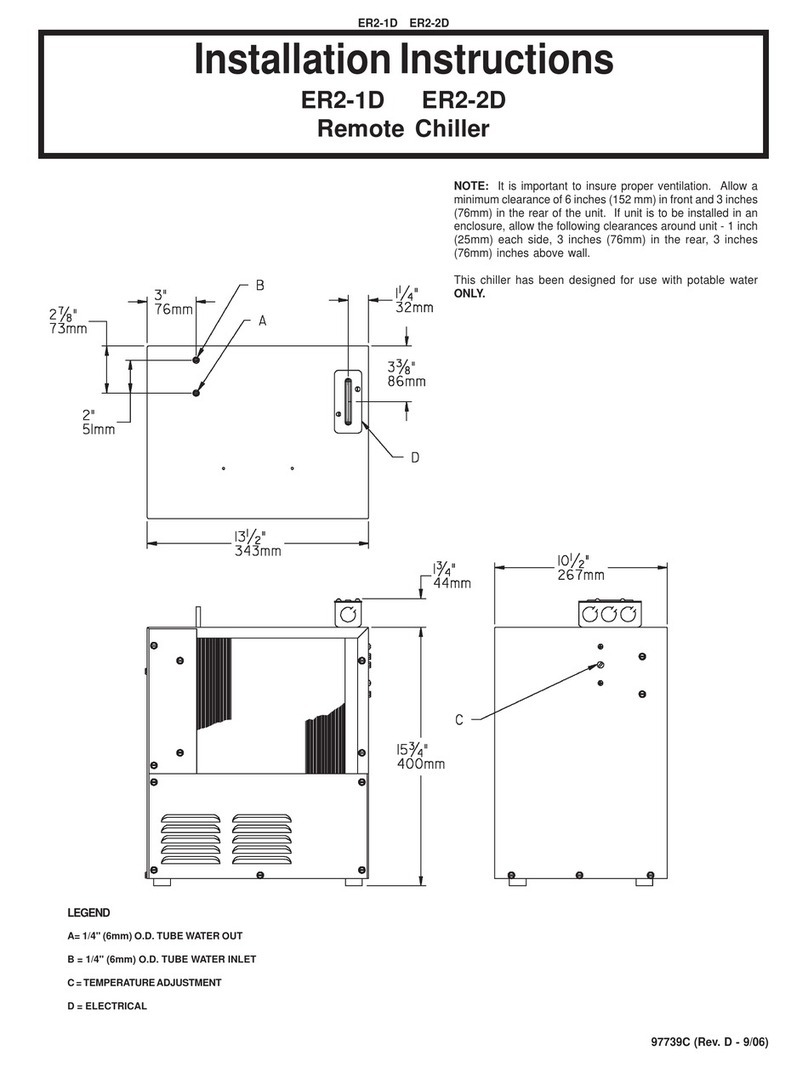

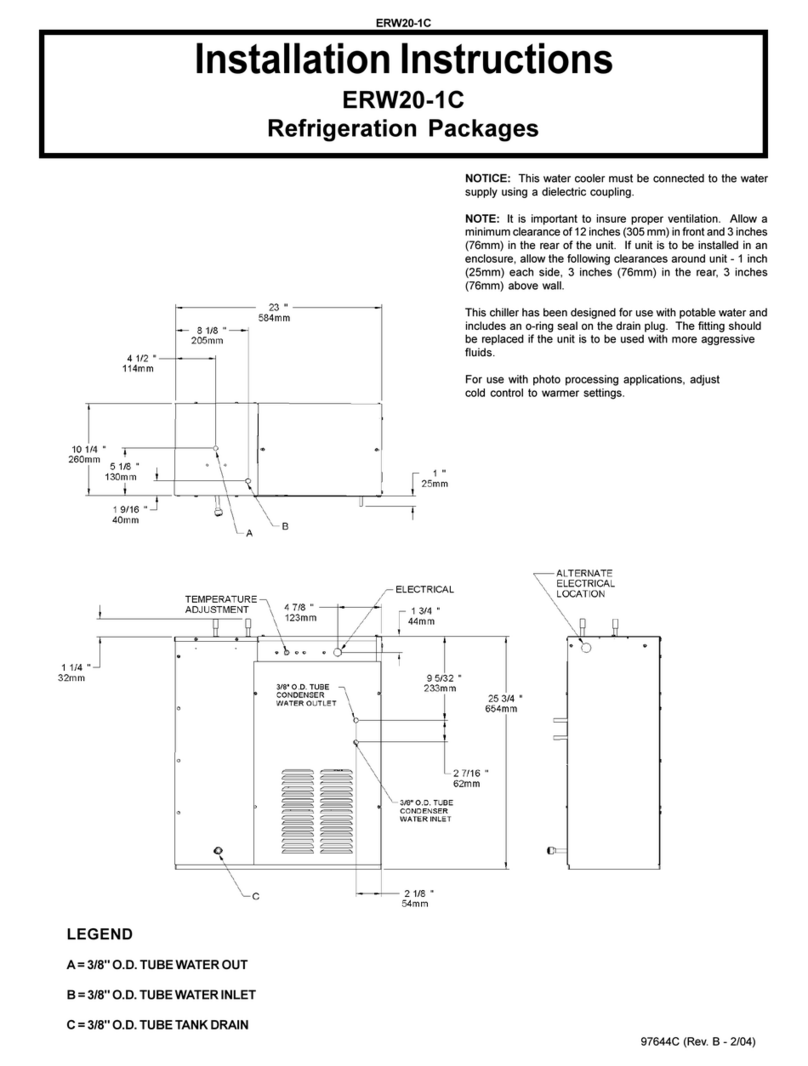

Water inlet and outlet are 1/4" (6 mm) O.D. tubes with connectors sup-

plied.

Connecting lines to be of copper, thoroughly ushed to remove all foreign

matter before being connected to cooler.

Connect cooler to building water mains with a shut-off valve and install

a 3/8" O.D. (10mm) unplated copper tube between the valve and cooler.

Remove burr from outside of water line. Insert water line into tting until it

reaches a positive stop, approximately 3/4" (19mm).

Installation Steps

1.

2.

3.

4.

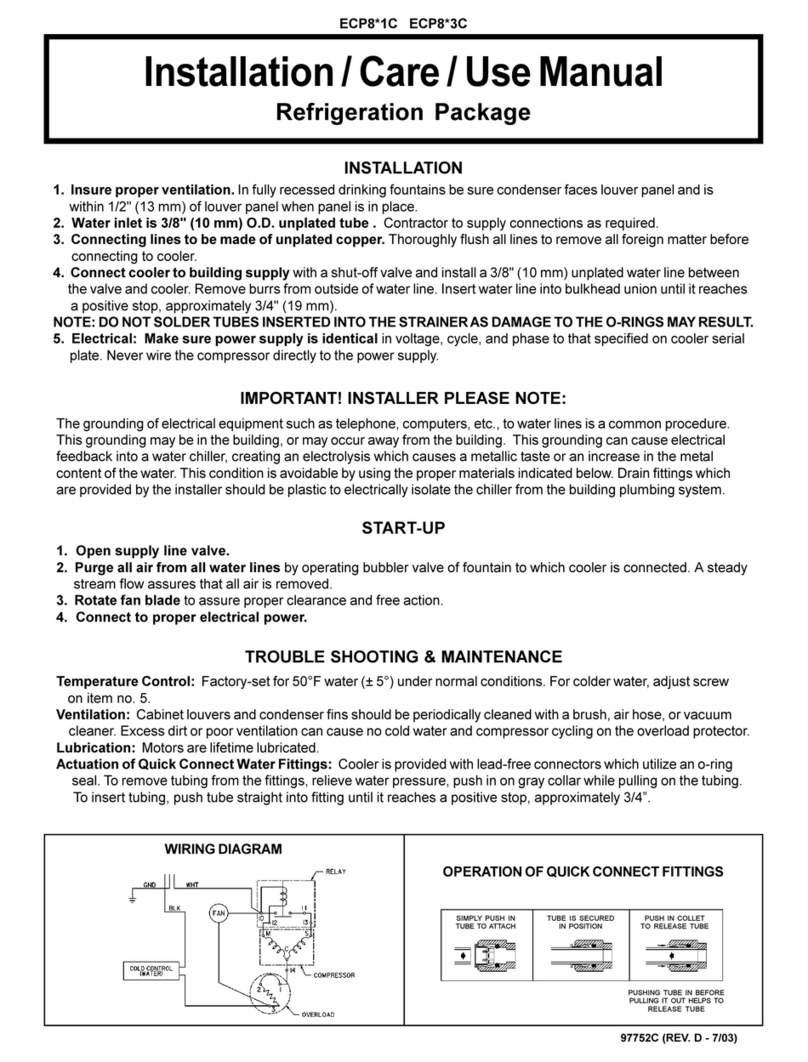

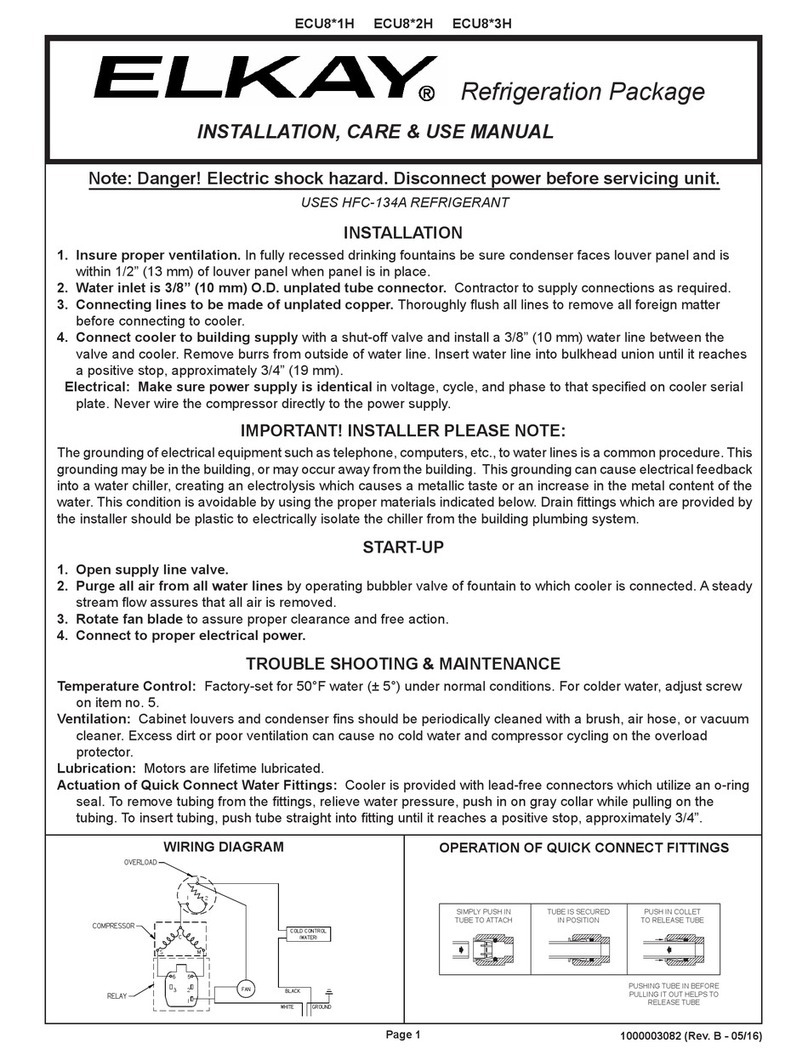

Wiring Instructions

1. Turn off electrical supply to chiller circuit

2. Remove top cover to gain access to electrical box

3. Join electrical wire to unit using 3/8” cable clamp

connector or appropriate conduit connector

4. Connect ground wire to ground screw (provided)

5. Connect black wire to 230VAC

6. Connect white wire to Neutral line

7. Replace top cover and turn on electrical supply.

Start-Up

1. Open water shut-off valve.

2. Purge air from all water lines by operating bubbler valve

of fountain to which cooler is connected. Steady water

stream assures all air is removed.

3. Rotate fan to insure proper clearance and free fan action.

4. Connect to electrical supply.

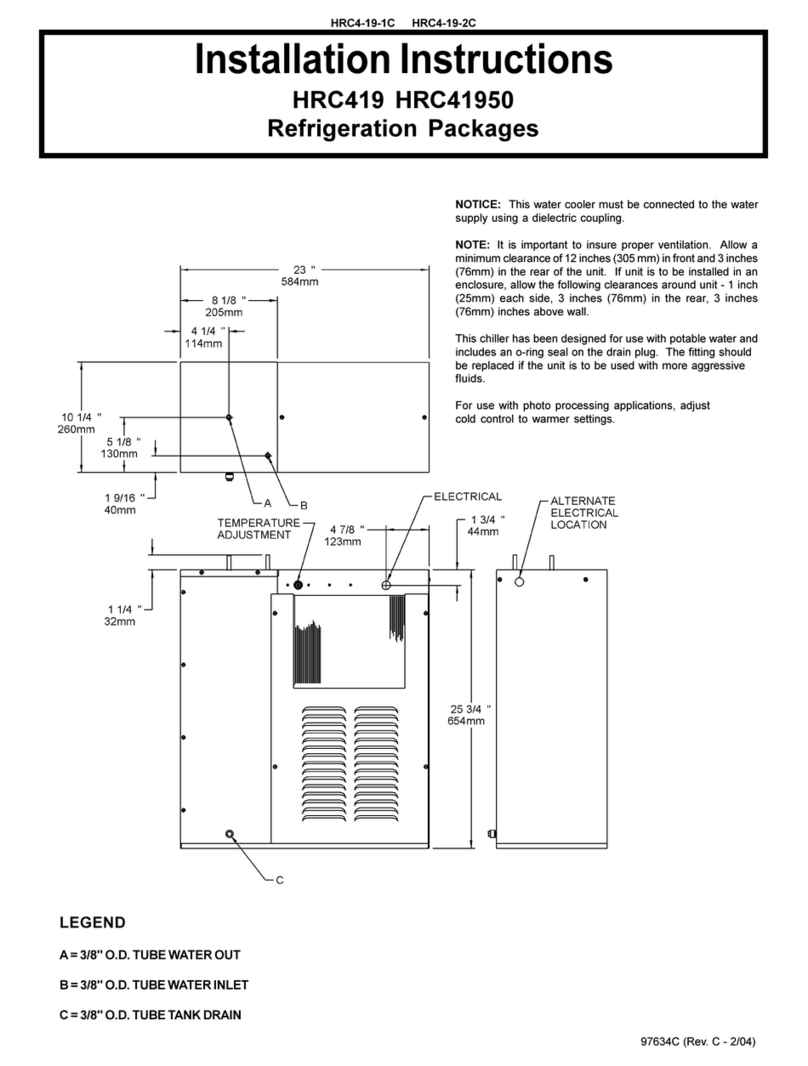

A) Air Vent

B) Condenser Side

Forward

C) Can be mounted

ush against either

side of cabinet

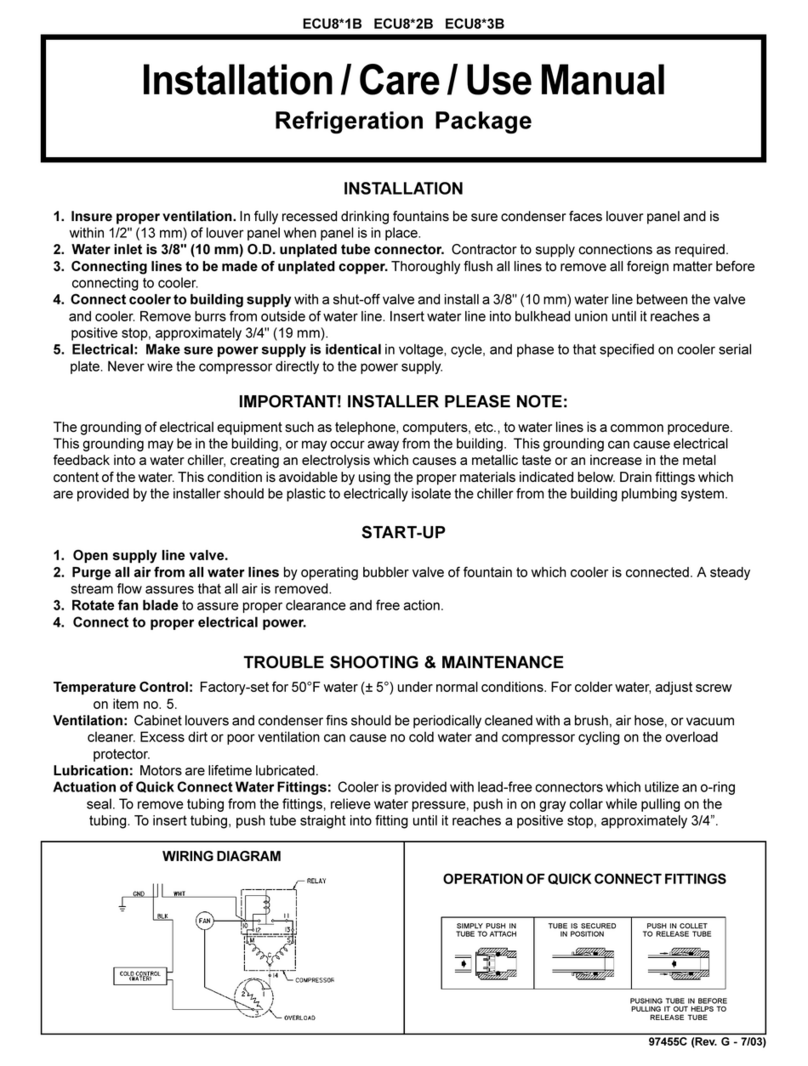

Water Mains Connection

A) 1/4” (6mm) O.D. Tube. Water Inlet to Chiller

B) Building Water Mains

C) Water Shut-Off Valve (not provided)

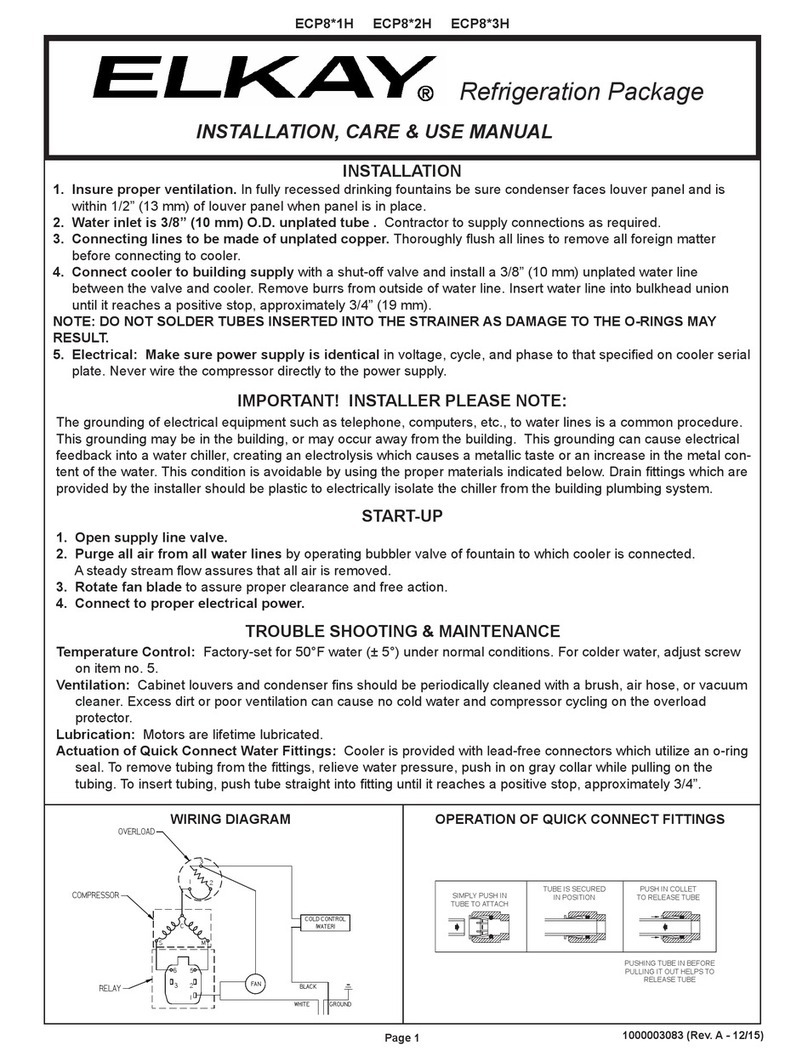

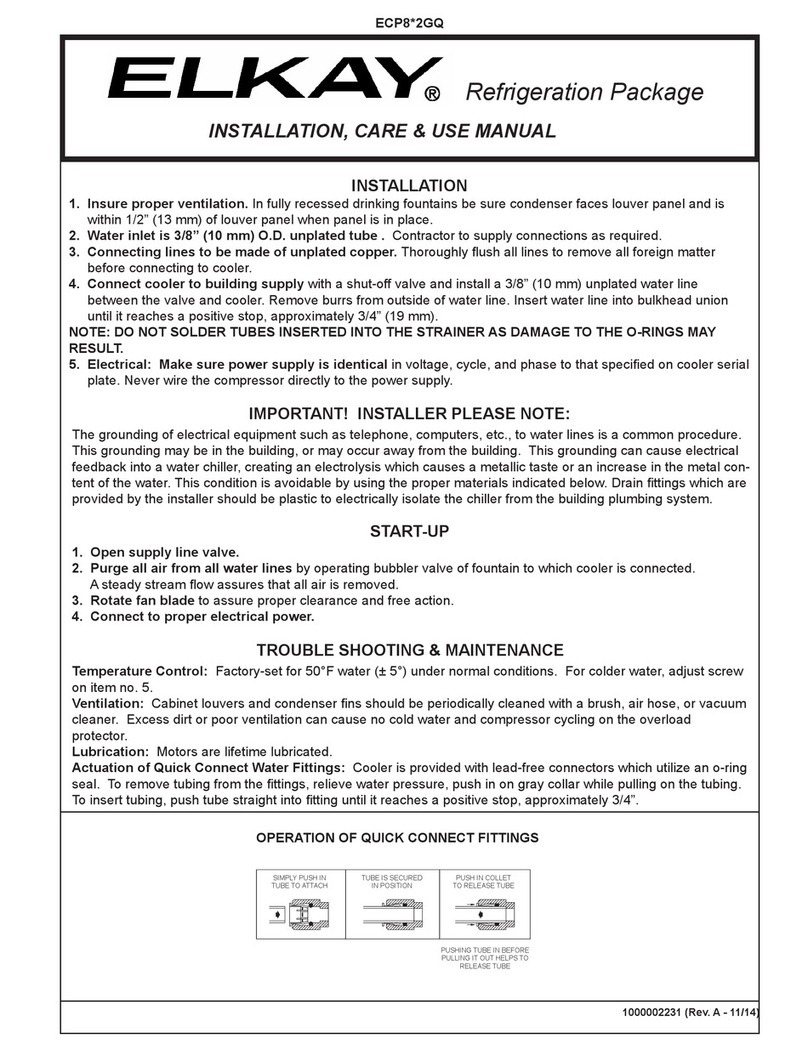

230Vac, 50Hz Wiring Diagram

A) White = Neutral

B) Black = 230Vac

C) Ground Screw = Earth

D) Fan

E) Temperature Control

F) Internal Overload Protector

G) PTC Starter

A B

C