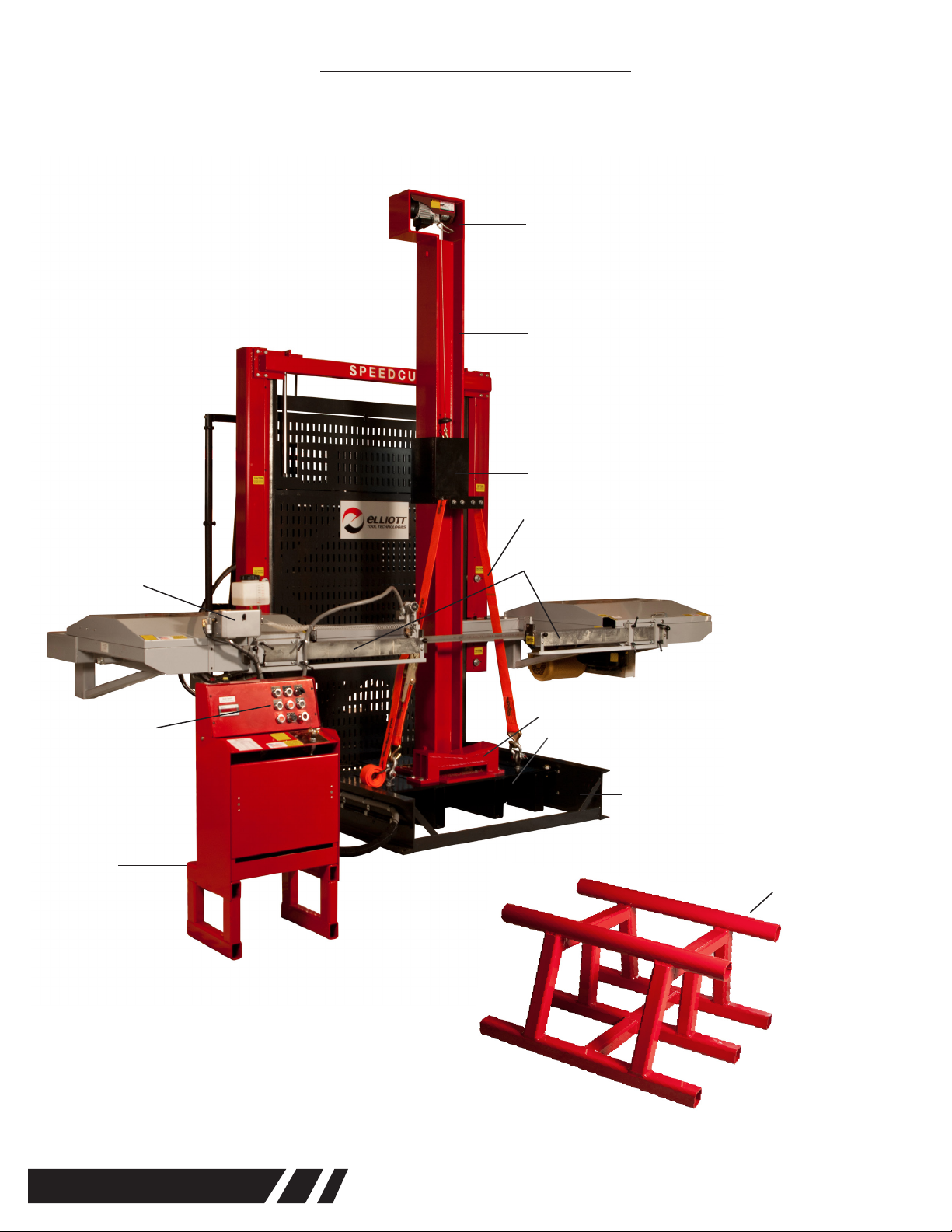

6 SpeedCut

Safety Instructions (cont.)

Read all safety and operating instructions contained in this manual prior to use of the machine.

Failure to follow all instructions listed below may result in electrical shock, re and/or serious injury.

• Do not operate this machine while tired, distracted, under the inuence of drugs or alcohol

or on medication that causes decreased control.

• Do not use machine in wet conditions. Keep work area clean and well lit.

• Do not force a machine or attachment to do a job or operate at a speed it was not

designed for.

• Check for misalignment, binding of moving parts, improper mounting, broken parts or any

other conditions that may affect operation before use. Inspect all fasteners for tightness to

ensure there are no loose nuts or bolts that may inhibit operation. Do not use a damaged

machine. Repair or replace any defective parts prior to use of the machine.

• Use proper accessories and use Elliott accessories only. For all repairs, insist on only

identical replacement parts.

• Always use properly grounded electrical outlets, and if using an extension cord, make sure

that it is of the proper size for the electrical load and it is equipped with a ground wire and

ground plug. See “Installation” on page 7 and “Electrical Systems” on page 21 for further

information.

• Inspect all hydraulic lines for leaks or tears prior to installation.

• Use only extension cords and plugs approved for outdoor use when working outdoors.

• Use appropriate safety equipment (i.e. safety glasses, ear plugs, dust masks, safety boots,

etc) when using this machine.

• Ensure that long hair or loose tting clothes are secure prior to use of the machine.

• Do Not Overreach. Keep proper footing and balance at all times.

• Never apply the machine to an unsecured work piece.

• Maintain a safe distance from the machine during use.

• Always disconnect the machine from the power source prior to performing any

maintenance or repairs.

• Keep guards in place and in good working order.

• When working on hydraulic circuits, the frame must be in the extreme down position

or mechanically blocked as the frame is always under pressure.

• Labels and Nameplates carry important information and will assist you in ordering spare

and replacement parts. If unreadable or missing, contact an Elliott service facility for a

replacement.

• Set up safety fencing around perimeter of machine to prevent unintended access

to machine, under moving frame or blade when in operation.