ELME AFCM-3 User manual

un

- 1 -

I

Indice

Una scelta di qualità…………… 2

Istruzioni e avvertenze

generali…………………….……. 3

Installazione del nuovo

apparecchio……………….……. 4

Pulizia……………………………. 5

Comandi e segnalazioni First

Class………………………..…… 6

Come iniziare la produzione di

granita, sorbetto o bibita

fredda………………….………… 7

Defrost timer………….………… 8

Comandi e segnalazione First

Class Millennium..…………….... 9

Come iniziare la produzione di

granita, sorbetto o bibita fredda

First Class Millennium..………... 12

Regole fondamentali di

sicurezza……………….…………

13

Smaltimento del vecchio

apparecchio…………….………. 13

Assistenza tecnica……….…….. 13

Installazione FC acqua………… 14

Problem Solving…………….….. 15

Procedura riarmo

pressostato………………….….. 16

Procedura sostituzione

coppiglia…………………………. 17

Certificato di garanzia………….. 83

Impianto elettrico……………….. 89

Impianto elettrico Millennium….. 90

Impianto frigorifero……………... 93

Esploso………………………….. 95

Descrizione Codici……….…….. 96

GB

Index

A quality choice…………………. 18

General instructions and

warnings…………………………. 19

Installing the new

machine…..……………….…….. 20

Cleaning…………………………. 21

First Class controls and

signals……….…………………... 22

How to start the production

slush, sherbets or cold drinks…. 23

Defrost timer………….…………. 23

First Class Millennium controls

and signals .…………………….. 24

How to start the production of

slush, sherbets or cold drinks

with FC Millennium.…….………. 27

Important security

rules……………………….……... 28

Old machine disposal………….. 28

Technical assistance…………... 28

FCW installation………………... 29

Problem Solving…………….….. 30

Pressure switch refit

procedure…..………………….... 31

Cotter pin

substitution……………………… 32

Warranty certificate…….………. 84

Electric system…………….….… 89

Millennium electric system ……. 90

Refrigerating system…………... 93

Exploded view………….……….. 95

Codes description……………… 96

F

Index

Un choix de qualité……………... 33

Instructions et remarques

générales………………….…….. 34

Installation de l’appareil……….. 35

Nettoyage……………….………. 36

Commandes et signaux du First

Class……………………………... 37

Comment commencer la

production de granité, sorbet ou

boisson froide.......….......……… 38

Defrost timer....………….……… 39

Commandes et signaux du First

Class Millennium….……………..

40

Comment commencer la

production de granité, sorbet ou

boisson froide avec First Class

Millennium..……………………... 43

Règles fondamentales de

sécurité……….……….………… 44

Mise au rebut du vieil

appareil…………….……………. 44

Service après-vente…….….…... 44

Installation des FCW………….... 45

Problem Solving…………….…...

46

Procédé mise en marche

pressestat..……………….……... 47

Remplacement de la

goupille…………………………... 48

Certificat de garantie…..……….. 85

Installation électrique….……….. 89

Installation électrique

Millennium……………………….. 90

Installation frigorifique…...…….. 93

Vues éclatées……………….….. 95

Codes et description…..……….. 97

D

Inhaltsverzeichnis

Eine Qualitätswahl……..……..... 49

Anweisungen und allgemeine

Hinweise………………..……...... 50

Installation der neuen Maschine

……………….……..................... 51

Reinigung……………….……..... 52

Bedientasten und Meldungen

First Class.................................. 53

Herstellung von Gramolaten,

Sorbets und eisgekühlten

Getränken.......…........................ 54

Defrost timer………….……….... 55

Bedientasten und Meldungen

First Class Millennium................ 56

Produktionsbeginn für

Gramolaten, Sorbets oder

Kalten Getränken First Class

Millennium.................................. 59

Grundlegende

Sicherheitsmassnahmen...…….. 60

Entsorgung der alten

Geräts………………..……......... 60

Technischer

Kundendienst………………....... 60

Installation der FCW.................. 61

Problem Solving……………....... 62

Rückstellung des

Druckwächters…..……………... 63

Ersetzen des

splints........……………………… 64

Garantieschein…………………. 86

Elektrik…………………..……..... 89

Elektrik Millennium……..……..... 90

Kühlanlage………………..…...... 93

Explosions-Darstellung……....... 95

Beschreibung der

Ersatzteile……………………..... 97

E

Índice

Una elección de calidad……..... 65

Instrucciones y advertencias

generales………………….......... 66

Instalación del nuevo

aparato…………...…...……….... 67

Limpieza………………….…....... 68

Mandos y señalizaciones First

Class...................................…... 69

Cómo iniciar la producción de

granizado, sorbete o bebida

fría...........................………….... 70

Defrost timer………..………....... 71

Mandos y señalizaciones First

Class Millennium.....………..….. 72

Cómo iniciar la producción de

granizado, sorbete o bebida fría

con First Class Millennium…….. 75

Normas fundamentales de

seguridad………..…..………...... 76

Eliminación del viejo

aparato…………..……..……...... 76

Asistencia técnica………....….... 76

Instalación de FCW..............….. 77

Problem Solving……………....... 78

Procedimiento de

restablecimiento del

presostato.................................. 79

Sustitución del

pasador.............………………… 80

Certificado de garantía……….... 87

Instalación eléctrica………......... 89

Instalación Eléctrica

Millennium.................................. 90

Aparato Frigorífico………...….... 93

Despiece……………..………..... 95

Código Descripción….……........ 98

- 18 -

ENGLISH

A quality choice

Choosing Elmeco, and in

particular First Class, the

new and only

multifunctional machine

with double augers,

demonstrates your attention

to innovation. Thanks for

understanding the

importance of working

with a company that does

not consider “quality” as an

abstract word. For Elmeco

quality is a concrete

commitment. It actually

means to clinch the

attention to the innovation

that characterized us as the

creators of the first slush

machine and that today

confirms our leadership in

the technical forefront. For

our company “Quality”

also means working trying

to always improve from a

management and

organizational point of

view following the Vision

2000 certification, and it

finally means to care about

the customers and to

dedicate investments and

resources to continuously

meet their needs.

On the other hand, for

those who decided to

choose Elmeco, quality

means being able to work

with reliable and lasting

products, to count on a

precise and qualified

assistance in order to work

with increasing satisfaction

and earnings.

- 19 -

ENGLISH

General instruction

and warnings

Before switching on the

machine carefully read the

information in this service

manual; this way you will be

able to install, use and maintain

the machine.

Keep the use and assembly

instructions, even for the next

buyer. The manufacturer

declines any responsibility for

damages deriving from the non-

observance of the following

instructions.

Install the machine according to

the assembly instructions. The

power supply must correspond

to the data on the plate on the

front side of the machine

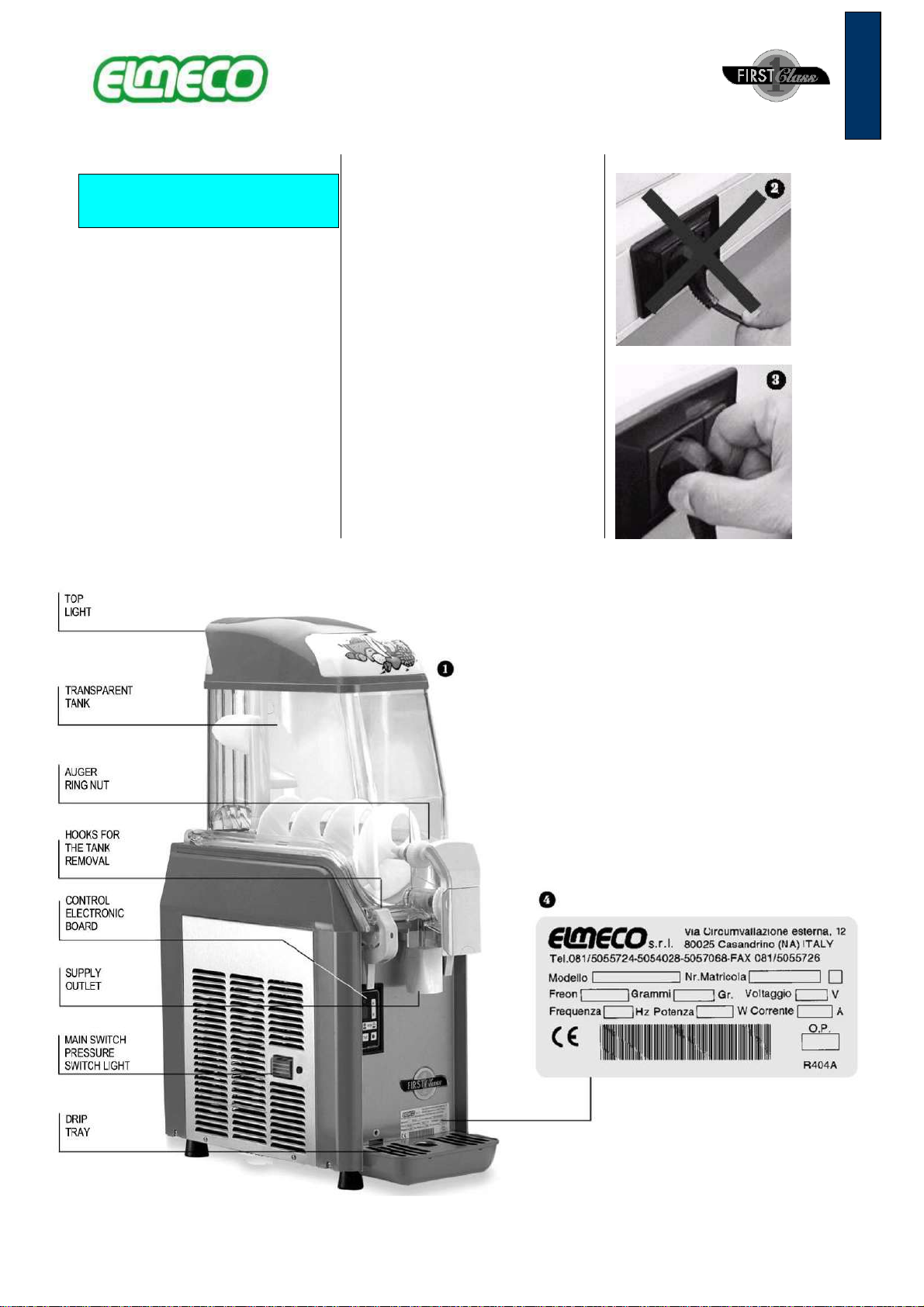

behind the drip tray (pic. 1).

- 20 -

ENGLISH

During maintenance and

cleaning, or in case of bad

functioning, disconnect the

machine from the power plug

(by pulling the plug and not the

cable) (pic. 2 and 3 pag.19).

Only specialized and

authorized staff can repair the

machine. Not perfect repairing

can be dangerous for the user.

Contact Elmeco for information

concerning the closer

authorized assistance centre.

Installing the new

machine

This machine for the production

of cold drink, slush, and

sherbets the absolute

homogeneity of the product and

the possibility to regulate its

density thanks to an innovative

electronic control. Before

installing the machine, verify

that:

• First Class is not placed by

an heat source;

• The machine has not been

damaged during

transportation. In case of

doubt, contact the supplier;

• The power supply system is

endowed with a grounding

that respects the rules of

law;

• The power supply system

capacity is adequate to the

maximum power of the

machine, as indicated on the

plate (pic. 4 pag.19).

In case of doubt, contact only

qualified staff.

In order to install the machine,

carefully read the following

instructions.

Warnings

This machine is only for the use

it has been manufactured for.

Any other usage is to be

considered as improper and

dangerous.

Machine description (pic. 1

pag.19):

• Top light

• Transparent tank

• Auger ring nut

• Hooks for the tank removal

• Control electronic board

• Supply outlet

• Main switch

• Pressure switch light

• Drip tray

• Plate data

Installation

It is suggested that the machine

is installed only by qualified

staff. A wrong installation can

cause damage to people or

things, for which things the

manufacturer declines any

responsibility.

Once the machine is unpacked,

verify the integrity of the

machine. The packaging

elements (plastic bags,

expanded polystyrene, nails,

etc.) must not be left at children

reach as they might be

dangerous.

Remove the protection plastic

stripes also from the internal

side of the grids.

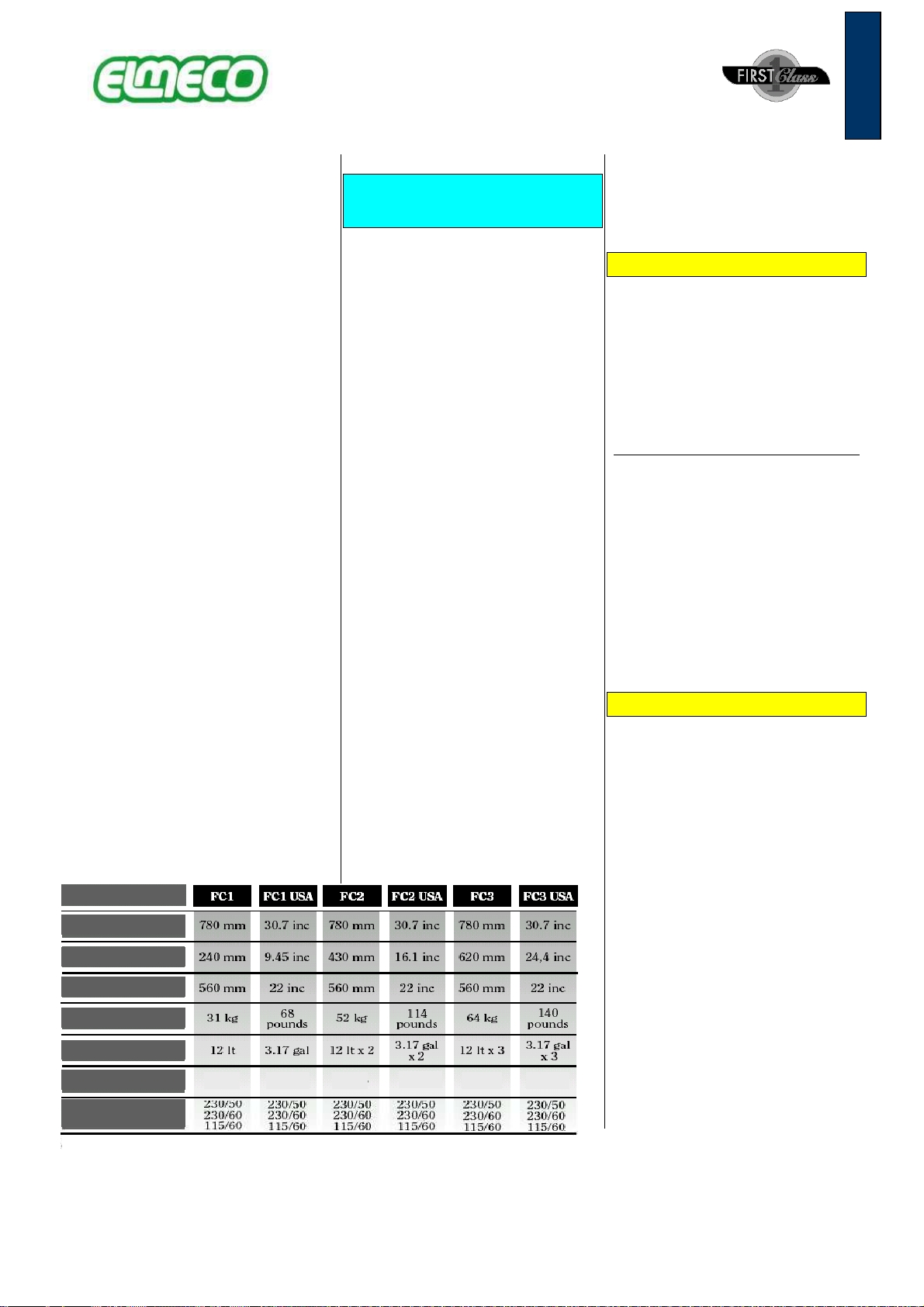

The Supplier is reserved to bring alterations without notice.

The relevant data the power are indicative. To do reference to the data of plate data restored on the machine.

450 w

0,61 hp

900 w

1200 w

0,61 hp

0,61 hp

MODEL

HEIGHT

VOLTAGE HZ

POWER

CAPACITY

WEIGHT

DEPTH

WIDTH

- 21 -

ENGLISH

We do not recommend to

connect the machine through

adaptors, multiple plugs and/or

extensions. If necessary, use

only materials that conform to

the safety rules in force, as for

the current intensity up to what

indicated on the plate (pic. 4

pag. 19).

Place the machine so as to

avoid any heat source to be

close to the grids. Verify that

there is a free space of 25 cm

at least around the machine

(pic. 5 pag. 99).

After connecting the machine to

the power supply and switching

on the main switch, verify that

air comes out from the side

grids (pic. 6 pag.99).

Right usage

Before switching on the

machine, it is necessary to

clean it as indicated in the

“Cleaning” paragraph.

Cleaning

Cleaning is very important for

the life and maintenance of the

machine; we recommend to

periodically clean the parts that

are in contact with the product

using the following procedure.

Warning!

Switch off the main switch

and disconnect the power

plug (pic. 7 pag. 99) before

starting any operation.

Use a solution of cold water

and sodium hypochlorite

(bleach) with a 10 grams (1/2

spoon) for 1 liter of water ratio.

Rinse with lukewarm water.

Warning! A greater quantity

of beach could damage the

material of the auger.

Warning! If the plastic parts

are washed in the

dishwashing machine, verify

that the temperature is not

higher than 85°C or 185°F,

because they could be

damaged.

Do not use any abrasive

powder.

Tank cleaning procedure

See the picture at the end of

this manual.

• Empty the tanks by opening

the outlets and blocking

them (pic. 8 pag. 99),

moving the little letter from

the left to the right.

• Remove the lamp (pic. 9

pag. 99), pour water in the

tanks and then empty them.

• Remove the auger ring nut

(pic. 10 and 11 pag. 99).

• Remove the tank

unscrewing the hooks grips

(pic. 12 pag. 99), if present,

and opening the hooks (pic.

13 pag. 99); lift the tank as

shown in pic. 14 and 15

pag. 99.

• Unscrew the ring nut (pic.

16 pag. 99) in order to

remove the vertical auger

(pic. 17 pag. 99).

• Remove the horizontal

auger; this way the inox

side of the tank is

completely open and ready

to be cleaned (pic. 18 and

19 pag. 99).

• Remove the outlet (pic. 20,

21, 22, 23 pag. 100) and

the tank gasket (pic. 24

pag. 100):

• Remove the lever cover

(pic. 20 pag. 100) by

pushing “PUSH”

downward; and remove

the lever (pic. 21 pag.

100);

• Rotate the ring nut

clockwise (pic. 22 e 23

pag. 100) and pull the

outlet.

• Dip the dismantled parts in

the solution of water and

bleach.

• Wash and dry.

• Wet the gasket before

inserting it in place (pic. 24

pag. 100), be careful to

place the gasket joint in one

of the back corners of the

tank in the proper

allocation.

• Reassemble everything.

• When you put the tank back

in its place verify that the

low tension contact wires

are in the guides of the

terminal board. If they are

not, the lamp and the

augers will not work (pic. 25

pag. 100).

• Connect the machine to the

power supply.

Warning!

Any time the covers (lamp)

are removed, for security

reasons, the augers and the

cooling system will stop

working.

Condenser cleaning

procedure

Remove the side panel of the 2

or 3 tanks machine, or the back

panel of the one tank machine

by unscrewing the screws on

the bottom and clean the

radiator with a soft brush or (if

possible) with compressed air.

- 22 -

ENGLISH

Outlet restriction

First Class has a new

accessory called Restriction

(pic. 28 pag. 100), it is a

shaped piece that is applied on

the ending part of the

transparent tank outlet. It has

the following advantages:

• The product, liquid (clod

drink) or semi-liquid (low

density slush), is canalized

directly in the glass;

• The restriction is easy to

pull out, therefore, it is

possible to easy wash the

ending part of the outlet

without having to dismantle

the whole transparent tank,

with a consequent decrease

of the machine cleaning

times. In summary, the only

part which is not

refrigerated, where an

accumulation of the product

is more likely to happen,

can be now removed and

washed.

This restriction has some

gaskets (O-ring) that must be

wet with water before inserting

them on the outlet terminal part.

This is to make the introduction

easier and to avoid that O-ring

goes outside their proper

locations.

On the restriction there is the

image of an arrow and of a

glass that, while inserting it,

must face the operator.

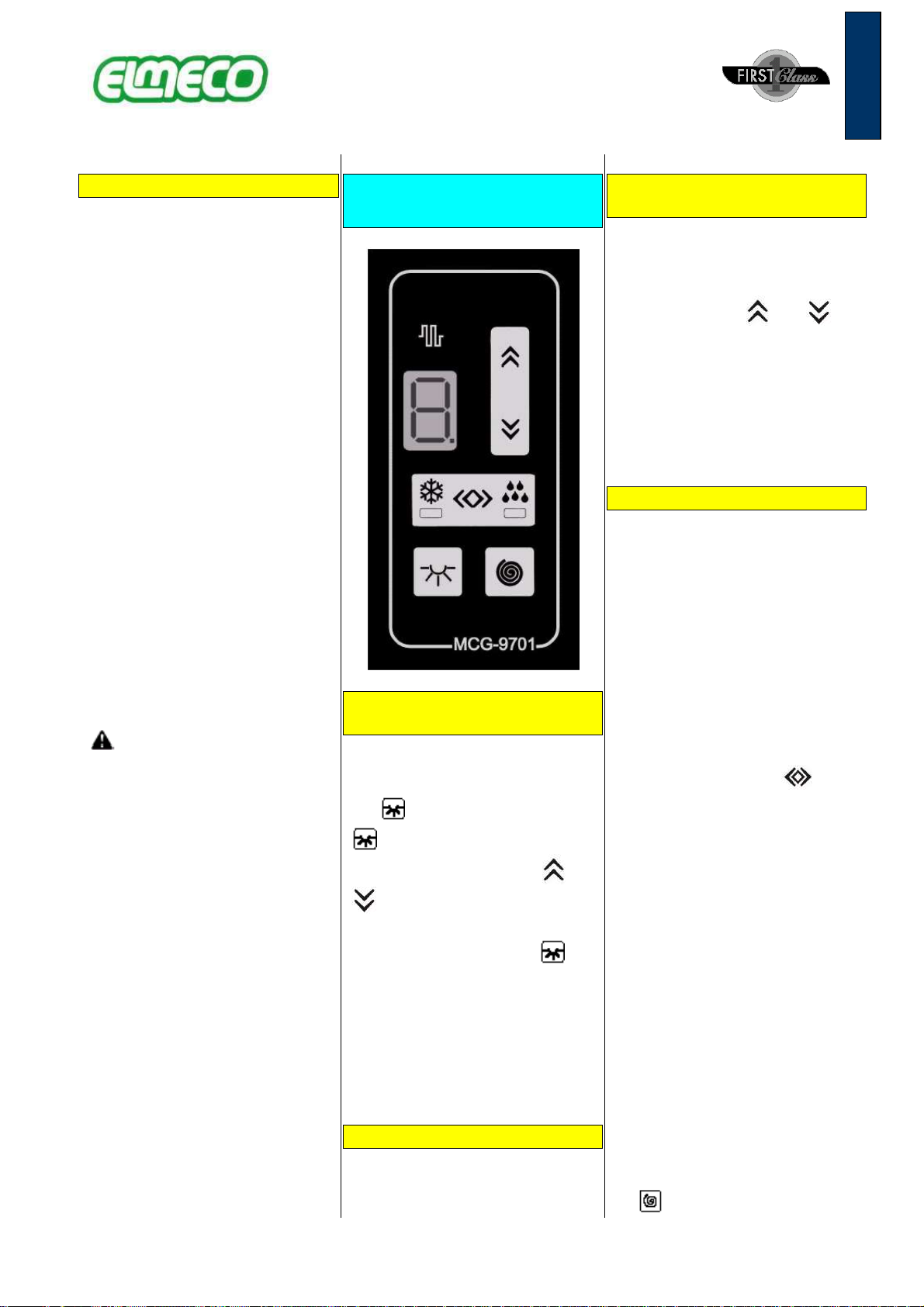

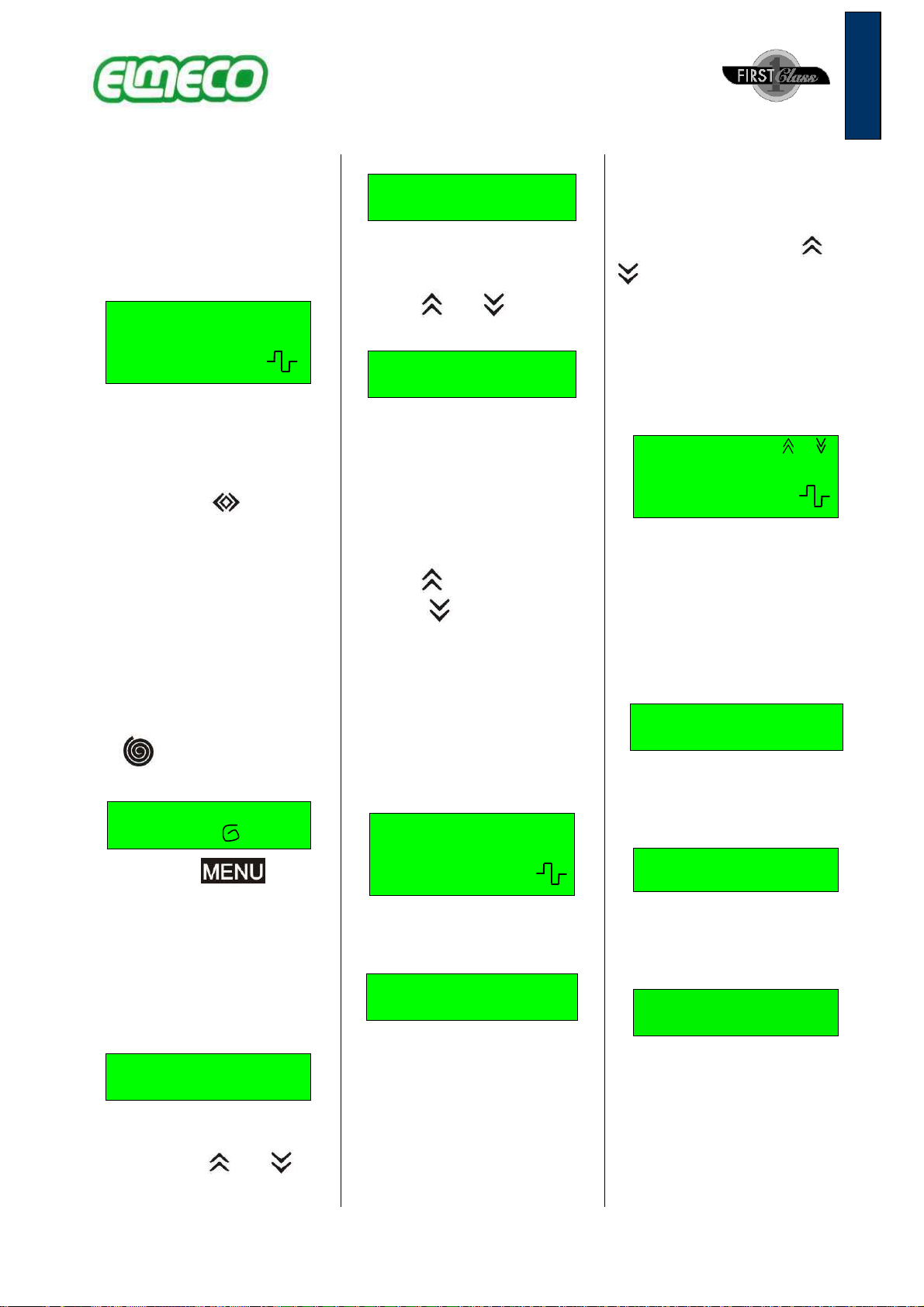

First Class controls

and signals

Lamp light On / Off Intensity

regulation

The light of the lamp can be

turned on and off by pressing

the button; if you keep the

button pressed and at the

same time you press the or

buttons, it is possible to

increase or decrease the light

intensity; if you keep the

button pressed, the display will

signal the light status. It will turn

off if the pressure of the button

caused the light to be turned off

and it will show a number that

indicates the level of the lamp

light intensity (2 min - 9 max).

Operator security

If you open the tank lifting the

lamp, the augers will stop.

Keyboard, augers and cooling

system block

It is possible to block the

keyboard. You unblock or block

the buttons by lifting the lamp

and pressing the and

buttons at the same time; the

block status is signaled on the

display through the decimal

point lighting.

For technical reason the

keyboard is unlocked when the

machine is switched off.

Gear electronic stop bypass

As you already know, for

security reasons, when a tank

is open, the augers stop

turning. However, the augers

stop can be also caused by a

malfunctioning of 1 and/or 2

contacts, or by the accidental

lost of one of the contact during

the cleaning phase; in this

case, it is possible to activate

the electronic bypass function

by pressing the granita-cold

drink selection button until

the augers start turning again.

In this situation, if you lift the

cover, the augers keep on

turning and the keyboard block

is deactivated; this is why the

electronic bypass is to be

considered only as a temporary

remedy and not as a definitive

solution which is, instead, the

substitution of the defective

contact or the installation of the

lost one.

Once the contact has been

substituted or installed again,

use the following procedure in

order to deactivate the

electronic bypass:

• Lift the cover: the augers go

on turning;

• Stop the augers pressing the

button;

- 23 -

ENGLISH

• If you press the button,

press the button: the

augers will turn;

• Wait for the augers to stop,

and then release the two

buttons;

• Replace the cover: the

auger will start moving

again.

System has been reset.

Self-diagnostics

Consult the Problem Solving

Section.

Configuration memory

All the functioning modes and

the regulations set are

registered in a non-volatile

memory which is active even

without power; therefore, when

you switch on the machine, the

tank keeps the configuration it

had when you switched it off, a

part from the keyboard lock (as

already said).

inimum level signal

All machines are endowed with

a probe that detects the product

minimum level in the tanks.

When the product is below this

level, the light of the lamp starts

blinking. If the product level

does not change, the light will

stop blinking after a minute.

How to start the

production of slush,

sherbets or cold drinks

Clean the machine as

described in the previous

paragraph.

Remove the covers and pour

the mix in the tanks.

Warning: When switching on

the machine, the poured

product must not be lower

than 10 °C in order to allow a

correct calibration of the

electronic kit.

Switch on the main switch (see

pic- fig. 7-pag. 99 at the end of

this manual).

Switch on the augers switch

.

Press the button in order

to select “slush” (slush led

lighting ) or “cold drink”

(cold drink led lighting).

In “slush” mode, in order to

increase the product density,

use the button, in order to

decrease it, use the button.

In “cold drink” mode, in order to

increase the product

temperature, use the button,

in order to decrease it, use the

button.

Here you are the table with the

correspondence between the

values on the display while in

“cold drink” mode and the °C/°F

degrees.

In order to turn on the lamp

light, press the button.

Warning: in order to have

slush, sherbets or cold drink,

you need a small quantity of

sugar per liter. The

recommended quantity is

generally reported in the

usage instructions. In case of

natural products, we suggest

to use a quantity that goes

from 12 and 22%.

If the horizontal auger is

blocked because of ice blocks

due to a lack of sugar or to

other reasons, such as foreign

bodies in the tank, the vertical

auger can undergo a break.

Warning: If the temperatures

exceed 35°C Elmeco is not

responsible for the

refrigerator performance

(that will be slower) and for

the correspondence between

the temperature selected on

the electronic board and the

drink temperature.

Timer defrost

(optional)

See the pictures at the end of

this manual.

“Timer defrost" function is

optional.

The machine is endowed with a

clock timer that, if properly

regulated, changes the "slush"

function in "cold drink" and

viceversa. This function grants

a cold product with a 5 °C

temperature (+/-1°C), even

during the night (Night Mode),

with a great advantage

especially for milk-based

products.

The Timer Defrost function is

not activated on the machine:

°C °F

2 2 – 6 35.6 – 42.8

3 3 – 7 37.4 – 44.6

4 4 – 8 39.2 – 46.4

5 5 – 9 41.0 – 48.2

- 24 -

ENGLISH

pins placed on the external side

of the commutation disk. Each

pin represents a range of 15

minutes. The setting and the

activation of the Night Mode

and Day Mode is done when

the machine is installed in the

following way:

• FC1 and FC3 left side panel

opening; FC2 back panel

opening;

• local time setting on the

timer. This setting is done

by turning the commutation

disk clockwise until the local

hour reached the arrows

marked with “F”;

• Night Mode and Day Mode

hour setting. This setting is

done by placing the pin

toward the centre of the

commutation disk;

• left side or back panel

closing

If a "d" appears on the display

on the electronic board, it

means that the Night Mode

function is active.

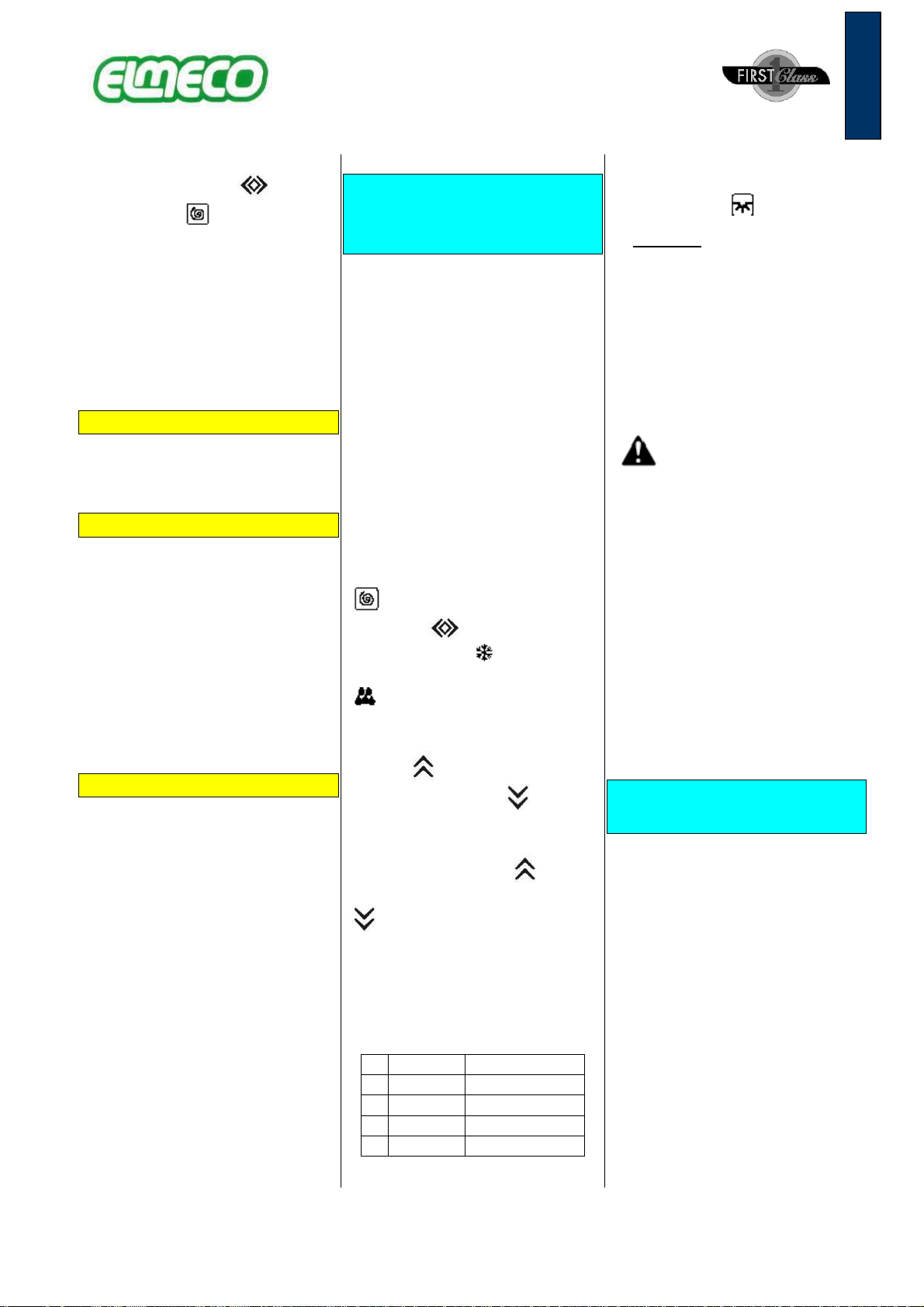

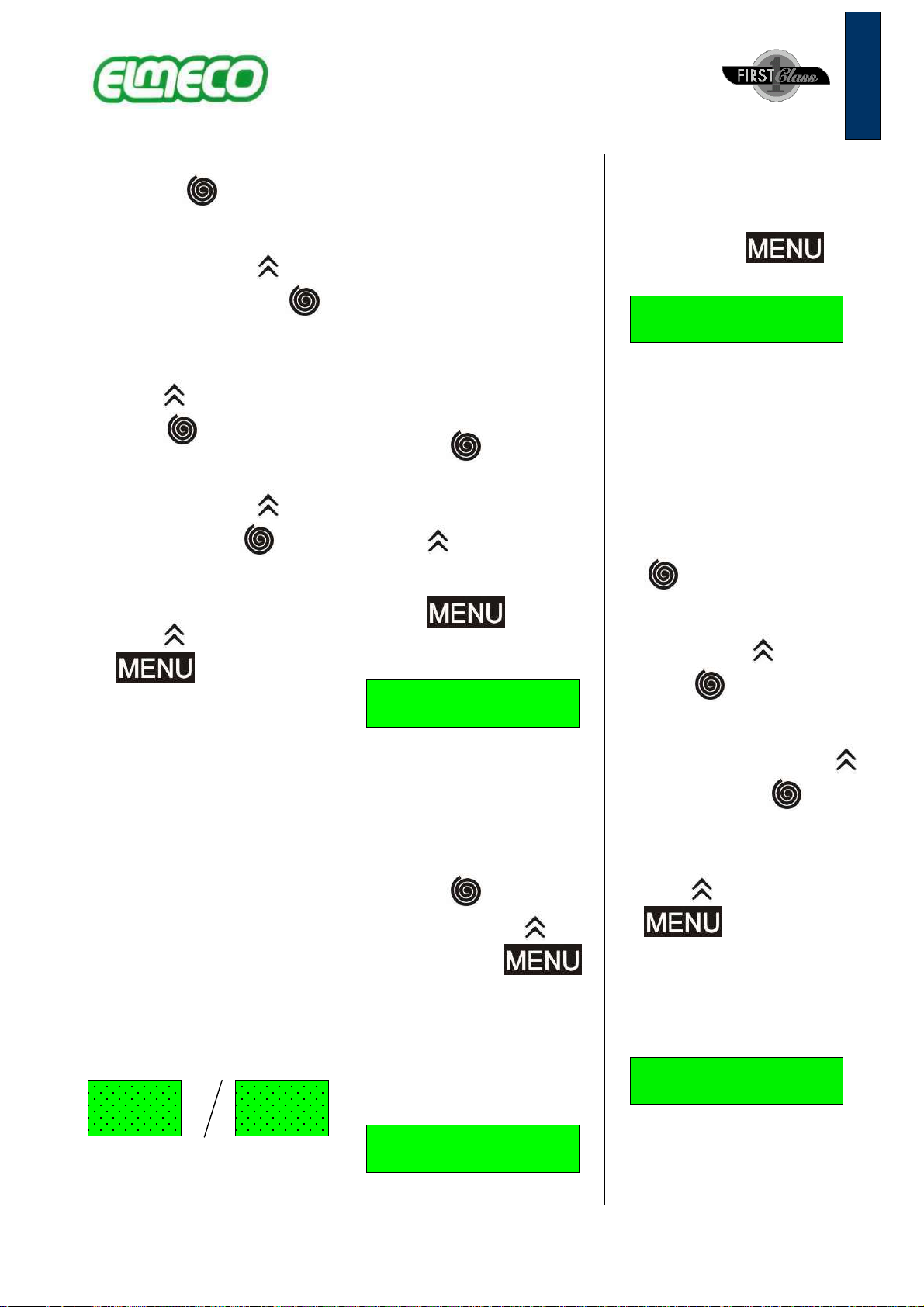

First Class Millennium

controls and signals

When you switch on the

electronic board, the display will

show

ELMECO / ITALIA

(0.15)

Where 0.15 indicates the tank

review number.

FC Millennium has a BASIC

version that only has the

electronic board like the one

shown before, and an

ADVANCED version that ha

san additional electronic kit in

the machine with additional

features connected to time.

WARNING: The screen with

the “/” symbol indicates that

the values are shown

alternatively.

After the screen shown above

the initial screen will be

displayed:

StandBy

Press

WARNING: The electronic

board will keep the settings it

had when the machine was

switched off.

When the tank is in stand-by

mode, the augers and the

cooling system are off. The

augers and the gear motor can

be turned on by pressing the

button. The screen will

show:

Motor on

Press < <> >

If you press the button, the

screen will display as follows:

Select / Degrees /

--

Y

(where Y is a variable number

between –5 and 15 for Cold

Drink Mode, which indicates the

temperature in °C at which the

product must be prepared).

Using and you can

increase or decrease the

temperature of the product. The

recommended temperature is

7°C .

If you press the button, the

screen will display as follows:

Select / Density /

--

*X

(where X is a variable number

between 0 and 9 and indicates

the density of the slush). If you

use the and buttons it is

possible to increase or

decrease the slush density

value.

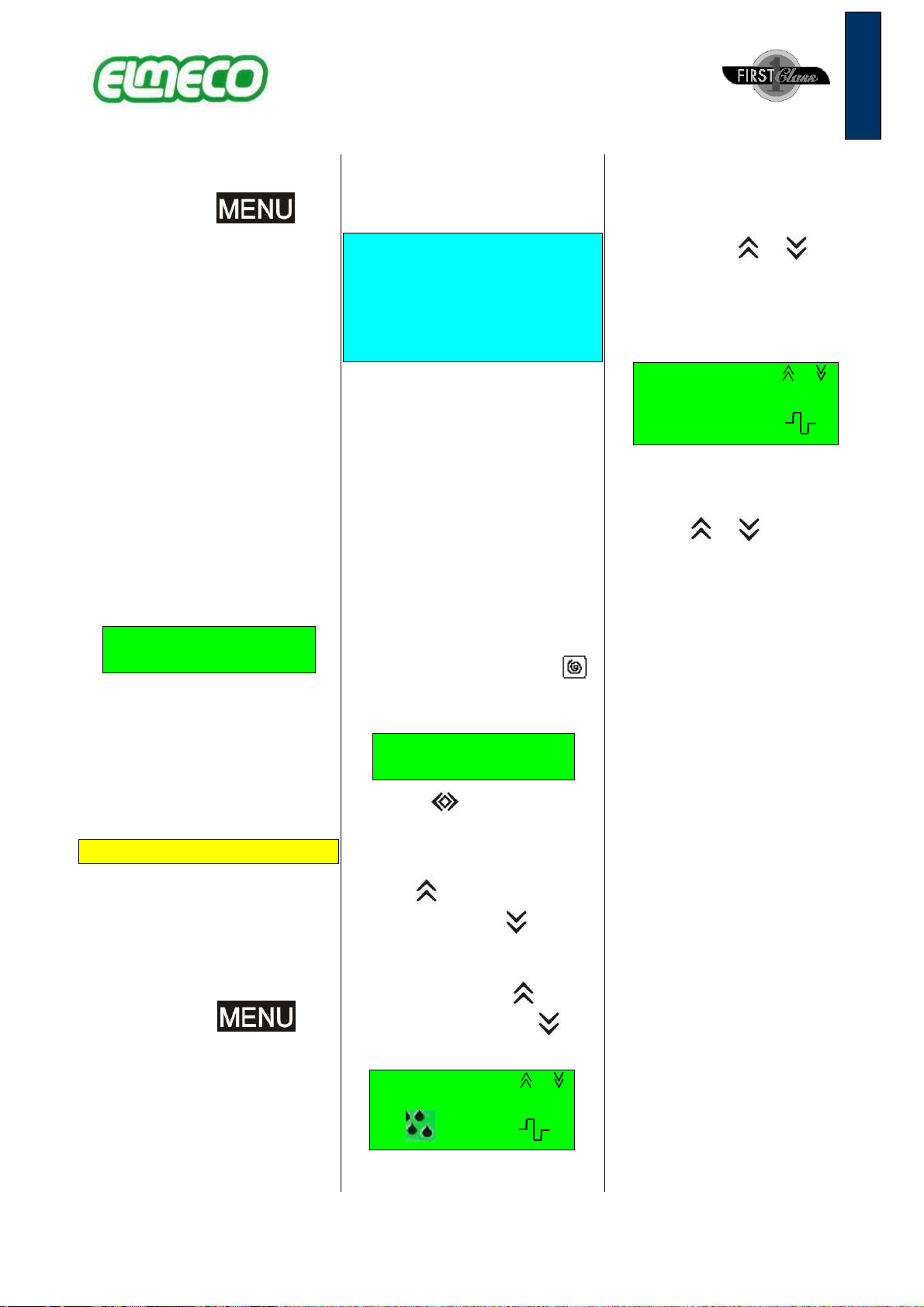

- 25 -

ENGLISH

WARNING: If, when the

electronic board is in Slush

Mode, the product

temperature is greater than

5°C, the following screen will

be displayed:

Auto / Setting / Wait

*X

This screen indicates that the

calibration process is taking

place. The calibration process

will take one minute to

complete.

If you press the button

(Cooling off- cold drink-

slush) you can switch the

machine functioning modes

alternatively. Each time you

press the button, the different

screens of cold drink – slush

and cooling off alternate. In this

latter position only the augers

rotate and no other action is

taken.

If you press the auger rotation

key , the display will

appear as follows:

StandBy

Press

By holding the button

for one second you will enter

the selection menu.

Please note that unless you

give any further instruction to

the electronic board in more 10

seconds time, the display will

automatically go back to the

initial screen.

LAMP

OFF / ON

This screen allows you to turn

ON or OFF the light in the lid,

by pressing the and

buttons of the electronic board.

ByPass

OFF / ON

In this screen you can activate

or deactivate the bypass

function by pressing the

increase and decrease

keys.

LowLevel

OFF / ON

This screen allows you to turn

ON or OFF the Low Level

control function (automatic

decrease of slush’s density to

no.1, when the level probe is

not covered with product for

more than 20 minutes); you can

do that by pressing the

increase key or the

decrease key. If you add

some product (liquid that

touches the level probe), the

function will be deactivated and

the slush preparation will reach

the density value that was

previously set on the electronic

board. When this function is

active, you will see the

following display:

Please/refill/LOWLEVEL

*1L

As for the selection menu, the

next screen is like the one

below:

KeyBoard

UNLOCK / LOCK

This screen allows you to

activate (LOCK) or deactivate

(UNLOCK) the “keyboard lock”

function by pressing the or

buttons. This function is

suitable in self-service places,

in order to avoid people from

changing the values set. When

the keyboard is locked, the

electronic board will show a

“dot” on the display as shown

on the screen below:

select/ Density / --

*X ■

If the machine is turned OFF

and ON, the electronic board

will be in LOCK position again.

WARNING: The keyboard

lock can be activated if the

electronic board is in

“Standby" or “MotorOn”

mode.

Washing

OFF / ON

Turning OFF and ON of the

washing function. If the function

is active, the electronic board

will show the screen below;

Washing

■

in this condition all buttons and

the cooling functions are NOT

active, a pat from the MENU

button.

TIME

hh:mm

This screen shows the time set

on the machine. If it is different

from the place where the

machine is installed, you can

change it by following the steps

below:

- 26 -

ENGLISH

1) press the button; 2) the

first value will start to blink. If

you want to change the value,

you need to press the

button; 3) if you press the

button; 4) the second value will

start to blink. If you want to

change the value, you need to

press the button; 5) if you

press the button; 6) the

third value will start to blink. If

you want to change the value,

you need to press the

button; 7) press the

button; 8) the fourth value will

start to blink. If you want to

change the value, you need to

press the button; 9) press

the button to exit this

function. The time will be

saved.

WARNING: During the time

adjustment, the date

(MM/DD/YY) will appear on

the upper line. It can be

different from the date of the

place where the machine is

installed, but the machine

will work without any

problem.

NOTE: First Class Millennium

BASIC does not display this

screen and all other screens

here reported in the dotted

square. These will only be

active in the ADVANCED

version.

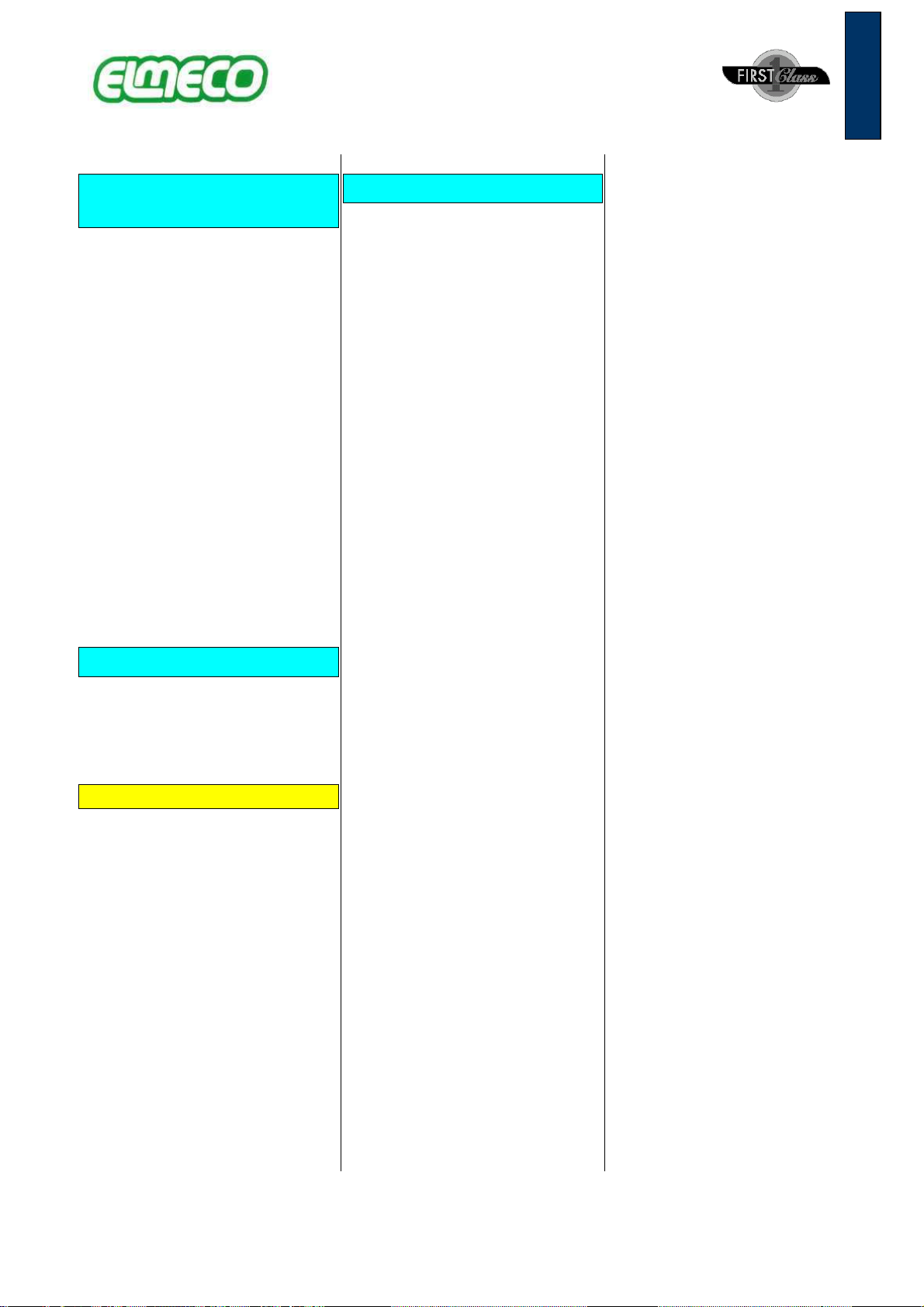

Defrost function: On the screen

you can see the defrost ON and

OFF time and the defrost

temperature alternatively. The

first screen indicates the value

of cold drink used in defrost

mode (set to 7°C); this screen

is used only for information.

The second screen (ON – OFF)

indicates the defrost function

start (ON) and stop (OFF) time.

If the two values are the same,

the function is deactivated. In

order to change the ON and

OFF time, follow the steps

below:

1) press the button; 2) the

first value of the upper line will

start to blink. If you want to

change the value, you need to

press the button; 3) repeat

the steps 1) and 2) until all ON

and OFF values are set; 4)

press the button to

exit the change function. The

time will be then saved.

Max Temp

T= _°C

In this screen you can activate

or deactivate the Critical

Temperature Control function.

When the critical temperature

value is ( _ ), the function is

deactivate; if you want to

activate it, you need to:

1) press the button; 2) set

the value pressing the

button; 3) press the

button to exit the change

function.

When you switch the machine

on, if the product temperature is

greater than the one set, the

display will blink and show:

Product

T > X

The “X” value represent the

critical temperature. In order to

stop stop the warning signal,

please press the

button.

CLEANING

000d - ---

In this screen you can activate

or deactivate the Cleaning

warning function. This function

is used if the user wants the

machine to show a clear

warning on the display that

reminds to clean the machine.

If the Cleaning warning function

is on (000d----) it is deactivated.

In order to activate it: 1) press

the button; 2) the first

value will start to blink. If you

want to change the value, you

need to press the button; 3)

press the button again 4)

the second value will start to

blink. If you want to change the

value, you need to press the

button. 5) press the

button; 6) the third value will

start to blink. If you want to

change the value, you need to

press the button; 7) press

the button to exit the

change function.

When the machine is turned on

and the values (---) are zero,

the display will blink showing

the cleaning warning:

CLEANING

REQUIRED

Clean the tank as described in

the usage manual pag. 21;

DEFROST

T=07°C ON 00:00

OFF 00:00

- 27 -

ENGLISH

In order to stop the warning

signal, press the

button; thus the count down will

start again for the next warning.

000d = time in days for the

cleaning warning to appear

- --- = count down (day to the

warning)

EXEMPLES:

100d = after 100 days the

machine will inform that it must

be cleaned up

050d = after 50 days the

machine will inform that it must

be cleaned up

007d = after 07 days the

machine will inform that it must

be cleaned up.

REFILL

ON / OFF

For machines with auto re-fill

set up ONLY! (This should be

ON only if the machine has the

auto refill installed). In this

screen you can activate or

deactivate the auto refill control

signal.

Alarms functions

First Class Millennium is

endowed with a direct signalling

of the problems found. When

the electronic board blinks, it

indicates that there is an active

alarm. To see what alarm is,

please press the

button for 1 second.

In the “Problem Solving”

section, you can see a

complete list of all possible

alarms at pag. 30.

If more than one alarm is

active, these will be indicated

with more messages that

appear alternatively.

How to start the

production of slush,

sherbets or cold drink

with First Class

Millennium

Clean the machine.

Remove the covers and put the

mix in the tanks.

Warning: the temperature of

the poured product must not

be lower than 10 °C in order

to allow a correct calibration

of the electronic kit that will

be indicated as described in

the previous paragraph.

Switch on the main switch (see

picture - 7 at the end of this

guide).

Switch on the auger switch .

The following screen will be

displayed:

Motor On

Press < <> >

Press the button to select

“slush” or “cold drink”.

With the “slush” mode, you can

increase the product density

with the button and

decrease it with the button.

With the “cold drink” mode, you

can increase the product

temperature with the button

and decrease it with the

button.

select/ Degrees / --

5

Cold drink.

It is possible to change the

product temperature from –5 to

15 °C using the or

buttons to increase or decrease

it respectively.

Warning: The recommended

temperature value is 7°C.

select/ Density / --

* 5

Slush.

It is possible to change the

product density from 1 to 9

using the or buttons to

increase or decrease it

respectively.

- 28 -

ENGLISH

Important security

rules

• Do not touch the machine

when you have wet hands

and/or feet.

• Do not use the machine

with bare feet.

• Do not allow children or

incompetent people to use

the machine.

• Do not leave the machine

exposed to atmospheric

agents.

• Do not pull the power

supply cable to disconnect

the machine from the

electric power.

• Do not remove the panels

before disconnecting the

machine from the electric

power.

Old machine disposal

The out-of-use machines must

be disabled. Disconnect the

plug from the electrical network

and cut the cable.

Ecological instructions

All refrigerating machines must

be disposed by the communal

disposal service or by an

equivalent private authorized

company. Take care not to

damage the rigid tubes of the

refrigerator until they are taken

back in order to be carefully

and ecologically disposed.

All packaging materials used

can be disposed without any

danger.

Technical assistance

The repairing of the machine

must be carried out by an

authorized service centre, using

only original spare parts.

- 29 -

ENGLISH

FCW installation (water

cooling system)

If the First Class you bought is

endowed with the water cooling

system, it is necessary to follow

these instructions.

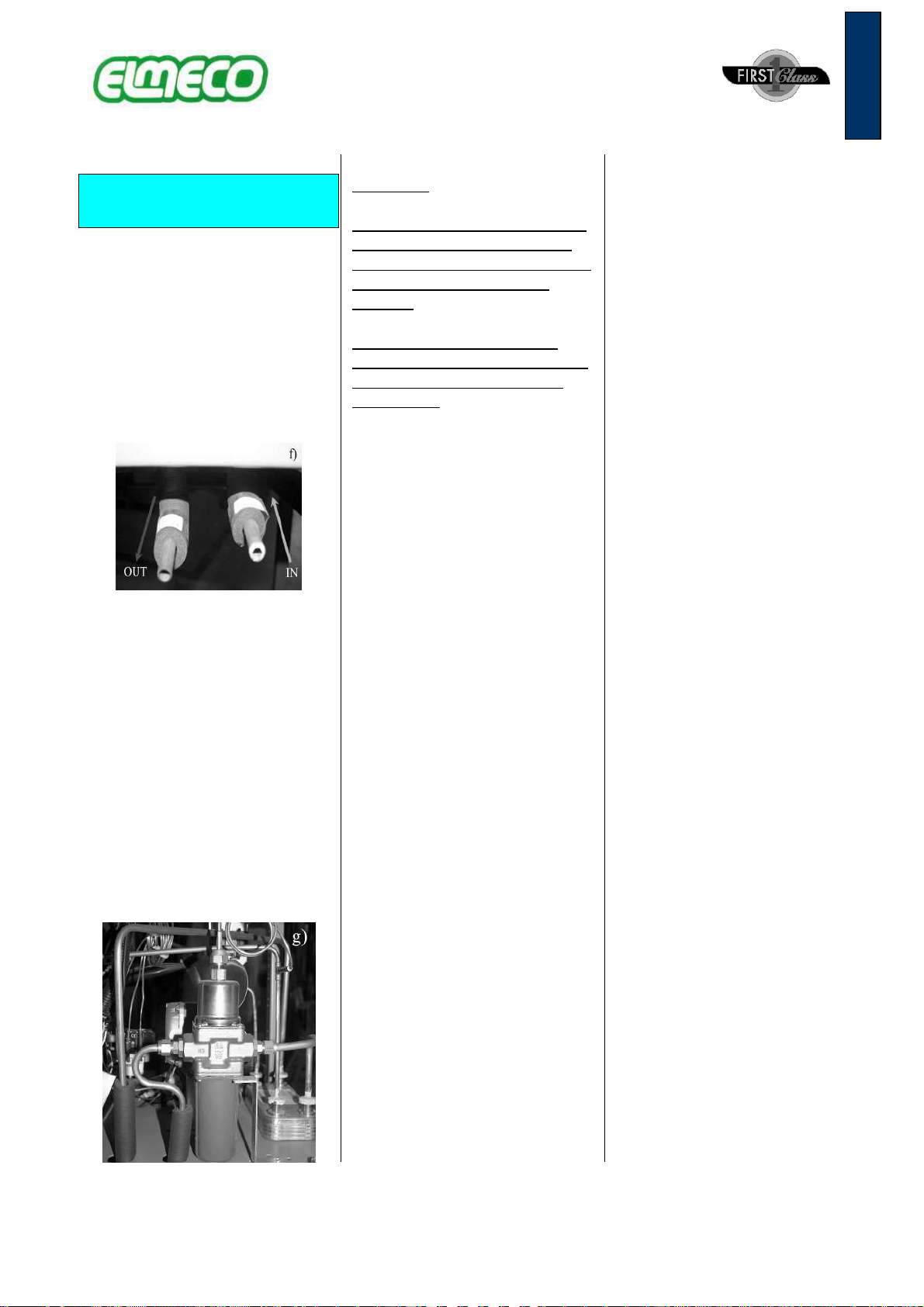

On the machine front side

(outlet side)

There are some water exit (left)

and entrance pipes (right) as

shown in the pic. f .

The quantity of water

necessary for the functioning

can change according to the

product cooling phases, with

higher values when starting the

slush production and values

that are close to zero when you

want to keep the slush. We

therefore recommend to

connect the machine to the

water network with the

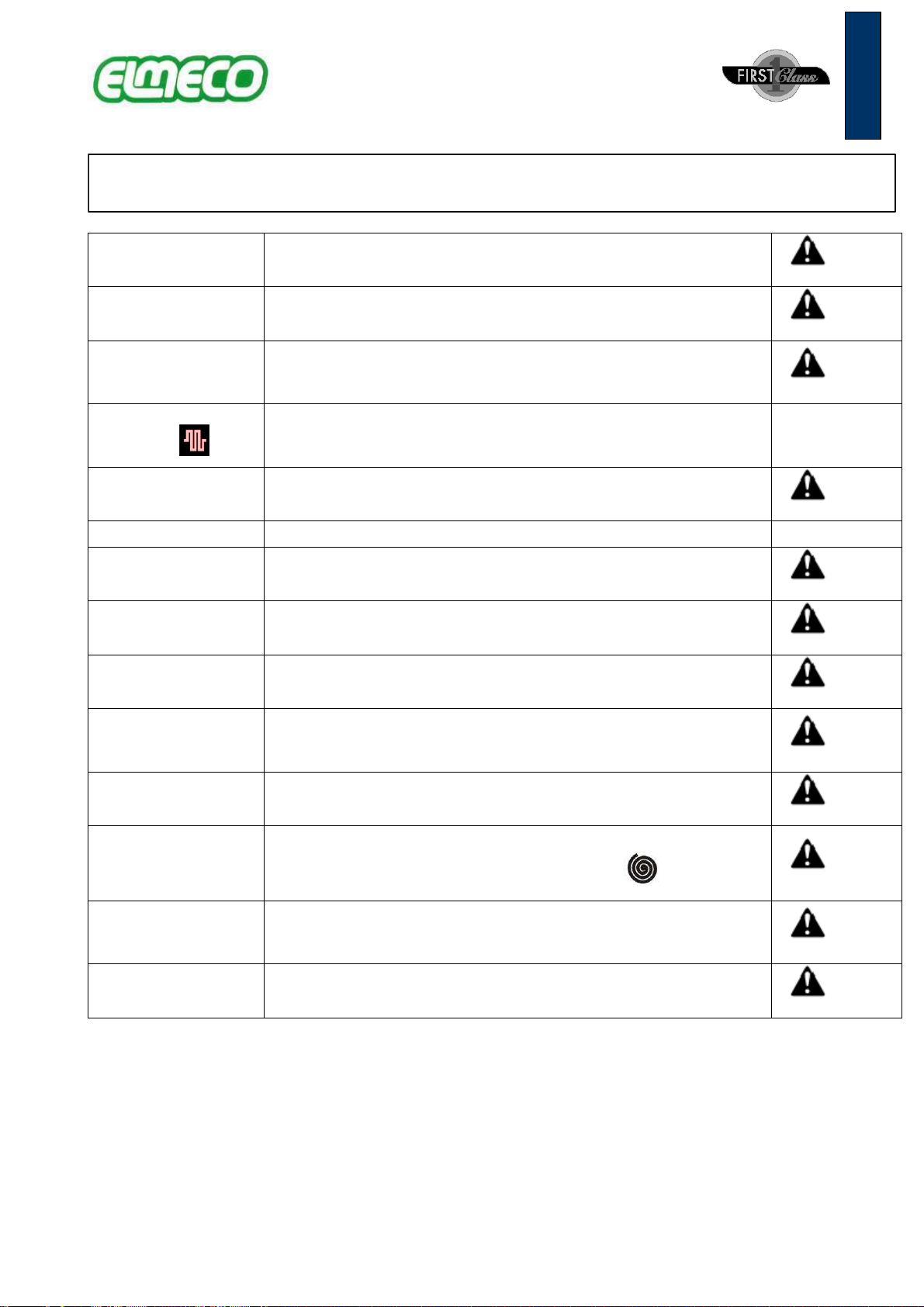

maximum capacity, thus the

pressure switch valve (pic. g) in

the machine will regulate the

flux according the real

necessity.

Important:

It is not possible to connect the

FCW water entrance with the

input of another machine based

on a water cooling system

(series).

It is not possible to connect

several machines based on the

water cooling system on the

same outlet.

- 30 -

ENGLISH

First Class Problem Solving

The electronic board displays "1

blinking"

Verify that the cable connecting the electronic board to the gear motor magnetic revolution counter is

firmly fixed to both elements. In case it needs to be substituted: disconnect the two connectors of the

old cable both from the reader and the electronic board; place the new cable with some insulating tape

or a small band on the existent electric installation. Disconnect

the power electric cable

The electronic board displays "2

blinking"

Replace the cable that connects the thermostat probe to the electronic board verifying that there is not

oxide on it; if so, clean the contacts and if the problem still exists, it is necessary to substitute the

thermostat probe. Disconnect

the power electric cable

The electronic board displays "8

blinking"

The electric power is not linear; there could a fluctuation of the entry tension due to tension changes, to

extensions or to multiple plugs to which First Class is connected. If the power tension is regular,

provide First Class with a single connection in order to solve the problem; if First Class in connected to

an autofill system, it is necessary to switch off and on First Class in order to make it work correctly

again. Disconnect

the power electric cable

The tank does not make cold, the

cooling light is off

1. Switch off the slush machine with the main switch;

2. discharge the product, if it is cold, and put in the tank a product with a temperature higher than

15°C;

3. wait 5 minutes at least and switch on the machine again.

The electronics calibration is automatic.

The augers do not turn in the tank

and the electronic board does not

work properly.

The cotter pin (item 35 of the exploded view pag. 95) broke down. For the cotter pin substitution

procedure see pag. 32 Disconnect

the power electric cable

During the augers rotation you

can hear a creaking. This noise derives from the vertical and horizontal augers gears. You can avoid this by simply go on

using the machine or putting some Vaseline on the plastic gears.

The machine does not make cold

and the slush and the pressure

switch light is ON. The pressure switch intervened. In order to refit it see pag. 31 Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

displays : “ALARM THERMAL “

Replace the cable that connects the thermostat probe to the electronic board verifying that there is not

oxide on it; if so, clean the contacts and if the problem still exists, it is necessary to substitute the

thermostat probe. Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

displays : "ALARM MOTOR "

Verify that the cable connecting the electronic board to the gear motor magnetic revolution counter is

firmly fixed to both elements. In case it needs to be substituted: disconnect the two connectors of the

old cable both from the reader and the electronic board; place the new cable with some insulating tape

or a small band on the existent electric installation. Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

displays : "ALARM VOLTAGE”

The electric power is not linear; there could a fluctuation of the entry tension due to tension changes, to

extensions or to multiple plugs to which First Class is connected. If the power tension is regular,

provide First Class with a single connection in order to solve the problem; if First Class in connected to

an autofill system, it is necessary to switch off and on First Class in order to make it work correctly

again. Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

displays : " ALARM LEVEL”

Level probe (item 16 of the exploded view pag. 95) missing or cover contact/level probe/terminal board

(item 37 of the exploded view pag. 95) not correct. Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

displays : " ALARM REFILL”

You can see this alarm only if the REFILL screen is ON. The alarm appear when the level probe does

not read the presence of the liquid in the tank, for longer than 2 minutes. In order to reset the alarm and

let the level control restart, switch off and on the electronic board with the button.

Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

displays : " ALARM DATE”

This alarm appear if the electronic board finds a problem on the date setting. In order to adjust the date

you need to use the programmer module.

NOTE. First Class Millennium Basic does not have this alarm.

Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

displays: "ALARM SOLVED"

This window will show up when one or more alarms will be solved. Disconnect

the power electric cable

- 31 -

ENGLISH

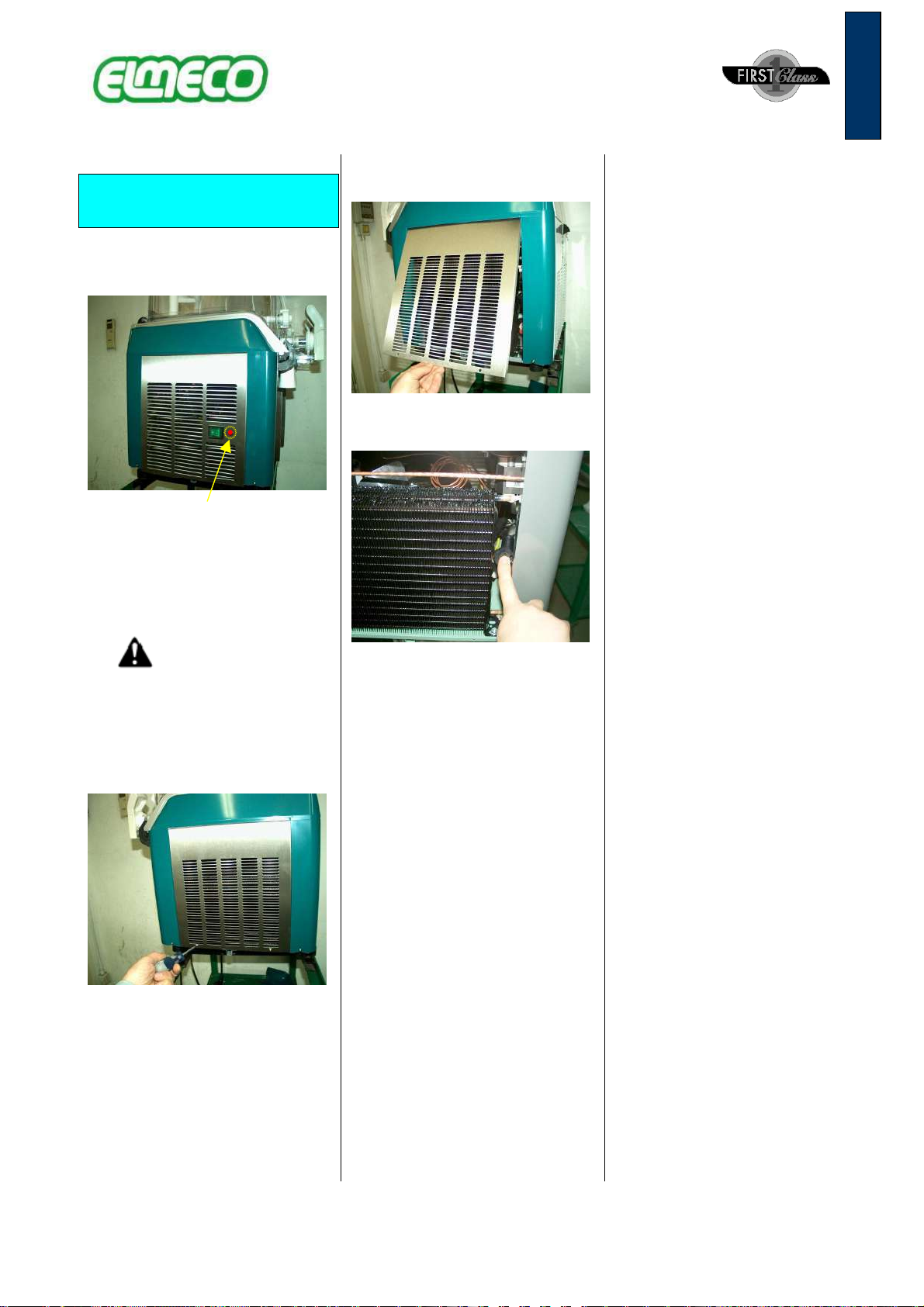

Pressure switch refit

procedure

When the pressure switch light,

near main switch in ON,

Pressure switch light

This indicates that the pressure

switch intervened to deactivate

the compressor. In order to refit

this device, it is important to

follow the instructions below:

1° Disconnect the power

cable.

2°Unscrew the crossed screws

at the bottom of the right side

panel from the side of the

condenser.

3°Slip the panel.

4°Press the button on the

pressure switch.

5°Close the panel and turn on

the machine again.

- 32 -

ENGLISH

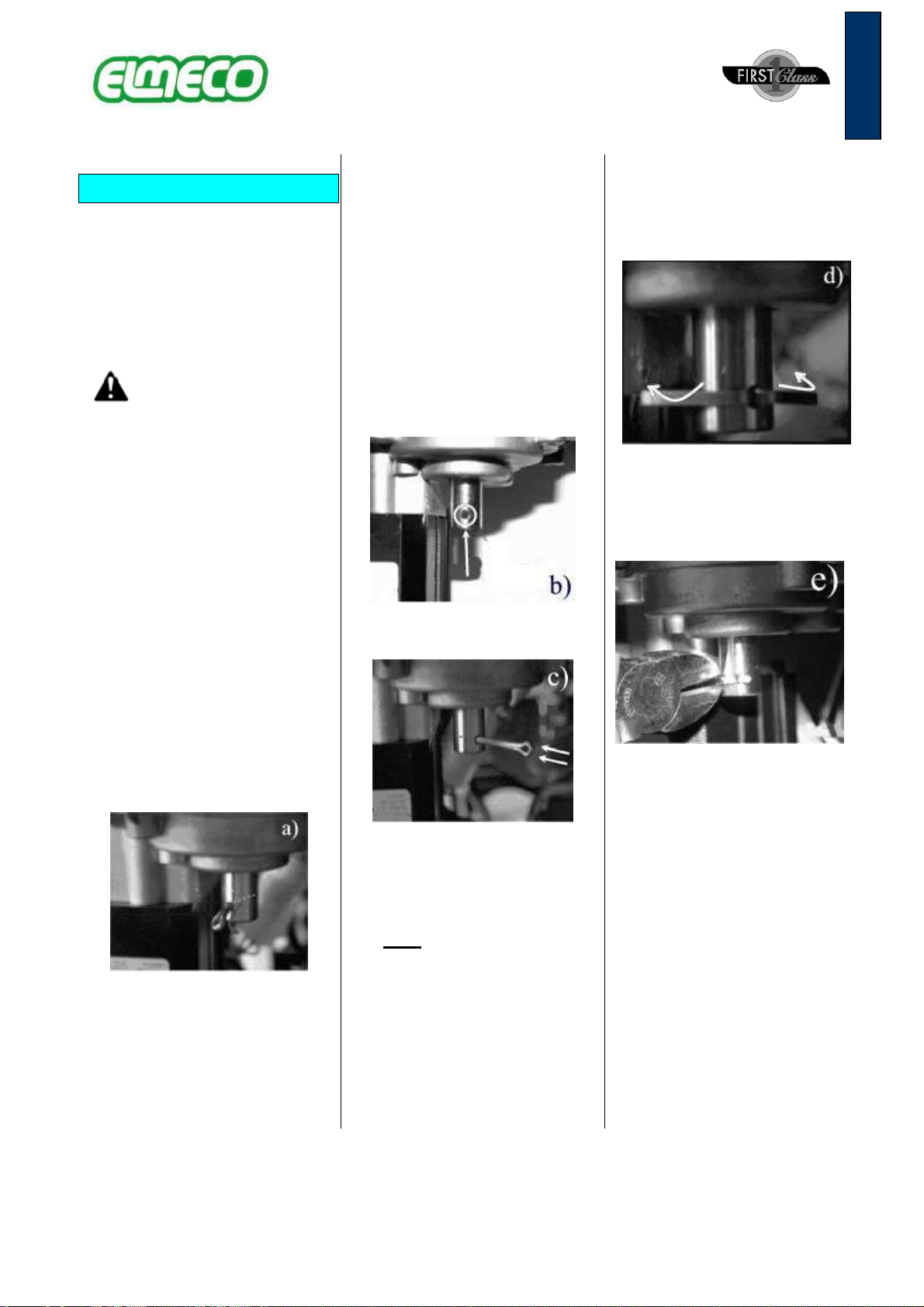

Cotter pin substitution

If the machine works but the

augers do not turn, it is possible

that the cotter pin, (item 35 of

the exploded view at pag. 95)

that connects the gear motor to

the transmission shaft, broke

down.

Disconnect the power

electric cable

After removing the back and

side panels, you can see the

breakdown trying to lift the ring

that fix the vertical auger (item

28 of the exploded view pag.

95). It can happen that it is

blocked or that, if you lift it, it

carries away the transmission

shaft with it (item 29 of the

exploded view pag. 95).

In the first case, it is necessary

to control that the transmission

shaft base is as high as the

gear motor (exit shaft). The lift

pin could be in the hole of the

gear motor slow shaft but it

should be deformed or broken

(see pic .a)

In the second case, the hole in

the gear motor should be

completely empty and some

remnants of the split pin will

certainly lie in the machine.

It is therefore necessary to

install a new split pin.

Place the transmission shaft so

as its hole is aligned with the

one present on the gear motor

exit shaft; it should be evident

when they are aligned;

Insert the split pin as shown in

the pic. c;

Verify that the head of the split

pin, in its rotation, does not

touch the gear motor and

respects a minimum distance.

Warning: do not reuse, in any

case, the old split pin;

With the help of a pliers, fold

the two ends of the split pin

downward as indicated by the

arrows in the pic. d;

Then, with a nippers, cut the

extremities in excess in order to

avoid a contact with the gear

motor during the rotation (see

pic. e).

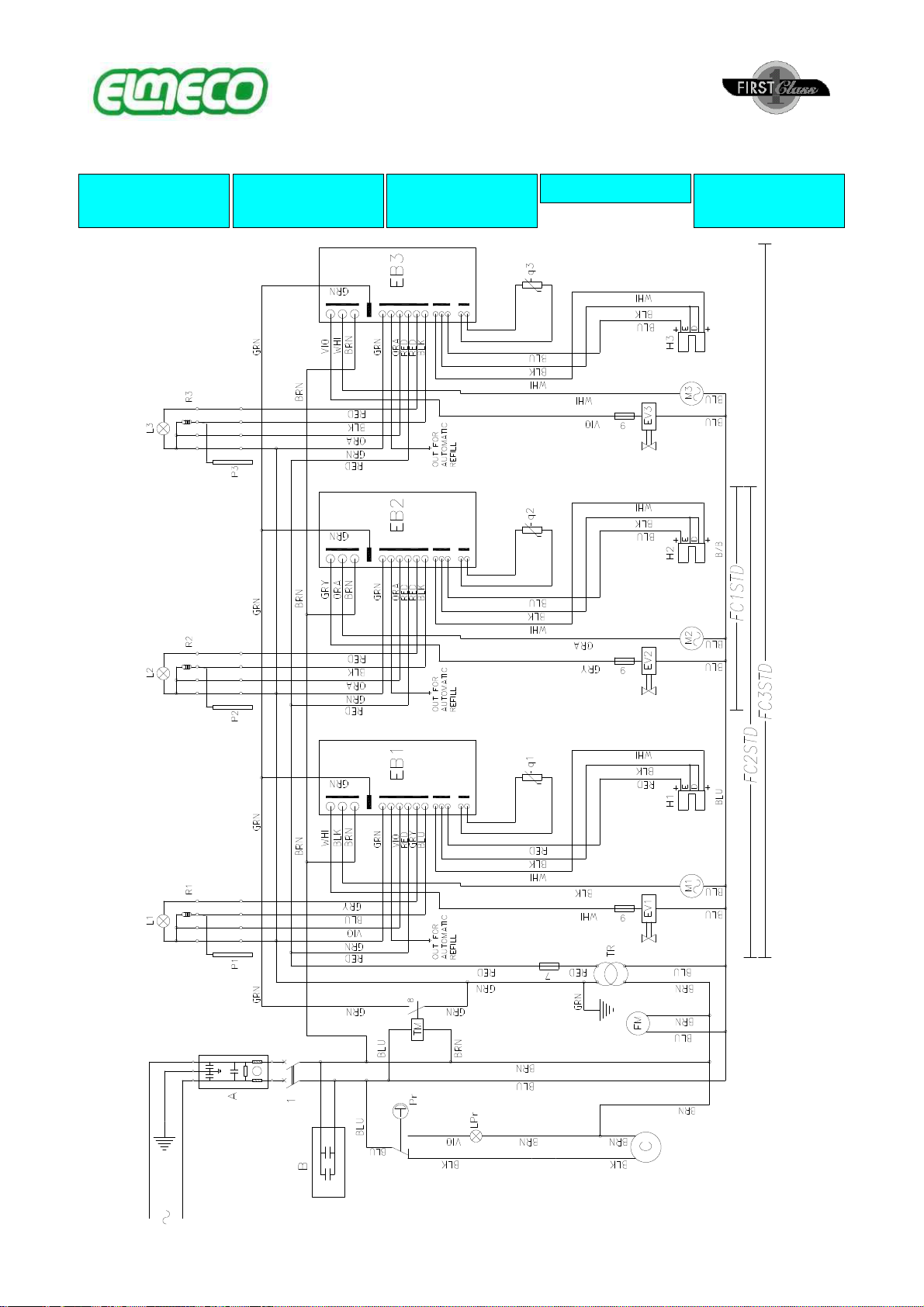

- 89 -

Impianto

Elettrico

Electric

System

Installation

Electrique

Elektrik

Instalación

Eléctrica

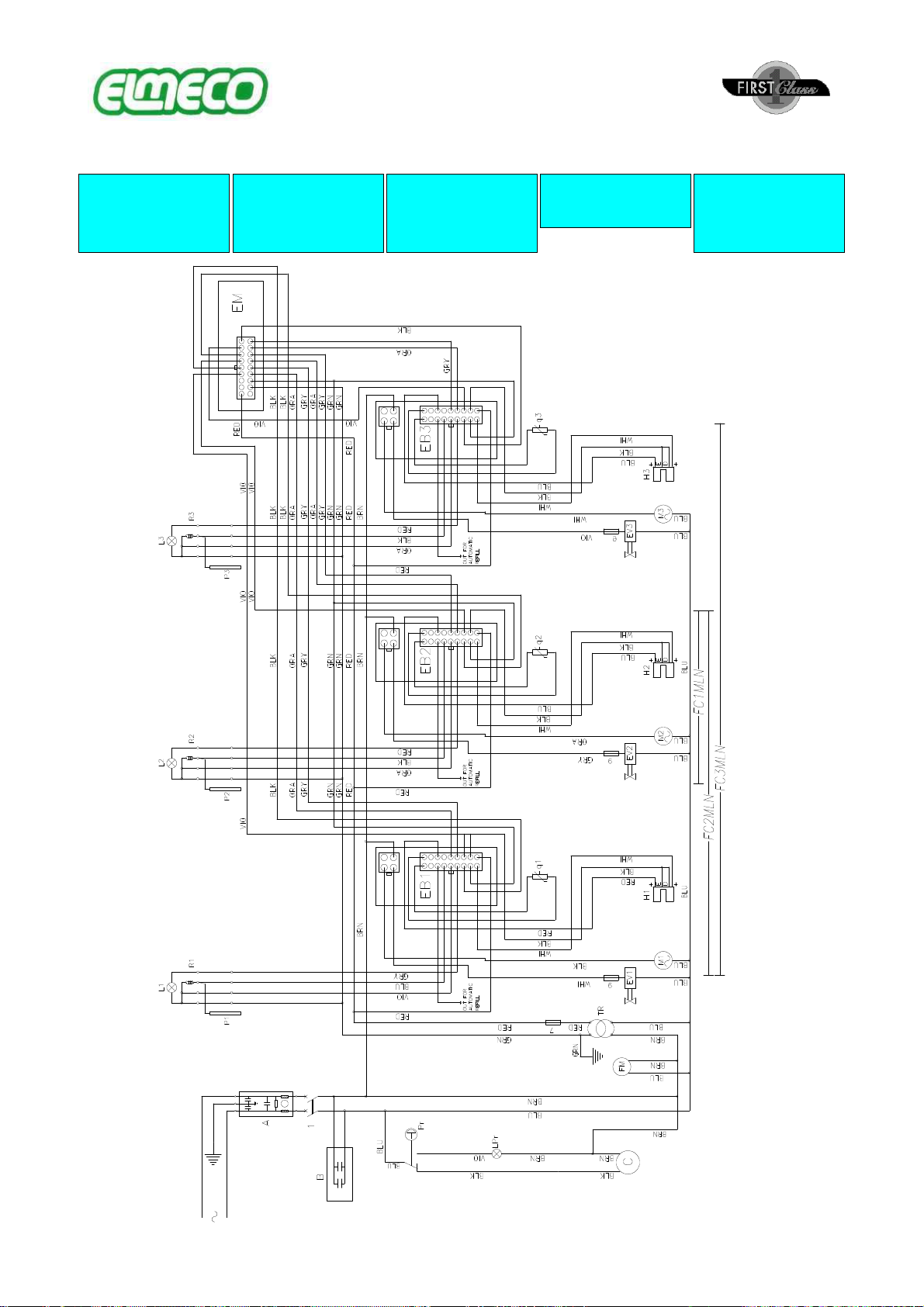

- 90 -

Impianto

Elettrico

Millennium

Millennium

Electric

System

Installation

Electrique

Millennium

Elektrik

Millennium

Instalación

Eléctrica

Millennium

This manual suits for next models

1

Other ELME Commercial Food Equipment manuals