Skope OD720N User manual

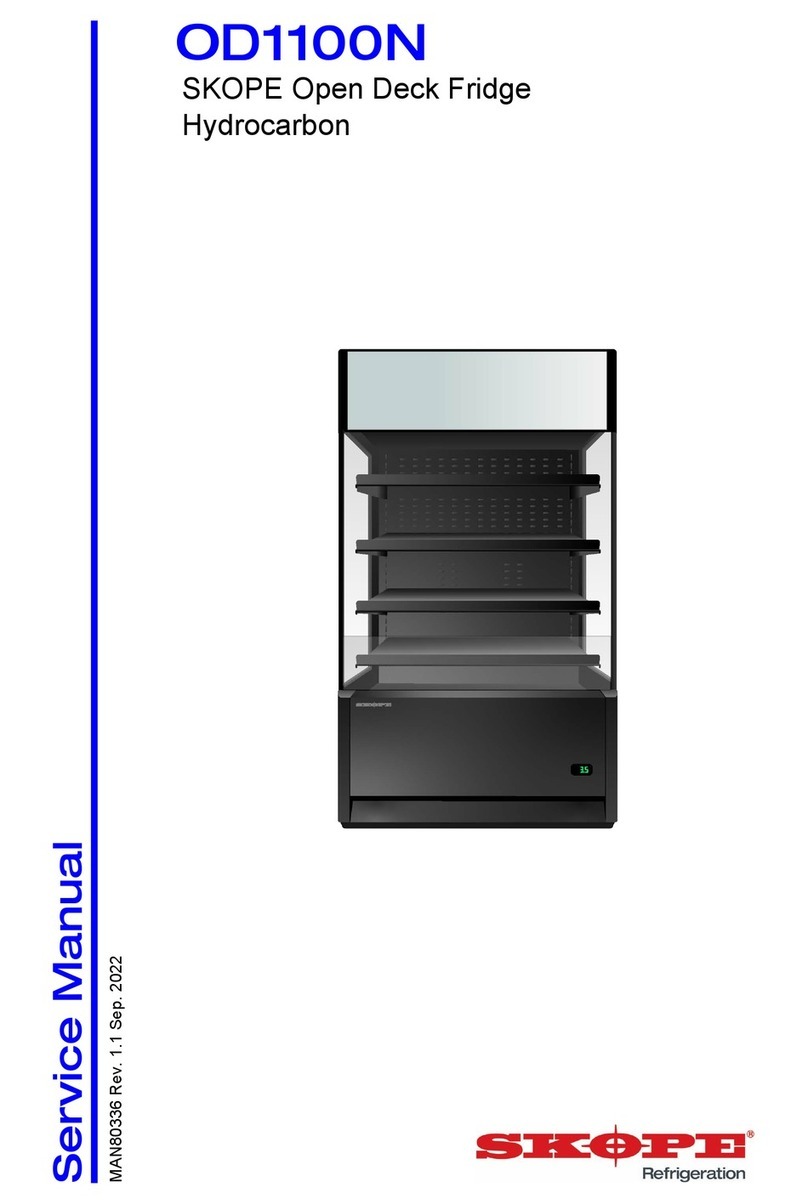

OD720N

Service Manual

MAN80307 Rev. 1.4 Jan. 2023

SKOPE Open Deck Cooler

Hydrocarbon

OD720N

SKOPE Open Deck Cooler

Service Manual

MAN80307

Rev. 1.4 Jan. 2023

© 2021 SKOPE Industries Limited. All rights reserved.

SKOPE Industries Limited reserves the right to alter specifications without notice.

is a registered trademark of SKOPE Industries Limited.

SKOPE INDUSTRIES LIMITED

Head Office

PO Box 1091, Christchurch

New Zealand

A.B.N. 73 374 418 306

AU: 1800 121 535

NZ: 0800 947 5673

E-mail: [email protected]

Website: www.skope.com

Trademark Infringement

The SKOPE trademark on this product is infringed if the owner, for the time being, does

any of the following:

• Applies the trade mark to the product after its state, condition, get-up or packaging

has been altered in any manner

• Alters, removes (including part removal) or obliterates (including part obliteration) the

trade mark on the product

• Applies any other trade mark to the product

• Adds to the product any written material that is likely to damage the reputation of the

trade mark

Notice of the above contractual obligations passes to:

• Successors or assignees of the buyer

• Future owners of the product

SKOPE OD720N

Service Manual CCEP iii

Contents

1 Specifications

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

OD720N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2 Electronic Controller

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Controller Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Buttons and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SCS Connect Field App. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

App Categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Faults and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3 Wiring

Model: OD720N – pre-June 2022 . . . . . . . . . . . . . . . . . . . . . . . . .13

Model: OD720N – June 2022 onwards . . . . . . . . . . . . . . . . . . . . .14

4 Spare Parts

Cabinet Assembly – OD720N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Refrigeration Cassette Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cassette Junction Box Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5 Installation

Climate Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cabinet Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Adjusting the Shelves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Gravity Shelf System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Replacement Procedures

Disconnect the Cabinet from the Power Supply . . . . . . . . . . . . . . . .22

Kick Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cladding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Removing and Refitting the Cladding . . . . . . . . . . . . . . . . . . . . . . 23

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Shelf Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Cabinet Electrics Gear Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Cabinet Electrics Gear Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Night Blind. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Night Blind Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Refrigeration System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Before Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

On-site Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Off-site Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Refrigeration Cassette Assembly . . . . . . . . . . . . . . . . . . . . . . . . .29

Cassette Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cassette Junction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Condenser Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Evaporator Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Compressor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Refrigeration Cassette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

SKOPE OD720N

Service Manual CCEP

iv

Cassette Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Electronic Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

QC Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Electronic Controller Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Replacing the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

PIR Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Control and Evaporator Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Condenser Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7 Maintenance

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Air Filter and Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8 Troubleshooting

Electronic Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Cabinet and Refrigeration Cassette . . . . . . . . . . . . . . . . . . . . . . . . . 43

5

SKOPE OD720N

Specifications

Service Manual CCEP

1 Specifications

Overview

This cabinet uses hydrocarbon (HC) R290 as its refrigerant. R290 is a natural refrigerant that

has a very low environmental impact.

Special service requirements are needed as R290 is a flammable refrigerant.

Safety hazards

The main R290 safety hazards are:

• Flammable refrigerant.

• Venting of R290 and compressor oil.

• Asphyxiation.

SKOPE does NOT recommend performing hazardous activities on the refrigeration system.

6Specifications

Service Manual CCEP

SKOPE OD720N

Models

This service manual is applicable to the SKOPE cabinets detailed below.

OD720N

Table 1: Model specifications

Model Description Type

OD720N Free-standing O72CLN

Table 2: Cabinet

Description Free-standing

Type O72CLN

Construction

Insulation 40mm thick, polyurethane foam. Cyclo-iso pentane

blowing agent: C5H10/C5H12

Doors n.a.

Fitted with manual night blind

Dimensions External Internal

Height 1540 mm 1058 mm

Width 1282 mm 1191 mm

Depth 836 mm (includes 46 mm stand-off) 633 mm

Floor area 1.07m2 (includes 46 mm stand-off)

Internal volume 798 litres

Shelves

3 adjustable angle (8°or flat) adjustable height shelves +

1 fixed angle (8°) bottom shelf. Fitted with gravity feed

system and shelf lighting.

Product loading

4 layers of 600ml PET bottles. Top and middle shelves:

14 facings × 5 deep, bottom shelf: 14 facings × 6 deep,

294 per cabinet.

Operating conditions

Max operating temp. 25°C @ 60% relative humidity (Climate Class 3)

Cabinet temp. range -1°C to +5°C

Electrical 220-240 Volts a.c. 50 Hz, single phase supply

Total run Amps 4.8 Amps (cassette 4.0 Amps)

GEMS energy

consumption 16.15 kWh/day

Energy star rating 3 stars

Sign lighting n.a.

Internal lighting 4 × 7.5 W LED shelf lights

Table 3: Refrigeration Cassette

Description R290 (hydrocarbon) Open Deck Cassette

Cassette model UBQENI-0034

Compressor Embraco NT6224U

Controller SCS Connect

Nominal capacity 1700 Watts

Refrigerant R290 / 135g

7

SKOPE OD720N

Electronic Controller

Service Manual CCEP

2 Electronic Controller

Overview

The cabinet is fitted with an SCS Connect electronic controller. The controller is located behind

the front kick panel.

The controller is pre-programmed. SKOPE does not recommend that settings be changed

unless it is absolutely necessary. To ensure efficient operation, the controller automatically

forces a defrost cycle when required.

Controller servicing can be performed via the controller faceplate, or the SCS Connect Field

app.

Controller Faceplate

Buttons and

Display The faceplate includes the front display panel and interface buttons.

IMPORTANT

The controller must only be adjusted by an authorised service

agent.

12 3 4 5

8 7

11

10

96

Table 4: Controller faceplate

No. Description

1Night Mode: Indicator. On during cooler night mode.

2

Display: Indicator. Digital display of cabinet air temperature or messages. The temperature

is what the sensor inside the cabinet detects, and not necessarily the product temperature.

However, they may be very close depending on how the controller is set to sense

temperature.

3Light Switch - Night Mode (back/abort): Button. Press to switch the lights on or off. Press and

hold to switch cabinet between day and night mode. Used during programming.

4Up: Button. Used for programming.

5Bluetooth: Indicator. On when ready to connect to a device. Flashing when connected to a

device.

6Defrost Cycle (next/enter): Button. Press and hold to initiate manual defrost. Used during

programming.

7Down: Button. Used for programming.

8Fault - Alarm: Indicator. On during fault or alarm. Note: Alarm message is also shown on the

display during alarm.

9Compressor: Indicator. On when the compressor is running.

10 Defrost Mode: Indicator. On during defrost cycle.

11 Fan: Indicator. On when fans running.

8Electronic Controller

Service Manual CCEP

SKOPE OD720N

Service Mode Service mode can be accessed and used via the controller faceplate, refer to Wellington Drive

Technologies documentation for further information.

Note: A 9 digit pin code is required to access service mode via the controller buttons. Contact

your User Manager to receive your activation code.

There are 5 main service mode categories when accessing and using service mode via the

controller faceplate:

Parameters

Provides access and editing of individual controller parameters.

It is not recommended that parameters are changed unless absolutely necessary. If incorrect

parameter settings are suspected, reload the complete parameter set.

Reset

Returns the controller back to factory or default settings.

Manual test

Allows inspection of input values from sensors, and check the effects of output adjustments to

peripherals, and to run preset test routines.

Statistics

Displays logged values and event counts to assist with fine tuning and diagnostics.

About

Lists the properties of the refrigeration system and the controller, including cabinet model

codes, firmware, hardware and software versions.

SCS Connect Field App

Connecting The SCS connect field app allows authorised Service Technicians wireless access to the

controller from mobile devices with Bluetooth capability. The app provides information on data

logging, alarm notification and diagnostic control.

Procedure 1: To install the SCS connect field app

1. Download and install the Connect Field app from Google Play or Apple Store

(search for “scs wellington” to find it).

2. When you first run the app, you will be requested to enter an activation code. Contact your User

Manager to receive your activation code (you must be connected to the internet at the time of

activation).

Your activation code is unique to you, and should NEVER be shared with anyone else, as it

determines your personal access level for the app. The same code will give you access to all SCS

apps you are authorised to use.

3. Once activation is complete, you must define a 4-digit PIN code. This can be any code unique to

you. Each time you start the app, you will be required to enter this same PIN code. This is to

prevent other people accessing the app from unlocked phones.

4. You can see which databases you have activate from the “Settings” screen. You can have more

than one database at the same time. Simply select ACTIVATE ANOTHER DATABASE, and enter

the new database’s unique activation code (see Step 2).

9

SKOPE OD720N

Electronic Controller

Service Manual CCEP

App

Categories Various options are available in the app menu to provide information about the connected

controller and its cabinet.

Home screen

The home screen shows a graphic representation of the current state of the cabinet being

controlled.

Output control

Provides control of the controller input sensors and switches, and output relays.

Edit parameters

Provides access and editing of individual controller parameters.

Note: Parameter changes must be recorded on warranty/job card.

It is not recommended that parameters are changed unless absolutely necessary. If incorrect

parameter settings are suspected, reload the complete parameter set.

Note: Updated parameters are not applied until DISCONNECT has been selected from the

menu (after loading new parameter set).

Load parameter file

Allows reloading of cabinet default parameter set or changing to new parameter set.

Note: Updated parameters may not be applied until DISCONNECT has been selected from

the menu (after loading new parameter set).

Statistics

Information from the past seven days on cabinet activity including temperatures, door

openings and alarms.

Procedure 2: To connect to a controller

1. Check that the Bluetooth logo on the top right of the controller faceplate is lit, indicating that the

controller is ready to connect to a device.

Note: A flashing Bluetooth logo indicates that the controller is currently connected to a device.

2. Open the SCS connect field app.

3. Select a controller to connect to from the list of visible controllers.

Note: This list is filtered by your activation permissions, so devices you are not authorised to

connect to will not be displayed.

4. Select ‘CONNECT’ to connect to the controller.

5. Check that the Bluetooth logo on the top right of the controller faceplate is flashing, indicating that

the controller is connected.

10 Electronic Controller

Service Manual CCEP

SKOPE OD720N

SCS info

Controller version and cabinet asset information.

SCS setup

Add or change SCS info (see above).

Disconnect

Disconnect from currently connected controller.

Settings

Change app general settings.

Faults and Alarms

Table 5 and Table 6 explain the faults and alarms that the electronic controller may log and

display.

If a fault occurs, the Fault - Alarm indicator is lit on the controller faceplate, but no message is

displayed. Faults do not affect product temperature, and require no action from the shop

owner.

Alarms are logged and the alarm message is displayed on the controller faceplate. Alarms may

result in abnormal product temperature.

Some faults and alarms can be cleared by the shop owner, and others can only be cleared by

a service technician.

If the cabinet is connected to the power supply and has warm product, check the SCS Connect

Field App for active fault or alarm, and investigate. If the cabinet does not have an active fault

or alarm, check the app statistics to determine if and when the controller signalled a fault or

alarm.

Refer to the tables below for faults and alarm descriptions and possible causes and actions.

Table 5: Faults (alarm indicator lit – no message displayed)

Description Possible root cause

Over-voltage protection

The maximum allowable mains supply voltage has been exceeded. The

cabinet has temporarily shut down to prevent damage and will restart

once the supply voltage decreases.

Should be a one off. If it continues, consider:

• line voltage/rural

• voltage setting parameter

• controller

Under-voltage protection

The mains supply voltage has dropped below the minimum allowable

level. The cabinet has temporarily shut down to prevent damage and

will restart once the supply voltage increases.

Should be a one off; if continues, consider:

• power supply overloaded/multi-box

• line voltage/rural

• voltage setting parameter

• controller

High condensing temperature protection

The system was operating at an elevated temperature and has

temporarily shut down to prevent damage. Extended operation in this

condition may result in ALARM 15, increased energy consumption and

a reduction in cabinet life. This alarm may be caused by very high

ambient temperature.

NO cassette swap required. Consider

• condenser not clean

• poor installation/ventilation problems

• condenser fan motor or blade

• controller

Excessive compressor cycling protection

The system has been turning on and off too frequently.

Take spare cassette in case there is a refrigeration system fault.

Consider:

• condenser blocked

• poor installation/ventilation problems

• cabinet or cassette gasket seals leaking

• door not self-closing or gasket leaking

• product hot or blocking cabinet airflow

• compressor overloaded from excess door openings/ambient

• fan motor or blade (condenser or evaporator)

• controller

• compressor or gas leak = SWAP cassette

11

SKOPE OD720N

Electronic Controller

Service Manual CCEP

Table 6: Alarms

Code Description Possible root cause

8

Estimated product temperature below allowable range

The estimated product temperature has been below the

allowable range for longer than the permissible time. Potential

causes are: an empty or partially filled cabinet, or low ambient

temperature.

• Low ambient

• App settings

• Controller

9

Estimated product temperature above allowable range

The estimated product temperature has been above the

allowable range for longer than the permissible time. Potential

causes are: excessive door openings, door being left open, or

warm product loaded into cabinet.

NO cassette swap required to be taken (but may be required as fault

could still be with sealed refrigeration system). Consider:

• condenser blocked

• poor installation/ventilation problems

• frozen or blocked evaporator coil

• cassette gasket leaking (to cabinet or lid seal)

• door leaking air (bad gasket or door not self-closing)

• product hot or blocking cabinet airflow

• overloaded from excess door openings/ambient

• fan motor or blade (condenser or evaporator)

• app settings

• controller

• compressor or gas leak = arrange SWAP cassette

15

Excessive condensing temperature protection

The system was operating at an excessive temperature and

has shut down to prevent permanent damage. This alarm may

occur due to very high ambient temperature.

NO cassette swap required. Consider:

• condenser not clean

• poor installation/ventilation problems

• condenser fan motor or blade

• controller

17

Control probe failure

A critical system sensor has failed and the cabinet can no

longer operate.

NO cassette swap required

• control probe/circuit

• controller

18

Electrical over-current protection activated

The compressor was drawing too much current and has shut

down to prevent permanent damage.

Take spare cassette in case refrigeration system fault. Consider:

• condenser blocked

• poor installation/ventilation problems

• cabinet or cassette gasket seals leaking

• door not self-closing or gasket leaking

• product hot or blocking cabinet airflow

• overloaded from excess door openings/ambient

• fan motor or blade (condenser or evaporator)

• controller

• compressor or gas leak = SWAP cassette

19

Failed to reach set temperature

The refrigeration system has been operating continuously for a

long period without reaching the set temperature.

Take spare cassette in case refrigeration system fault. Consider:

• condenser blocked

• poor installation/ventilation problems

• frozen or blocked evaporator coil

• cabinet seal leaking/door/cassette

• product hot or blocking cabinet airflow

• overloaded from excess door openings/ambient

• fan motor or blade (condenser or evaporator)

• controller

• compressor or gas leak = SWAP cassette

20

Over cooling product

The internal temperature is too low. The system has

temporarily shut down until the temperature has returned to

normal. This can occur if the set temperature has been raised

by a large amount.

Confirm if really too cold. If required, change the parameters.

22

Evaporator fan over-current protection

The current supplied to the evaporator fan motor is too high.

NO swap cassette required. Consider:

• faulty fan motor

• fan blade fault (imbalance/debris/blockage)

• controller

23

Condenser fan over-current protection

The current supplied to the condenser fan motor is too high.

NO cassette swap required. Consider:

• faulty fan motor

• fan blade fault (imbalance/debris/blockage)

• controller

24 Controller communication error

Controller has lost communication channels.

• App

• Controller/circuit

25 Controller update failed

Controller update could not be completed.

• App

• Controller/circuit

12 Electronic Controller

Service Manual CCEP

SKOPE OD720N

26 Controller hardware failure

Controller hardware has failed.

• App

• Controller/circuit

27

Probe failure

A non-critical system probe has failed. The cabinet will

continue to operate with partial function but requires service.

NO cassette swap required. Consider:

• evaporator probe or connections

• controller

28

No downward tendency

The temperature is no longer decreasing.

Take spare cassette in case refrigeration system fault. Consider

• condenser blocked

• poor installation/ventilation problems

• cabinet or cassette gasket seals leaking

• door not self-closing or gasket leaking

• product hot or blocking cabinet airflow

• overloaded from excess door openings/ambient

• fan motor or blade (condenser or evaporator)

• controller

• compressor or gas leak = SWAP cassette

29

Compressor cutting out

The compressor cut out on its internal protection or pressure

switch.

Take spare cassette in case refrigeration system fault. Consider:

• condenser blocked

• poor installation/ventilation problems

• cabinet seal leaking/door/cassette

• product hot or blocking cabinet airflow

• overloaded from excess door openings/ambient

• fan motor or blade (condenser or evaporator)

• controller

• compressor or gas leak = SWAP cassette

30

Excessive automatic defrosting

The system is automatically defrosting too frequently.

Take spare cassette in case refrigeration system fault. Consider:

• door not self-closing or gasket leaking

• evaporator probe

• evaporator motor or fan

• controller

• compressor or gas leak = SWAP cassette

31

Compressor stalling

The compressor is stalling on start up.

Take spare cassette in case refrigeration system fault. Consider:

• condenser blocked

• poor installation/ventilation problems

• cabinet or cassette gasket seals leaking

• door not self-closing or gasket leaking

• product hot or blocking cabinet airflow

• overloaded from excess door openings/ambient

• fan motor or blade (condenser or evaporator)

• controller

• compressor or gas leak = SWAP cassette

Table 6: Alarms (continued)

Code Description Possible root cause

13

SKOPE OD720N

Wiring

Service Manual CCEP

3 Wiring

Model: OD720N – pre-June 2022

RD

BN

BN

S2-2 P2-2

P2-1 S2-1

S1-1 P1-1

P1-N S1-N

T1-1

BN

BU

T1-N

BU

BN

P7 S7

WH

BK

P6 S6

WH

BK

P9 S9

BK

S5- P5-2

BK

BU

BU

Fan

Fan

BN BU

BK

S3-4 P3-4

S3-2 P3-2 P3-1 S3-1

LED Ballast

N

L

+

-

BU

BU

BU

Appliance

Sensor

Evaporator

Sensor

EMC Filter

BN

BU

BN BU

L N

GNYE

GNYE

E

Cabinet

Lighting

BN

BN

BK

WH

WDTL

SCS

Controller

L N

C

R

R

DI1

0V AD1

DI2

0V AD2

DI3

0V AD3

DI4

5V

0V

AD4

DI5

0V

LED1

LED2

LED3

AD5

SSR

S1

S2

SSR

Comp.

BK

PIR Sensor

(Reach-in), plus

program port

(Blue 4-way)

BN

S4-4 P4-4

S4-2 P4-2 P4-1 S4-1

P8 S8

WH

BK

Condenser

Sensor BU

S11-1 P11-1

S11-2 P11-2

S11-3 P11-3

S10-1 P10-1

BN

BN

Element

S5-1 P5-1

GN

BU

RD

S10-2 P10-2

BK

BU

BU

BK

BK

RD

RD

BK

S11-4 P11-4

S11-5 P11-5

BK

WH

RD

RD

S13 P13

RD

S13 P13

S13 P13

S12-2 P12-2

RD

RD

RD

S13 P13

RD

BK

S12-1 P12-1

BU

BU

BU

BN

GY

BN

BU

WH

WH/BK

WH

WH/BK

WH

WH/BK

WH

WH/BK

Curtain Switch

BK

Compressor

LEGEND

T1 Unit Junction Box Terminal S7/P7 Evaporator Sensor Socket/Plug (Black 2-way)

S1/P1 IEC Isolation Socket/Plug S8/P8 Condenser Sensor Socket/Plug (Red 2-way)

S2/P2 Compressor Socket/Plug (Blue 4-way) S9/P9 Door/Curtain Switch Socket (White 2-way)

S3/P3 Fan Motor Socket/Plug (Red 4-way) S10/P10 LED Driver Output Socket/Plug (Red 2-way)

S4/P4 Fan Motor Socket/Plug (Red 4-way) S11/P11 Cabinet Supply Socket/Plug (6-way)

S5/P5 LED Driver/Plug (on Unit) (White 3-way) S12/P12 Heater Socket/Plug (Black 3-way)

S6/P6 Appliance Sensor Socket/Plug (Blue 2-way) S13/P13 Cabinet Lighting Sockets/Plugs (Red 2-way)

WIRE COLOURS

BK Black

BN Brown

RD Red

OG Orange

GN Green

BU Blue

GY Grey

WH White

GNYE Green-Yellow

Based upon IEC 757 Standard

14 Wiring

Service Manual CCEP

SKOPE OD720N

Model: OD720N – June 2022 onwards

RD

BN

BN

S2-2 P2-2

P2-1 S2-1

S1-1 P1-1

P1-N S1-N

T1-1

BN

BU

T1-N

BU

BN

P7 S7

WH

BK

P6 S6

WH

BK

P9 S9

BK

S5- P5-2

BK

BU

BU

Condenser Fan

Evaporator Fan

BN BU

BK

S3-4 P3-4

S3-2 P3-2 P3-1 S3-1

LED Ballast

N

L

+

-

BU

BU

BU

Appliance

Sensor

Evaporator

Sensor

EMC Filter

BN

BU

BN BU

L N

GNYE

GNYE

E

Cabinet

Lighting

BN

BN

BK

WH

WDTL

SCS

Controller

L N

C

R

R

DI1

0V AD1

DI2

0V AD2

DI3

0V AD3

DI4

5V

0V

AD4

DI5

0V

LED1

LED2

LED3

AD5

SSR

S1

S2

SSR

Comp.

BK

PIR Sensor

(Reach-in), plus

program port

(Blue 4-way)

BN

S4-4 P4-4

S4-2 P4-2 P4-1 S4-1

P8 S8

WH

BK

Condenser

Sensor BU

S11-1 P11-1

S11-2 P11-2

S11-3 P11-3

S10-1 P10-1

WH

RD

Element

S5-1 P5-1

GN

BU

RD

S10-2 P10-2

BK

BU

BU

BK

BK

RD

RD

BK

S11-4 P11-4

S11-5 P11-5

BK

WH

RD

RD

S13 P13

RD

S13 P13

S13 P13

S12-2 P12-2

RD

RD

RD

S13 P13

RD

BK

S12-1 P12-1

BU

BU

BU

BN

GY

BN

BU

WH

WH/BK

WH

WH/BK

WH

WH/BK

WH

WH/BK

Curtain Switch

BK

Compressor

WIRE COLOURS

BK Black

BN Brown

RD Red

OG Orange

GN Green

BU Blue

GY Grey

WH White

GNYE Green-Yellow

Based upon IEC 757 Standard

LEGEND

T1 Unit Junction Box Terminal S7/P7 Evaporator Sensor Socket/Plug (Black 2-way)

S1/P1 IEC Isolation Socket/Plug S8/P8 Condenser Sensor Socket/Plug (Red 2-way)

S2/P2 Compressor Socket/Plug (Blue 4-way) S9/P9 Door/Curtain Switch Socket (White 2-way)

S3/P3 Fan Motor Socket/Plug (Red 4-way) S10/P10 LED Driver Output Socket/Plug (Red 2-way)

S4/P4 Fan Motor Socket/Plug (White 4-way) S11/P11 Cabinet Supply Socket/Plug (6-way)

S5/P5 LED Driver/Plug (on Unit) (White 3-way) S12/P12 Heater Socket/Plug (Black 3-way)

S6/P6 Appliance Sensor Socket/Plug (Blue 2-way) S13/P13 Cabinet Lighting Sockets/Plugs (Red 2-way)

>> Socket and Plug O Terminal

15

SKOPE OD720N

Spare Parts

Service Manual CCEP

4 Spare Parts

Cabinet Assembly – OD720N

2

9

3

30

18

18

18

11

4

5

6

7

8

16

12

31

31

31

31

10

19

20

21

22

24

1

25

26

27

29

23

13 14 15 17

28

999

32

Table 7: Parts – Cabinet OD720N

Item Description SKOPE Part No. CCEP-NZ Part No.

1Cladding – left hand side O720/009L-EX TBC

2Cladding – right hand side O720/009R-EX TBC

3Glass unit (left and right hand side) GLA12200 150103195

4Filter HB0070204892 150100863

5Kick panel assembly O720/131A-EX 150103197

6Night blind bracket O720/678-32 TBC

7Upstand PLY12196 150103208

8Cassette assembly UBQENI-0034-P TBC

9LED shelf light ELL12193 150103192

10 Shelf – bottom O720/590A-32 150103198

11 Shelf – mid O720/590B-32 150103199

16 Spare Parts

Service Manual CCEP

SKOPE OD720N

12 Top shelf assembly – white O720/590C-32 150103200

13 M3 x16 mm Nylon Ph C/Snk Scr Blk FAS11917 TBC

14 Night blind sensor HB0074091444 150100034

15 M3 nylon nut black FAS11918 TBC

16 PIR sensor O332N/X03 150103196

17 PIR sensor bracket O720/U07-32 TBC

18 Shelf bracket STY12223-32 150103210

19 Honeycomb air guide PLX12199 TBC

20 Return air grille O720/586-32 TBC

21 OD720N manual night blind SXX12195 150103212

22 Night blind spigot bush PLM10342 150103206

23 Sign clear polycarbonate PLY12255 TBC

24 Sign insert holder PLE11375-1160 TBC

25 Top lid PLM12191BK TBC

26 Rear cabinet stop SM12BV/106 TBC

27 Shelf bracket wire clip PLM12298 150103207

28 Electrics gear tray assembly O720/G29 TBC

29 EMC/EMI filters ELZ10136 150103193

30 Castors SXX11977 150103211

31 Matting + ticket strips CCEP source – MFT TBC

32 Overlay upstand acrylic PLY12197 TBC

–OD720 mains flex OD720/E53 TBC

–Lighting lead – 1930 mm (not shown) O720/X01 150103202

–Lighting lead – 1700 mm (not shown) O720/X02 150103203

–Lighting lead – 1450 mm (not shown) O720/X03 150103204

–Lighting lead – 550 mm (not shown) O720/X04 150103205

–Unit to cab lighting loom (not shown) O720/X05 TBC

–Cab IEC flex (not shown) O720/X06 TBC

Table 7: Parts – Cabinet OD720N (continued)

Item Description SKOPE Part No. CCEP-NZ Part No.

17

SKOPE OD720N

Spare Parts

Service Manual CCEP

Refrigeration Cassette Assembly

20

1

7

19

6

8

18

17

15

9

10

5

8

2

13

12

16

14

11

19

7

6

8

6

7

4

8

3

6

7

21

18 Spare Parts

Service Manual CCEP

SKOPE OD720N

Table 8: Parts – Refrigeration cassette

Item Description SKOPE Part No. CCEP-NZ Part No.

1Cassette UBQENI-0034-P TBC

2Condensate tray UP10N00003 150103216

3Compressor CPR12170 150103190

4Drier DRY11210 150103191

5Condenser coil CLS12068 150103179

6Fan blades FAN1168 150102216

7Wall ring HB0070109669 TBC

8Fan motors ELM11309 150102489

9Side cover – left hand US04N00010 TBC

10 Condensate line UT03N00021 150103217

11 Condensate tray hold down bracket UP10N00004 TBC

12 Suction line assembly UA0400018 150103214

13 Side cover – right hand US04N00011 TBC

14 Cassette rear guard UX02N00002 150103223

15 Lifting arm UX01N00001 TBC

16 Probe bracket US09N00001

17 Evaporator tub UA0500015 150103215

18 Evaporator coil CLS12067 150103178

19 Fan guard UX02N00001 150103222

20 Gaskets/seals – perimeter RUE12210-OD720-KIT 150103209

21 Process tube UT04N00001 TBC

–Evaporator fan extension flex (not shown) UW0100094 TBC

–Condenser fan extension flex (not shown) UW0100065 TBC

–OD720 evaporator probe – black (not shown) UW0300037-150BK 150103218

–OD720 control probe – blue (not shown) UW0300037-150BU 150103219

–OD720 condenser probe – red (not shown) UW0300037-150RD 150103220

19

SKOPE OD720N

Spare Parts

Service Manual CCEP

Cassette Junction Box Assembly

2

5

1

3

4

6

Table 9: Parts – Cassette junction box

Item Description SKOPE Part No. CCEP-NZ Part No.

1Cassette junction box assembly UA0300028 150103213

2Mounting bracket – controller US07N00015 TBC

3LED driver (MEAN WELL LPF-60-24) ELZ12205 150103194

4ICE retaining clip US07N00017 TBC

5W/Drive SCS Controller – CCEP ELZ11488-1627 150102785

–Junction box loom (not shown) UW0300041 150103221

20 Installation

Service Manual CCEP

SKOPE OD720N

5 Installation

Climate Class The cabinet is designed to operate within a climate class 3 environment (25°C @ 60% relative

humidity).

Cabinet

Location The cabinet should not be left exposed to direct sunlight at any time as this may cause

distortion of plastic parts.

The cabinet must not be situated where it is affected by air-conditioning air outlets, ventilation

fans or air re-circulation fans, as this will compromise the airflow and product temperature in

the open cabinet zone.

There must be no air movement directly into the cabinet opening. Air movement will cause

failure of the air curtain over the product, resulting in excessive temperature rise. Detectable

air draft will adversely affect the cabinet operation. Maximum air movement across the cabinet

opening must not exceed 0.2 m/s.

Ventilation Keep the ventilation slots in the front panel clear at all times. Never store cardboard cartons

or other objects in front or behind the cabinet. To maximise airflow on the rear of the cabinet,

ensure rear stand-off’s are fully extended when cabinet is installed.

Power Cord The cabinet has a flexible power cord fitted with a 3-pin plug, which exits the rear of the

cabinet. Pull the power cord around so that it’s not trapped before you position the cabinet.

Shelves

Adjusting the

Shelves

The cabinet is fitted with four metal shelves. The three top shelves are height and angle

adjustable, and removable. The angled bottom shelf is not adjustable. The top two shelves are

the same depth, shelf three is slightly deeper and the bottom shelf deeper again.

The three top shelves are each held in place by two cantilevered shelf brackets which clip into

cut-outs in the cabinet back duct. The top three shelves can be adjusted at 28mm increments

(see image below).

IMPORTANT

Do not leave the cabinet exposed to direct sunlight as this may

cause distortion of the plastic cladding.

IMPORTANT

There must be no air movement directly into the cabinet opening.

CAUTION

To prevent over-heating and conserve energy, ensure air flows

freely all around the cabinet, including underneath and on top.

Position for

level shelves

Position for

angled shelves

Excess shelf light

cable holes

Table of contents

Other Skope Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Structural Concepts

Structural Concepts Reveal NR3613DSV user manual

Oktober

Oktober 7 Operation manual

Fri-Jado

Fri-Jado TDR auto-clean Service manual

Bourgeat

Bourgeat 872002 Instructions for use and maintenance

GIGA

GIGA IBE4 Installation, Operating and Maintenance Instructions for the Installer and the User

Taylor

Taylor c713 Operator Training

JAC

JAC Paniform User instructions

Proluxe

Proluxe FAST-FIRE'D BLAZE PIZZA DOUGHPRO DP2010MBZE Operation manual

Amitek

Amitek FT1L Installation, operating and service instructions

Skymsen

Skymsen PD3TS instruction manual

Falcon

Falcon G2962 User instructions

Thermo King

Thermo King VM-405 PBBD2 operating manual