MECHANICAL ADJUSTMENT

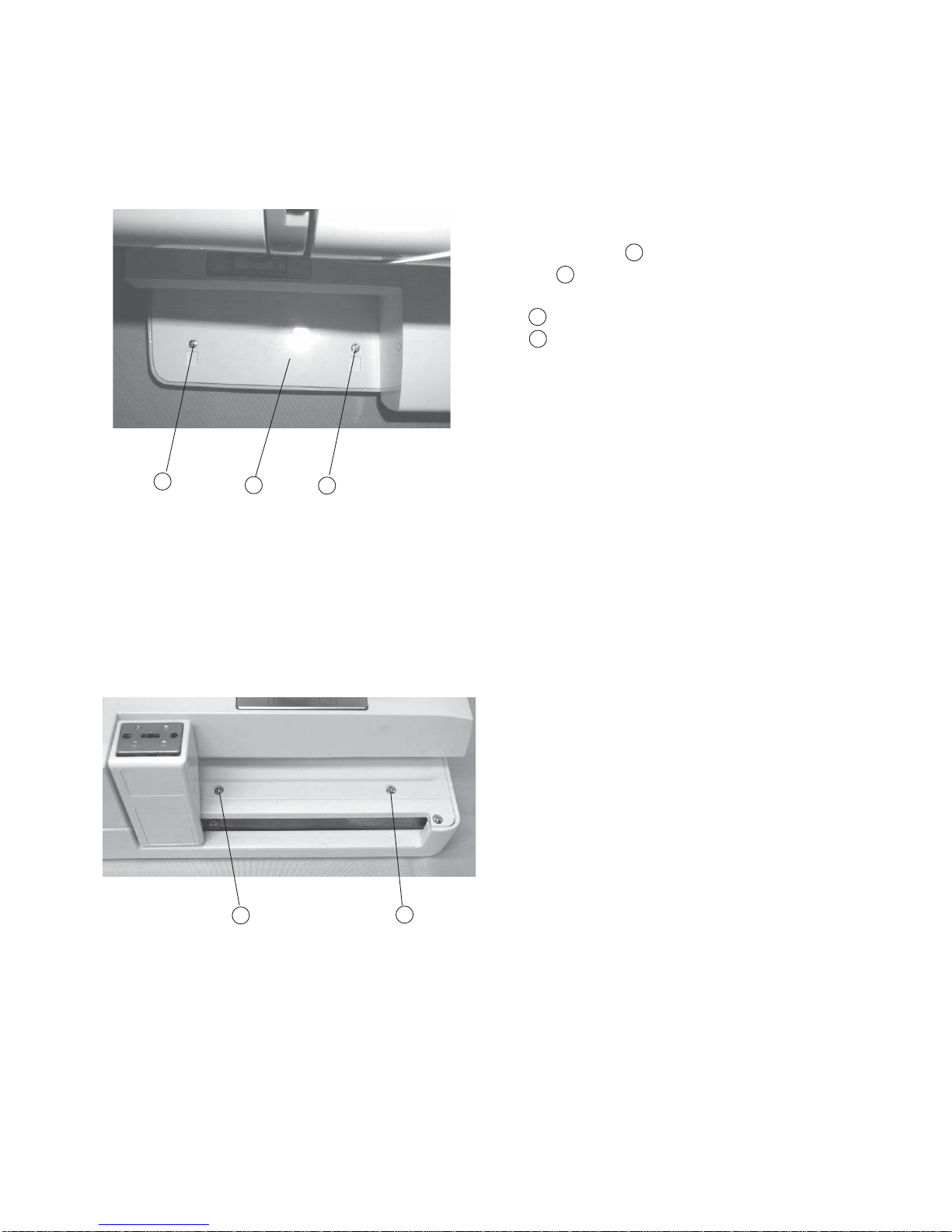

Changing External Parts (1) Face Cover................................................................. 1

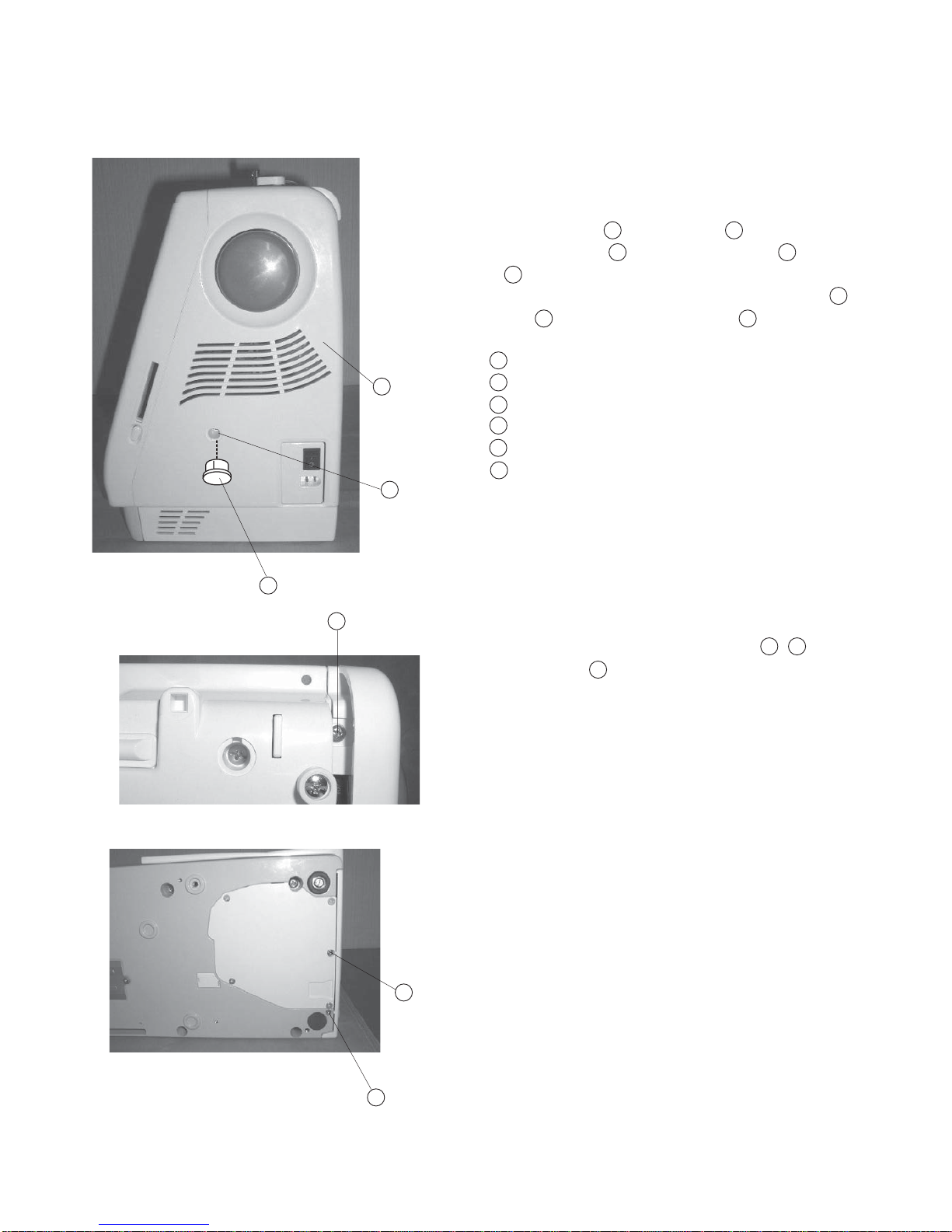

Changing External Parts (2) Belt Cover..................................................................... 2

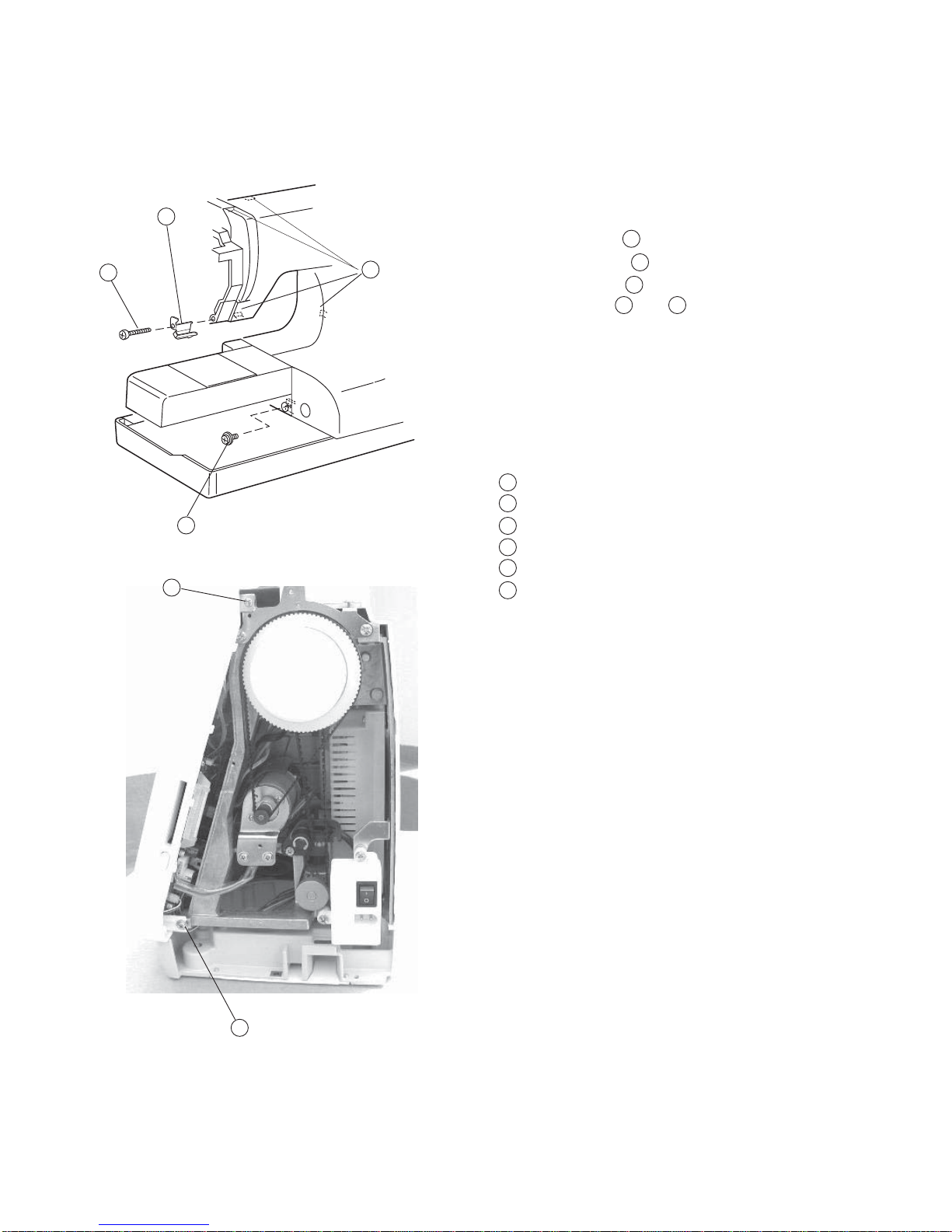

Changing External Parts (3) Base Cover................................................................... 3

Changing External Parts (4) Bed Cover/ Base Cap................................................... 4

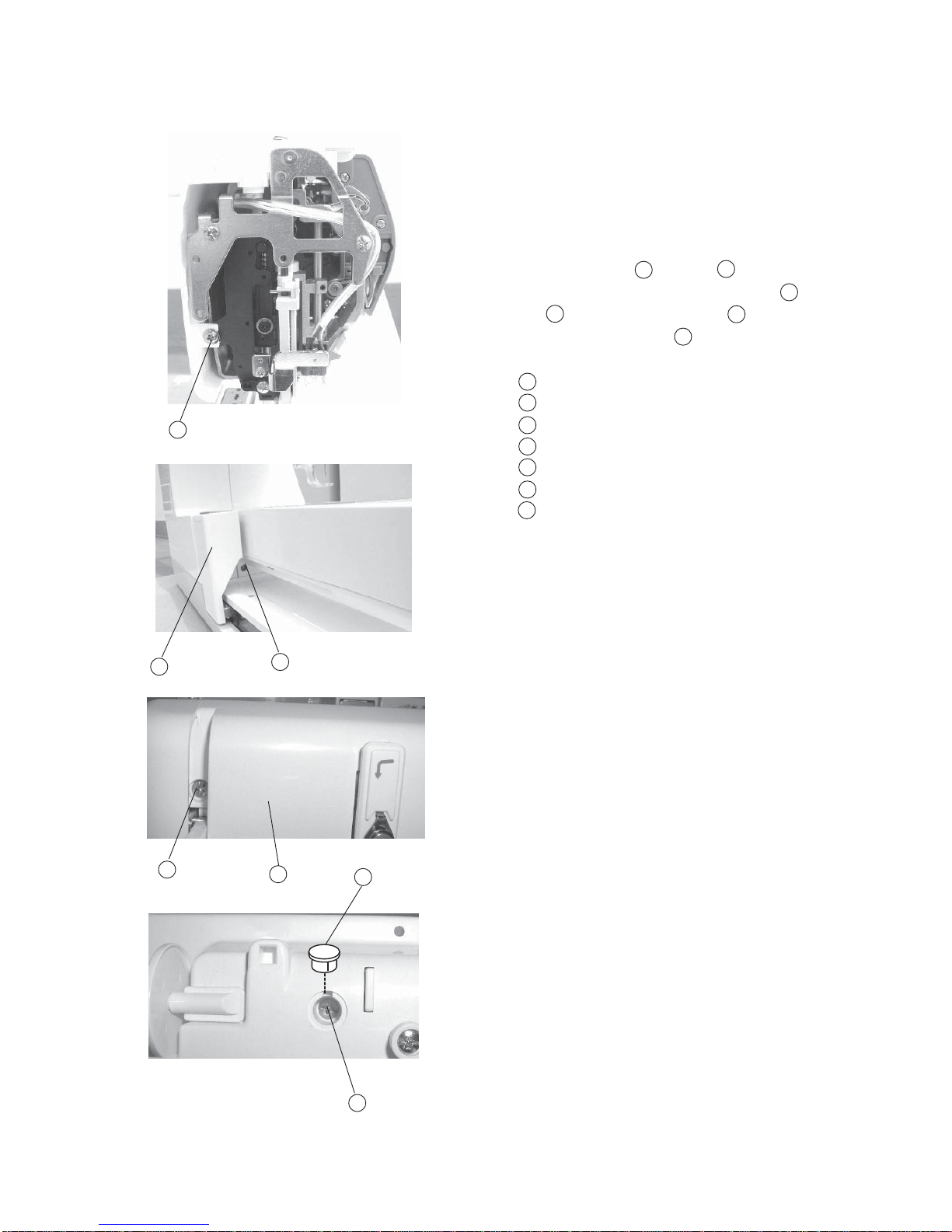

Changing External Parts (5) Base Unit...................................................................... 5

Changing External Parts (6) Front Cover................................................................... 6

Changing External Parts (7) Rear Cover .................................................................. 7

Adjusting Needle Drop Position ................................................................................. 8

Adjusting Hook Timing ............................................................................................... 9

Adjusting Needle Bar Height..................................................................................... 10

Adjusting Clearance between Needle and Hook ...................................................... 11

Adjusting Backlash between Hook Drive Gear and Lower Shaft Gear ..................... 12

Adjusting Upper Shaft Shield Plate Position ............................................................. 13

Adjusting Nedle Thread Tension ............................................................................... 14

Adjusting Tension Release Mechanism for Knee Lifter............................................. 15

Changing Thread Tension Unit.................................................................................. 16

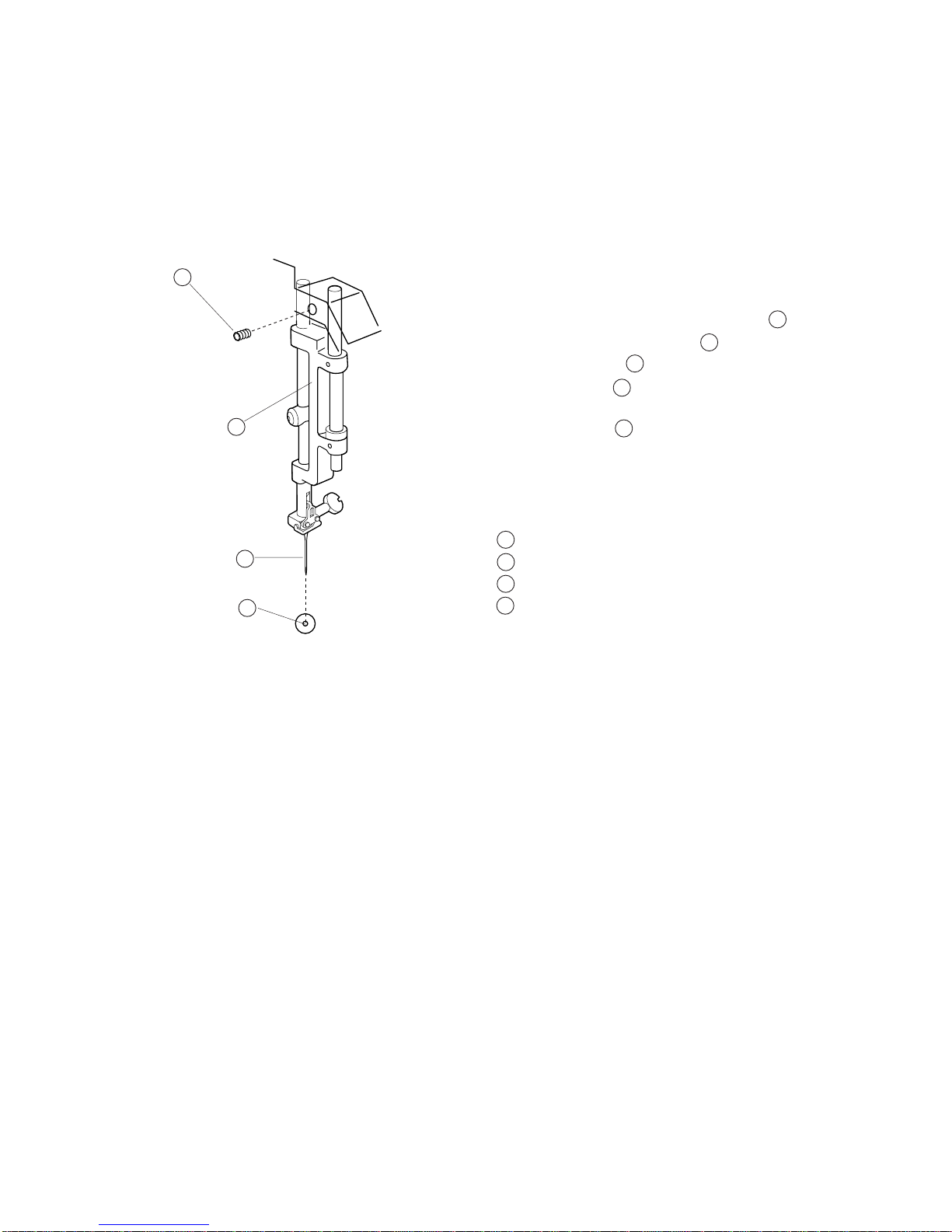

Replacing Threader Plate and Adjustment ............................................................... 17

Adjusting Height of Embroidery Foot P..................................................................... 18

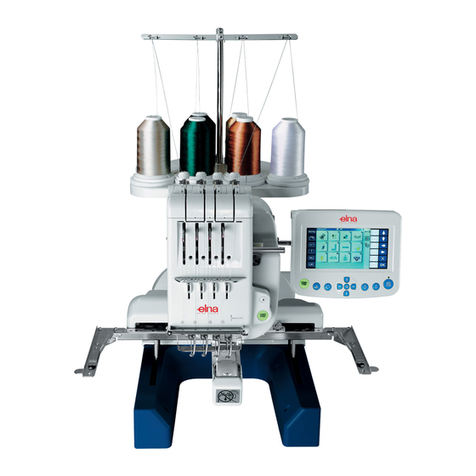

ADJUSTMENT FOR ELECTRICAL COMPONENTS

Connector Connection Diagram................................................................................ 19

Replacing Printed Circuit Board................................................................................ 20

Replacing Touch Panel ............................................................................................. 21

Replacing Printed Circuit Board F ............................................................................ 22

Adjusting Slide Volume ............................................................................................. 23

Replacing DC Motor and Motor Belt Tension Adjustment......................................... 24

Replacing Carriage Plate (Unit) ................................................................................ 25

Adjusting X andY Sensors ....................................................................................... 26

Adjusting X andY Sensors (Instant Adjustment) ...................................................... 27

Adjusting X Motor Gear ............................................................................................ 28

Replacing Switching Power Supply........................................................................... 29

TABLE OF CONTENTS