ELNA 6200 - User manual

Other ELNA Sewing Machine manuals

ELNA

ELNA EC 11 User manual

ELNA

ELNA 6004 User manual

ELNA

ELNA 505 User manual

ELNA

ELNA eXpressive 830 User manual

ELNA

ELNA eXplore 150 User manual

ELNA

ELNA eXcellence 580+ User manual

ELNA

ELNA eXtend covermax User manual

ELNA

ELNA Elnita User manual

ELNA

ELNA 500 ELECTRONIC User manual

ELNA

ELNA E9020 User manual

ELNA

ELNA eXplore 320 User manual

ELNA

ELNA Carina User manual

ELNA

ELNA EnVision 8006 Wiring diagram

ELNA

ELNA 444 User manual

ELNA

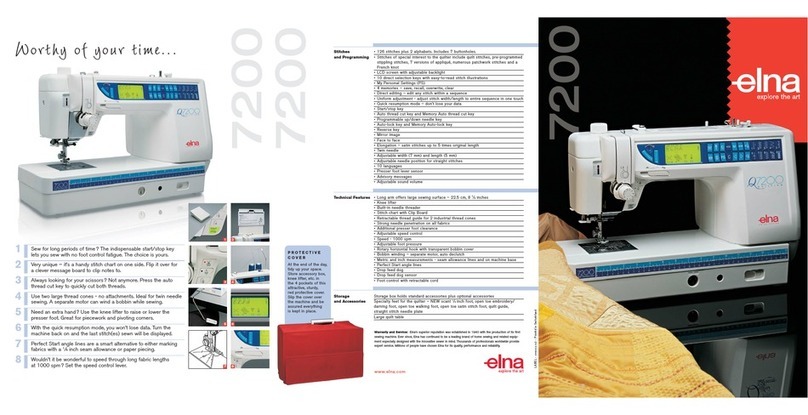

ELNA 7200 User manual

ELNA

ELNA 8200 User manual

ELNA

ELNA EN VISION CE 20 - LEAFLET User manual

ELNA

ELNA eXperience 520 User manual

ELNA

ELNA 3003 User manual

ELNA

ELNA eXperience 550 User manual