INDEX

WHAT TO DO WHEN ......................................................................................................... 1 to 3

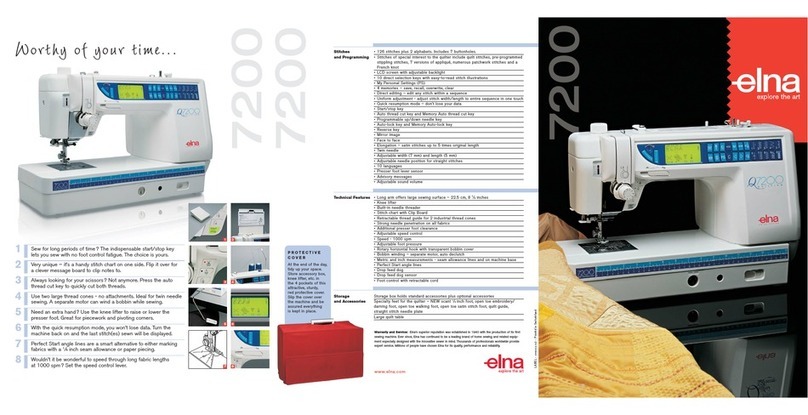

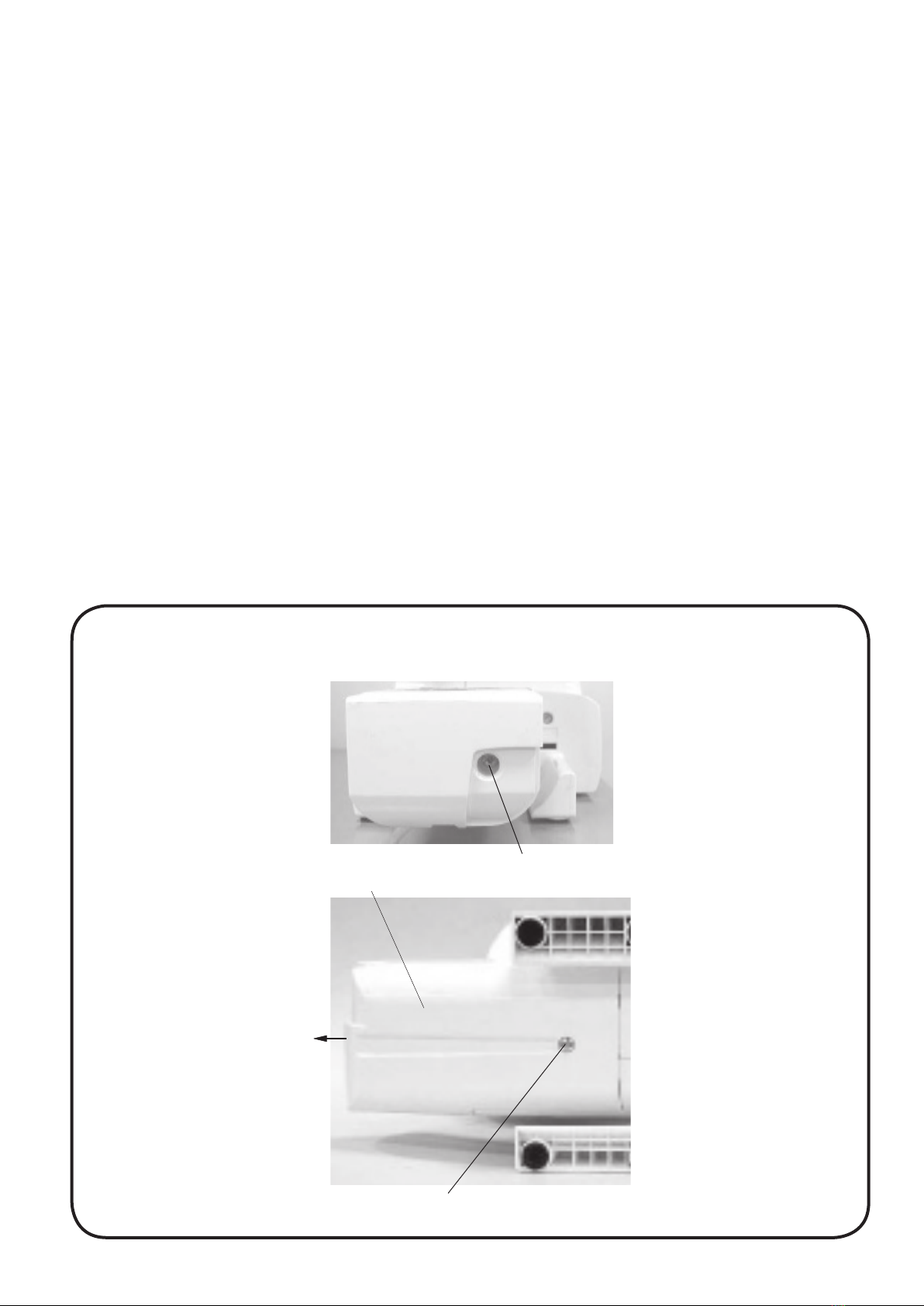

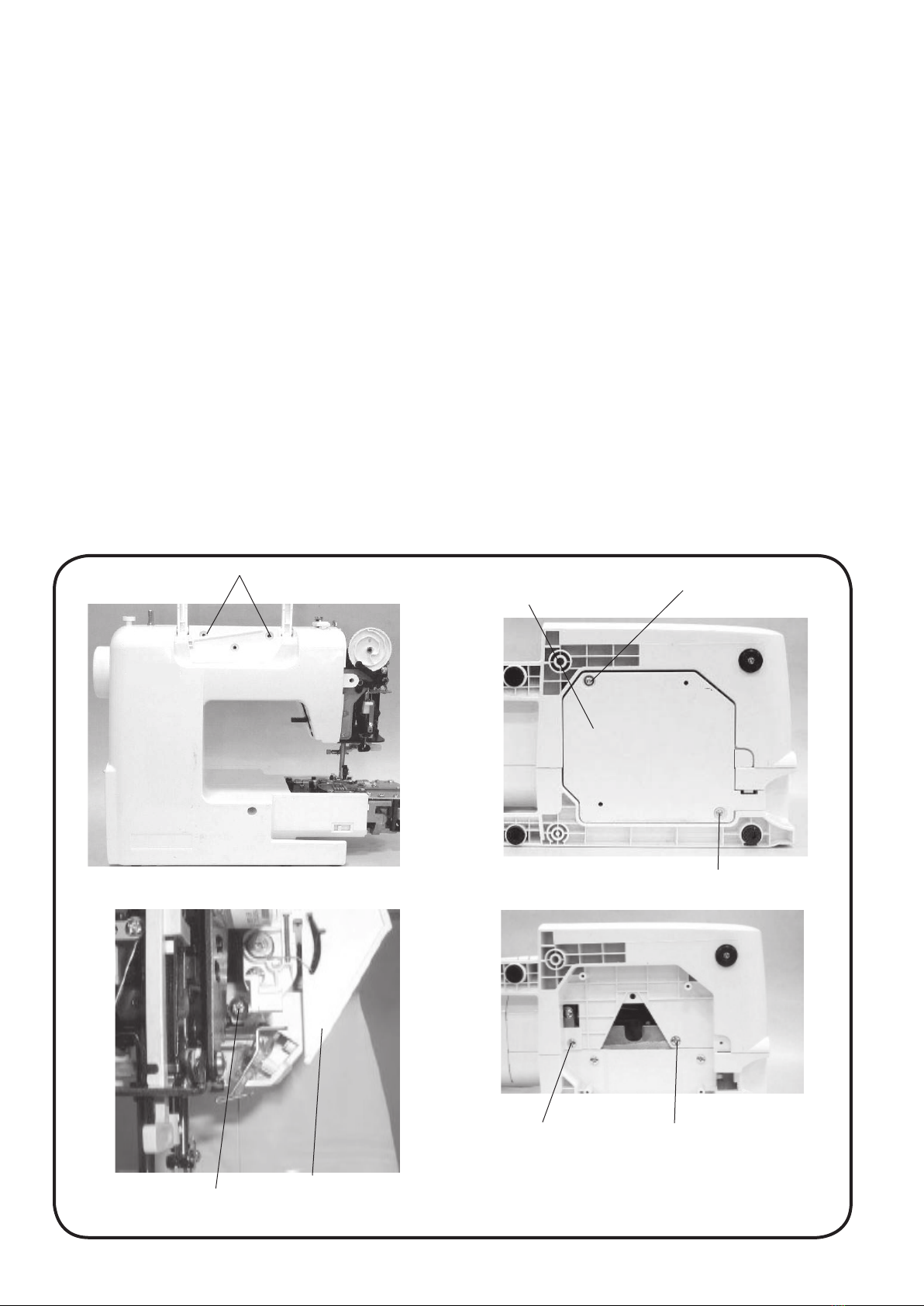

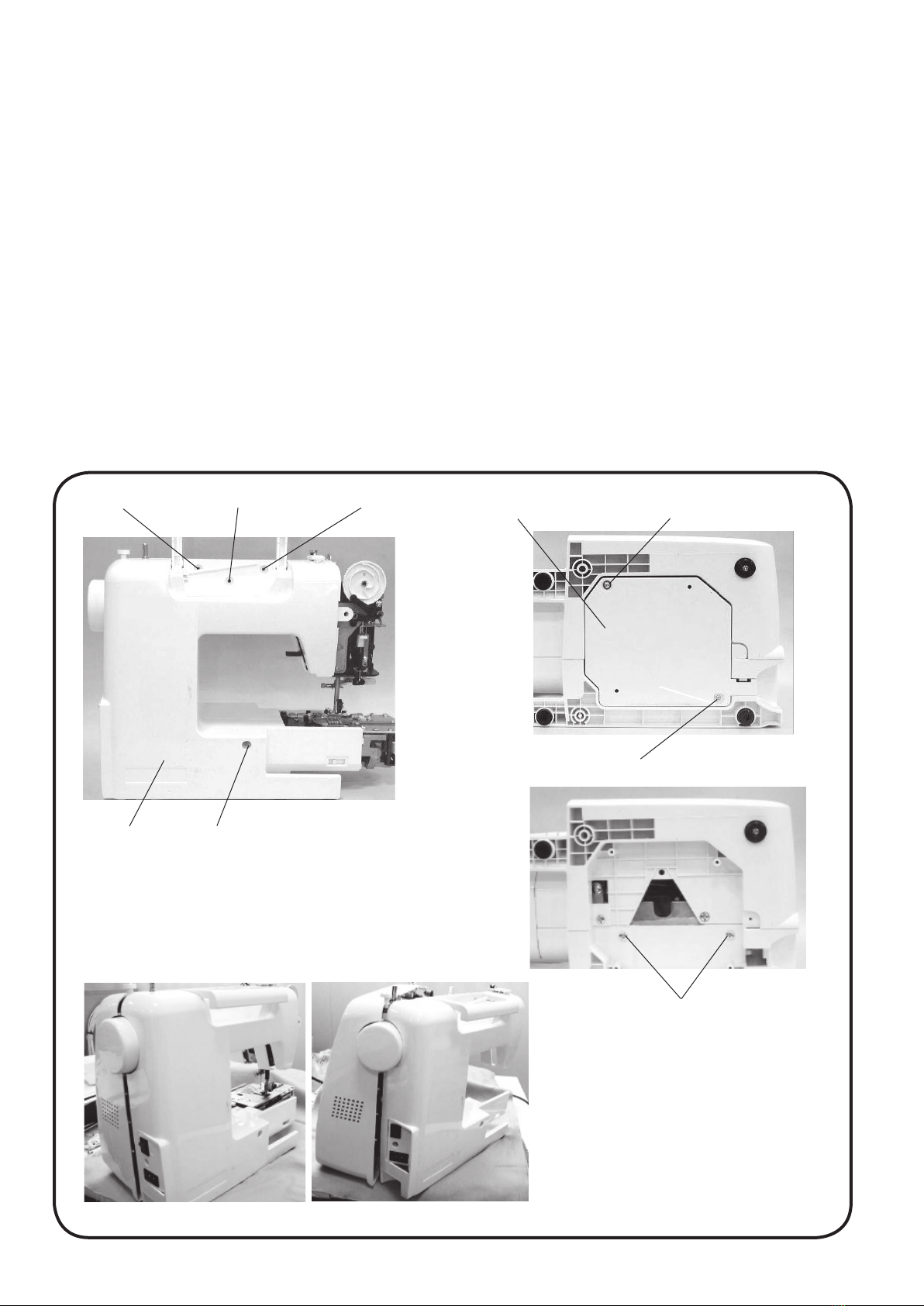

CHANGING EXTERNAL PARTS

FACE COVER ........................................................................................................................... 4

FREE ARM COVER ................................................................................................................. 5

FRONT COVER ............................................................................................................... 6 to 7

REAR COVER......................................................................................................................... 8

MECHANICAL ADJUSTMENT

PRESSER BAR HEIGHT ........................................................................................................ 9

NEEDLE DROP POSITION..................................................................................................... 10

ADJUSTMENT OF HOOK TIMING ......................................................................................... 11

ADJUSTMENT OF NEEDLE BAR HEIGHT ........................................................................... 12

CLEARANCE BETWEEN NEEDLE AND TIP OF HOOK ROTARY ........................................ 13

FEED DOG HEIGHT ............................................................................................................... 14

FEED DOG ADJUSTMENT ..................................................................................................... 15

TOP TENSION ........................................................................................................................ 16

REPLACING THE ELECTRONIC COMPONENTS

CIRCUIT BOARD-A CONNECTION........................................................................................ 17

SELF-DIAGNOSTIC TEST.............................................................................................. 18 to 22

CIRCUIT BOARD-A........................................................................................................ 23 to 24

DRIVING MOTOR ................................................................................................................... 25

SWITCHING REGULATOR UNIT ........................................................................................... 26

ADJUSTING BUTTONHOLE LEVER POSITION.................................................................... 27

PARTS LIST................................................................................................................... 28 to 41