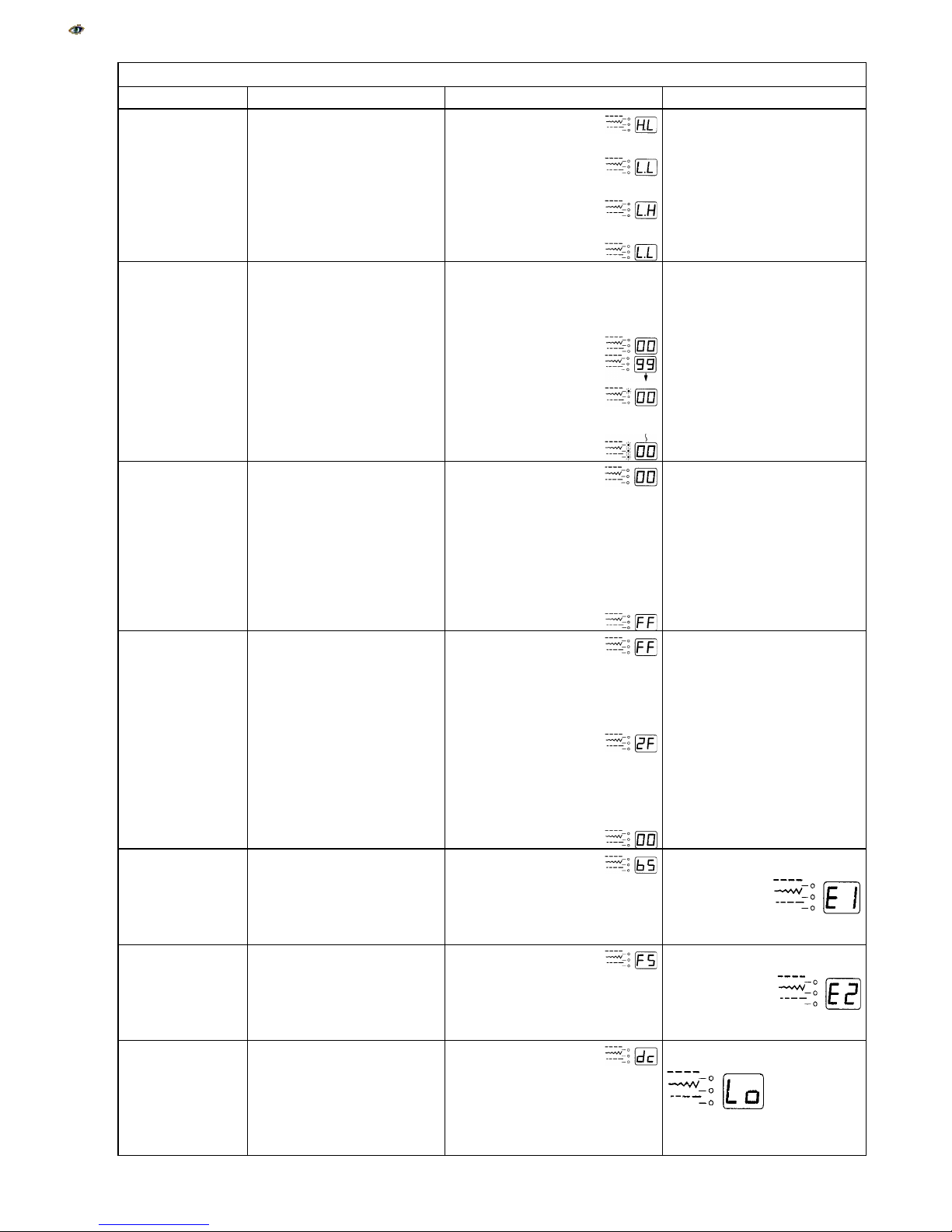

SELF DIAGNOSTIC SHEET

STEP PROCEDURE CORRECT CONDITION DEFECTIVE CONDITION

01

7 Segment LED Turn on the power switch while

simultaneously pressing the

needle up/down button and the

reverse button.

Press the reverse button five

times to select menu item “6”.

Press the needle up/down

button: the LED indicates “01”

for one second.

If you don’t press the reverse

button within 2.5 seconds, the

machine automatically reverts

to normal sewing mode.

•

Beep sounds when the buttons

are pressed.

•

LED displays “8.8”, and blinks in

1-sec intervals.

•

No beep sound.

•

Does not enter

Self-Diagnostic mode.

•

LED does not blink on or

off.

1. Replace A-board.

02

MODE LED Press needle up/down button,

LED displays “02” for one

second.

7-segment LED displays “Ld”.

3 mode LED blink in 1-sec.

intervals.

•

LED does not blink.

1. Replace A-board

03

SWITCH Press needle up/down button,

LED displays “03” for one

second.

Press buttons S1to S8.

•

LED indicates [-----].

•

Button number is displayed

when the button is pressed.

•

•

LED display is different

from that shown to the left.

•

1. Replace A-board.

04

BOBBIN

WINDER

SWITCH

Press needle up/down button,

LED displays “04” for one

second.

•

Move the bobbin winder

spindle to the right.

•

Return it to the left.

LED indicates”II” LED display is different from that

shown to the left.

1. Adjust bobbin winder

switch position.

2. Replace bobbin winder

switch.

3. 3. Replace A-board.

05

NOT

APPLICABLE

TO THIS

MODEL

Skip this step by pressing the

needle up/down button.

06

BUTTONHOLE

SENSOR

Press needle up/down button,

LED displays “06” for one

second.

1. Lower the buttonhole lever.

2. Move the buttonhole lever

back and forth.

When the buttonhole lever

is pulled, LED displays “H”.

When the buttonhole lever

is free (center).

When the buttonhole lever

is pushed LED displays H.

LED display is different from that

shown to the left.

1. Adjust the buttonhole sensor

position.

2. Replace buttonhole sensor.

3. Replace A-board.

6