BCU 480 · Edition 06.07

2

t= To be continued

Contents

Burner control units BCU 480 ....................... 1

Contents........................................2

1 Application.....................................4

2 Examples of application ..........................6

2.1 Stage-controlled main burner with alternating

pilot burner ......................................6

2.2 Stage-controlled main burner with permanent

pilot burner ......................................7

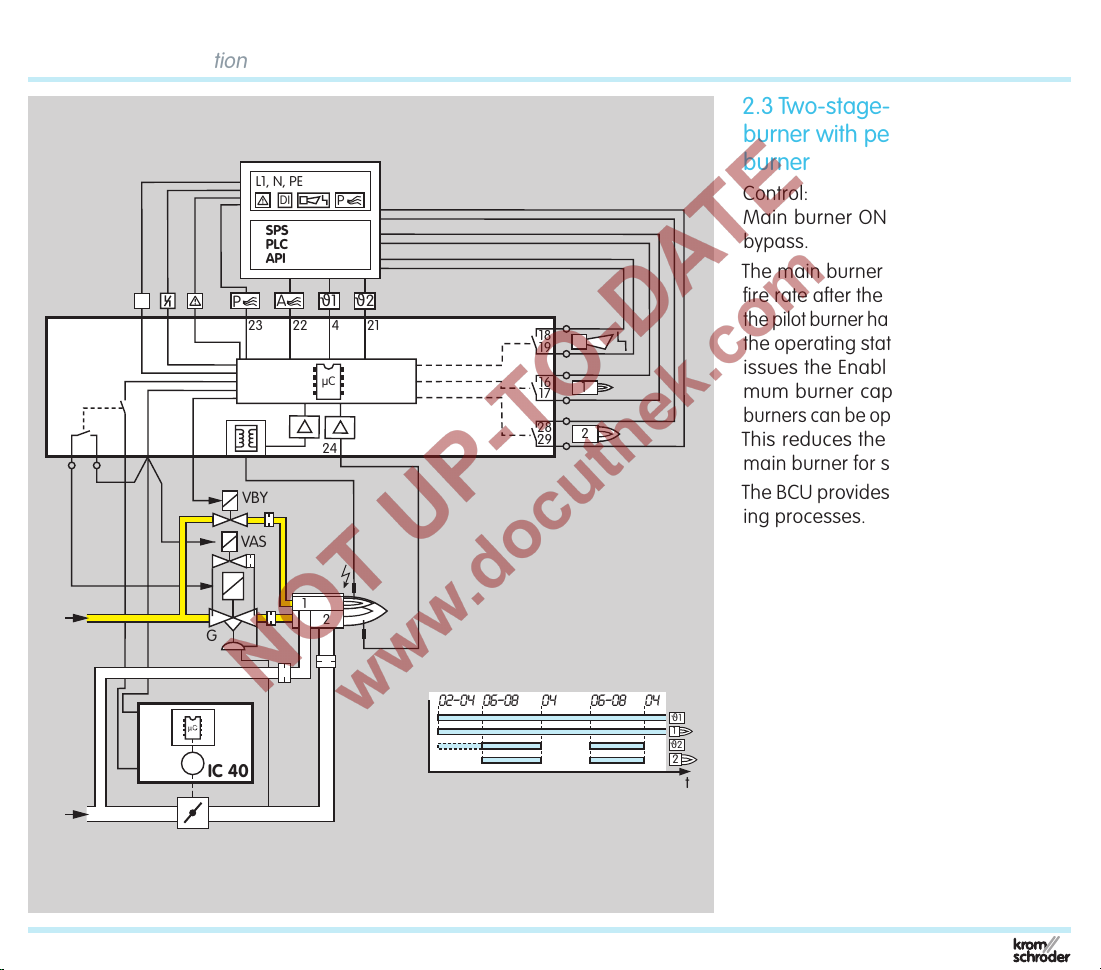

2.3 Two-stage-controlled main burner with permanent

pilot burner ......................................8

2.4 Modulating-controlled burner ....................9

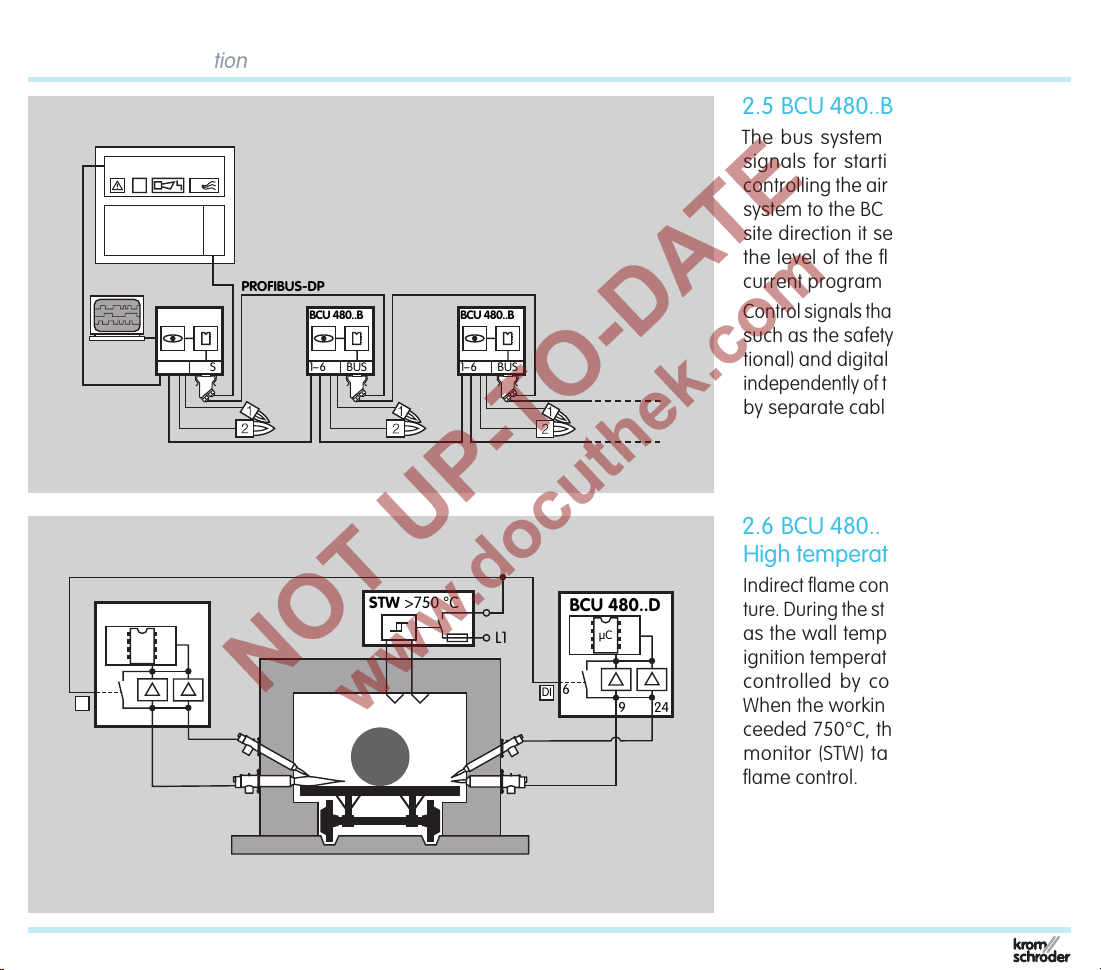

2.5 BCU 480..B1 for PROFIBUS-DP ...................10

2.6 BCU 480..D:High temperature equipment .........10

3 Certification ....................................11

3.1 EC type-tested and certified ......................11

3.2 AGA .........................................11

3.3 FM ..........................................11

3.4 Profibus User Organisation ......................11

4 Function...................................... 12

4.1 Connection diagrams ..........................12

4.1.1 BCU 480.........................................12

4.1.2 BCU 480..B1 with Profibus ..........................13

4.1.3 BCU 480..P with 16-pin industrial plug connector .......14

4.2 BCU 480 program sequence ....................16

4.3 Program status and fault messages ..............19

5 Parameters ...................................20

5.1 Scanning the parameters . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Flame control.................................22

5.2.1 Flame signal, pilot burner ......................... 22

5.2.2 Flame signal, main burner ........................ 22

5.2.3 Program status when the most recent fault occurred .. 22

5.2.4 Switch-off threshold of the flame amplifier ........... 22

5.2.5 High temperature operation in the case of BCU..D2 or

BCU..D3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2.6 UVS check...................................... 26

5.3 Pilot and main burner monitoring ................27

5.3.1 Permanent pilot burner ........................... 28

5.3.2 Interrupted pilot burner ........................... 28

5.4 Behaviour in start-up position/standby............29

5.4.1 Flame simulation check in start-up position/standby ... 29

5.4.2 Minimum burner pause time tBP ................... 30

5.5 Behaviour during start-up ......................31

5.5.1 Safety time on start-up tSA ..........................31

5.5.2 Flame proving period tFS ......................... 32

5.5.3 Minimum combustion time tB..................... 32

5.5.4 Burner start-up attempts.......................... 33

5.6 Behaviour during operation .....................35

5.6.1 Safety time during operation tSB for pilot and

main burners........................................ 35

5.6.2 Fault lock-out or restart, pilot burner ................ 35

5.6.3 Immediate fault lock-out following flame failure....... 35

5.6.4 Fault lock-out or restart, main burner.................37

5.7 Air valve control on BCU..L ......................39

5.7.1 Purge .......................................... 39

5.7.2 Cooling in start-up position/standby ................ 39

5.7.3 Burner start..................................... 39

5.7.4 Air valve opens in the case of external activation

(not during start-up) .................................. 40

5.7.5 Air valve opens in the case of external activation

(even during start-up) ..................................41

5.7.6 Air valve opens with valve V2 ...................... 42

5.7.7 Air valve opens with operating signal ............... 43

5.7.8 Low fire over run time tKN after a normal shut-down ... 44

5.7.9 Behaviour of the air valve in the event of a

fault lock-out ........................................ 45

5.8 Manual mode ................................46

5.8.1 Manual mode limited to 5 minutes.................. 46