BA-en-2088-2207_ES60 7

• If electrically conductive substrates or substrates coated with conduc-

tive material (e.g. metal foil or metal composites) are used, the mains

supply must be interrupted (see chapter 4.2 "Operating mode with con-

ductive substrats”, page 13).

•Before carrying out any work involving the units, the machine which has

the units fitted must not be in operation (see chapter 5 "Maintenance”,

page 14, chapter 6 "Trouble-shooting”, page 15).

• Any work involving the units must be carried out by qualified electrici-

ans (see chapter 5 "Maintenance”, page 14, chapter 6 "Trouble-shoo-

ting”, page 15).

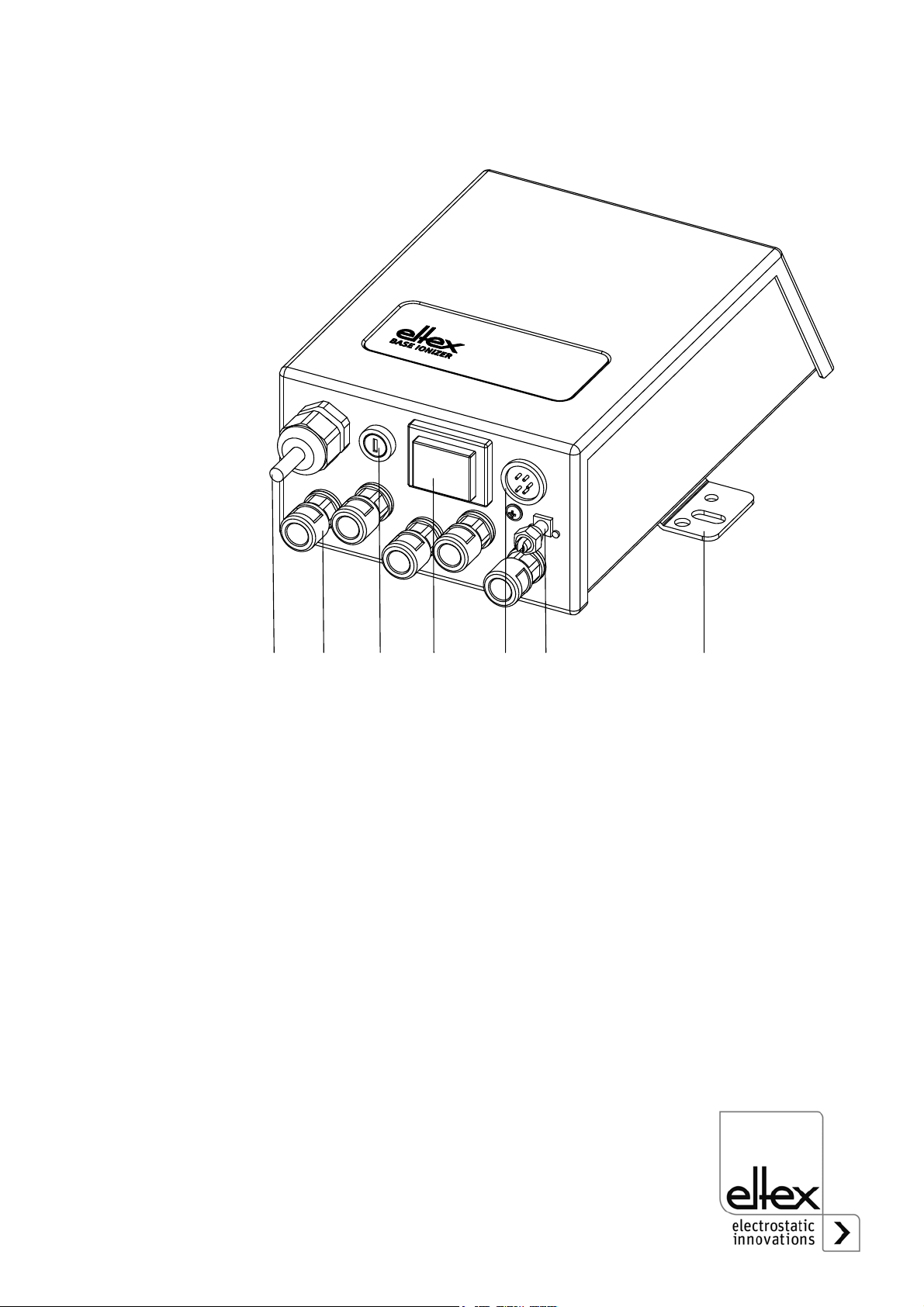

• Before starting the unit make sure that the appliance is permanently

grounded via the grounding terminal (5, Fig. 1). The ground cable

should have a minimum cross section of 1.5 mm2(see chapter 3.2

"Ground connection”, page 10).

• Check the power supplies and the discharging bars at regular intervals

for any damage to the electrical wiring and the high voltage cables. Any

damaged components must be repaired or replaced before continuing

to operate the units.

• If the housing cover is removed and the supply voltage is switched on

at the same time, contact protection is no longer effective. Always dis-

connect the power before opening the power supply units.

• The protection class IP54 only applies if the housing cover is closed

and the cable connections are shrouded.

• Connect/disconnect the discharging bars only if the power supply unit is

switched off (see chapter 3.4 "Connecting the high voltage cable”,

page 10).

• In applications involving moving bars, the high voltage cable must be

attached such that there is no cable movement near the connection

zone of the power supply unit (see chapter 3.4 "Connecting the high

voltage cable”, page 10).

• Both the lengths of the high voltage cable and of the active bars are

limited, observe maximum lengths (see chapter 3.5 "Maximum active

bar length and length of the high voltage cable”, page 11).

•To ensure that no voltage is supplied to the bars when the material web

is at rest, enabling the supply voltage to the power supply via machine

contact is recommended. If the material web is at rest, or if the machine

is not in operation, no high voltage is supplied to the bars in this case

(see chapter 3.6 "Connecting the supply voltage”, page 12).

•Before starting up the power supply the user must make sure that the

power supply and the bars have been installed and assembled cor-

rectly. The supply voltage can then be switched on (see chapter 4.1

"Startup”, page 13).