2

Electronic unit Type 12B2 for series 1200 panels

INTRODUCTION

With the Digit Digit 2 Wires electronic unit Type 12B2 it is possible to

build series 1200 audio panels with alphanumeric keyboard and dis-

play complete with 2-line, 16-character each, display.

The electronic units are to be used with series 1200 plates and

components, supplied separately.

Selection of the elements starts with the plate for the standard electro-

nic unit, continuing with the addition of any extra plates that make it

possible to expand the standard modules. To complete the panel, the

box and frame versions are selected according to the type of panel

installation; surface wall-mounted or flush-mounted.

DESCRIPTION

Type 12B2 corresponds to the electronic unit for building an electronic

audio plate with alphanumeric keyboard and display.

This unit provide the facility to create exclusively audio door entry instal-

lations with only 2 polarised wires to the cable riser.

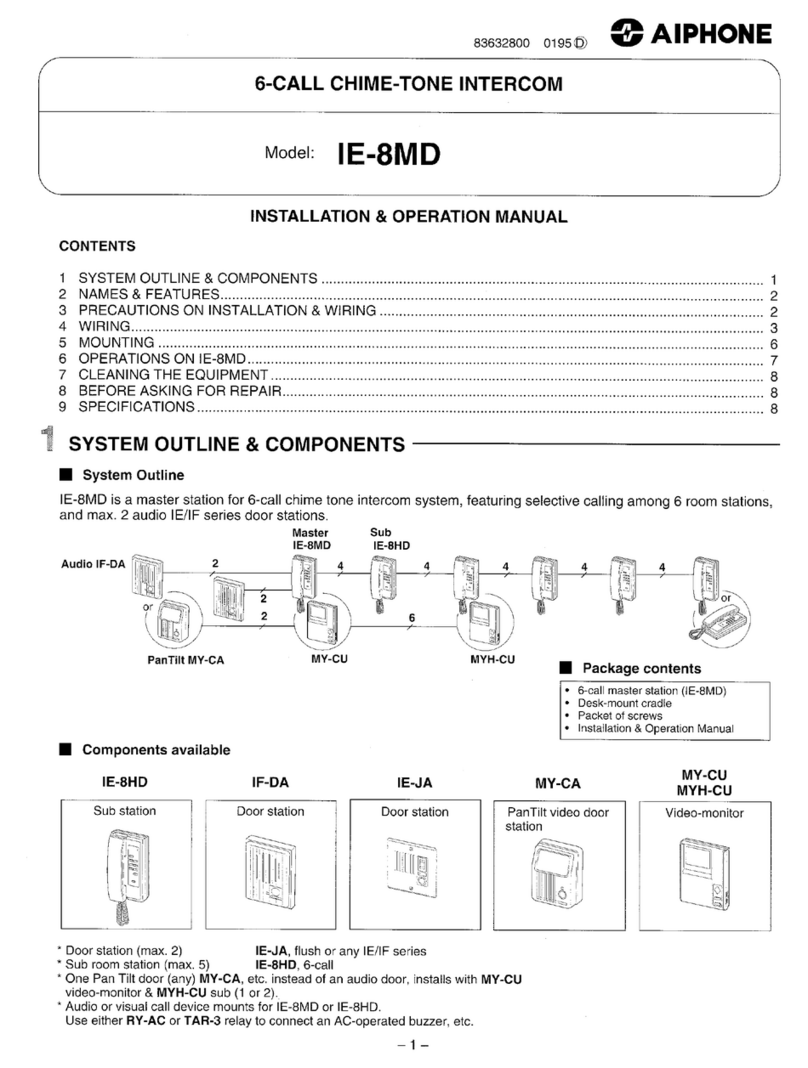

The entrance panels are designed to operate either alone or together

with other entrance panels by interconnecting the specific terminal

boards; a maximum of 2 additional panels can be connected in parallel

with the main panel by adding one additional wire from one entrance

panel to the next. (no more than 3 panels per installation).

Electronic entrance panels can also generate different call codes by

means of the numerical keypad, with values from 1 to 9999. A maximum

of 200 users can be configured in the system.

Facility to connect one interphone to another interphone with the same

call (max. 2 interphones connected in parallel).

The front of the panels feature "External Volume - 2", "Internal Volume

- 3" and "Audio Balance - 1" controls, which are preset in the factory. If

necessary we recommend exclusively adjustment of "External Volume"

and, if necessary, adjustment of "Balance" in the case of feedback on

the speech unit, turning the specific trimmer slightly clockwise or anti-

clockwise until the feedback howl is eliminated. In addition, the entran-

ce panel can be programmed directly from the keypad for the technical

parameters programming phase.

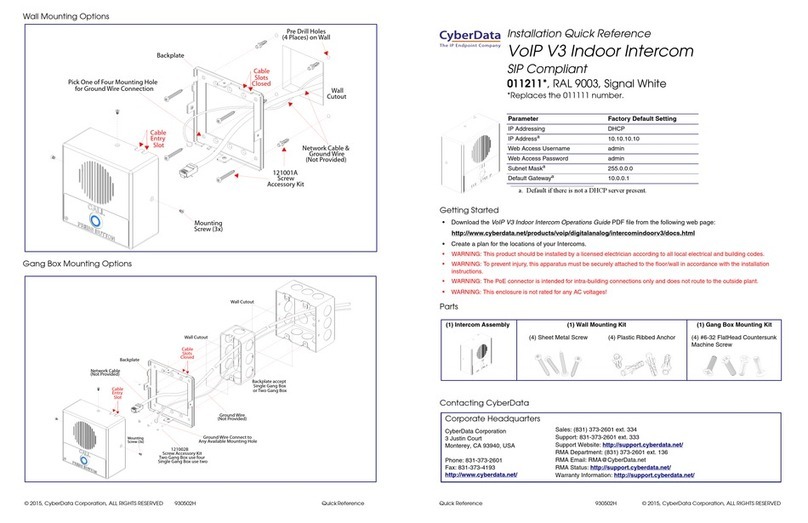

INSTALLATION

The assembling and the installation of the electronic units for the 1200

series plates require the following phases:

1- Define the plate for the electronic base unit and possible additional

plates (see components on page 3).

2- Define the back boxes and the frames for the surface wall-mount or

flush-mount installation (see accessory on page 4).

3- Install the flush-mounted wall box or surface-mounted wall box at

suitable height. Route the wires through the hole at the bottom of the

box.

4- Fix the rainproof cover on the back box.

5- Fix the terminal box of the base module to the module holder frame

of the entrance panel.

6- Connect the terminal block to the system as shown in the wiring dia-

gram.

7- Fix the module holder frame to the back boxes

8- Connect the electronic unit of the base module to the plates with

name-tags.

9- Insert the electronic unit and the additional modules in the module

holder frame of the entrance panel.

10-Insert the microphone of the electronic base unit in the module hol-

der frame of the entrance panel (Fig. 8, Part 1).

11- Program the entrance panel.

12- Insert the external plate of the electronic unit in the module holder

frame and the additional entrance panels in the remaining module

holder frames.

13- Close the panel

BASIC MODULES

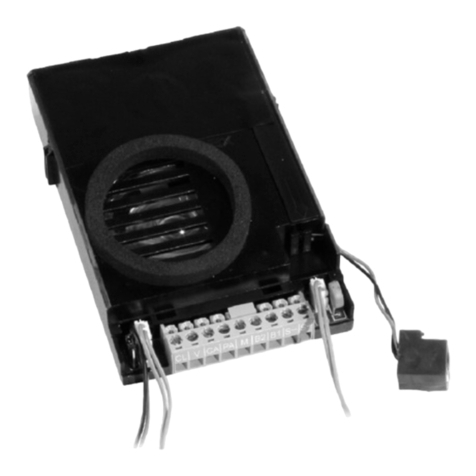

The basic modules comprise: an electronic unit and a connection termi-

nal block. The electronic unit is equipped with a speech unit, a backlit

alphanumeric display, a keypad, and wiring for connecting the terminal

block.

SAFETY INSTRUCTIONS / INTRODUCTION

SAFETY INSTRUCTIONS FOR INSTALLERS

- Carefully read the instructions on this leaflet: they give important infor-

mation on the safety, use and maintenance of the installation.

- After removing the packing, check the integrity of the set. Packing

components (plastic bags, expanded polystyrene etc.) are dangerous

for children. Installation must be carried out according to national safe-

ty regulations.

- It is convenient to fit close to the supply voltage source a proper bipo-

lar type switch with 3 mm separation (minimum) between contacts.

- Before connecting the set, ensure that the data on the label corre-

spond to those of the mains.

- Use this set only for the purposes designed, i.e.for electric door-open-

er systems. Any other use may be dangerous. The manufacturer is not

responsible for damage caused by improper, erroneous or irrational

use.

- Before cleaning or maintenance, disconnect the set.

- In case of failure or faulty operation, disconnect the set and do not

open it.

- For repairs apply only to the technical assistance centre authorized by

the manufacturer.

- Safety may be compromised if these instructions are disregarded.

- Do not obstruct opening of ventilation or heat exit slots and do not

expose the set to dripping or sprinkling of water.

- Installers must ensure that manuals with the above instructions are left

on connected units after installation, for users' information.

- All items must only be used for the purposes designed.

WARNING: to avoid the possibility of hurting yourself, this unit must be

fixed to the wall according to the installation instructions.

- This leaflet must always be enclosed with the equipment.

Directive 2002/96/EC (WEEE)

The crossed-out wheelie bin symbol marked on the product indicates that

at the end of its useful life, the product must be handled separately from

household refuse and must therefore be assigned to a differentiated col-

lection centre for electrical and electronic equipment or returned to the

dealer upon purchase of a new, equivalent item of equipment.

The user is responsible for assigning the equipment, at the end of its life,

to the appropriate collection facilities.

Suitable differentiated collection, for the purpose of subsequent recycling

of decommissioned equipment and environmentally compatible treat-

ment and disposal, helps prevent potential negative effects on health and

the environment and promotes the recycling of the materials of which the

product is made. For further details regarding the collection systems

available, contact your local waste disposal service or the shop from

which the equipment was purchased.

Risks connected to substances considered as dangerous (WEEE).

According to the WEEE Directive, substances since long usually used on

electric and electronic appliances are considered dangerous for people

and the environment. The adequate differentiated collection for the sub-

sequent dispatch of the appliance for the recycling, treatment and

dismantling (compatible with the environment) help to avoid possible

negative effects on the environment and health and promote the recy-

cling of material with which the product is compound.