EM LABS CR Series User manual

OPERATION MANUAL

CR Series split cylinder resonator

EM LABS INC.

April 6, 2020

1

Table of Contents

1. Product Overview.............................................................................................................2

Appearance and structure of the resonator..........................................................................2

Product specifications..........................................................................................................3

Accessories...........................................................................................................................3

2. Measurement....................................................................................................................4

Sample preparation..............................................................................................................4

About sample size.............................................................................................................4

About thickness measurement .........................................................................................5

Measurement procedure......................................................................................................6

Before starting measurement ...........................................................................................6

Instrument connection.....................................................................................................6

For accurate measurement ...............................................................................................7

3. Maintenance and Repairs.................................................................................................8

Health check with stable samples.........................................................................................8

Daily cleaning ......................................................................................................................8

Simple troubleshooting........................................................................................................8

Repair...................................................................................................................................8

First Edition: April 6, 2020

2

1. Product Overview

This section outlines the product.

CR series split cylinders are designedto be used with a network analyzer and measure complex

relative permittivity of dielectric materials. In order to accurately measure low permittivity

and low loss materials, the loss of the resonator is designed and manufactured extremely small.

In addition, since the sample can be easily inserted/removed, you can efficiently measure

samples. Measurement can proceed according to the instructions of the permittivity

measurement software.

Appearance and structure of the resonator

As shown in the figure below, the part where the resonator is split into two is the sample

insertion space. There are two coaxial connectors on the side for connecting the network

analyzer. By inserting the measurement sample, then tilting the fixing lever, the sample is

firmly fixed, which enables reproducible measurement.

3

Product specifications

Model number

Resonance characteristic

Connector type

Frequency (GHz)

Un-loaded Q

Mode

CR-710

10

20,000

TE011

2.92 mm(f)

CR-720

20

14,000

CR-724

24

14,000

CR-728

28

14,000

CR-735

35

10,000

CR-740

40

10,000

CR-750

50

7,000

2.4 mm(f)

CR-760

60

6,000

1.85 mm(f)

CR-780

80

6,000

1 mm(f)

Operating temperature: 0 to 40℃

Accessories

There is no accessory. Proper coaxial cables are required for analyzer connection according

to the network analyzer to be used.

4

2. Measurement

This section provides measurement tips.

Sample preparation

It is necessary to prepare the measurement sample into a plate shape according to the fixture

to use. Since the thickness of the sample is used to calculate permittivity, it is important to

accurately measure the thickness. Also, in order to accurately measure the thickness, it is ideal

that the sample is flat and uniform. It is the first step of accurate measurement to properly

prepare the sample.

About sample size

The optimum thickness of the sample depends on the dielectric properties of the sample and

the resonator to be used, but 100 μm is a good starting point. In addition, it is necessary to

cut the materials properly so that it fits well in the fixture. The higher the frequency and the

higher the permittivity, the thinner the sample needs to be. For example, a lower permittivity

(2.5) material with 100μm thickness is appropriate up to 80 GHz.

The following chart shows typical maximum measurable thickness vs. permittivity and

frequency. Please note that the sample may need to be significantly thinner if the material has

relatively high loss (tanδ>0.01). It is recommended to prepare a sample as thin as possible if

the measurement software cannot find resonance, and thus cannot measure.

5

It is also necessary to cut the materials properly so that it fits well in the fixture. The

following table provides the proper sample size for the resonators.

Resonator

Short side(mm)

Long side (mm)

10 GHz

58 –63

70 - 80

20 - 80 GHz

30 –35

40 –50

About thickness measurement

When actually measuring permittivity, you need to input sample thickness according to the

measurement software instruction. It is recommended to measure the sample thickness in

advance. Since the error of the input value causes the error of the permittivity measurement,

accurate measurement is necessary.

It is generally recommended to measure three or more points with a micrometer, and use

the average value. In that case, it is important to measure the thickness of the part used for

permittivity measurement. The figure and table below show the position of the part to be

measured.

Model

Radius r (mm)

CR-710

20

CR-720

10

CR-724

8

CR-728

7.5

CR-735

6

CR-740

5

CR-750

4

CR-760

3.5

CR-780

2.5

6

Measurement procedure

Start the permittivity measurement software and follow the instructions on the screen to

perform the measurement. Please refer to the software manual for detailed procedure. This

section focuses on key points to know on the hardware operation for proper measurement.

Before starting measurement

Before starting the permittivity measurement software and starting the actual measurement,

please make sure that the following preparation has been completed.

・The temperature of the resonator is stable. It is recommended to start measurement at

least 30 minutes after setting the fixture in the actual measurement environment.

・The network analyzer has been warmed up. (Follow the recommended warm-up time of

the network analyzer)

・The size of the samples has been measured and recorded.

・A torque wrench and spanner for connector connection must be prepared. Tweezers and

gloves for handling samples are prepared, if necessary.

Instrument connection

Connect the split-cylinder resonator to the network analyzer to measure permittivity. Since

the connector type varies depending on the frequency band, please use the appropriate cable

respectively. The type of connector is described in the product specifications.

NOTE

It is important to use a torque wrench to apply proper torque when

tightening the connector. Excessive torque can damage the connector.

Torque shortage causes measurement errors and rotation of the center

conductor, which can damage the connector. Also, be careful to rotate

only the nut of the male connector. Rotating the center conductor

leads to wear and damage of the connector.

7

For accurate measurement

The split cylinder resonator is designed and manufactured to measure permittivity with high

accuracy. There are some key points in order to make full use of its performance.

About particles on sample surface

If particles adhere to the surface of the sample, the space between the resonators when the

sample is sandwiched is widened accordingly. Since the distance between the resonators

affects the resonance frequency, it causes an error in permittivity measurement.

This effect is particularly significant in thin film measurement. Wipe the surface with a

nonwoven fabric before measuring the sample. If there is a possibility that particles attached

to the sample may be transferred to the sample insertion space of the resonator, gently

sandwich the nonwoven fabric with a small amount of alcohol and then pull it up for cleaning.

About cables

Minimize the cable movement during measurement. Also, minimize the movement of the

resonator.

8

3. Maintenance and Repairs

This section explains daily maintenance and simple troubleshooting.

Health check with stable samples

It is recommended to periodically measure samples with stable characteristics and check the

condition of the measurement system.

Daily cleaning

The split cylinder is basically maintenance free. If the surface of the sample insertion space

becomes contaminated due to transfer from the sample etc., gently sandwich the nonwoven

fabric with a small amount of alcohol then pull it up for cleaning.

NOTE

Do not disassemble the fixture for cleaning as it may cause malfunction.

Especially, do not touch the inside of the resonator. Performance may

deteriorate greatly.

Simple troubleshooting

This section explains what to do when an error occurs in the measured value. Please make

sure that the cable is securely connected. Clean the surface of the sample insertion space

according to Daily cleaning. If the problem remains, then the fixture needs to be repaired.

Repair

If repair is necessary, contact us directly from our website.

https://www.emlabs.jp

This manual suits for next models

9

Table of contents

Popular Measuring Instrument manuals by other brands

Tractel

Tractel Handifor 20 Operating and maintenance instructions

Fuji Electric

Fuji Electric ZFK8 Series instruction manual

International Light Technologies

International Light Technologies ILT1700 instruction manual

Keysight

Keysight N2818 user guide

CDR

CDR SLB222 Short guide

SMP

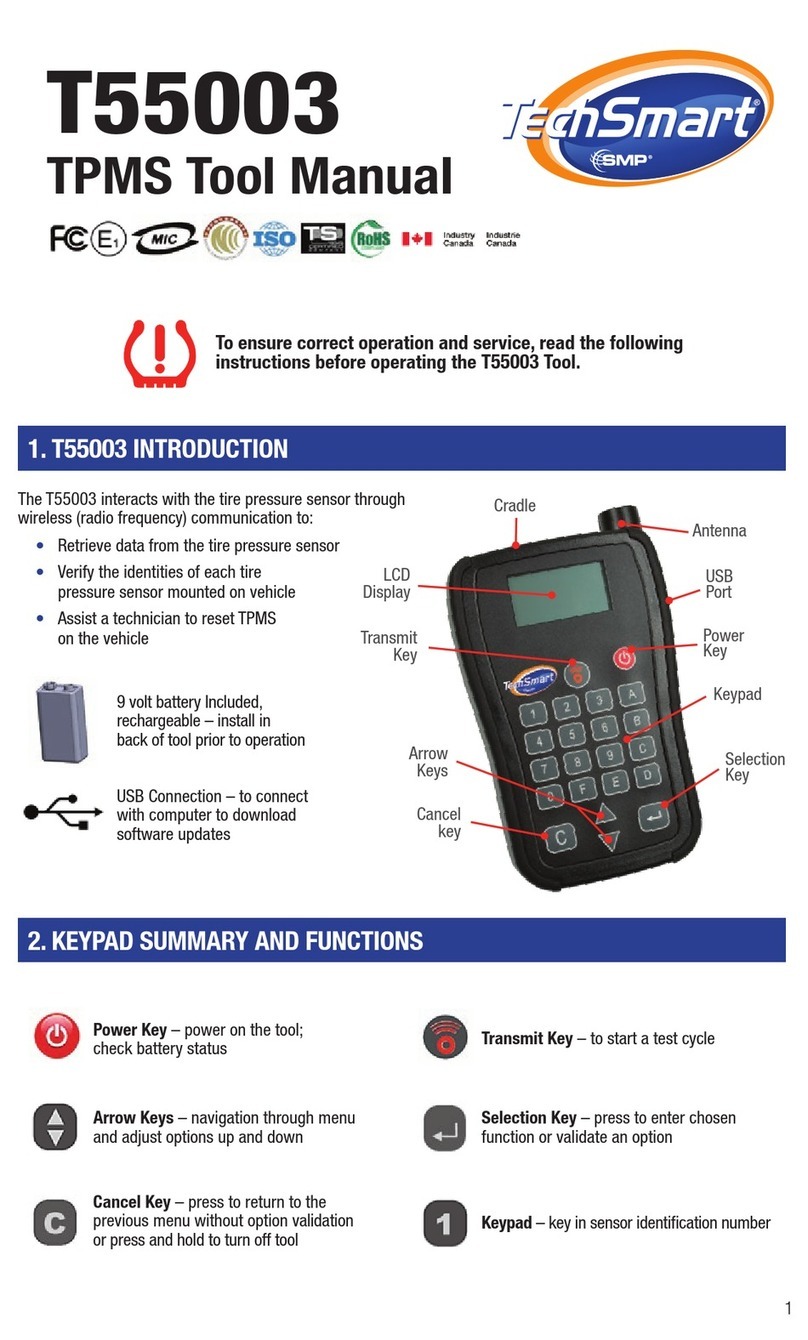

SMP TechSmart T55003 manual

FMT Swiss AG

FMT Swiss AG 23295 operating instructions

Panametrics

Panametrics DigitalFlow DF868 Programming manual

Fritsch

Fritsch PULVERISETTE 7 EASY GTM operating instructions

YOKOGAWA

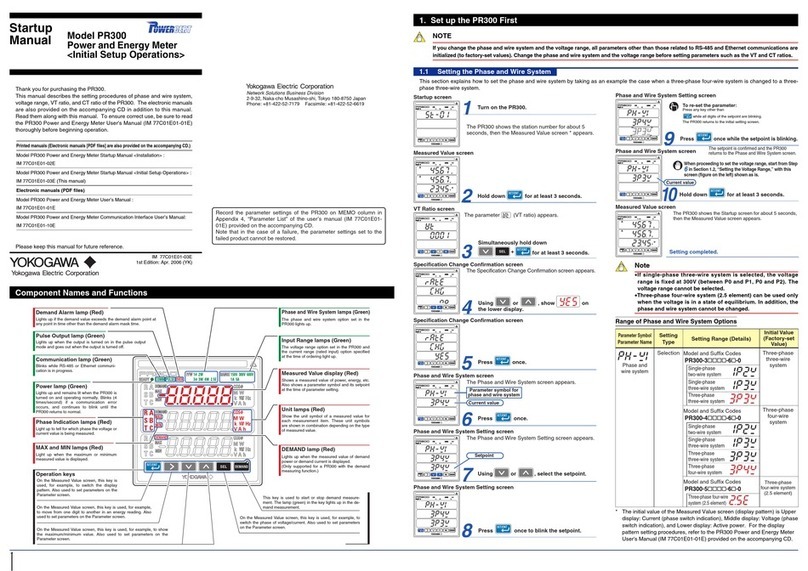

YOKOGAWA PR300 Startup manual

Leica Geosystems

Leica Geosystems DISTO D810 quick start

Kobold

Kobold MIM Series operating instructions