9.3.1. What is degassing?.......................................................................................... 31

9.3.2. Setting the degassing time............................................................................... 31

9.3.3. Degassing operation ........................................................................................ 31

9.4. Filament Change.............................................................................................................. 32

9.4.1. Cautions in operation....................................................................................... 32

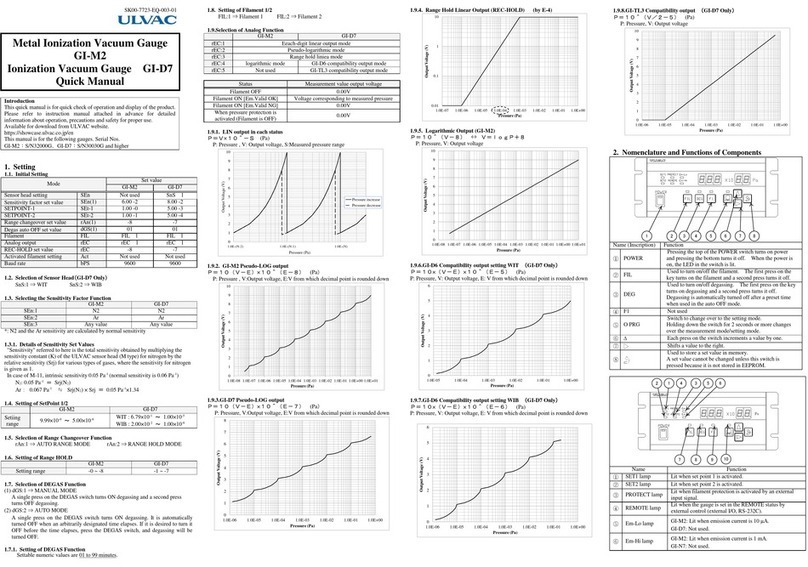

9.5. Changing over Recorder Output...................................................................................... 33

9.5.1. Setting of recorder mode ................................................................................. 33

9.5.2. Measurement value output in each status........................................................ 33

9.5.3. LIN output....................................................................................................... 33

9.5.4. LOG output ..................................................................................................... 35

9.5.5. Resolution and output period........................................................................... 36

10. EXTERNAL INPUTS/OUTPUTS.................................................................................. 37

10.1. Set Point Output .............................................................................................................. 37

10.2. Option Board ................................................................................................................... 38

10.3. EXT-I/O Connector......................................................................................................... 39

10.4. External Digital Output ................................................................................................... 40

10.5. External Control Input..................................................................................................... 43

10.6. Method of External Control............................................................................................. 45

11. HOW TO USE COMMUNICATION (RS-232C) .......................................................... 46

11.1. Communication Specifications........................................................................................ 46

11.1.1. Key specifications ........................................................................................... 46

11.1.2. Baud rate setting.............................................................................................. 46

11.1.3. Communication cable/connector..................................................................... 46

11.2. List of Commands ........................................................................................................... 47

11.3. Explanation of Command Action.................................................................................... 48

11.3.1. Changing over remote/local control ................................................................ 48

11.3.2. Reading the emission valid signal................................................................... 48

11.3.3. Control of filament.......................................................................................... 48

11.3.4. Control of degassing........................................................................................ 48

11.3.5. Reading the gauge status ................................................................................. 49

Setting sensitivity factor.................................................................................. 49

11.3.7. Setting specific sensitivity factor..................................................................... 49

11.3.8. Setting and reading the setpoint ...................................................................... 49

11.3.9. Reading the measured pressure value.............................................................. 50

11.3.10. Reading the external protection status............................................................. 50

11.3.11. Setting of filter................................................................................................. 50

11.3.12. Control of offset .............................................................................................. 50

11.3.13. Reading the controller status ........................................................................... 50

11.3.14. Error resetting.................................................................................................. 51

11.3.15. Setting the recorder output .............................................................................. 51

11.4. Cautions in Operation...................................................................................................... 51

12. TROUBLESHOOTING .................................................................................................. 52

12.1. Cause and measures where emission current doesn’t flow.............................................. 59

12.2. About the malfunction indication.................................................................................... 59

13. APPENDIX ..................................................................................................................... 60

13.1. Principles of Operation.................................................................................................... 60

13.1.1. Basic structure of ion gauge ............................................................................ 60

13.1.2. Problems of ion gauge..................................................................................... 61

13.1.3. Axial symmetric transmission (AT) gauge...................................................... 62

13.1.4. Micro current measurement............................................................................. 63

13.2. Types of Measurable Gas and Specific Sensitivity ......................................................... 64

14. APPENDIX: TEST MODE............................................................................................. 66

15. WARRANTY.................................................................................................................. 67

16. EC DECLARATION OF CONFORTMITY................................................................... 68

17. China RoHS Declaration ................................................................................................. 69

18. CERTIFICATE OF DECONTAMINATION ................................................................. 70

19. RELATED DRAWINGS ................................................................................................ 71