Embedded Planet epConnected Vehicle Operational manual

www.embeddedplanet.com

Embedded Planet Inc. | v1.0.0 | 25 Feb 2022

epConnected Vehicle

4G LTE-M Cellular Modem + GNSS, CAN interface, I/O, Bluetooth, & Sensors

Product User Manual

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 1 of 39

About This Manual

The epConnected Vehicle User Manual provides detailed information encompassing the design,

description, and integration of the epConnected V device. For elaboration on drawings, software, or other

specific product details there may be other sources of information to which this document points as reference.

For the latest documentation, including document & certification updates, please always refer to the Embedded

Planet documentation page: https://www.embeddedplanet.com/product-documentation

Product Web Page

The epConnected Vehicle product page by Embedded Planet provides description & resources related

to this product. This page can be located at https://www.embeddedplanet.com/connected-vehicle

Acrynyms & Abbreviations

Term Description

EPI Embedded Planet, Inc.

ToF Time-of-Flight

IoT Internet of Things

PCBA Printed Circuit Board Assembly

epCV epConnected Vehicle

I/O Inputs/Outputs

GPIO General Purpose Inputs / Outputs

IC Integrated Circuit [component]

BT Bluebooth

BLE Bluetooth Low Energy

IMU Inertial Measurement Unit [sensor]

LiPo Lithium-Ion Polymer

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 2 of 39

Contents

1. Introduction ...................................................................................................................................................... 4

2. Orderable Part Numbers .................................................................................................................................. 5

3. Additional Resources ......................................................................................................................................... 6

4. Feature Callouts ................................................................................................................................................ 7

4.1. Feature Callouts | Basic Board Information ............................................................................................. 7

4.2. Feature Callouts | Connectors & Hardware (Board)............................................................................... 8

4.3. Feature Callouts | Connectors & Hardware (Enclosure) ......................................................................... 9

5. Block Diagrams ................................................................................................................................................. 10

5.1. Block Diagram | System .............................................................................................................................. 10

5.2. Block Diagram | Board ............................................................................................................................... 11

6. Device Specifications ........................................................................................................................................ 12

7. Agora Module ................................................................................................................................................... 13

8. Sensors ............................................................................................................................................................. 13

9. Power ............................................................................................................................................................... 14

9.1. Power | Battery .......................................................................................................................................... 14

9.2. Power | Internal Power ..............................................................................................................................15

10. Programming, Debugging, & Development ...................................................................................................... 17

11. Component Interfaces ..................................................................................................................................... 17

11.1. Component Interfaces | Outputs (U5) ...................................................................................................... 17

11.2. Component Interfaces | GPIO Expander (U6) .......................................................................................... 17

11.3. Component Interfaces | UART Managers ................................................................................................ 18

11.4. Component Interfaces | CAN Managers ................................................................................................. 18

12. Pinouts .............................................................................................................................................................. 19

12.1. Pinouts: MCU Pinout.................................................................................................................................... 19

12.2. Pinouts: TagConnect Programming Header (J2) ..................................................................................... 21

12.3. Pinouts: Arm Cortex Programming Header (J3) ...................................................................................... 21

12.4. Pinouts: Power/CAN Pinout (J5) ............................................................................................................... 22

12.5. External I/O Pinout (J6) ............................................................................................................................ 23

12.6. OBDII Cable Pinout ................................................................................................................................... 25

13. Antennae ......................................................................................................................................................... 26

14. Electrical Specifications ................................................................................................................................... 27

14.1. Pin Map + Maximum/Minimum Operation Ratings .................................................................................... 27

15. Mechanical Specifications................................................................................................................................ 29

15.1. Physical Parameters ................................................................................................................................. 29

15.2. Enclosure ................................................................................................................................................. 29

15.3. Mechanical Drawings ............................................................................................................................... 29

15.4. Environmental Specifications.................................................................................................................. 35

16. Regulatory Information ................................................................................................................................... 35

16.1. Cellular Certifications & Endorsements .................................................................................................. 35

16.2. RoHS Compliance ...................................................................................................................................... 36

16.3. Interferance Statement .......................................................................................................................... 36

16.4. FCC and ISED Compliance........................................................................................................................ 36

16.5. Wireless Notice ........................................................................................................................................ 37

16.6. Antenna Notice: FCC & ISED ..................................................................................................................... 37

16.7. End-Product Labeling Requirements ....................................................................................................... 38

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 3 of 39

16.8. FCC Additional Testing, Part 15 Subpart B Disclaimer ............................................................................. 38

17. Revision History ................................................................................................................................................ 39

Table 1 – Part Number Configurator ....................................................................................................................... 5

Table 2 – Option Configurator ................................................................................................................................ 5

Table 3 – Example Configurations ........................................................................................................................... 6

Table 4 – Basic Board Information .......................................................................................................................... 7

Table 5 - Board connectors & Hardware ................................................................................................................. 8

Table 6 – Enclosure Connectors & Hardware ......................................................................................................... 9

Table 7 – Device specifications ............................................................................................................................... 12

Table 8 – U6 pin assignments ................................................................................................................................. 17

Table 9 – U4 pin assignments ................................................................................................................................. 18

Table 10 – MCU Pinout (BT840 via Agora) ................................................................................................................ 19

Table 11 –TagConnect debug header pinout (J2) ................................................................................................... 21

Table 12 – Arm Cortex debug header pinout (J3)................................................................................................... 21

Table 13 – Power/CAN connector (J5) pinout ......................................................................................................... 22

Table 14 – J5 to DB9 pin map .................................................................................................................................. 22

Table 15 – J6 header pin list ................................................................................................................................... 24

Table 16 – OBDII cable pinout ................................................................................................................................. 25

Table 17 – Pin Map + Maximum/Minimum Operation Ratings ................................................................................. 27

Table 18 – physical parameters ............................................................................................................................. 29

Table 19 – environmental specifications ............................................................................................................... 35

Table 18 – FCC & ISED max gain by band................................................................................................................ 37

Table 17 – revision history ...................................................................................................................................... 39

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 4 of 39

1. Introduction

The epConnected Vehicle provides a solution for bringing wireless data collection & management to vehicle

interfaces. The device is composed of a carrier board that connects an integrated Agora to a vehicle’s OBDII port,

bringing the capabilities of an Agora to the vehicle. The epConnected Vehicle can collect data from input I/O and

provide control through driving output I/O. Monitored data can be sent over available wireless methods on the

Agora (Cellular, Bluetooth) with control actions performed through the nRF52840 microcontroller module on the

Agora or control through cloud applications. The board is powered through an OBDII cable (12V) with a lithium

battery backup for lightweight activities after the ignition is turned off & the OBDII power source is shut off. The

epConnected Vehicle includes a plastic housing with user interfaces for CAN/power, cellular antenna (SMA), GNSS

antenna (SMA), and data I/O, as well as flanges for mounting.

Powered by Agora

The epConnected Vehicle leverages the capabilities of the Agora module by Embedded Planet. Agora is an IoT

solution platform that incorporates the processing power of an onboard MCU with the wireless connectivity of

cellular, Bluetooth, & LoRa while collecting sensor data. Onboard sensors can include 6-axis IMU, 9-axis IMU, Time-

of-Flight (ToF) distance, temperature/humidity, temperature/humidity/pressure/VOC gas, and sound/microphone.

The cellular module is available in configurations that include GNSS capabilities. Some configurations of Agora

include custom plastics & a LiPo battery with recharging capabilities. Agora can operate as a standalone module or

be integrated into new or existing hardware designs. To learn more about Agora & how to leverage its capabilities,

visit https://www.embeddedplanet.com/agora.

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 5 of 39

2. Orderable Part Numbers

This table shows the flexibility of possible device configurations. Availability of specific configurations is

contingent on current stocking & ordering conditions. Please contact Embedded Planet sales to ask about a

configuration not found in the Embedded Planet shop: [email protected]om. The Embedded Planet shop is

hosted at https://shop.embeddedplanet.com.

TABLE 1 – PART NUMBER CONFIGURATOR

Configuration:

EPCNCT

-

VEH1.2

-

A

1

2

3

4

5

6

7

8

TABLE 2 – OPTION CONFIGURATOR

Option Designator Description Notes

1

Environment

(Agora PCBA)

1

None

A

Bosch BME680: temp, humidity, pressure, gas

B

SiLabs Si7021

-

A20: temp, humidity

C

BOTH

(

BME680

+

Si7021

-

A20

)

: temp,

humidity

+

pressure, gas

default

2

Inertia

(Agora PCBA)

2

None

D

6

-

Axis IMU:

InvenSense ICM

-

20602

|

3

-

axis accel, 3

-

axis gyro

E

9

-

Axis IMU:

ST LSM9DS1

|

3

-

axis accel, 3

-

axis gyro, 3

-

axis mag

F

BOTH (6

-

Axis + 9

-

Axis IMU):

ICM

-

20602

&

ST LSM9DS1

(gyro, accel + mag)

default

3

Time of Flight

(Agora PCBA)

3

None

G

ST VL53L0X

default

4

Reserved

4

None

5

Reserved

5

None

6

Reserved

6

None

7

Battery

Backup

7

None

J

Internal 4.3V LiPo and Charger (Carrier PCB Mounted)

default

8

Customer I/O

8

None

K

4 inputs, 6 outputs, 2 RS

-

232, Voltage Monitor (Carrier PCB Mounted)

default

#

Feature

1

Environment sensor

2

Inertia

sensor

3

Range sensor

4

Reserved

5

Reserved

6

Reserved

7

Backup Battery

8

External

I/O

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 6 of 39

Below are some example configurations for the epConnected Vehicle device:

TABLE 3 – EXAMPLE CONFIGURATIONS

Full

Configuration P

art

N

umber

Configuration Description

EPCNCT

-

VEH1.2

-

A123456

78

No

optional

features

included

EPCNCT

-

VEH1.2

-

A

C

FG

456

JK

All

optional

features

included

(Default)

EPCNCT

-

VEH1.2

-

A

AEG

456

JK

Only

one

of each available feature

included

3. Additional Resources

Agora module:

https://www.embeddedplanet.com/agora

epConnected Vehicle:

https://www.embeddedplanet.com/connected-vehicle

Embedded Planet Documentation:

https://www.embeddedplanet.com/product-documentation/#connected-vehicle

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 7 of 39

4. Feature Callouts

4.1. Feature Callouts | Basic Board Information

TABLE 4 – BASIC BOARD INFORMATION

Category Reference Component Type Description / Purpose

Label 1 Label Serialization & board identification

Modem 2 Agora PCBA module Cellular/GNSS connectivity, sensors

1: Serial Number /

Board ID label

2: Agora

PCBA

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 8 of 39

4.2. Feature Callouts | Connectors & Hardware (Board)

TABLE 5 - BOARD CONNECTORS & HARDWARE

Category Reference Component Type Description / Purpose

Mechanical 1 Board mounting holes Mounting hardware for use with enclosure

Connector 2 JST / Battery Connector input for LiPo battery power

Connector 3 Power & CAN Interface for CAN & power input

Connector 4 I/O array Interface for assorted I/O

Mechanical 5 Agora mounting posts For securing Agora to the host board

Connector 6 ARM Cortex For programming/debug (SWD)

Connector 7 TagConnect For programming/debug (SWD)

Connector 8 Tectonic Edge™ Board Edge/Finger interface for Agora

1: Board mounting

holes (x4)

2:

JST Battery

Connector

3:

Power & CAN

connector (J

5)

5

:

Agora

mounting posts

4

:

I

/

O Connector (J6)

6: ARM Cortex

programming/

debug connector

7: TagConnect programming/

debug connector

8:

Tectonic Edge™

connector for Agora

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 9 of 39

4.3. Feature Callouts | Connectors & Hardware (Enclosure)

TABLE 6 – ENCLOSURE CONNECTORS & HARDWARE

Category Reference Component Type Description / Purpose

Mechanical 1 Enclosure mounting holes For securing device enclosure

Connector 2 Power/CAN Connector for power & CAN bus

Connector 3 I/O array Connector for external I/O array

Connector 4 GNSS antenna External SMA-style GNSS antenna port

Connector 5 Cellular antenna External SMA-style Cellular antenna port

1:

Mounting holes on each

side of the enclosure (x2)

4: GNSS antenna

connector (SMA)

5: Cellular

antenna

connector

(SMA)

2: Power/CAN

connector

3: I/O connector

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 10 of 39

5. Block Diagrams

5.1. Block Diagram | System

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 11 of 39

5.2. Block Diagram | Board

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 12 of 39

6. Device Specifications

TABLE 7 – DEVICE SPECIFICATIONS

Feature/Specification Description

Cellular Capabilities

Cellular Technologies: LTE-M (LTE CAT M1), SMS

Lower power modes: PSM, eDRX

Operating Frequencies: 699MHz to 1980MHz

Cellular Operating Mode: Half-duplex FDD

RF Output Power: Up to +23 ±2 dBm (Power Class 3)

Internet Protocols IPv4/IPv6 stack with TCP and UDP protocols

TLS/DTLS

LTE CAT M1 Specification

Bands (WW): B1(2100), B2(1900), B3(1800), B4(AWS1700), B5(850), B8(900), B12(700),

13(700), B18(800), B19(800), B20(800), B26(850), B28(700)

Bands (NA): B2(1900), B4(AWS1700), B12(700) B13(700)

Uplink: up to 375 kbps

Downlink: up to 300 kbps

SIM

Removable: 4FF (nano) SIM card slot

Board-mounted: MFF2

Internal: Telit simWISE™

Cellular Certifications

PTCRB: Complete (Agora)

AT&T: Complete (Agora)

Verizon: Complete (Agora)

GNSS Specifications

Constellations: GPS, GLONASS, BeiDou, Galileo, QZSS

Tracking Sensitivity: -161dBm

Navigation Sensitivity: -158dBm

Cold Start Sensitivity: -146dBm

Input Voltage Nominal: 12V (supplied via OBDII)

Voltage Range: 5-20 VDC

Dimensions In plastics housing: 102.3 mm x 59.3 mm x 43 mm (4.03 in x 2.33 in x 1.69 in)

Environmental

Operating Temperature Range (with battery): 0°C to +45°C

Storage Temperature Range (with battery): 0°C to +45°C

Humidity Range (with battery): 20% RH to 60±25% RH

Operating Temperature Range (without battery): -17°C to +80°C

Storage Temperature Range (without battery): -17°C to +80°C

Humidity Range (without battery): 20% RH to 90% RH

Sensor Options Environmental: Temperature, humidity, barometric pressure, VOC gas

Inertial: 6-axis IMU, 9-axis IMU (accelerometer, gyroscope, magnetometer)

Range: Time-of-Flight (ToF)

Fault-Protected I/O 12V/350mA analog outputs: x6

12V digital inputs: x3

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 13 of 39

7. Agora Module

The epConnected Vehicle leverages the Agora board by Embedded Planet for its cellular + GNSS connectivity as

well as for its sensor options. The MCU on Agora is Nordic’s nRF52840; details of this MCU can be found here:

https://www.nordicsemi.com/Products/Low-power-short-range-wireless/nRF52840. Shown below is a figure

outlining the basic features on Agora as relevant to the epConnected Vehicle. More detail on the Agora board is

available through the Embedded Planet website & documentation.

8. Sensors

The epConnected Vehicle board is designed to accommodate up to 5 Agora-mounted sensors across 3 different

sensor categories. The following sensor options are available:

Environmental

o Temperature, humidity

SiLabs Si7021-A20

o Temperature, humidity, barometric pressure, VOC gas

Bosch BME680

Inertial

o 6-Axis IMU (accelerometer, gyroscope)

InvenSense ICM-20602

o 9-Axis IMU (accelerometer, gyroscope, magnetometer)

ST LSM9DS1

Range/Tampering

o Time-of-Flight (ToF)

ST VL53L0X

For more detail on sensor functions, specifications, development, or more please refer to the Agora Product User

Manual which can be found at https://www.embeddedplanet.com/product-documentation/#agora.

Tectonic Edge

™

interface

BT840 (nRF52840)

MCU+bluetooth

module

Telit ME910

cellular+GNSS

module

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 14 of 39

9. Power

The epConnected Vehicle board is designed to be powered by 12V through an OBDII cable connected to J5. The

12V input on the PCB includes input protection elements designed to guard against egregious fault conditions and

withstand alternator load dump conditions. A 1.1A, 60V resettable PTC fuse (polyfuse) in line with the 12V input

protects against potential high input current levels. A series rectifier diode at the 12V input assures a one-way flow

of energy at the connector. There is a TVS diode positioned for transients at the 12V input with a reverse stand-off

voltage of 22V and a maximum clamping voltage of 35.5V. A capacitor bank provides conditioning & stability on the

system side of the protection circuitry.

9.1. Power | Battery

The battery backup option for the epConnected Vehicle includes a small LiPo battery. This battery assists

in the safe & consistent shutdown of the system when the +12V system power becomes cut from the system

due to the vehicle turning off. If the system is in the middle of a transmission, sensor reading, or other sensitive

process, the backup battery can help ensure that the process is carried through to completion before the

system is fully shut down. A voltage monitor input to the epConnected Vehicle system monitors for the

presence of 12V power and alerts the system if the power is cut off, allowing the system to move into a state of

preparation for soft shutdown.

The battery provided with the epConnected Vehicle is a 3.7V, 500mAh rechargeable Lithium-Ion

Polymer (LiPo) battery. The output ranges from 4.2V when completely charged down to 3.0V. The battery

includes protection circuitry to keep the battery voltage from going too high or low; the battery will cut out

when completely dead at 3.0V. When power is applied through the 12V system the battery charging is active.

The battery is only meant to be charged using the onboard circuitry using the JST battery connection; never

charge the battery using a non-recommended charging method. For the epConnected Vehicle the battery

charge current limit is set to 450mA, and the charge termination voltage is set to 4.2V. The charge manager IC

used is the Microchip MCP73831. More on the Microchip MCP73831 can be found at

https://www.microchip.com/en-us/product/MCP73831.

If the 12V input is cut (e.g., the vehicle that is supplying power is turned off), the PWR_STATUS GPIO line

will transition from high (3.3V) to low (0V) to indicate the loss of system input power. The system can then

finish its current operations using the battery backup and then do a safe power shutoff once ready. The

PWR_STATUS line corresponds to GP5 (pin 15) of the MCP23008 LiPo charger IC. This IC is connected to the

Agora over I2C bus using the address 0b01001110 (0x4E).

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 15 of 39

The following shows an example battery voltage discharge curve of the internal system when it

continues to operate on battery power after the removal of system +12V power:

The following depicts a typical battery voltage curve during charging (+12V applied to the system via the

OBDII interface powers the battery charging circuitry):

9.2. Power | Internal Power

Power to the CAN-specific components is provided by a dedicated, onboard 3.3V regulator. The enable

to this regulator is tied to the CAN_WAKE_CTRL signal which is controlled by P0.06 of the nRF52840. This is an

active-high signal.

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 16 of 39

The Power Block Diagram for the epConnected Vehicle is depicted below:

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 17 of 39

10. Programming, Debugging, & Development

The processing power of the epConnected Vehicle is provided through the Agora module mounted to it.

Programming & debug access to the Agora module for the development of custom applications is available through

the epConnected Vehicle host board. The host board provides both an Arm Cortex SWD header and a TagConnect

footprint for programming & debug use. Alternately, users may remove the Agora from the host board and program

it with a Flidor development board by Embedded Planet. Flidor contains an OpenSDA programming and debug

interface that can support simple drag-and-drop programming of files onto the target device (in this case the target

is the epConnected Vehicle board).

More on Flidor can be found at https://www.embeddedplanet.com/product-documentation/#flidor

Available documentation on programming the epConnected Vehicle device (including example software or other

development resources) can be found at https://www.embeddedplanet.com/product-documentation/#connected-

vehicle

11. Component Interfaces

11.1. Component Interfaces | Outputs (U5)

For detail on the output component interface, please refer to the section titled External I/O Pinout (J6).

11.2. Component Interfaces | GPIO Expander (U6)

The GPIO expander component U6 is an MCP23008. It is configured in I2C mode with the address 0x4E.

The interrupt line is from the CAN interface (U3) and optionally the I/O expander (U6 through R3). The

expander must be configured as open drain when R3 is populated. The reset, enable, interrupt, and chip select

signals for this device are active-low.

TABLE 8 – U6 PIN ASSIGNMENTS

Category

Signal

U6 Pin

UART

UART2_RESET#

U6 GP4 (pin 14)

System

PWR_STATUS

U6: GP5 (pin 15)

System

GPO_EN#

U6: GP6 (pin 16)

System

GPO_CS#

U6: GP7

(pin 17)

System

IO_INT# *

U6: INT (pin 6)

Input

IN0

U6: GP0 (pin 10)

Input

IN1

U6: GP1 (pin 11)

Input

IN2

U6: GP2 (pin 12)

Input

IN3 (voltage monitor output)

U6: GP3 (pin 13)

For more detail on the MCP23008, please refer to https://www.microchip.com/en-us/product/MCP23008.

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 18 of 39

11.3. Component Interfaces | UART Managers

The RS-232 transceiver IC is an ST3232BTR (U4). This component drives both of the two RS-232

interfaces hosted on the epConnected Vehicle device. The first UART interface communicates with the

Agora MCU through UART signals, while the second UART interface is converted to the I2C bus using a

SC16IS750IBS (U3). The I2C address for this component is 0x9A. The interrupt signal IO_INT# is shared

between U3 and U8 (U6 optional; not connected by default).

For more detail on the ST3232BTR please refer to https://www.st.com/en/interfaces-and-

transceivers/st3232b.html

For more detail on the C16IS750IBS please refer to https://www.nxp.com/part/SC16IS750IBS#/

TABLE 9 – U4 PIN ASSIGNMENTS

Signal

U4 pin

RS232_TX_OUT_CON_2

T2OUT (pin 7)

RS232_RX_IN_CON_2

R2IN (pin 8)

RS232_TX_IN_CON

R1IN (pin 13)

RS232_RX_OUT_CON

T1OUT (pin 14)

TX_OUT

(to MCU)

T1IN (pin 11)

RX_IN

(to MCU)

R1OUT (pin 12)

RX (U3 pin 24)

R2OUT (pin 9)

TX (U3 pin 23)

T2IN (pin 10)

11.4. Component Interfaces | CAN Managers

The CAN interface for the epConnected Vehicle consists of a TI SN65HVD231 CAN transceiver (U9) paired with

an MCP2515 CAN controller (U8). The MCP2515 communicates with the MCU over a SPI interface. The chip

select line for this component (CAN_CS#) is controlled by pin P1.09 on the nRF52840 MCU.

For more on the SN65HVD231, please refer to https://www.ti.com/product/SN65HVD231/.

Power to the CAN components can be discretely managed by the MCU. For more detail on this, please

refer to the power section of this manual.

Embedded Planet, Inc. epConnected Vehicle | Product User Manual Version: 1.0.0 | 25 Feb 22

Embedded Planet, Inc. | 31225 Bainbridge Rd Suite N, Solon, OH 44139 | 216-245-4180 | www.embeddedplanet.com | Page 19 of 39

12. Pinouts

12.1. Pinouts: MCU Pinout

TABLE 10 – MCU PINOUT (BT840 VIA AGORA)

Fanstel

Pin nRF52840 pin Function Connected to Tectonic

Edge™ Pin

1 P0.26/SDA SDA Sensors B7

2 P0.27/SCL SCL Sensors B6

3 P0.00/XL1 32.768kHz Crystal -

4 P0.01/XL2 32.768kHz Crystal -

5 P0.02/AIN0 Battery Voltage ADC Battery Voltage Monitor -

6 P0.03/AIN1 Board ID ADC Board ID resistor divider -

7 P0.09/NFC1 NFC JST connector -

8 P0.10/NFC2 NFC JST connector -

9 VDD Power Vin A12

10 GND Common COM A5

11 P0.11/TRACEDATA2 LoRa_MOSI/TRACEDATA2 LoRa Module B2

12 P1.00/TRACEDATA0 SWO/TRACEDATA0 EP Debug Header A18

13 P0.13 Debug_TX EP Debug Header and cell aux UART B12

14 P0.18/nRESET BT840 Reset EP Debug Header A17

15 SWCLK SWD clock EP Debug Header A16

16 SWDIO SWD data EP Debug Header A15

A0 VSS Common COM A8

A1 P0.28/AIN4 CELL_PWR_EN Telit cell module -

A2 P0.29/AIN5 PB Pushbutton -

A3 P0.04/AIN2 INT_LIGHT_TOF Light sensor INT and ToF sensor INT -

A4 P0.05/AIN3 LED_RED LED -

A5 P0.07/TRACECLK LoRa_SCLK/TRACECLK LoRa Module B3

A6 P1.08 CELL_CTS Telit cell module A4

B0 VSS Common COM A14

B1 P0.25 I2S_SD Microphone B11

B2 P0.30/AIN6 CELL_ON_OFF Telit cell module B9

B3 P0.31/AIN7 SENSOR_PWR_EN Load Switch B10

B4 P0.06 I2S_SCK Microphone A7

B5 P0.08 I2S_WS Microphone A6

B6 P1.03 CELL_DSR Telit cell module -

C0 VSS Common COM B5

C1 P0.24 CELL_HW_SHUTDOWN Telit cell module -

C2 P0.22 QSPI IO2 QPSI Flash -

C3 P0.17 QSPI CS# QPSI Flash B15

C4 P0.15 CELL_DCD Telit cell module -

C5 P1.02 CELL_TX Telit cell module A1

C6 P1.04 CELL_DTR Telit cell module -

D0 VSS Common COM B8

Table of contents

Other Embedded Planet Modem manuals

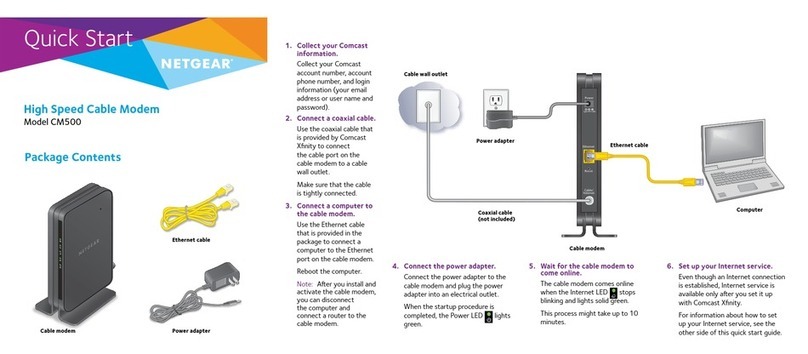

Popular Modem manuals by other brands

Primus

Primus CBN8000 Setup guide

3Com

3Com 3C892 - OfficeConnect ISDN Lan Modem Router user guide

Mitsubishi Electric

Mitsubishi Electric MAM-AM20 instruction manual

ELPRO

ELPRO 615M-1 quick start guide

Pentagram

Pentagram Cerberus Wi-Fi Lite Installation and user manual

Four-Faith

Four-Faith F8X14 Series user manual